Comprehensive Guide to Repairing the 1999 Suzuki Quadrunner 500

In the realm of off-road machines, ensuring optimal performance and longevity requires a comprehensive understanding of their intricate systems. A well-structured resource can significantly aid enthusiasts and professionals alike in tackling various challenges that may arise during operation. This guide aims to provide crucial insights into the upkeep and troubleshooting of these powerful vehicles.

From engine diagnostics to routine service checks, each section is designed to equip users with the knowledge necessary to maintain their machines effectively. Emphasis is placed on practical steps and safety measures, enabling both novices and seasoned mechanics to navigate the complexities of their vehicles with confidence. The goal is to empower owners with the tools they need to keep their rides in peak condition.

By delving into detailed instructions and helpful tips, this guide fosters a deeper appreciation for the mechanics behind these remarkable machines. Whether for casual rides or competitive ventures, understanding the fundamental principles of maintenance is essential for enhancing performance and ensuring a smooth experience on rugged terrains.

Overview of the 1999 Suzuki Quadrunner 500

This section provides a comprehensive examination of a prominent all-terrain vehicle designed for adventure enthusiasts. Known for its robust performance and versatile features, this machine has garnered attention for both recreational and utility applications. With a blend of power and agility, it stands out in its category, appealing to a wide range of users.

Key Features

The vehicle boasts an array of specifications that enhance its functionality and rider experience. Below is a summary of the notable characteristics:

| Feature | Description |

|---|---|

| Engine Type | Four-stroke, single-cylinder |

| Displacement | Approx. 500 cc |

| Transmission | Automatic with low and high range |

| Drive System | Selectable 2WD/4WD |

| Brakes | Hydraulic disc brakes |

Performance and Handling

Engine performance is complemented by a well-engineered suspension system, providing a smooth ride over various terrains. The balance between power delivery and handling makes it suitable for both novice riders and seasoned veterans. The inclusion of adjustable features further enhances the adaptability of this vehicle, ensuring it meets diverse riding preferences.

Common Issues with Quadrunner 500

When it comes to off-road vehicles, certain challenges often arise that can hinder performance and reliability. Understanding these frequent problems can help owners maintain their machines effectively and avoid costly repairs. This section delves into the typical concerns that enthusiasts may encounter, providing insights for better care and usage.

Electrical Problems

One prevalent issue involves the electrical system, where components such as the battery, wiring, and ignition may malfunction. Symptoms often include difficulty starting or intermittent power loss. Regularly inspecting connections and ensuring that the battery is fully charged can mitigate these problems.

Suspension Wear

Another common challenge is the wear and tear of the suspension system. Over time, components like shocks and bushings may degrade, leading to a rough ride and diminished handling. It is advisable to perform routine checks and replace worn parts promptly to ensure a smooth driving experience.

Essential Tools for Repairs

Having the right set of tools is crucial for effective maintenance and troubleshooting. These instruments not only facilitate the work but also ensure that tasks are completed safely and efficiently. A well-equipped workspace can significantly enhance the overall experience and outcome of any project.

Basic Hand Tools

To start, a collection of hand tools is indispensable. Items such as wrenches, screwdrivers, and pliers form the backbone of any toolkit. Adjustable wrenches are particularly versatile, allowing for adjustments to various sizes of nuts and bolts. Similarly, a range of screwdrivers–including both flat and Phillips head–will cover most fastening needs. These essentials are foundational for any mechanical work.

Specialty Equipment

In addition to standard hand tools, certain specialized equipment can make a significant difference. For example, a multimeter is invaluable for diagnosing electrical issues, while a compression tester can help assess engine performance. Furthermore, a reliable socket set streamlines the process of loosening and tightening fasteners in hard-to-reach areas. Investing in these tools ensures that you can tackle a wider range of tasks with confidence.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your all-terrain vehicle. By following a systematic approach, you can effectively address various aspects of maintenance, from routine inspections to specific component care. This guide will provide you with detailed instructions to keep your machine in top condition.

1. Pre-Ride Inspection: Before each use, conduct a thorough examination of the vehicle. Check fluid levels, tire pressure, and ensure that all lights and signals are operational. Look for any signs of wear or damage, particularly in the tires and suspension components.

2. Oil Change: Regular oil changes are crucial for engine health. Drain the old oil, replace the oil filter, and refill with the recommended type and amount of oil. It’s advisable to perform this every 100 hours of operation or as specified in the guidelines.

3. Air Filter Maintenance: Inspect and clean the air filter regularly to ensure optimal airflow to the engine. A clogged filter can reduce performance and fuel efficiency. Replace it if it’s excessively dirty or damaged.

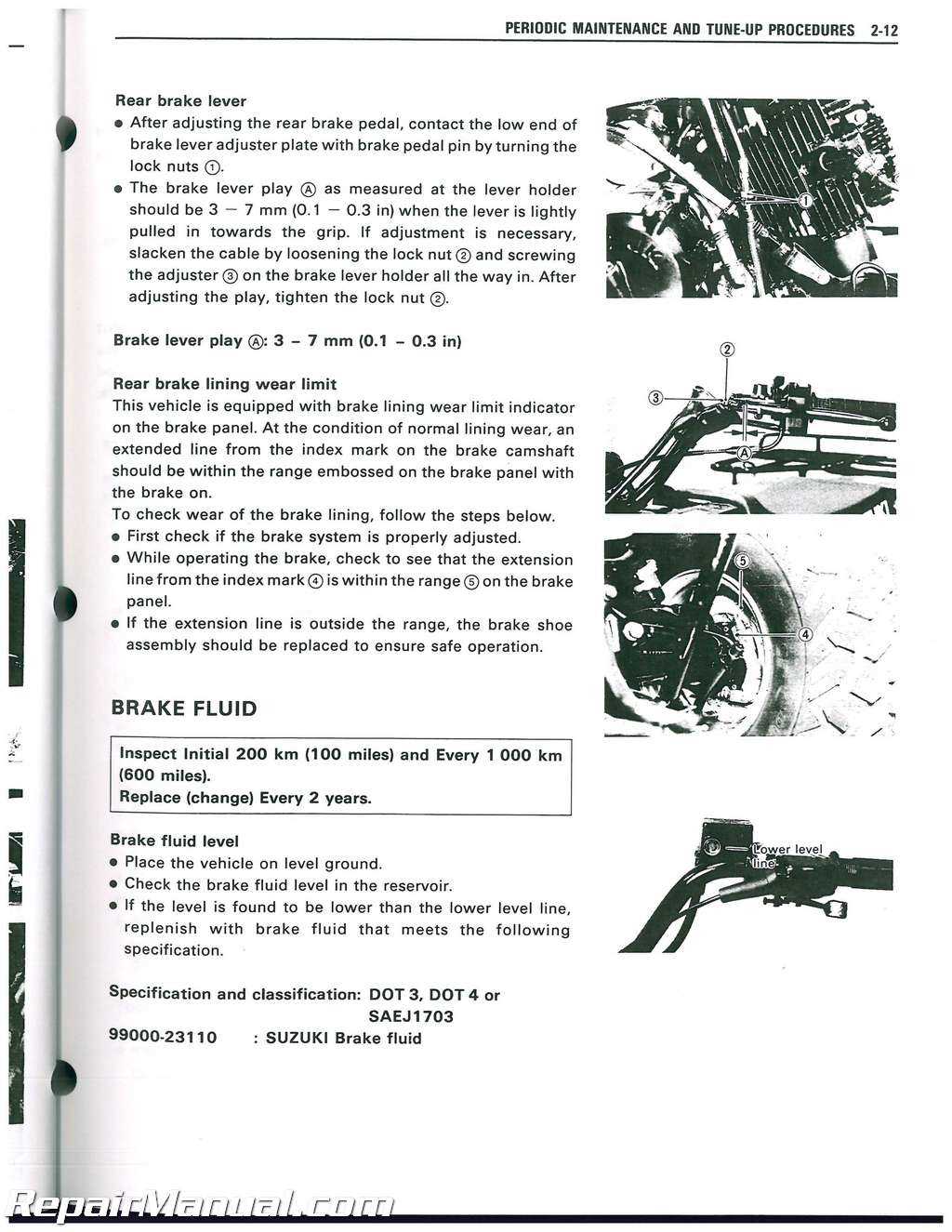

4. Brake Inspection: Check the brake system for wear on pads and rotors. Test the brakes to ensure they engage smoothly and effectively. Replace any components that show signs of wear or reduced performance.

5. Tire Care: Monitor tire tread and pressure regularly. Inflate tires to the recommended specifications, and rotate them as necessary to promote even wear. Inspect for punctures or cuts that could compromise safety.

6. Battery Maintenance: Ensure that the battery terminals are clean and free from corrosion. Check the battery charge and connections regularly. Replace the battery if it shows signs of weakness or failure.

7. Chain and Sprocket Inspection: If your vehicle is equipped with a chain drive, inspect the chain for tension and wear. Lubricate the chain regularly and replace it if it becomes excessively worn or damaged.

By adhering to these step-by-step procedures, you can maintain your vehicle’s performance, safety, and reliability, ultimately enhancing your riding experience.

Electrical System Troubleshooting Guide

The electrical system of an all-terrain vehicle is crucial for its performance and reliability. Understanding how to diagnose issues within this system can save time and enhance the overall experience of ownership. This guide will help identify common electrical problems, outline potential causes, and suggest methods for resolution.

Symptoms of Electrical Issues

Common indicators of electrical malfunctions include dim lights, failure to start, or erratic behavior of the dashboard indicators. If any of these symptoms arise, it’s essential to conduct a thorough investigation of the system.

Step-by-Step Diagnosis

Start by checking the battery. Ensure it is charged and the terminals are clean and secure. A weak battery is often the root cause of various electrical problems.

Next, inspect the fuses. A blown fuse can disrupt the entire electrical system and is usually easy to replace. Look for signs of damage or corrosion on the fuse box.

Wiring Inspection

Examine the wiring for frays, breaks, or corrosion. Damaged wires can lead to short circuits or intermittent connections. Use a multimeter to test continuity and ensure proper connections throughout the system.

Testing Components

If issues persist, test individual components such as the ignition switch, relays, and sensors. Each part should operate within specified parameters. Consult the manufacturer’s specifications for accurate measurements.

Conclusion

By systematically following these steps, you can effectively troubleshoot and resolve electrical issues, ensuring your vehicle remains in peak condition. Regular maintenance and checks can prevent many problems before they occur.

Engine Components and Functions

This section explores the essential parts of an engine and their respective roles in ensuring optimal performance. Understanding these components can enhance maintenance efforts and improve longevity.

- Cylinder: The chamber where fuel and air mix and ignite.

- Piston: Moves up and down within the cylinder, converting energy from combustion.

- Cylinder Head: Houses valves and spark plugs, sealing the combustion chamber.

- Crankshaft: Transforms linear motion of the piston into rotational motion.

- Valves: Control the flow of air and fuel into the cylinder and exhaust gases out.

- Camshaft: Operates the opening and closing of the valves in sync with the piston movement.

Each component plays a vital role, contributing to the overall efficiency and effectiveness of the engine’s operation.

Transmission and Drivetrain Basics

The transmission and drivetrain systems are essential components that ensure a vehicle’s power is efficiently transferred from the engine to the wheels. These systems are designed to optimize performance, enhance control, and improve overall driving experience. Understanding their functions and interactions is crucial for effective maintenance and troubleshooting.

The transmission plays a pivotal role in managing engine output, allowing the driver to select different speeds and torque levels. This adaptability is achieved through various gear ratios, which facilitate smooth acceleration and deceleration. Manual and automatic options provide distinct driving experiences, each with unique benefits.

On the other hand, the drivetrain encompasses all parts that deliver power to the wheels, including the driveshaft, axles, and differential. This system ensures that the power generated by the engine is effectively transmitted to the ground, allowing for movement. The configuration of the drivetrain can vary, with options such as two-wheel drive and four-wheel drive, each suited for different terrains and conditions.

Regular inspections and maintenance of both transmission and drivetrain systems are vital to prevent potential issues. Common problems may include fluid leaks, abnormal noises, or difficulty in shifting gears. Addressing these concerns promptly can help maintain optimal functionality and prolong the lifespan of the vehicle.

Wheel and Tire Care Tips

Maintaining the wheels and tires of your vehicle is essential for optimal performance and safety. Proper care not only extends the life of these components but also enhances your overall driving experience. Here are some effective strategies to ensure your tires remain in top condition.

Regular Inspection

Frequent checks of your tires can help identify issues before they become significant problems. Look for signs of wear such as uneven tread, cracks, or bulges. Additionally, monitor the tire pressure regularly; under-inflated tires can lead to decreased fuel efficiency and increased risk of blowouts.

Proper Cleaning

Cleaning your wheels and tires is vital for both aesthetics and longevity. Use a gentle soap and water solution to remove dirt and brake dust. Avoid harsh chemicals that can damage the rubber. A tire dressing can also be applied to protect the rubber and enhance its appearance, providing a layer of protection against UV rays.

Incorporating these tips into your maintenance routine will help ensure that your vehicle’s wheels and tires remain safe, efficient, and visually appealing.

Fluid Change and Maintenance Schedule

Regular upkeep and timely fluid changes are essential for ensuring optimal performance and longevity of your all-terrain vehicle. Adhering to a well-structured maintenance plan can prevent unexpected issues and enhance the overall riding experience. This section outlines the recommended intervals for fluid changes and routine maintenance tasks.

Recommended Fluid Change Intervals

- Engine Oil: Change every 100 hours of operation or at least once a year, whichever comes first.

- Transmission Fluid: Check and replace every 200 hours or as specified by the manufacturer.

- Coolant: Inspect annually and replace every two years to ensure efficient cooling.

- Brake Fluid: Change every two years to maintain braking efficiency.

Routine Maintenance Tasks

- Check air filter condition monthly and clean or replace as necessary.

- Inspect spark plug for wear and replace annually.

- Examine tires for proper inflation and tread wear regularly.

- Lubricate all moving parts according to the manufacturer’s guidelines.

- Inspect the battery terminals and clean any corrosion every six months.

Following this schedule will help keep your vehicle in top condition, ensuring a safe and enjoyable ride. Regular checks and fluid changes not only prevent wear but also enhance performance and reliability on various terrains.

Safety Tips for Repair Work

When engaging in maintenance tasks, ensuring personal safety and the integrity of the equipment is paramount. Implementing appropriate precautions can help prevent accidents and injuries, allowing for a smoother and more efficient process. Following these guidelines can lead to a safer working environment and a more successful outcome.

Personal Protective Equipment

Always wear suitable personal protective gear when undertaking maintenance activities. This includes gloves, goggles, and ear protection to shield against potential hazards. Ensure that your footwear is sturdy and provides adequate support to prevent slips and falls.

Work Area Organization

Maintain a clean and organized workspace. Remove any clutter that could pose a tripping hazard or obstruct movement. Proper lighting is essential to clearly see your surroundings and the components you are working on. Additionally, having all necessary tools and parts within reach will minimize distractions and enhance focus on the task at hand.

Upgrading Your Quadrunner Performance

Enhancing the capabilities of your all-terrain vehicle can significantly elevate your riding experience. By focusing on various components, you can boost power, improve handling, and increase overall efficiency. This section explores several effective methods to unlock the full potential of your machine.

Engine Modifications

One of the most impactful ways to increase performance is by upgrading the engine. Consider installing a high-flow air filter to improve airflow, which can lead to better combustion and increased horsepower. Additionally, re-mapping the fuel injection system or installing a performance exhaust can enhance engine efficiency, providing a noticeable boost in torque and throttle response.

Suspension Upgrades

Upgrading the suspension system can dramatically improve handling and ride quality. High-performance shocks and springs can provide better damping and responsiveness, allowing for a smoother ride over rough terrain. Adjusting the ride height can also enhance stability and cornering performance, making your vehicle more capable on various surfaces.

Where to Find Replacement Parts

Finding the right components for your all-terrain vehicle can be crucial for maintaining its performance and longevity. Whether you’re looking for original equipment or aftermarket options, there are various resources available to help you locate the necessary items.

Online Resources

- Manufacturer Websites: Check the official sites for authorized dealers and listings of available parts.

- E-commerce Platforms: Websites like eBay, Amazon, and specialized ATV parts retailers offer a wide range of options.

- Forums and Community Groups: Enthusiast forums can provide leads on where to find specific parts and advice from fellow riders.

Local Options

- Local Dealerships: Authorized dealers often carry a selection of parts and can order specific items if not in stock.

- Salvage Yards: These can be treasure troves for used components at lower prices.

- Repair Shops: Local mechanics may have connections to suppliers and can recommend where to look.