Repair Manual for 2004 Suzuki Eiger 400 4×4

Ensuring the longevity and optimal performance of your all-terrain vehicle requires a thorough understanding of its systems and components. A well-structured resource can significantly simplify the troubleshooting and upkeep processes, allowing enthusiasts and owners alike to effectively manage their vehicles.

In this section, we delve into essential practices and insights that can enhance your vehicle’s functionality. By following detailed instructions and guidelines, you can address common issues and perform routine checks to maintain peak performance.

Equipped with this knowledge, you will be empowered to tackle maintenance tasks confidently. Whether you’re a novice or an experienced user, having access to this information can make all the difference in achieving a smooth and reliable ride.

This section addresses frequent challenges encountered by users of all-terrain vehicles and offers practical solutions. Understanding these common problems can enhance the overall performance and longevity of your machine.

Starting Difficulties

Many operators face issues with engine starting, which can stem from various factors. Here are some possible causes and their solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Dead battery | Charge or replace the battery |

| Engine cranks but doesn’t start | Fuel delivery issue | Check fuel level and lines for blockages |

| Unusual noises during start | Loose connections | Tighten all electrical connections |

Overheating Problems

Overheating can lead to serious damage. It is essential to identify and address the causes promptly:

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine temperature rises excessively | Low coolant levels | Top off coolant and check for leaks |

| Engine shuts down from overheating | Clogged radiator | Clean or replace the radiator |

| Overheating during operation | Poor airflow | Ensure vents are clear of debris |

Maintenance Schedule Recommendations

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle. Following a structured maintenance routine helps identify potential issues before they escalate, ultimately saving time and costs associated with repairs. Below are some recommended intervals for various maintenance tasks.

- Oil Change: Every 3,000 to 5,000 miles or every six months, whichever comes first.

- Air Filter Replacement: Check every 12,000 miles; replace as necessary.

- Brake Inspection: Inspect every 10,000 miles and replace pads when worn.

- Tire Rotation: Every 5,000 to 7,500 miles to ensure even wear.

- Fluid Levels Check: Monthly inspection of all essential fluids.

Following these guidelines can significantly enhance your vehicle’s reliability and performance. Always refer to specific recommendations for your model for the best results.

Tools Needed for Repairs

When undertaking maintenance on your vehicle, having the right instruments at your disposal is crucial. The proper equipment not only facilitates the process but also enhances safety and efficiency. Whether you are a seasoned technician or a novice, understanding the essential tools can make a significant difference in your experience.

Basic hand tools such as wrenches, sockets, and screwdrivers form the foundation of any maintenance kit. These are indispensable for loosening and tightening various components. Additionally, pliers and wire cutters are helpful for handling cables and connections.

For more specialized tasks, investing in diagnostic tools can provide valuable insights into the vehicle’s performance. Items like multimeters and code readers help identify issues that may not be visible during a routine inspection. Furthermore, safety gear, including gloves and goggles, is essential to protect yourself during any procedure.

Having a well-organized toolbox ensures that you can easily access everything you need, minimizing downtime and frustration. A comprehensive selection of tools tailored to your specific needs will prepare you for any challenge that arises during the process.

Step-by-Step Repair Guide

This section provides a comprehensive overview of the procedures necessary for maintaining and restoring your vehicle to optimal condition. Following these guidelines can help you ensure that every component functions correctly, promoting longevity and reliability.

Preparation Before Starting

Before diving into the process, it is crucial to gather the necessary tools and materials. Ensure you have a clean workspace and that all safety equipment is at hand. This preparation minimizes the risk of accidents and makes the task more efficient.

Executing the Procedures

Begin with a systematic approach, tackling one issue at a time. Refer to your guidelines for specific steps related to each component. Regular checks for wear and tear can prevent minor issues from becoming significant problems. Always verify that parts are properly fitted and functioning after each step, ensuring that everything aligns with the required specifications.

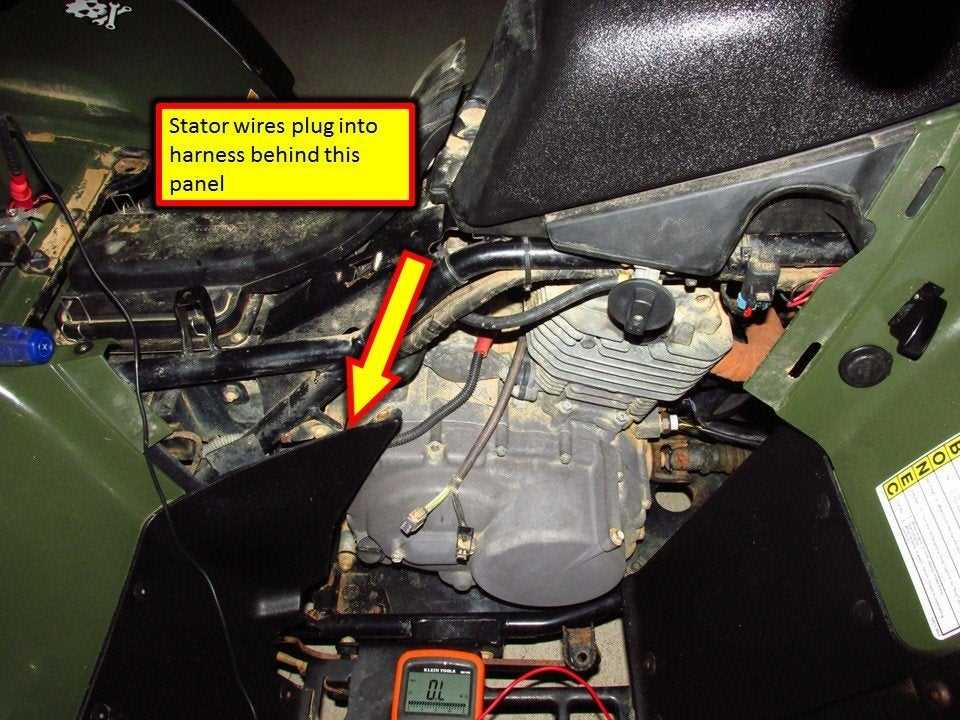

Electrical System Troubleshooting

Troubleshooting the electrical components of your vehicle can be essential for ensuring optimal performance. This section will guide you through identifying and resolving common issues that may arise within the electrical system. Understanding the basic functions and connections can help pinpoint problems effectively.

Common Symptoms of Electrical Issues

Recognizing the signs of electrical malfunctions is crucial. Common symptoms include flickering lights, failure to start, or erratic gauge readings. Each of these indicators may suggest a different underlying issue, such as a weak battery or loose connections. Inspecting these symptoms promptly can prevent further complications.

Steps for Effective Troubleshooting

Begin your troubleshooting process by checking the battery condition and connections. Ensure terminals are clean and tight. Next, examine fuses for any signs of damage, as a blown fuse can disrupt power flow. Utilize a multimeter to check voltage levels at various points. This systematic approach allows for accurate identification of electrical faults and facilitates timely repairs.

Engine Maintenance Tips

Keeping your engine in optimal condition is essential for ensuring smooth performance and longevity. Regular care can prevent unexpected breakdowns and improve overall efficiency. Here are some fundamental practices to maintain your engine effectively.

Regular Oil Changes

Changing the engine oil at appropriate intervals is crucial. Fresh oil lubricates moving parts, reduces friction, and helps maintain a stable operating temperature.

| Interval | Type of Oil |

|---|---|

| Every 3,000 miles | Synthetic |

| Every 5,000 miles | Conventional |

Inspect Cooling System

Monitoring the cooling system can prevent overheating issues. Ensure that the coolant levels are adequate, and check for leaks or worn hoses regularly.

Transmission and Drivetrain Insights

The transmission and drivetrain system is a crucial component of any all-terrain vehicle, influencing both performance and handling. Understanding the mechanics behind these systems can significantly enhance the maintenance and functionality of your vehicle.

A well-functioning transmission ensures smooth gear shifts, which are vital for optimizing power delivery. Regular inspections can help identify wear and tear early, allowing for timely interventions. This proactive approach can prevent costly repairs down the line.

The drivetrain encompasses various parts, including axles and differentials, which work together to transfer power to the wheels. Each component plays a distinct role in ensuring efficient power transfer, enhancing traction, and contributing to overall stability. Familiarity with these elements can aid in troubleshooting potential issues and improve overall driving experience.

Maintaining fluid levels and checking for leaks are essential practices to ensure the longevity of both transmission and drivetrain systems. Regularly consulting a service guide can provide valuable information on the appropriate types of fluids and service intervals required for optimal performance.

Suspension and Steering Checks

Regular evaluation of the suspension and steering systems is crucial for maintaining optimal performance and safety. These components are essential for providing stability and comfort during operation. Ensuring that they function properly can significantly enhance the overall driving experience.

Visual Inspection

Begin with a thorough visual inspection of the suspension elements. Look for signs of wear, damage, or misalignment. Check for any leaks from the shock absorbers or struts, as this can indicate that they need replacement. Additionally, examine the condition of the bushings and joints for cracks or excessive play, which may compromise functionality.

Steering System Assessment

Next, assess the steering mechanism. Check the steering fluid level and ensure there are no leaks in the system. Test the steering for responsiveness; any stiffness or unusual noises may signal issues with the steering gear or linkage. Proper alignment is also vital, so consider having the alignment checked if the vehicle pulls to one side.

Body and Frame Care

Maintaining the outer structure and chassis of your vehicle is crucial for its longevity and performance. Regular attention to these components ensures they remain in optimal condition, preventing rust and damage that can compromise overall integrity.

Start by routinely cleaning the exterior surfaces to remove dirt, grime, and any corrosive substances. This not only enhances appearance but also helps in identifying early signs of wear. Applying protective coatings can further shield against the elements, preserving the finish.

Inspect the frame for any signs of cracking or bending. Addressing minor issues promptly can prevent larger complications down the line. Ensure all fasteners are secure, as vibrations during operation can loosen them over time.

Lastly, consider periodic treatments to deter rust formation. Utilizing sprays or sealants designed for metal surfaces can greatly extend the lifespan of the body and frame, keeping your vehicle looking and performing its best.

Safety Precautions for Repairs

When undertaking maintenance tasks on any vehicle, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to established guidelines ensures not only the well-being of the individual performing the work but also the integrity of the vehicle itself. Taking proactive measures and being aware of potential hazards can significantly enhance the repair experience.

Essential Safety Guidelines

Before starting any work, consider the following precautions to ensure a secure environment:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Use gloves, goggles, and appropriate clothing to shield against injuries from sharp objects and harmful substances. |

| Work in a Ventilated Area | Ensure the workspace is well-ventilated to avoid inhaling fumes and harmful gases from chemicals or engine components. |

| Disconnect the Battery | Always disconnect the battery before performing electrical work to prevent shocks or short circuits. |

| Use Proper Tools | Employ the right tools for each task to avoid damage to components and ensure efficient work. |

| Keep a First Aid Kit | Maintain a stocked first aid kit nearby in case of minor injuries during maintenance tasks. |

Awareness of Surroundings

Always stay alert to your surroundings while working. Be cautious of moving parts, hot surfaces, and the potential for spills or leaks. Keeping the workspace organized can reduce the risk of accidents, allowing for a more effective and safe repair process.