Complete Repair Manual for 2006 Suzuki Forenza

In the realm of vehicle ownership, understanding the intricacies of maintenance can significantly enhance longevity and performance. A comprehensive guide serves as an invaluable resource, providing insights into troubleshooting and enhancing the functionality of your automobile. Whether you are a seasoned enthusiast or a novice driver, having access to detailed instructions and specifications can empower you to address issues with confidence.

For those looking to navigate the complexities of automotive upkeep, knowledge of essential components and systems is crucial. From basic oil changes to more intricate repairs, being equipped with the right information enables owners to tackle problems head-on. This resource not only illuminates the typical challenges faced by drivers but also offers preventative strategies to avoid common pitfalls.

Ultimately, investing time in understanding your vehicle can lead to significant savings and a more enjoyable driving experience. By leveraging expert advice and practical tips, you can transform the often-daunting task of maintenance into a manageable and rewarding endeavor. Embrace the journey of automotive care with the right guidance at your fingertips.

Overview of the 2006 Suzuki Forenza

This section provides a comprehensive look at a compact vehicle known for its practicality and affordability. Designed to cater to the needs of everyday drivers, it blends comfort with functionality, making it a suitable choice for various lifestyles.

Key Features

- Spacious interior with ample legroom

- User-friendly technology and controls

- Efficient fuel consumption

- Versatile cargo space

Performance and Handling

The model offers a balanced performance, making it easy to navigate through urban environments. Its handling characteristics are designed for smooth rides, ensuring comfort on longer journeys. The engine delivers reliable power while maintaining fuel efficiency.

- Front-wheel drive for improved traction

- Responsive steering for enhanced maneuverability

- Variety of engine options to suit different preferences

Common Issues with the Forenza

Every vehicle can experience a range of typical challenges throughout its lifespan. Understanding these potential problems can help owners maintain their automobiles effectively and avoid more serious complications down the road.

Electrical Problems: One frequent concern is the electrical system, which may exhibit issues such as faulty wiring or malfunctioning components. Symptoms can include dashboard warning lights, inconsistent power supply to accessories, or difficulties starting the engine.

Engine Performance: Another area to monitor is engine performance. Drivers often report symptoms like reduced power, stalling, or unusual noises. These issues might stem from problems with fuel delivery, ignition systems, or even internal engine components.

Transmission Difficulties: Shifting issues can also arise, leading to rough transitions or slipping gears. This can often be linked to low fluid levels, leaks, or worn-out parts within the transmission system.

Suspension Wear: Over time, the suspension system may show signs of wear, affecting ride quality and handling. Common indicators include excessive bouncing, noise while driving over bumps, or uneven tire wear.

Being aware of these typical issues allows owners to take proactive measures, ensuring a smoother and more reliable driving experience.

Maintenance Tips for Long Life

Ensuring the longevity of your vehicle involves a series of consistent practices that promote optimal performance and reliability. Regular attention to key components can prevent common issues and enhance the overall driving experience. This section outlines essential maintenance strategies to keep your automobile running smoothly for years to come.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Improves engine efficiency and longevity |

| Tire Rotation | Every 6,000 miles | Ensures even tire wear and extends tire life |

| Brake Inspection | Every 10,000 miles | Enhances safety and prevents costly repairs |

| Fluid Checks | Monthly | Prevents overheating and mechanical failures |

| Air Filter Replacement | Every 15,000 miles | Improves air quality and engine performance |

By adhering to these maintenance practices, vehicle owners can significantly enhance the reliability and lifespan of their automobiles, ensuring they remain a dependable mode of transportation.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for any maintenance task. Proper tools not only enhance efficiency but also ensure that the job is done correctly and safely. Here’s a guide to the fundamental equipment you should consider when tackling automotive issues.

Basic Hand Tools

- Wrenches: A set of various sizes is essential for loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for a range of tasks.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Socket Set: Provides versatility and ease for working with fasteners in tight spaces.

Specialized Equipment

- Torque Wrench: Ensures fasteners are tightened to the manufacturer’s specifications.

- Jack and Jack Stands: Essential for safely lifting the vehicle for underbody access.

- OBD-II Scanner: Helps diagnose electronic issues by reading error codes from the vehicle’s computer.

- Multimeter: Useful for checking electrical systems and components.

Equipping yourself with these essential tools will facilitate smoother and more effective maintenance processes, ultimately extending the lifespan of your vehicle.

Step-by-Step Repair Procedures

This section outlines a systematic approach to fixing various issues that may arise in your vehicle. Each step is designed to ensure clarity and ease of understanding, enabling you to follow along effectively.

Begin by gathering the necessary tools and materials required for the task. This includes wrenches, screwdrivers, and replacement parts. Ensure that everything is organized to streamline the process.

Next, safely elevate the vehicle if you’re working underneath it. Use jack stands to provide stability and security. Always prioritize safety to prevent accidents while performing maintenance tasks.

Identify the problem area and inspect it thoroughly. Look for any signs of wear, damage, or leaks. Document your observations, as this will help you determine the necessary actions to take next.

Once the issue is diagnosed, proceed with the appropriate disassembly. Carefully remove any components that obstruct access to the problem area. Keep track of all screws and parts to ensure a smooth reassembly later.

After addressing the issue, reassemble the components in the reverse order of disassembly. Ensure that all fasteners are tightened to the manufacturer’s specifications, which can often be found in various reference guides.

Finally, conduct a thorough test of the vehicle to confirm that the repairs were successful. Monitor for any unusual sounds or behaviors during operation, as these can indicate further adjustments may be needed.

Understanding Engine Specifications

Engine specifications provide essential insights into the core characteristics of a vehicle’s power unit. Knowing these details can help in identifying compatibility with various components, understanding performance capabilities, and evaluating overall efficiency. From fuel capacity to power output, each element plays a critical role in determining how effectively the engine operates under different conditions.

Key engine characteristics typically include displacement, cylinder configuration, and compression ratio. Displacement, often measured in liters or cubic centimeters, indicates the total volume of all cylinders, which directly influences power potential. The cylinder configuration, such as inline or V-type, affects the engine’s balance, size, and vibration levels. Meanwhile, the compression ratio, which represents the difference between the cylinder’s maximum and minimum volume, impacts both efficiency and power output.

Beyond these, torque and horsepower are two crucial figures. Torque reflects the engine’s rotational force, while horsepower gauges the total power output. Together, these specifications help to assess how well an engine handles acceleration, load, and speed. Understanding these core elements is fundamental for anyone interested in vehicle performance or modifications.

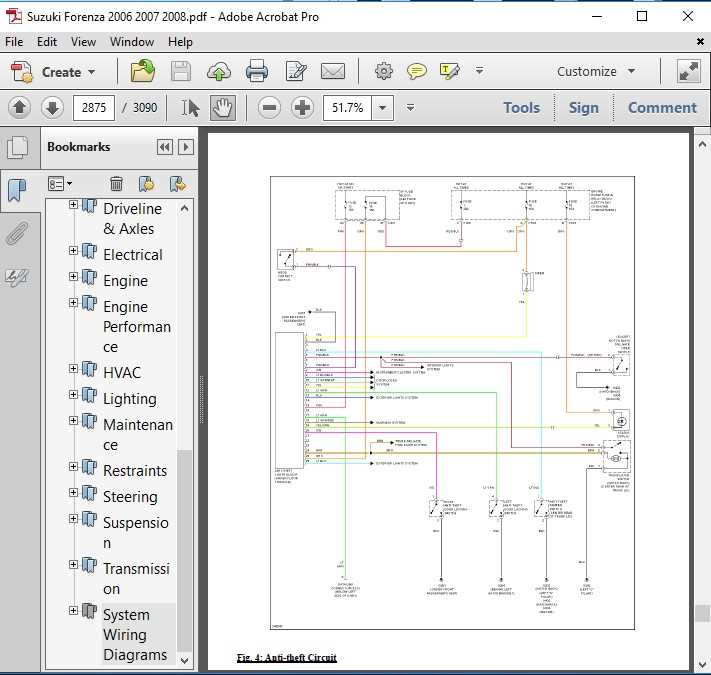

Electrical System Troubleshooting Guide

Understanding the electrical framework of a vehicle is essential for diagnosing issues effectively. This guide offers an overview of common electrical concerns, helping identify and resolve problems within the system to maintain optimal performance. Whether it’s diagnosing a non-starting engine, handling lighting malfunctions, or addressing battery concerns, having a structured approach is crucial.

Battery Issues: One frequent problem is related to the power source, often indicated by dim lights or a weak start. A thorough examination of the power levels, along with checking for corrosion on terminals, can help pinpoint the problem. If necessary, replace or recharge the unit to ensure consistent power flow.

Fuses and Relays: Blown fuses or faulty relays can interrupt various circuits, leading to component failures. Locate the fuse box and inspect each fuse visually. If any are damaged, replace them with a new one of the same rating. Relays, which control larger electrical loads, should be tested as well to confirm functionality.

Wiring and Connectors: Loose or corroded connectors can lead to intermittent power flow and various malfunctions. Inspect wiring for signs of wear or damage, and ensure all connections are secure. Tightening or replacing worn connectors can restore stable current across the system.

Alternator Performance: The alternator plays a key role in charging the power source and supplying energy to electrical components. If there’s frequent battery drainage, it may be time to test the alternator. A voltmeter can help assess its output; any irregular readings may indicate the need for service or replacement.

With these steps, many electrical issues can be identified and resolved, ensuring the vehicle’s systems continue to operate efficiently and reliably.

Transmission Care and Repair

Proper attention to the transmission is essential for ensuring the longevity and reliability of any vehicle. Regular maintenance, timely inspections, and addressing minor issues early can prevent more serious complications, helping to keep the transmission system in optimal condition.

| Maintenance Task | Frequency | Details |

|---|---|---|

| Fluid Check | Every 15,000 miles | Inspect and top off transmission fluid, ensuring levels are within the recommended range. |

| Fluid Replacement | Every 30,000 miles | Drain and refill with fresh fluid to remove impurities and keep the transmission running smoothly. |

| Filter Replacement | Every 60,000 miles | Replace the transmission filter to prevent clogging and to maintain fluid flow efficiency. |

| Inspection of Components | Annually | Inspect seals, gaskets, and connectors for any signs of wear or leakage. |

| Transmission Flush | Every 100,000 miles | A complete flush to clear out

Recommended Fluids and Parts

To ensure optimal vehicle performance and longevity, it’s essential to choose the appropriate fluids and key parts tailored for each component. Following specific recommendations allows for improved efficiency, a smoother ride, and reduces the risk of unexpected maintenance needs. Essential Fluids

Key Replacement Parts

|