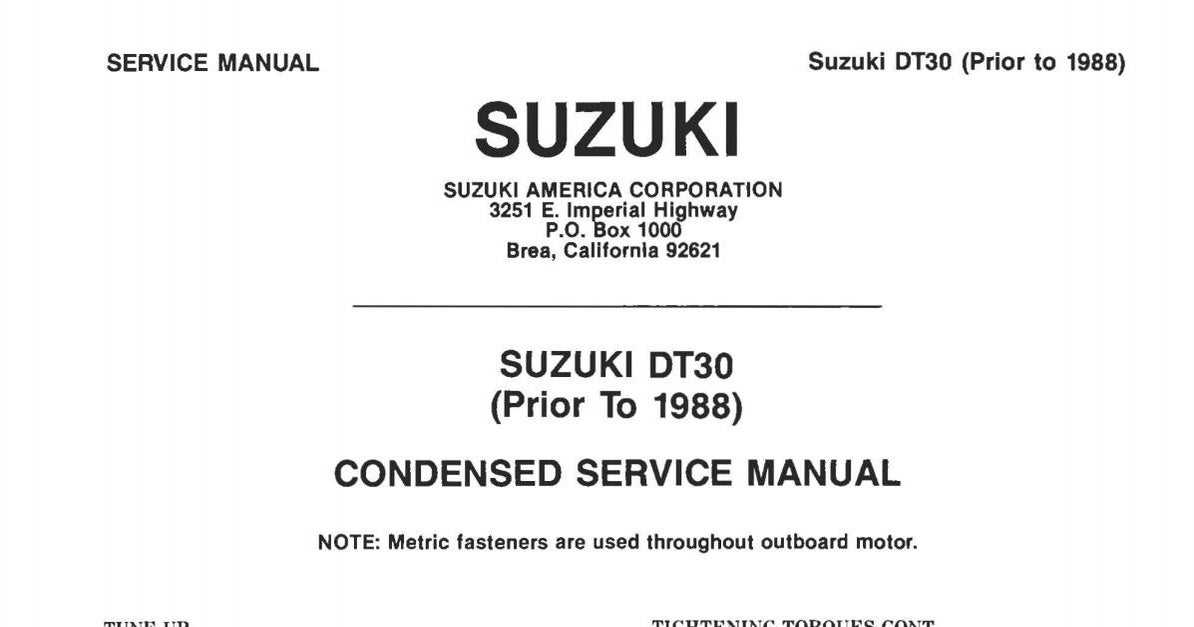

Suzuki DT40 Repair Guide for Smooth Maintenance

Maintaining a marine engine is crucial for ensuring optimal performance and longevity. This resource serves as a valuable tool for enthusiasts and professionals alike, providing insights into the intricate workings of a specific outboard model. By understanding its components and functions, users can effectively troubleshoot issues and perform necessary upkeep.

Knowledge of proper techniques can significantly reduce the likelihood of costly repairs and enhance the overall efficiency of the vessel. This guide covers essential procedures, from routine checks to advanced adjustments, equipping users with the skills needed for successful operation. It emphasizes the importance of regular maintenance in prolonging the lifespan of the engine.

Whether you are facing minor challenges or embarking on more complex projects, this resource aims to empower users with the confidence to tackle repairs and modifications. The structured approach not only demystifies the process but also encourages a hands-on understanding of marine technology, ensuring that every trip on the water is as enjoyable as possible.

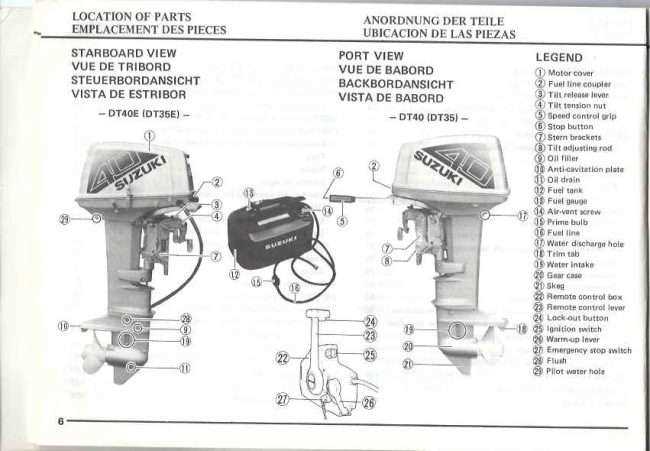

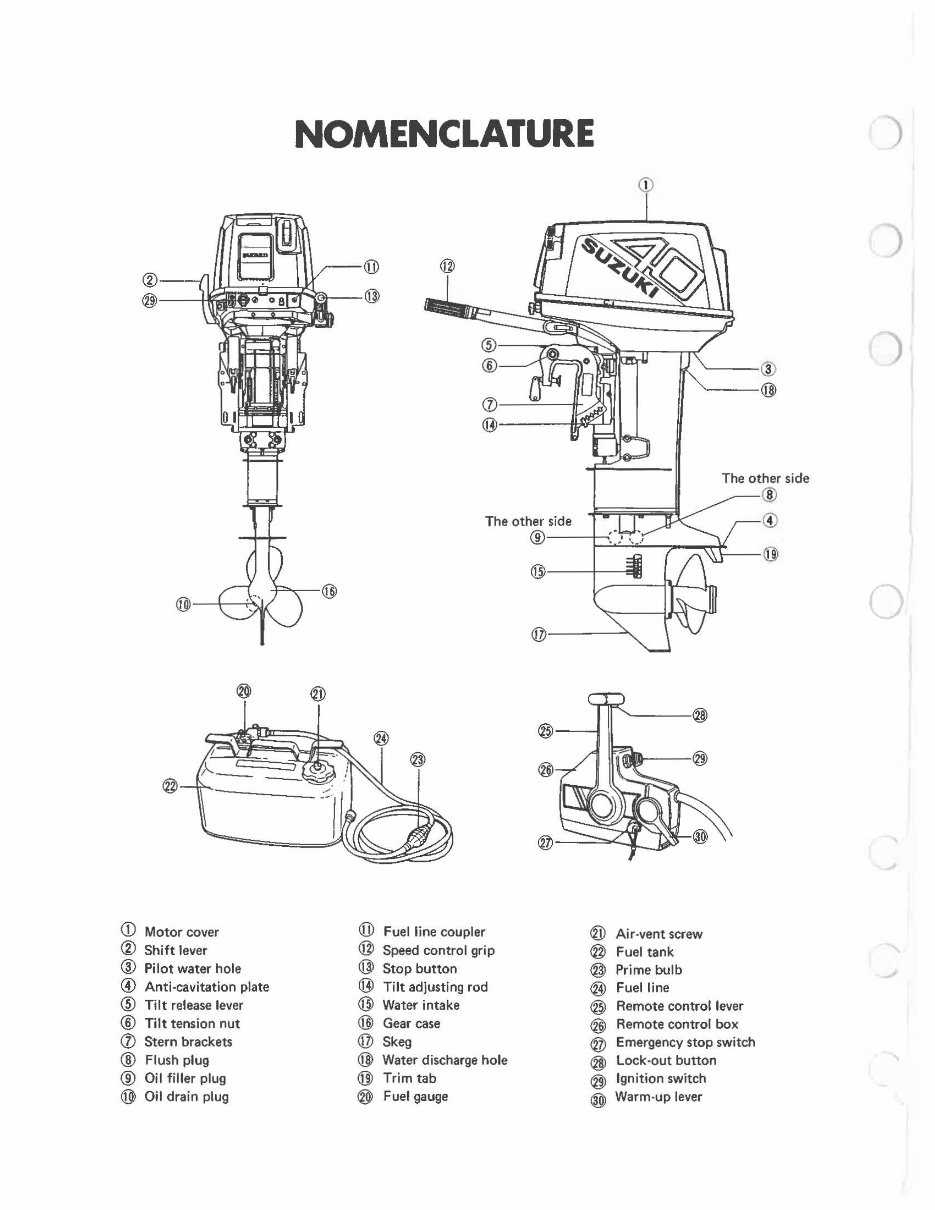

Suzuki DT40 Overview

This section provides a comprehensive look at a specific outboard motor model known for its reliability and performance on the water. Designed for both recreational and professional use, it offers a blend of power and efficiency, making it a favored choice among boating enthusiasts.

Key Features

The highlighted model boasts a robust engine that ensures smooth operation in various conditions. Its lightweight design enhances maneuverability, while advanced engineering contributes to fuel efficiency. Users appreciate the ease of maintenance, which allows for quick servicing and adjustments.

Applications

Common Issues with Suzuki DT40

When it comes to watercraft engines, certain problems frequently arise, impacting performance and reliability. Understanding these common complications can aid in timely maintenance and enhance the overall experience on the water.

Typical Problems Encountered

- Fuel Delivery Issues

- Clogged fuel filters

- Faulty fuel pumps

- Incompatible fuel types

- Electrical Failures

- Dead batteries

- Corroded connections

- Malfunctioning ignition coils

- Overheating Concerns

- Blocked cooling passages

- Low coolant levels

- Faulty thermostats

Symptoms to Watch For

- Difficulty starting the engine

- Unusual noises during operation

- Excessive smoke emissions

- Inconsistent power output

Being aware of these issues and their symptoms can help in maintaining a smooth operation, ensuring a safe and enjoyable time on the water.

Essential Tools for Repair

Having the right equipment is crucial for any maintenance task. A well-equipped workspace not only enhances efficiency but also ensures that each job is completed to the highest standard. Below is a list of indispensable instruments that will assist in various service activities, ensuring everything runs smoothly.

| Tool | Description |

|---|---|

| Socket Set | Includes various sizes to accommodate different fasteners, essential for loosening and tightening components. |

| Wrench | Used for gripping and turning nuts and bolts, available in adjustable and fixed sizes. |

| Screwdriver Set | A variety of heads and sizes are necessary for working with screws, enabling precise adjustments. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components, available in several types for specific tasks. |

| Multimeter | Essential for testing electrical systems, allowing for the diagnosis of electrical issues accurately. |

| Oil Can | For lubricating parts, helping to maintain smooth operation and prevent wear. |

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening or damage. |

Step-by-Step Maintenance Procedures

Regular upkeep of your marine engine is crucial for optimal performance and longevity. Following a structured approach ensures that all components are functioning correctly and that potential issues are addressed before they escalate. This section outlines essential maintenance tasks to keep your equipment in peak condition.

Essential Maintenance Tasks

The following table summarizes key maintenance activities, their frequency, and recommended procedures:

| Task | Frequency | Procedure |

|---|---|---|

| Change Engine Oil | Every 100 hours | Drain old oil, replace oil filter, refill with new oil. |

| Inspect Fuel System | Every season | Check for leaks, replace filters, clean fuel lines. |

| Check Cooling System | Every 50 hours | Flush system, inspect hoses, ensure proper flow. |

| Examine Electrical Connections | Every 6 months | Inspect terminals, clean corrosion, ensure secure connections. |

| Inspect Propeller | Before each outing | Check for damage, clean debris, ensure proper alignment. |

Final Thoughts

Consistent attention to these maintenance procedures will significantly enhance the reliability and efficiency of your marine equipment. By adhering to these guidelines, you can enjoy peace of mind while out on the water, knowing your engine is well taken care of.

Engine Troubleshooting Techniques

When dealing with performance issues in outboard motors, understanding effective diagnostic methods is essential for identifying and resolving problems. This section outlines various approaches to pinpoint engine malfunctions, ensuring optimal functionality and longevity.

| Issue | Potential Causes | Troubleshooting Steps |

|---|---|---|

| Engine Won’t Start | Dead battery, faulty ignition system, fuel blockage | Check battery charge, inspect ignition components, examine fuel lines |

| Overheating | Coolant blockage, damaged thermostat, low fluid levels | Inspect coolant passages, replace thermostat, top off fluids |

| Loss of Power | Clogged filters, worn spark plugs, propeller issues | Clean or replace filters, check spark plug condition, inspect propeller for damage |

| Strange Noises | Loose components, internal damage, exhaust issues | Secure all fittings, perform internal inspection, check exhaust system |

By systematically evaluating these potential issues, operators can effectively diagnose and address problems, ensuring their engines operate smoothly and efficiently.

Fuel System Inspection Guidelines

Ensuring optimal performance of the fuel delivery mechanism is essential for the efficient operation of any engine. This section outlines key procedures for assessing the various components of the fuel system, aiming to identify potential issues that could hinder performance or lead to malfunctions. Regular evaluation helps maintain the overall health of the engine, ensuring longevity and reliability.

Visual Inspection

Start with a thorough visual assessment of the fuel lines, connections, and components. Look for signs of wear, such as cracks or leaks, which can lead to fuel loss and affect engine efficiency. Ensure that all fittings are secure and that there are no loose connections. Additionally, check for any corrosion or rust on metal parts that may compromise the system’s integrity.

Functional Testing

After the visual inspection, conduct functional tests to evaluate the operation of the fuel pump and filter. Listen for unusual sounds from the pump, which may indicate wear or failure. Verify that fuel flows freely through the filter, replacing it if any blockages are detected. Monitoring fuel pressure with a gauge can also provide insight into the system’s health, helping to pinpoint issues before they escalate.

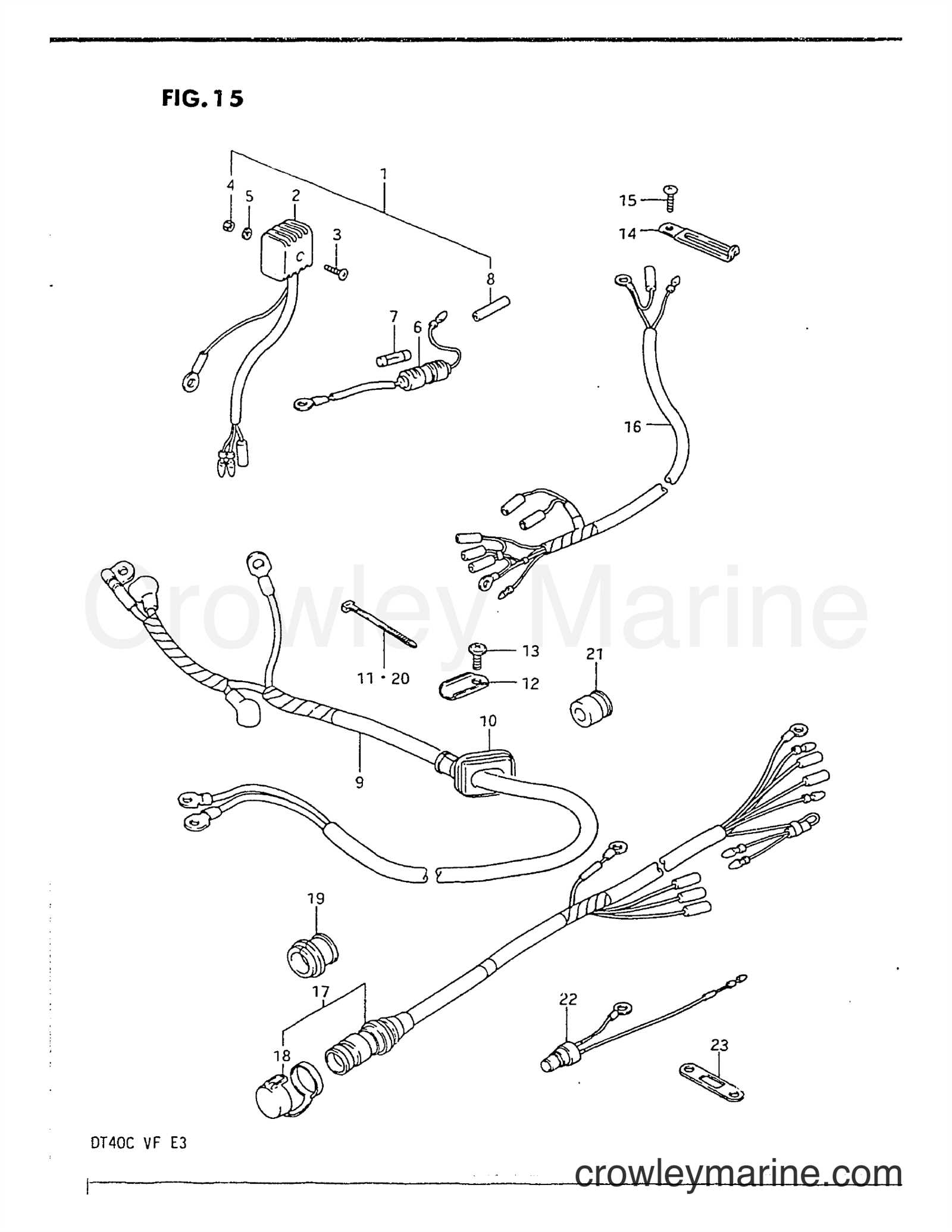

Electrical Components and Diagnostics

This section focuses on the essential electrical elements found in outboard motors and the methods used to assess their functionality. Understanding these components is crucial for maintaining optimal performance and ensuring reliable operation.

Key electrical components typically include:

- Batteries

- Wiring harnesses

- Switches

- Relays

- Ignition systems

- Alternators

- Sensors

To diagnose issues effectively, follow these steps:

- Visual Inspection: Check for damaged wiring, loose connections, or signs of corrosion.

- Testing Voltage: Use a multimeter to measure voltage at various points in the circuit.

- Continuity Checks: Ensure that current flows properly through switches and relays.

- Component Testing: Isolate and test individual parts, such as the battery and ignition system, to confirm they function correctly.

- Error Code Retrieval: For motors equipped with diagnostic ports, use appropriate tools to read error codes and troubleshoot accordingly.

Regular checks and understanding of these components not only enhance performance but also prolong the lifespan of the motor. Proper diagnostics can save time and prevent costly repairs in the long run.

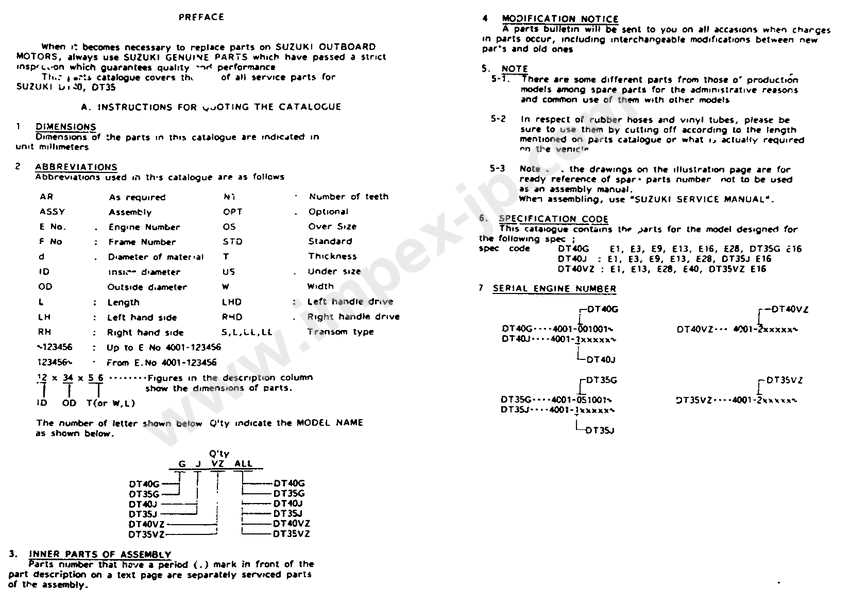

Rebuilding the Carburetor Explained

Over time, the fuel delivery system in marine engines can become less efficient due to wear and deposits. Rebuilding the carburetor is a vital process that restores functionality and enhances performance. This section outlines the key steps and considerations necessary for a successful overhaul.

Before diving into the rebuilding process, it’s essential to gather the right tools and materials:

- Clean work area

- Basic hand tools (screwdrivers, wrenches)

- Carburetor cleaner

- Replacement gaskets and O-rings

- Service manual for specific diagrams

Here’s a step-by-step approach to rebuilding:

- Disassembly: Carefully remove the carburetor from the engine. Take note of the position of each component for easier reassembly.

- Inspection: Examine all parts for wear and damage. Pay close attention to the float, needle valve, and jets.

- Cleaning: Use carburetor cleaner to remove any build-up. Ensure all passages are clear and free from obstruction.

- Replacement: Install new gaskets and O-rings to prevent leaks. Replace any worn or damaged components identified during inspection.

- Reassembly: Carefully put all parts back together, following the order in which they were removed. Ensure everything is tightened to the manufacturer’s specifications.

- Adjustment: Set the float height and mixture screws according to recommended settings to optimize performance.

Once rebuilt, the carburetor should be reinstalled and the engine tested for performance. Regular maintenance will ensure longevity and reliability of the fuel delivery system.

Propeller and Gearbox Maintenance

Proper upkeep of the propeller and gearbox is essential for optimal performance and longevity of marine engines. Regular attention to these components ensures efficient operation and minimizes the risk of mechanical failures during use. Understanding the key aspects of maintenance can lead to a smoother experience on the water.

Regular inspection and servicing of the propeller and gearbox can prevent potential issues and improve overall efficiency. Key areas to focus on include wear and tear, lubrication, and alignment. By adhering to a systematic maintenance routine, users can significantly enhance the reliability of their vessel.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Before each use | Check for damage or corrosion |

| Propeller Removal | Every season | Clean and check for nicks or bends |

| Gearbox Oil Change | Every 100 hours | Use recommended oil type |

| Check Alignment | Annually | Ensure proper fit to prevent vibration |

Maintaining the propeller and gearbox not only enhances performance but also ensures safety on the water. Regular checks and timely repairs can save time and costs in the long run, making it a worthwhile investment for any maritime enthusiast.

Preventive Measures for Longevity

Ensuring the durability and reliability of your marine engine requires consistent attention and proper care. By implementing a few essential practices, you can significantly extend the lifespan of your equipment and enhance its performance over time. These measures not only safeguard your investment but also contribute to safer and more enjoyable outings on the water.

Regular Maintenance Tasks

- Check and replace the oil at recommended intervals to maintain optimal lubrication.

- Inspect fuel lines and filters to prevent clogs and ensure efficient fuel delivery.

- Examine the cooling system regularly for blockages and leaks to avoid overheating.

- Clean or replace spark plugs to ensure reliable ignition and efficient combustion.

Environmental Considerations

- Store the engine in a dry, sheltered area to prevent corrosion and damage from the elements.

- Avoid operating in shallow or debris-filled waters to minimize wear and tear.

- Use appropriate antifouling agents to protect against marine growth when the engine is not in use.

Replacing Worn Parts Effectively

Ensuring the longevity and optimal performance of your equipment often involves addressing components that show signs of wear. Timely replacement of these elements is crucial to maintain efficiency and prevent further damage. This section highlights effective strategies for identifying and replacing worn components to enhance overall functionality.

1. Identifying Worn Components: The first step is to conduct a thorough inspection. Look for signs of fatigue, such as cracks, fraying, or corrosion. Regular maintenance checks can help you catch these issues early, ensuring that your machinery operates smoothly.

2. Sourcing Quality Parts: When it comes to replacements, always opt for high-quality components. Investing in durable parts not only ensures better performance but also reduces the frequency of future replacements. Research reliable suppliers and consider OEM (Original Equipment Manufacturer) options for the best fit.

3. Proper Installation: Replacing parts correctly is essential for seamless operation. Follow the manufacturer’s guidelines closely. Utilize the right tools and techniques to ensure that each component is fitted securely. Taking the time to install parts correctly can save you from headaches down the road.

4. Regular Maintenance: After replacing worn items, implement a routine maintenance schedule. Regular upkeep can prolong the lifespan of your new components and enhance overall system performance. Keeping track of usage and wear can help you anticipate future replacements.

By following these practices, you can effectively manage the replacement of worn components, ensuring your equipment remains in peak condition and continues to serve its purpose efficiently.

Finding Replacement Parts Online

Locating components for your outboard engine can be a straightforward process with the right approach. The internet provides a wealth of resources, making it easier to find necessary items without the hassle of visiting multiple stores. Utilizing online platforms can save time and potentially money while ensuring you have access to a broad range of products.

When searching for parts, it’s essential to consider reputable websites that specialize in marine supplies. These platforms often offer detailed descriptions and specifications, helping you make informed decisions. Additionally, user reviews can provide insight into the reliability and quality of the components.

| Website | Specialty | Notes |

|---|---|---|

| MarineParts.com | General marine supplies | Wide selection; competitive pricing |

| BoatParts.com | Outboard and inboard engines | Detailed inventory; good customer service |

| eBay | Used and new parts | Varied pricing; auction options available |

| Amazon | Various marine products | Fast shipping; customer reviews |

Always verify the compatibility of the parts with your specific model before making a purchase. It’s advisable to have your engine’s specifications on hand to ensure a perfect fit. By leveraging online resources effectively, you can streamline the process of sourcing the parts you need.