Comprehensive Guide to Repairing Suzuki F6A

This section serves as a thorough overview for enthusiasts and professionals seeking to enhance their understanding of engine upkeep. Focusing on fundamental principles and essential procedures, it aims to provide insights that facilitate optimal performance and longevity of the unit.

Delving into key aspects of mechanical care, this guide emphasizes troubleshooting techniques, component servicing, and preventive measures. By adhering to the outlined strategies, users can effectively manage various challenges that may arise during operation, ensuring a smoother experience on the road.

Furthermore, the content encourages a proactive approach to maintenance, equipping individuals with the knowledge necessary to tackle potential issues head-on. With a clear emphasis on systematic methods, this resource is invaluable for those committed to excellence in engine functionality.

Understanding the Suzuki F6A Engine

This section explores the fundamental aspects of a compact and efficient power unit widely used in various vehicles. Known for its reliable performance and engineering simplicity, this engine design has made a significant impact in its category, appealing to enthusiasts and everyday drivers alike.

Key Features and Specifications

This engine is characterized by its lightweight construction and compact dimensions, which contribute to its agility and fuel efficiency. Its straightforward design facilitates maintenance, allowing for easier access to essential components. Notable specifications include a multi-valve setup and a turbocharged variant, enhancing power output while maintaining economical fuel consumption.

Common Applications

The versatility of this power unit is evident in its widespread application across various models. It is particularly favored in smaller vehicles, where space and weight considerations are paramount. Its ability to deliver adequate power while remaining compact has solidified its position in the automotive market.

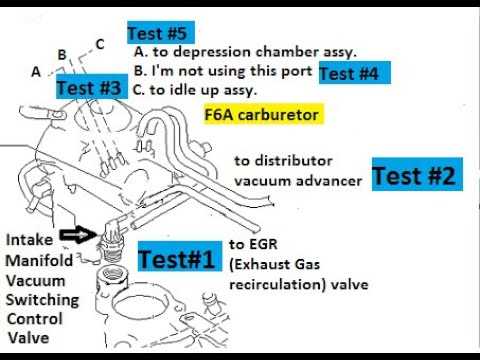

Common Issues and Troubleshooting Tips

When dealing with small engines, various challenges can arise that may impact performance and reliability. Understanding these frequent problems and having strategies for addressing them can significantly enhance the maintenance process and extend the lifespan of the vehicle.

Engine Overheating: One prevalent issue is overheating, which can stem from low coolant levels, a faulty thermostat, or a blocked radiator. Regularly checking coolant levels and ensuring proper airflow can help mitigate this problem.

Starting Difficulties: If the engine fails to start, it may be due to a weak battery, faulty ignition system, or fuel delivery issues. Conducting a systematic inspection of the battery, spark plugs, and fuel lines is essential for diagnosing the root cause.

Unusual Noises: Strange sounds from the engine can indicate mechanical wear or misalignment. It is crucial to pay attention to any irregular noises and perform timely inspections to identify and rectify potential issues before they escalate.

Fuel Inefficiency: A noticeable decrease in fuel efficiency can result from various factors, including dirty air filters, improper tire pressure, or fuel system problems. Regular maintenance checks and replacing filters as needed can help maintain optimal fuel consumption.

Brake Performance: Issues with braking can pose serious safety risks. Signs such as squeaking or grinding noises may indicate worn brake pads or insufficient brake fluid. Immediate attention to brake components is vital for ensuring safe operation.

By proactively identifying these common problems and employing effective troubleshooting techniques, owners can maintain optimal performance and enhance the longevity of their vehicles.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of any mechanical system. Adhering to a structured timeline for service tasks not only enhances performance but also prevents potential issues before they arise. This guide outlines a recommended maintenance schedule aimed at maximizing reliability and functionality.

Daily Checks

- Inspect fluid levels (engine oil, coolant, brake fluid).

- Check for any leaks or unusual noises.

- Examine tire pressure and condition.

- Ensure all lights and signals are operational.

Weekly Maintenance

- Clean the air filter and replace if necessary.

- Inspect battery terminals for corrosion and ensure secure connections.

- Check brake performance and adjust if needed.

- Lubricate moving parts as specified in the service guidelines.

Monthly Tasks

- Replace engine oil and filter.

- Inspect and adjust drive belts and hoses.

- Examine suspension components for wear or damage.

- Test all safety features and emergency equipment.

Following this maintenance schedule will help maintain optimal functionality, leading to a more enjoyable and trouble-free experience. Regular attention to these tasks ensures that potential problems are addressed proactively, contributing to the overall health of the system.

Essential Tools for Repair Work

Undertaking mechanical tasks requires a well-equipped toolkit to ensure efficiency and effectiveness. Having the right instruments not only facilitates smoother operations but also enhances the overall outcome of the job. Below are some indispensable items that every technician should consider for various maintenance activities.

Wrenches: A diverse selection of wrenches is crucial for loosening and tightening bolts. Both standard and metric sizes are important to accommodate different specifications.

Screwdrivers: A good set of screwdrivers, including both flathead and Phillips, is essential for accessing various components. Magnetic tips can also prove beneficial in retrieving dropped screws.

Pliers: Pliers come in handy for gripping, twisting, and cutting wires or other materials. Needle-nose pliers are particularly useful for reaching tight spots.

Socket Set: A comprehensive socket set allows for quick and easy adjustments on fasteners. Consider including both deep and shallow sockets for versatility.

Torque Wrench: Ensuring bolts are tightened to the correct specifications is vital for safety and performance. A torque wrench helps achieve the appropriate tension.

Diagnostic Tools: Advanced diagnostic tools can provide insights into the condition of various systems, enabling precise troubleshooting and effective maintenance strategies.

Equipping oneself with these fundamental tools significantly enhances the ability to conduct thorough and successful mechanical interventions. Proper preparation and the right instruments are key to achieving desired results.

Step-by-Step Repair Procedures

This section outlines a series of detailed methods designed to guide you through the restoration and maintenance process. By following these structured steps, you can effectively address common issues and enhance performance.

-

Preparation

- Gather all necessary tools and parts.

- Ensure a clean workspace to avoid contamination.

- Review the vehicle’s specifications and guidelines.

-

Initial Inspection

- Check for visible damage or wear on components.

- Test all systems to identify specific faults.

- Document any issues for reference.

-

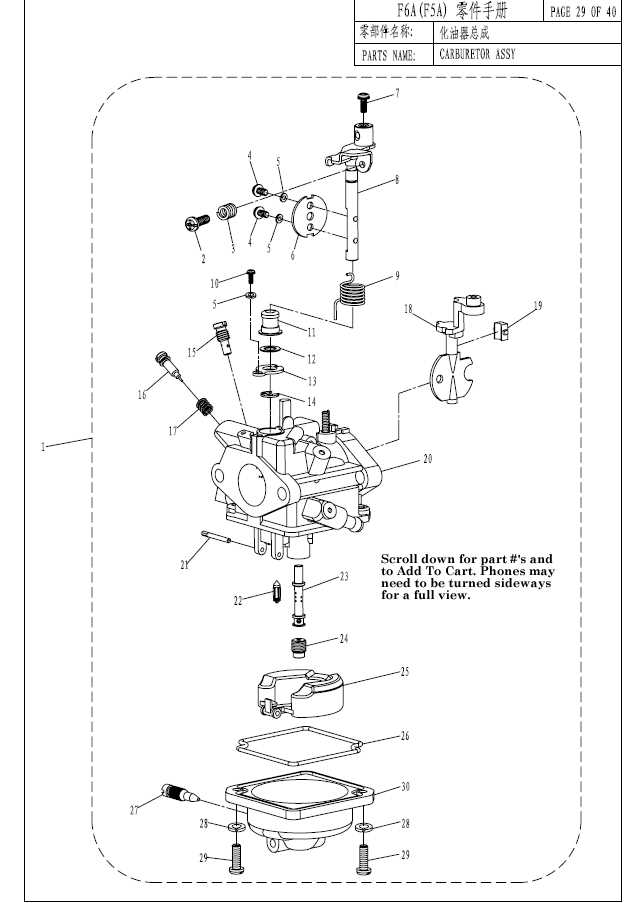

Disassembly

- Carefully remove components following the correct order.

- Label parts and fasteners to aid reassembly.

- Keep track of small items to prevent loss.

-

Repair and Replacement

- Replace damaged or worn parts with high-quality substitutes.

- Follow specific instructions for each component being addressed.

- Utilize proper techniques to ensure secure fittings.

-

Reassembly

- Reassemble components in reverse order of disassembly.

- Ensure all fasteners are tightened to the manufacturer’s specifications.

- Double-check alignment and connections.

-

Final Checks

- Perform a thorough inspection of the completed work.

- Test the vehicle to ensure everything operates correctly.

- Make any necessary adjustments based on performance.

By adhering to these systematic procedures, you can effectively maintain and enhance your vehicle’s functionality, ensuring longevity and optimal performance.

Replacing Engine Components Effectively

Replacing critical components within an engine is essential for maintaining optimal performance and longevity. This process requires careful planning and execution to ensure that each part functions harmoniously with others.

To effectively replace engine components, follow these key steps:

- Preparation:

- Gather necessary tools and replacement parts.

- Consult relevant documentation for specifications.

- Prepare a clean workspace to avoid contamination.

- Disassembly:

- Carefully remove old components, noting their arrangement.

- Use appropriate techniques to prevent damage during removal.

- Organize parts for easy identification during reassembly.

- Installation:

- Align new components according to specifications.

- Secure each part properly to avoid future issues.

- Double-check connections to ensure everything is fitted correctly.

- Testing:

- Start the engine and monitor for unusual sounds or leaks.

- Check performance metrics to confirm proper operation.

- Conduct a thorough inspection after initial use.

By adhering to these guidelines, the process of component replacement can be streamlined, resulting in enhanced efficiency and reliability of the engine.

Electrical System Diagnostics Explained

Diagnosing issues within an electrical system is crucial for ensuring optimal performance and reliability. This process involves identifying malfunctions, understanding their causes, and determining appropriate solutions. Effective diagnostics can save time, reduce costs, and enhance overall functionality.

One of the primary steps in this diagnostic approach is to evaluate the electrical components systematically. This includes examining the wiring, connectors, and power sources. Using specialized tools, technicians can check for voltage, continuity, and resistance, which are essential indicators of a properly functioning system.

Understanding common symptoms can greatly aid in troubleshooting. For instance, flickering lights or intermittent power loss often signal underlying issues. By recognizing these signs, one can focus on specific areas that require attention, streamlining the diagnostic process.

Moreover, utilizing diagnostic software can enhance accuracy. Such tools analyze data and provide real-time feedback, allowing for a more thorough assessment. With this technology, technicians can quickly pinpoint problematic areas and develop effective strategies for resolution.

In conclusion, a methodical approach to diagnosing electrical systems is vital. By leveraging knowledge, experience, and the right tools, one can ensure that all components work harmoniously, leading to improved performance and longevity.

Upgrading Parts for Enhanced Efficiency

Improving the performance and efficiency of your vehicle often involves enhancing various components. By selecting high-quality parts and optimizing their functionality, you can achieve better fuel economy and overall effectiveness.

Here are some key areas to consider when upgrading components:

- Air Intake System: Upgrading the air intake can lead to improved airflow, resulting in better combustion and increased power output.

- Exhaust System: A performance exhaust system can reduce back pressure and enhance engine breathing, contributing to higher efficiency.

- Fuel Injectors: Installing high-performance injectors can improve fuel atomization and delivery, optimizing the combustion process.

- Engine Management Software: Reprogramming the engine control unit (ECU) can fine-tune the performance parameters for maximum efficiency.

- Suspension Upgrades: Enhanced suspension components can improve handling and stability, allowing for a more efficient driving experience.

Each of these upgrades not only boosts performance but also contributes to a more enjoyable and efficient driving experience. By carefully selecting and installing the right components, you can significantly enhance the capabilities of your vehicle.

Fluid Types and Maintenance Practices

Proper management of fluids is essential for ensuring the longevity and optimal performance of any engine. Understanding the various types of fluids required and their maintenance procedures can greatly enhance functionality and reduce wear over time.

Types of Fluids

- Engine Oil: Vital for lubrication, it minimizes friction and protects components from wear. Choosing the right viscosity is crucial.

- Coolant: Helps regulate engine temperature. It’s important to maintain the correct mixture to prevent overheating and corrosion.

- Transmission Fluid: Essential for smooth gear shifting. Regular checks can prevent costly repairs.

- Brake Fluid: Critical for safe braking. It must be replaced periodically to maintain effectiveness.

- Power Steering Fluid: Ensures easy maneuverability. Regular inspection helps avoid steering issues.

Maintenance Practices

- Regularly check fluid levels and top them off as needed to ensure optimal performance.

- Follow the manufacturer’s recommendations for fluid changes, as this varies depending on usage and conditions.

- Inspect for leaks and address them promptly to avoid fluid loss and potential damage.

- Utilize high-quality fluids that meet industry standards to enhance reliability and efficiency.

- Maintain a log of fluid changes and inspections to track maintenance history effectively.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both the individual and the equipment. Proper precautions can help prevent accidents and promote a secure working environment. This section outlines essential guidelines to follow during such activities.

Personal Protective Equipment

Wearing appropriate protective gear is fundamental. Utilize gloves to shield your hands from sharp objects and hazardous materials. Safety glasses are vital to protect your eyes from debris, while sturdy footwear can prevent injuries from heavy components.

Workspace Organization

A tidy workspace enhances safety. Keep tools organized and free of clutter to minimize the risk of tripping or misplacing equipment. Ensure that all necessary tools are within reach, reducing the temptation to leave the work area and potentially expose yourself to hazards.

Frequently Asked Questions by Owners

This section addresses common inquiries from individuals who own this compact engine. It aims to provide clarity and assistance for those seeking guidance on various aspects of maintenance and troubleshooting.

General Maintenance

- What are the recommended intervals for oil changes?

- How often should I check the coolant levels?

- What type of fuel is best suited for optimal performance?

Troubleshooting Issues

- What should I do if the engine won’t start?

- How can I identify unusual noises coming from the engine?

- What are the signs of overheating, and how can I prevent it?