Suzuki King Quad 700 Repair Guide

Owning an all-terrain vehicle (ATV) brings the thrill of conquering rugged landscapes and exploring uncharted paths. However, such adventures often lead to wear and tear on the machine, making proper upkeep essential. This guide dives into the key aspects of maintaining your ATV, ensuring it remains dependable across all terrains.

From engine upkeep to suspension adjustments, each component requires regular attention for optimal performance. Here, we’ll explore practical steps and expert tips on how to manage, troubleshoot, and restore various mechanical aspects of your off-road vehicle, making maintenance accessible even for those with limited mechanical experience.

Whether you’re dealing with minor adjustments or more significant fixes, this guide will provide step-by-step instructions to keep your ATV in peak condition. With these insights, you’ll be equipped to handle routine tasks and unexpected issues confidently, preserving the quality and longevity of your vehicle for countless adventures ahead.

Comprehensive Guide to Suzuki King Quad 700

In this section, we delve into a detailed exploration of a renowned all-terrain model, designed for rugged trails and diverse landscapes. This guide covers its primary components, essential maintenance techniques, and troubleshooting tips to ensure optimal performance and longevity.

Key Features and Specifications

Built for versatility and durability, this vehicle is equipped with advanced systems that support both recreational and work-related activities. Key attributes include a high-capacity engine, responsive handling, and sturdy suspension, making it suitable for a variety of environments.

- Engine Power: Delivers ample power for challenging terrains, allowing smooth transitions between different surfaces.

- Handling: Offers a stable and responsive experience, even in rough conditions.

- Suspension System: Absorbs shocks effectively, ensuring a comfortable ride across various landscapes.

Regular Maintenance Tips

Proper upkeep is essential for ensuring long-term functionality. Here are core maintenance steps to keep in mind:

- Inspect Fluid Levels: Regularly check and top up fluids to avoid engine strain and overheating.

- Clean the Air Filter: Ensure clean air intake by washing or replacing the air filter periodically.

- Examine Tires: Regularly inspect tire pressure and tread to maintain grip and control.

Understanding the Engine System

The engine system is the powerhouse of any vehicle, designed to convert fuel into motion with efficiency and durability. By grasping the fundamental components and the way they interact, users can better comprehend how maintenance and adjustments can improve engine performance and prolong its lifespan.

Core Components of the Engine

At the heart of the system are several key parts, including the cylinder, piston, crankshaft, and combustion chamber. Each of these plays a crucial role in generating the necessary power for the vehicle to operate. The piston moves within the cylinder, compressing air and fuel, while the combustion chamber ignites this mixture, creating a controlled explosion that drives the piston. This energy transfers through the crankshaft, which then powers the wheels, resulting in forward movement.

Fuel and Air Intake Process

The fuel and air intake process is essential for engine efficiency. The air filter ensures clean air enters the system, while the fuel injectors manage the precise fuel amount. The intake valves open to allow the air-fuel mixture to enter the combustion chamber, ensuring optimal power and reducing emissions. By maintaining these parts, one can enhance fuel efficiency and achieve smoother operation.

Understanding these basics offers a solid foundation for troubleshooting and optimizing performance, ensuring the engine remains a reliable component over time.

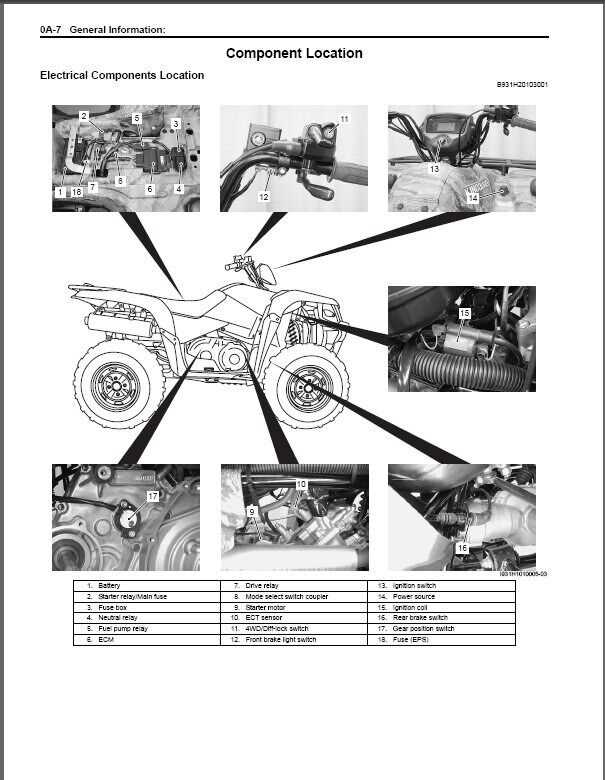

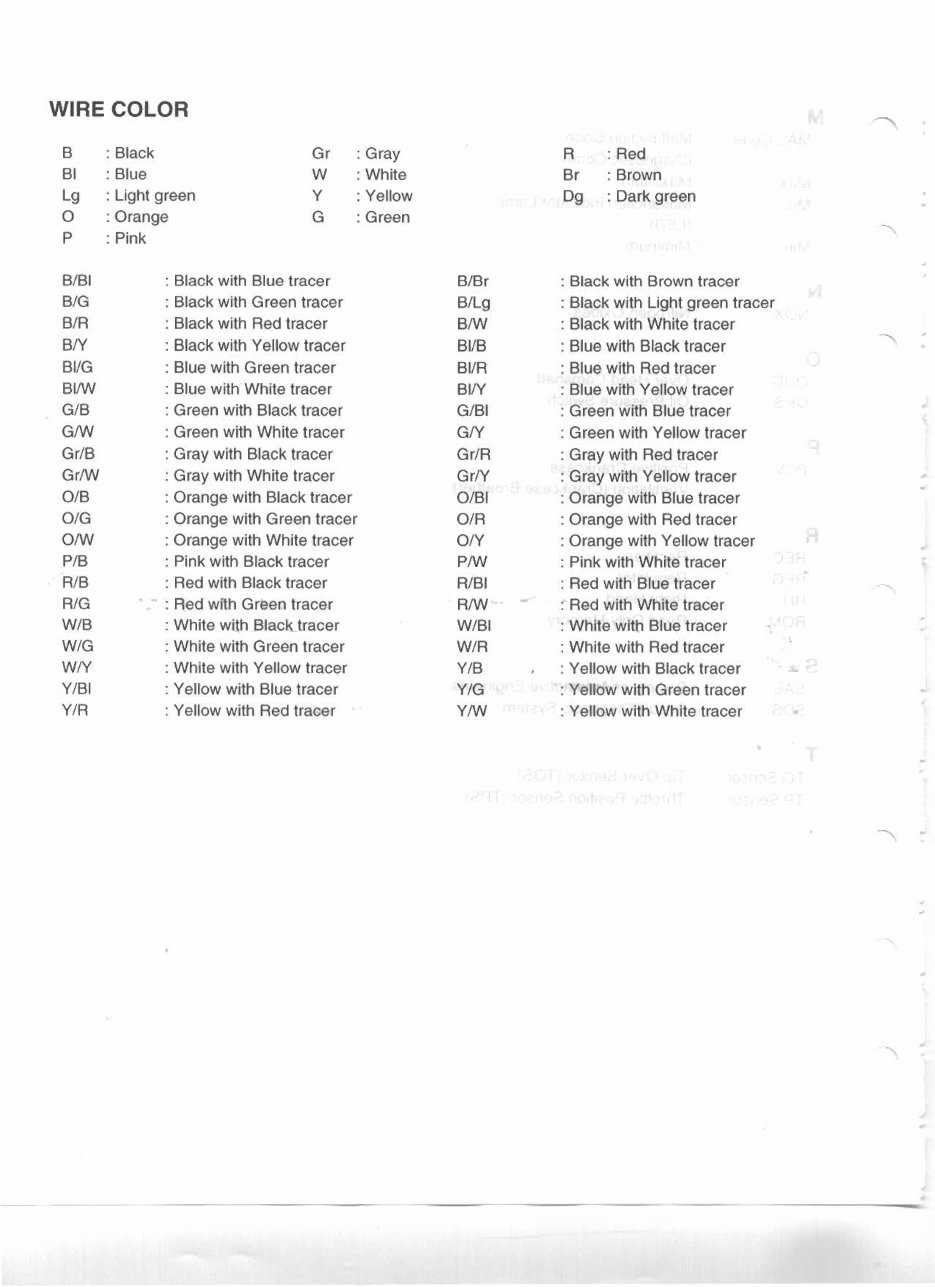

Electrical Components and Troubleshooting

Understanding the main electrical components and basic troubleshooting steps is essential for ensuring optimal functionality. Regularly checking these components helps prevent issues and supports overall performance, while troubleshooting techniques help pinpoint and resolve faults efficiently.

Key Electrical Components

Various essential elements contribute to the electrical system. Some of the primary parts include the battery, alternator, ignition coil, and wiring harness. Each of these elements plays a role in powering and regulating different systems, making a basic familiarity with their functions critical for diagnosing potential issues.

| Component | Function | Common Issues |

|---|---|---|

| Battery | Supplies power to start the engine and run electrical features | Weak or dead cells, corroded terminals |

| Alternator | Charges the battery and powers electrical systems while the engine runs | Overheating, worn bearings, low voltage output |

| Ignition Coil | Transforms battery voltage to a higher level to ignite the engine | Faulty coils, lack of spark, engine misfires |

| Wiring Harness | Connects and organizes electrical circuits | Damaged insulation, short circuits, loose connections |

Troubleshooting Tips

When electrical issues arise, start with a visual inspection. Check for loose connections, corrosion, and damaged wires. Use a multimeter to test for voltage and continuity across the battery and key components. By following these steps, minor issues can often be detected and resolved before they lead to larger problems.

Transmission Maintenance Tips

Ensuring the longevity and smooth operation of your vehicle’s transmission requires regular maintenance and attention to detail. This essential system benefits from periodic checks and adjustments to keep it running effectively, minimizing wear and preventing costly issues.

1. Check Transmission Fluid Regularly

Transmission fluid plays a crucial role in cooling and lubricating the components. Regularly inspect the fluid level and condition, looking for signs of discoloration or a burnt smell, which may indicate overheating or contamination. Refill or replace the fluid as needed, following recommended intervals.

- Use the correct type of fluid to avoid compatibility issues.

- Inspect fluid for debris, which may signal internal wear.

- Replace filters along with fluid changes for optimal performance.

2. Monitor Transmission Temperature

Overheating is one of the most common causes of transmission failure. Keeping the temperature within recommended limits helps preserve fluid quality and reduces the risk of component damage. Consider installing a temperature gauge if your vehicle lacks one to monitor heat levels effectively.

- Regularly inspect and clean the cooling system.

- Ensure proper airflow around transmission components.

- Consider additional cooling options if you operate in hot or challenging conditions.

By following these maintenance practices, you can help prevent common issues and ensure that your vehicle’s transmission performs smoothly for years to come.

Suspension Inspection and Repair Guide

Regular assessment of the suspension system ensures a stable and responsive ride, as well as improved handling on diverse terrains. This section provides essential steps for checking and addressing common issues related to suspension components, helping maintain the system’s overall performance and longevity.

Visual Inspection: Start by examining the main parts of the suspension, looking for any visible signs of wear, such as cracks, corrosion, or loosened connections. Check the springs and shock absorbers for any signs of oil leakage or damage, as these may indicate the need for replacement.

Testing Flexibility and Alignment: Next, assess the flexibility and movement of each suspension element. Push down on each corner to test the responsiveness and note any unusual stiffness or squeaks, as these could signal underlying issues. Ensure alignment of the suspension system, as poor alignment may lead to uneven wear and compromised handling.

Repair Recommendations: For minor issues, such as tightening loose bolts or replacing worn bushings, basic tools may be used to restore functionality. For more significant repairs, such as damaged shock absorbers or springs, replacing these components entirely is often recommended to maintain safety and vehicle stability.

Regular checks and timely repairs not only extend the lifespan of the suspension system but also enhance overall control and comfort during operation. By proactively addressing potential issues, the risk of unexpected breakdowns or further complications is minimized.

Cooling System: Common Issues

The cooling system is vital for maintaining optimal operating temperatures in any vehicle. Regular maintenance and awareness of potential problems can significantly extend the life of the engine and enhance performance. Below are some frequent issues encountered within this crucial system.

- Overheating: This can occur due to low coolant levels, blocked hoses, or a malfunctioning thermostat.

- Coolant Leaks: Leaks can originate from hoses, gaskets, or the radiator itself, leading to insufficient coolant and subsequent overheating.

- Clogged Radiator: Dirt and debris can obstruct the radiator, reducing its efficiency and causing overheating.

- Faulty Water Pump: A failing water pump may not circulate coolant properly, resulting in temperature irregularities.

- Thermostat Issues: A malfunctioning thermostat can cause the engine to run too cold or too hot, affecting overall performance.

Identifying these issues early can prevent more significant damage and costly repairs. Regular checks and servicing are recommended to ensure the cooling system operates effectively.

Brake System Maintenance Checklist

Regular upkeep of the braking system is essential for ensuring optimal performance and safety. A systematic approach to maintenance helps identify potential issues early, thereby prolonging the life of components and enhancing reliability.

Inspect Brake Pads: Check the condition of the brake pads for wear. Replace them if the material is worn down to the indicator line or if uneven wear is noticeable.

Examine Brake Fluid: Ensure the brake fluid level is adequate and that the fluid appears clean. Contaminated or low fluid may lead to reduced braking effectiveness.

Check Brake Lines: Inspect the brake lines for signs of leaks, cracks, or damage. Any visible wear should prompt immediate replacement.

Test Brake Functionality: Perform a test to ensure the brakes engage smoothly and effectively. Listen for any unusual noises that may indicate problems.

Verify Brake Rotors: Inspect the rotors for warping or scoring. If uneven surfaces are detected, resurfacing or replacement may be necessary.

Lubricate Moving Parts: Apply appropriate lubricant to moving components of the braking system to prevent wear and ensure smooth operation.

Review Owner’s Guide: Consult the manufacturer’s guidelines for specific maintenance recommendations and intervals to keep the braking system in top condition.

Fuel System Diagnostics

The fuel system is a crucial component of any motorized vehicle, responsible for delivering the necessary energy to the engine. Proper functioning of this system ensures optimal performance and efficiency. Diagnosing issues within the fuel system requires a systematic approach to identify potential faults that may affect overall functionality.

Begin by examining the fuel delivery process, which includes checking the fuel pump’s operation and verifying that fuel reaches the engine at the correct pressure. Next, inspect the fuel lines and connections for leaks or blockages that could impede flow. Additionally, assess the fuel filter’s condition, as a clogged filter can significantly impact performance.

Next, evaluate the fuel injectors or carburetor, depending on the vehicle’s design. Ensuring that these components are clean and functioning properly is vital for maintaining an efficient combustion process. Lastly, consider the fuel quality itself, as contaminated or incorrect fuel can lead to various operational issues.

Troubleshooting Steering and Handling

This section focuses on identifying and resolving common issues related to steering and handling systems. Proper functioning of these components is essential for safe and effective operation, ensuring that the vehicle responds accurately to the operator’s commands.

Here are some common problems you might encounter:

- Unresponsive Steering: This issue may arise due to a lack of fluid, worn-out components, or misalignment.

- Excessive Play: Loose steering may indicate worn bushings, joints, or a damaged steering shaft.

- Pulling to One Side: This could be a result of improper tire pressure, uneven tire wear, or misaligned wheels.

- Noise While Turning: Unusual sounds during turns may suggest failing bearings or a need for lubrication.

To effectively address these concerns, consider the following steps:

- Inspect fluid levels and top off if necessary.

- Check for any visible signs of wear or damage in the steering components.

- Verify tire pressure and ensure even wear across all tires.

- Conduct a thorough examination of the suspension system for any potential issues.

Regular maintenance and prompt attention to these areas can significantly enhance the performance and safety of your vehicle.

Essential Tools for Repairs

When undertaking maintenance or restoration tasks, having the right instruments is crucial for achieving optimal results. The selection of proper equipment not only enhances efficiency but also ensures safety during the process. Below are the fundamental tools that are necessary for any hands-on job.

Basic Hand Tools

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for handling screws.

- Pliers: Useful for gripping and manipulating small components.

- Hammers: Essential for driving nails or adjusting parts.

- Measuring Tape: For accurate measurements to ensure proper fitting.

Specialized Equipment

- Diagnostic Tools: To identify issues effectively.

- Jack Stands: For safely elevating the vehicle.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Fluid Extractors: For draining fluids without mess.

- Toolbox: To organize and store your tools systematically.

Preparing Your ATV for Storage

Storing your all-terrain vehicle properly is essential for ensuring its longevity and optimal performance. When the riding season comes to an end, taking the right steps to prepare your machine for storage can prevent potential issues and costly repairs in the future.

Begin by cleaning your vehicle thoroughly. Remove dirt, mud, and debris from both the exterior and undercarriage to prevent corrosion and rust buildup. Pay attention to hard-to-reach areas where grime may accumulate.

Next, drain fluids as needed. This includes the fuel, which should be treated with a stabilizer to prevent degradation, and the oil, which should be changed to remove contaminants. Additionally, check and replace any filters if necessary.

Lastly, ensure the battery is charged and stored in a cool, dry place. Disconnecting it from the vehicle can also help prevent drainage during the storage period. Cover your vehicle with a breathable tarp to protect it from dust and moisture, ensuring that it remains in good condition until the next riding season.