Suzuki Outboard Repair Guide

Effective upkeep of marine propulsion systems is essential for ensuring optimal performance and longevity. This section provides comprehensive insights into the essential procedures and troubleshooting techniques needed for maintaining these vital components.

Understanding the intricacies of engine function is crucial for both novice and experienced users. By following structured guidelines, you can tackle common issues and implement preventive measures that enhance reliability and efficiency.

Equipped with the right knowledge and tools, you can confidently navigate the challenges associated with engine maintenance. This resource aims to empower users with practical advice and actionable steps to keep their marine engines in prime condition.

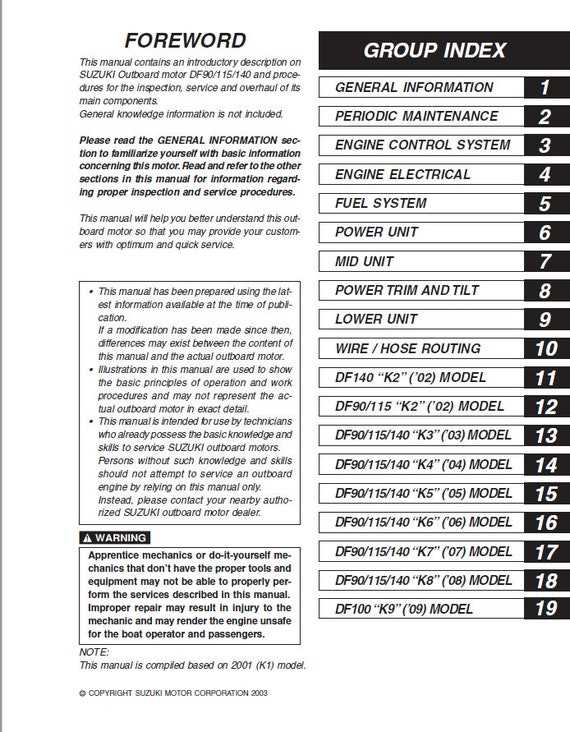

This section provides a comprehensive introduction to the world of marine propulsion systems. Understanding the fundamental aspects of these engines is essential for effective maintenance and troubleshooting. From their basic components to operational principles, the focus will be on ensuring optimal performance and longevity.

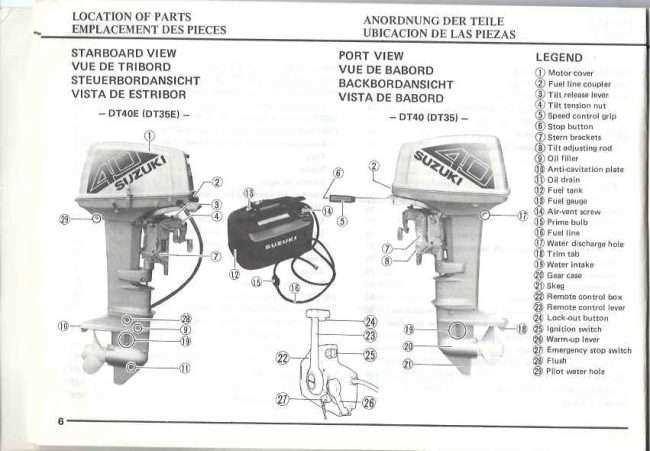

Key Components of Marine Propulsion Systems

- Powerhead: The heart of the engine, responsible for generating thrust.

- Lower Unit: Houses the gears and propeller, transferring power to the water.

- Fuel System: Essential for delivering the right mixture of fuel and air.

- Cooling System: Prevents overheating, ensuring safe operation.

Importance of Regular Maintenance

Maintaining marine engines is crucial for reliability and performance. Regular check-ups and servicing can prevent common issues, enhance fuel efficiency, and prolong the lifespan of the equipment.

- Routine oil changes to ensure smooth operation.

- Inspecting the fuel system for leaks and blockages.

- Monitoring the cooling system to avoid overheating.

- Checking electrical connections and battery health.

Common Maintenance Practices

Regular upkeep is essential for ensuring optimal performance and longevity of marine engines. Adopting systematic procedures can prevent issues and enhance efficiency, making your experience on the water more enjoyable.

Here are some fundamental practices to consider:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Check Fluid Levels | Before each use | Ensure that oil and fuel levels are sufficient for operation. |

| Inspect Propeller | Monthly | Look for signs of damage or wear that could affect performance. |

| Clean Fuel System | Annually | Remove contaminants from the fuel lines and filters to maintain flow. |

| Test Battery | Every season | Check the battery condition and connections to ensure reliable starts. |

| Inspect Hoses and Cables | Every use | Examine for signs of wear, cracks, or leaks that could lead to failures. |

Identifying Common Issues

Understanding typical problems that arise in marine engines is essential for maintaining optimal performance. This section focuses on recognizing symptoms that may indicate underlying difficulties, enabling timely intervention and effective solutions.

Engine Performance Problems

One of the most common concerns involves fluctuations in engine performance. Symptoms such as stalling, reduced power, or difficulty starting may suggest issues with fuel delivery, air intake, or ignition systems. Regular monitoring and quick diagnostics can help address these issues before they escalate.

Cooling System Malfunctions

Another frequent issue pertains to the cooling system. Signs such as overheating or inconsistent temperature readings can indicate blockages, leaks, or pump failures. Keeping an eye on coolant levels and temperature gauges can prevent serious damage and ensure efficient operation.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with marine engines. Following these structured steps will help ensure a thorough examination and resolution of various problems.

Initial Inspection

Begin by conducting a visual assessment of the unit. Check for any obvious signs of wear or damage, such as cracks, leaks, or corrosion. Ensure that all connections are secure and that there are no loose components.

Troubleshooting Common Issues

After the initial inspection, focus on diagnosing specific symptoms. For example, if the engine fails to start, examine the fuel system, ignition components, and battery connections. Systematically eliminate potential causes to pinpoint the issue effectively.

Tools Needed for Repairs

To effectively maintain and restore marine engines, having the right equipment is essential. Proper tools ensure efficiency and accuracy during the process, making tasks easier and more manageable.

- Wrenches: Various sizes for loosening and tightening components.

- Screwdrivers: A set of flathead and Phillips types for different screws.

- Pliers: Useful for gripping and twisting wires or small parts.

- Socket Set: Ideal for reaching tight spaces and securing nuts and bolts.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Multimeter: For checking electrical connections and diagnosing issues.

Having these essential tools at hand will greatly facilitate the maintenance and troubleshooting of marine engines.

Understanding Engine Components

Every engine comprises various parts that work together to generate power and ensure optimal performance. Familiarity with these elements is crucial for effective maintenance and troubleshooting. Each component plays a distinct role, contributing to the overall functionality of the machinery.

The power unit serves as the heart of the system, converting fuel into mechanical energy. It is essential to understand its operation to diagnose issues accurately. Fuel delivery systems are equally important, ensuring that the engine receives the correct mixture of air and fuel for efficient combustion.

Cooling mechanisms prevent overheating, while ignition systems initiate the combustion process, providing the necessary spark to start the engine. Understanding how these components interact can significantly enhance the longevity and efficiency of the equipment.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is crucial to prioritize safety to prevent accidents and injuries. Implementing appropriate measures ensures that both the individual performing the work and the surrounding environment remain protected. Adhering to safety guidelines can significantly reduce risks associated with handling tools and equipment.

Personal Protective Equipment

Utilizing personal protective gear is essential. Always wear safety goggles to shield your eyes from debris and gloves to protect your hands from sharp edges and chemicals. Additionally, consider wearing a mask if you are exposed to dust or fumes during the process.

Work Environment

Maintaining a clean and organized workspace is vital. Ensure that all tools are in good condition and stored properly when not in use. Keep the area well-ventilated to avoid inhaling harmful substances. Never work in confined spaces without proper ventilation, as this can lead to hazardous situations.

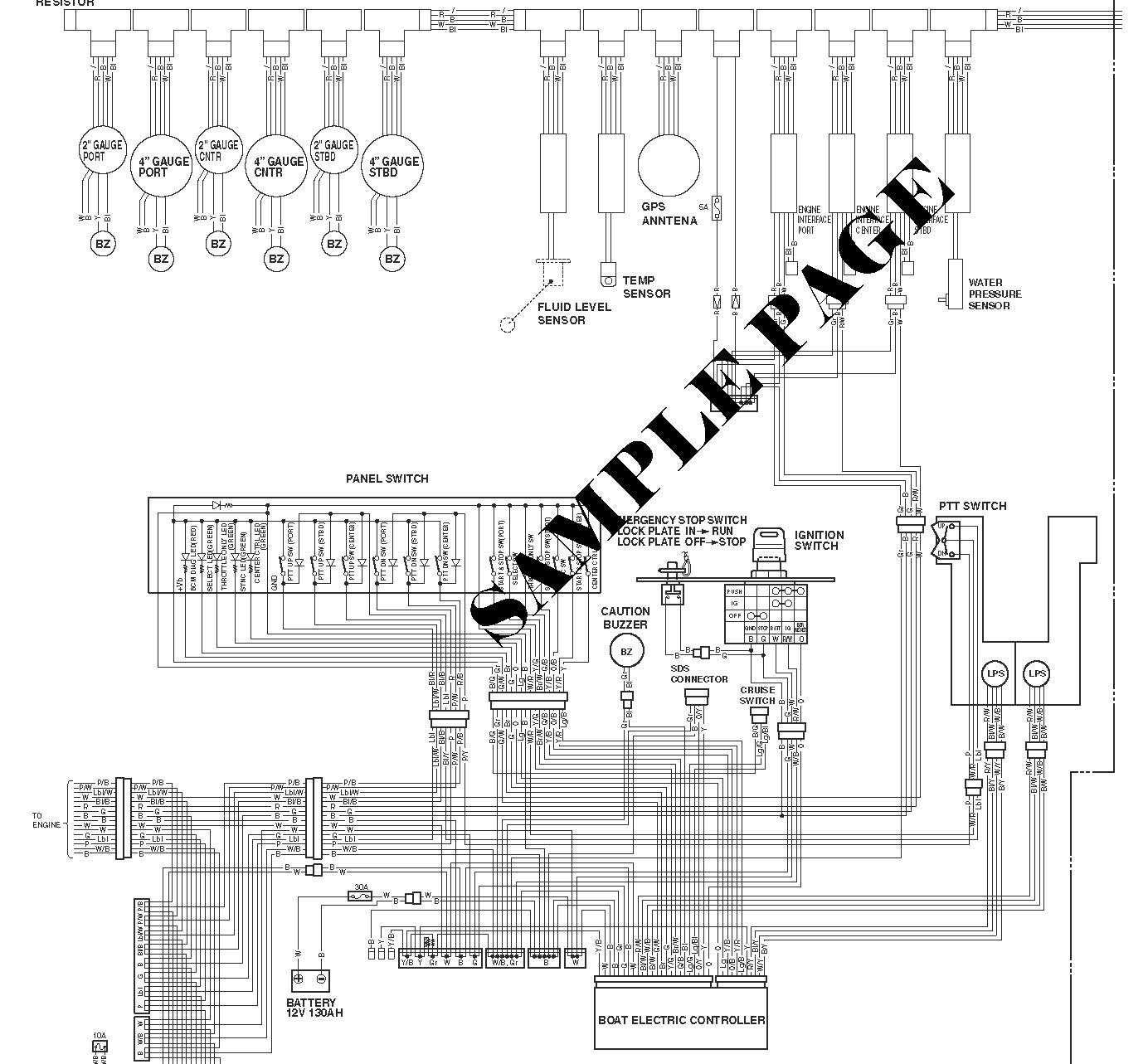

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining the functionality of marine engines. Understanding common symptoms can help diagnose problems effectively, ensuring a smooth operation on the water.

Here are some typical electrical issues and their potential causes:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Engine not starting | Dead battery | Check battery charge and connections |

| Flickering lights | Loose wiring | Inspect and tighten connections |

| Blown fuses | Overloaded circuit | Replace fuses and check for short circuits |

| Inconsistent power | Faulty ignition system | Test ignition components and replace as needed |

By systematically assessing these issues, you can restore functionality and enhance the reliability of your marine engine.

Regular Inspection and Testing

Conducting frequent evaluations and assessments of marine engines is crucial for maintaining optimal performance and preventing potential issues. These procedures help ensure that all components function properly and any anomalies are identified early.

Visual Checks: Begin with a thorough visual inspection to identify any signs of wear, corrosion, or damage. Look for leaks and ensure that all connections are secure.

Functional Testing: Perform routine tests on various systems, such as fuel and electrical components, to confirm they are operating effectively. This step is essential for identifying any irregularities that may affect overall functionality.

Fluid Analysis: Regularly analyze fluids, including oil and coolant, to detect contamination or degradation. Maintaining clean and effective fluids is vital for the longevity of the engine.

Safety Equipment Inspection: Ensure that safety devices, such as kill switches and emergency shut-off mechanisms, are functional. Regular testing of these elements is critical for safe operation.

Parts Replacement Recommendations

When maintaining marine engines, timely component replacement is crucial for ensuring optimal performance and longevity. Identifying the right moments for replacement can prevent larger issues and enhance overall functionality.

Key Components to Monitor

- Propeller: Inspect for damage or wear regularly.

- Fuel Filter: Replace periodically to ensure clean fuel flow.

- Spark Plugs: Change as needed for efficient ignition.

- Battery: Check condition and replace if signs of corrosion appear.

Replacement Frequency

- Inspect the propeller every 50 hours of use.

- Change the fuel filter annually or after a set number of hours.

- Replace spark plugs every 100 hours or at the start of each season.

- Test battery health before every season and replace as necessary.

Regular monitoring and timely replacements not only extend the life of the equipment but also enhance safety and reliability on the water.

Upgrades for Improved Performance

Enhancing the efficiency and functionality of marine engines can significantly elevate the overall boating experience. Implementing targeted modifications can lead to improved speed, fuel efficiency, and responsiveness on the water.

One of the most effective upgrades involves optimizing the fuel system. Installing a high-performance fuel injector can ensure a better fuel-air mixture, which in turn enhances combustion efficiency. Additionally, upgrading the fuel pump can provide a consistent and adequate supply of fuel, ensuring that the engine runs smoothly even under demanding conditions.

Another area to consider is the exhaust system. A performance exhaust can reduce back pressure, allowing for improved airflow. This change can lead to a noticeable boost in horsepower and torque, making the vessel more agile and responsive. Furthermore, reducing the weight of the exhaust components can contribute to overall performance gains.

Upgrading the ignition system is also crucial. Utilizing a high-energy ignition coil and performance spark plugs can enhance ignition efficiency, resulting in a more powerful and cleaner burn. This not only improves performance but also contributes to lower emissions.

Lastly, ensuring that the propeller is suited to the specific application can make a significant difference. Choosing the right pitch and diameter can optimize thrust and speed, tailoring the vessel’s capabilities to meet the user’s needs.