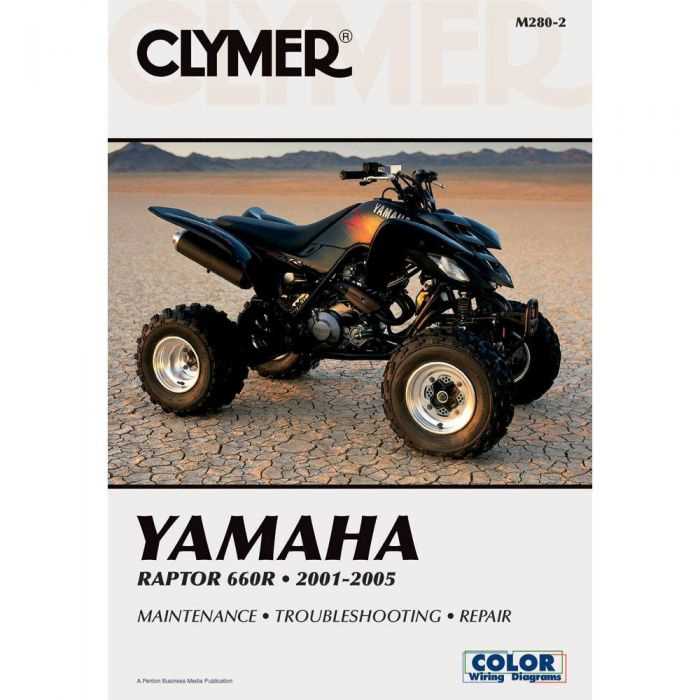

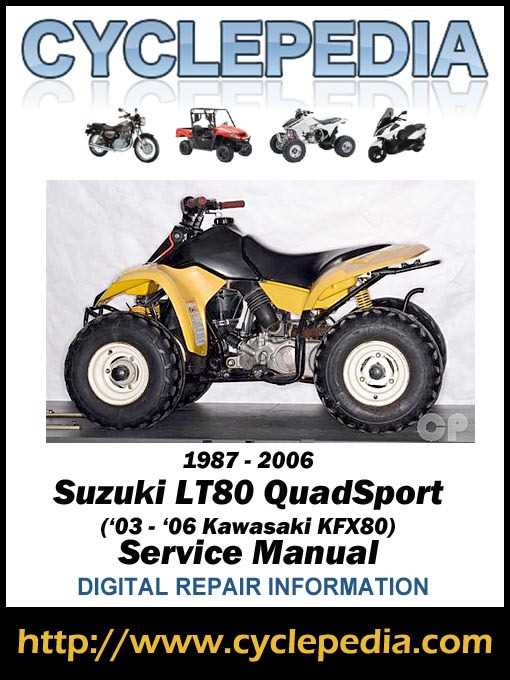

Suzuki Quadsport 80 Comprehensive Repair Guide

In the world of off-road adventures, ensuring optimal performance and safety of youth-oriented all-terrain vehicles is essential. Understanding the intricacies of these machines not only enhances their longevity but also provides a thrilling riding experience for young enthusiasts. This guide serves as a comprehensive resource for individuals looking to delve into the upkeep and troubleshooting of their vehicles.

From engine checks to wheel alignment, a thorough understanding of the various components is crucial. By addressing common issues and performing routine maintenance tasks, owners can keep their machines in peak condition. This knowledge not only empowers riders but also fosters a sense of responsibility towards their equipment.

Whether you’re a seasoned rider or a newcomer, familiarizing yourself with the essential practices can prevent potential problems down the line. Engaging with this informative guide will equip you with the skills needed to tackle minor repairs and enhancements, ensuring that every ride is as exhilarating as the last.

Suzuki Quadsport 80 Overview

The 80cc all-terrain vehicle represents a blend of compact design and robust performance, making it an ideal choice for younger enthusiasts and those new to off-road adventures. Engineered for versatility, this model is known for its user-friendly features and reliable mechanics.

Performance is a key aspect, as it offers an excellent balance of power and control, allowing riders to navigate various terrains with ease. The lightweight frame contributes to agility, while the suspension system enhances comfort during rides.

In terms of features, this model boasts a straightforward control layout that aids in learning and mastering driving skills. Safety elements are also prioritized, ensuring a secure riding experience for novices. With its durable construction and well-thought-out design, this vehicle stands out as a solid option for families seeking recreational fun.

Common Issues with Quadsport 80

When dealing with this type of off-road vehicle, enthusiasts often encounter several recurring challenges that can impact performance and safety. Understanding these common problems can aid in timely maintenance and enhance the overall riding experience.

1. Engine Performance Problems: A frequent concern involves the engine struggling to start or losing power during operation. This can be attributed to fuel delivery issues, such as clogged filters or old fuel, which hinder optimal combustion.

2. Electrical System Failures: Riders may face difficulties with the electrical components, including battery drainage or malfunctioning lights. Inspecting wiring connections and ensuring the battery is in good condition are crucial steps in addressing these issues.

3. Suspension Wear: Over time, the suspension system can become less effective due to wear and tear. This may result in a rough ride and decreased stability. Regularly checking shock absorbers and bushings is essential for maintaining comfort and control.

4. Tire Issues: Proper tire maintenance is vital for safety and performance. Common problems include uneven wear, low pressure, and punctures. Regular inspections and timely replacements can help avoid accidents and improve traction.

5. Brake Malfunctions: Brake performance is crucial for safety, and issues such as squeaking or reduced stopping power can arise. Regularly checking brake pads and fluid levels is necessary to ensure the system operates effectively.

By being aware of these prevalent issues, owners can take proactive measures to maintain their vehicles and enjoy a smoother, safer ride.

Essential Tools for Repairs

Having the right instruments at hand is crucial for efficient maintenance and troubleshooting. A well-equipped workspace not only enhances productivity but also ensures that tasks are completed safely and effectively. Below is a list of fundamental tools that every enthusiast should consider for tackling various mechanical challenges.

Basic Hand Tools

- Wrenches (open-end and box-end)

- Screwdrivers (flathead and Phillips)

- Plier sets (needle-nose, slip-joint)

- Socket set with ratchet

- Torque wrench

Specialized Equipment

- Multimeter for electrical diagnostics

- Compression tester for engine assessment

- Oil filter wrench

- Chain breaker and rivet tool

- Lubrication gun for maintenance

Equipping yourself with these essential tools will empower you to address a wide range of issues and enhance the longevity of your machinery.

Step-by-Step Maintenance Guide

Proper upkeep of your all-terrain vehicle ensures optimal performance and longevity. This guide provides a systematic approach to regular care, helping you avoid common issues and keep your machine running smoothly.

1. Regular Cleaning

Begin by cleaning the exterior after each ride. Use a soft brush and mild detergent to remove dirt and debris. Pay special attention to the air filter, as a clean filter enhances engine efficiency.

2. Check Fluid Levels

Periodically inspect oil, coolant, and fuel levels. Ensure they are within the recommended range to prevent overheating and mechanical failure. Top off or change fluids as needed.

3. Tire Maintenance

Examine tire pressure and tread regularly. Proper inflation improves handling and safety. Replace tires that show excessive wear or damage.

4. Inspect Brakes

Brake function is critical for safety. Check brake pads for wear and test responsiveness. Replace any worn components immediately to maintain reliable stopping power.

5. Battery Care

Inspect the battery for corrosion and ensure terminals are clean and tight. A well-maintained battery can prevent starting issues and prolong its lifespan.

6. Lubrication of Moving Parts

Apply appropriate lubricant to joints, chains, and cables to minimize friction. Regular lubrication can enhance performance and reduce wear on moving components.

7. Follow the Schedule

Adhere to the manufacturer’s service schedule for additional tasks, such as valve adjustments and spark plug replacements. Staying on top of these tasks will help maintain peak performance.

Engine Troubleshooting Tips

When encountering issues with your all-terrain vehicle’s power unit, systematic analysis can often reveal the underlying problems. Understanding the common symptoms and knowing how to address them can lead to effective solutions and restore performance.

Here are some essential troubleshooting steps to guide you through the process:

| Symptom | Possible Causes | Recommended Actions |

|---|---|---|

| Engine won’t start | Dead battery, faulty ignition switch, or fuel supply issues | Check battery connections, test the ignition switch, and ensure fuel is reaching the engine. |

| Overheating | Low coolant levels, blocked air intake, or malfunctioning thermostat | Inspect coolant levels, clear air passages, and test the thermostat for proper operation. |

| Loss of power | Clogged air filter, worn spark plug, or fuel quality | Replace the air filter, check the spark plug condition, and use high-quality fuel. |

| Excessive smoke | Oil leaks, improper fuel mixture, or internal damage | Inspect for leaks, verify fuel mixture ratios, and perform a compression test. |

By methodically addressing these areas, you can pinpoint issues and apply the necessary fixes to ensure optimal functionality of your vehicle’s engine.

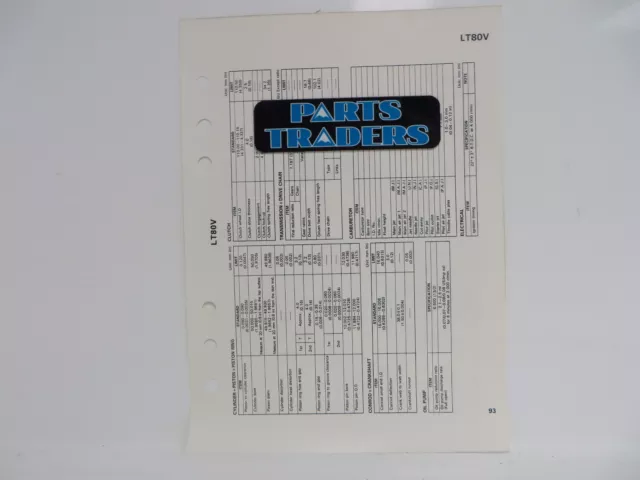

Transmission and Gear Adjustments

This section focuses on the essential aspects of maintaining and fine-tuning the transmission and gear systems of your all-terrain vehicle. Proper adjustments can significantly enhance performance, ensuring smoother operation and improved responsiveness on various terrains.

Understanding the Gear Mechanism

The gear mechanism plays a crucial role in the overall functionality of the vehicle. Familiarizing yourself with its components will aid in diagnosing issues and making necessary adjustments. Key parts include:

- Transmission casing

- Gear shafts

- Clutch assembly

- Shift linkage

Adjustment Procedures

To ensure optimal performance, follow these steps for making adjustments:

- Inspect the Linkage: Ensure that the shift linkage is properly aligned and free from wear.

- Check Fluid Levels: Verify that the transmission fluid is at the recommended level and in good condition.

- Adjust the Clutch: If the clutch engages too late or too early, adjustments can be made to the cable or hydraulic system.

- Test Gear Engagement: Shift through all gears to confirm smooth engagement without any grinding or slipping.

Regular maintenance and timely adjustments will help prolong the life of the transmission system and enhance the overall riding experience. Always consult the specific guidelines for your model to ensure accuracy during the adjustment process.

Brake System Inspection Process

The brake system is a critical component for ensuring safety and optimal performance in any vehicle. Regular examination of this system not only helps maintain efficiency but also prevents potential malfunctions that could lead to hazardous situations. Understanding the key steps involved in the inspection process is essential for proper upkeep.

Visual Inspection

Begin with a thorough visual examination of all visible components. Look for any signs of wear, such as cracked or frayed brake lines, and inspect the condition of the brake pads and rotors. Ensure that there are no leaks present, as fluid loss can significantly impact braking effectiveness. Any noticeable corrosion should be addressed promptly to prevent further deterioration.

Functional Testing

Once the visual check is complete, conduct a functional test of the braking system. Engage the brakes while stationary to assess the responsiveness and listen for any unusual noises. If the brakes feel spongy or unresponsive, it may indicate air in the system or other underlying issues. Additionally, evaluate the braking performance during a controlled test ride, ensuring that the vehicle stops smoothly and efficiently.

In summary, maintaining a reliable brake system requires diligent inspections that encompass both visual assessments and functional evaluations. Prioritizing this process will help ensure a safe and enjoyable experience on the road.

Electrical Components and Wiring

This section delves into the essential elements and connections that power and control the vehicle’s systems. Understanding the intricacies of these parts is crucial for maintaining optimal performance and ensuring safety during operation. Proper functioning of electrical components directly influences the overall reliability and efficiency of the machine.

Wiring Harness: The wiring harness serves as the backbone of the electrical system, linking various components and allowing them to communicate. It is vital to inspect for wear, fraying, or corrosion that may disrupt the flow of electricity.

Battery: The battery is the energy source that powers the starter motor and other electrical devices. Regular testing and maintenance are important to ensure it holds a proper charge and functions effectively under load.

Ignition System: The ignition system is responsible for initiating combustion within the engine. Key elements include the spark plug and ignition coil. Ensuring these components are in good condition is essential for reliable starting and performance.

Lighting System: Proper illumination is critical for safety. This includes headlights, taillights, and turn signals. Regular checks for burnt-out bulbs and electrical connections will enhance visibility and signaling.

Fuses and Relays: These protective devices prevent overload and short circuits in the electrical system. Knowing their locations and functionality is crucial for troubleshooting issues when they arise.

In summary, a thorough understanding of electrical components and wiring not only aids in diagnosing problems but also enhances the overall experience of operating the vehicle. Regular maintenance and attention to these systems can lead to improved reliability and longevity.

Suspension and Wheel Alignment

Proper suspension and wheel alignment are crucial for optimal performance and safety. They ensure a smooth ride, enhance handling, and prevent premature wear on tires and components. Regular maintenance in these areas can significantly improve the overall riding experience and longevity of the vehicle.

Suspension System Overview

The suspension system plays a vital role in absorbing shocks and maintaining tire contact with the ground. It comprises various components that work together to provide stability and comfort. Key elements include:

- Shock absorbers

- Springs

- Linkages

- Frame connections

Inspecting and maintaining these components is essential to prevent issues that can affect handling and safety.

Wheel Alignment Importance

Wheel alignment affects how well the vehicle drives and how evenly the tires wear. Proper alignment helps in achieving better fuel efficiency and control. Key aspects to check include:

- Camber: The angle of the wheels in relation to the ground.

- Toe: The direction the wheels point in relation to each other.

- Caster: The angle of the steering axis in relation to vertical.

Regular checks and adjustments can lead to improved performance and increased tire lifespan.

Cleaning and Lubrication Techniques

Maintaining optimal performance of your off-road vehicle requires regular attention to cleanliness and proper lubrication. These practices not only enhance the longevity of components but also ensure smooth operation, allowing for a more enjoyable riding experience.

Effective Cleaning Methods

Start by removing dirt and debris from the exterior. Use a gentle pressure washer or hose, avoiding direct contact with sensitive areas. For stubborn grime, a soft brush and mild detergent can be employed. After cleaning, ensure all surfaces are thoroughly dried to prevent corrosion.

Proper Lubrication Procedures

Utilize high-quality lubricants for various components, focusing on joints, bearings, and cables. Apply grease to moving parts to reduce friction and wear. Regularly check and replenish oil levels in the engine and transmission, adhering to manufacturer specifications for the best results.

| Component | Cleaning Method | Lubrication Type |

|---|---|---|

| Exterior | Pressure wash or hose | N/A |

| Chain | Brush off debris | Chain lubricant |

| Engine | Wipe with cloth | Engine oil |

| Bearings | Wipe clean | Grease |

Safety Precautions for Repairs

When undertaking maintenance on your all-terrain vehicle, ensuring a safe working environment is paramount. Adhering to certain guidelines can help prevent accidents and injuries, allowing for a smoother process and better outcomes.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and sturdy footwear to shield yourself from potential hazards. Protective gear can significantly reduce the risk of injury while you work.

Additionally, ensure that your workspace is clean and well-lit. A clutter-free area minimizes distractions and helps you locate tools and parts quickly. Proper lighting is essential for spotting small components and identifying any potential issues.

Before beginning any task, disconnect the battery or power source to prevent accidental starts. This precaution is crucial in avoiding electrical shocks or unintended movements of the vehicle.

Moreover, familiarize yourself with the vehicle’s components and assembly. Understanding how everything fits together not only aids in the repair process but also enhances safety by reducing the likelihood of mistakes.

Lastly, if you’re unsure about a particular procedure or encounter a problem, consult with an experienced technician or refer to reliable resources. Seeking guidance can prevent costly errors and ensure that you are working safely.