Comprehensive Guide to Repairing the 1984 Toyota Pickup

Maintaining a reliable mode of transportation is essential for ensuring smooth journeys and longevity. This section delves into the intricacies of servicing a classic utility vehicle, focusing on its essential components and systems. Understanding the fundamental aspects of upkeep can empower owners to perform essential tasks and enhance their driving experience.

From routine inspections to troubleshooting common issues, having access to detailed instructions and insights can make a significant difference. This guide will cover critical procedures, practical tips, and necessary tools that are crucial for preserving performance and functionality. With the right knowledge, even novice enthusiasts can tackle various challenges with confidence.

Additionally, exploring the various aspects of maintenance not only promotes efficiency but also fosters a deeper appreciation for the craftsmanship behind such vehicles. As one embarks on the journey of upkeep, the satisfaction of restoring and enhancing a classic ride becomes an exciting endeavor.

Overview of the 1984 Toyota Pickup

This section provides a comprehensive look at a compact utility vehicle known for its reliability and versatility. Originally introduced in the early 1980s, this model quickly gained popularity among consumers seeking both performance and durability in a workhorse vehicle. Its design and engineering reflect a balance between functionality and comfort, making it suitable for various driving conditions.

Design and Features

The vehicle boasts a sturdy frame and a simple yet practical exterior. Its compact size allows for easy maneuverability, while the spacious cabin offers ample legroom and storage options. Inside, drivers will find essential features that enhance the driving experience, including comfortable seating and straightforward controls.

Performance and Handling

Equipped with a robust engine, this model delivers commendable power and efficiency. The vehicle’s suspension system is designed to absorb bumps and provide a smooth ride, making it ideal for both urban commuting and off-road adventures. With reliable traction and handling, it remains a favored choice among enthusiasts and everyday users alike.

Common Issues and Solutions

Vehicles often face a variety of challenges that can hinder their performance and reliability. Understanding these frequent problems and their corresponding remedies can help owners maintain their vehicles effectively.

- Engine Overheating

- Check coolant levels regularly.

- Inspect for leaks in the cooling system.

- Ensure the thermostat is functioning properly.

- Transmission Slipping

- Examine the transmission fluid for contamination.

- Ensure the fluid is at the correct level.

- Consider a transmission fluid flush if necessary.

- Electrical Issues

- Inspect battery connections for corrosion.

- Test the alternator to ensure proper charging.

- Replace any faulty fuses or relays.

- Braking Problems

- Check brake fluid levels frequently.

- Inspect brake pads for wear and tear.

- Consider bleeding the brake system to remove air.

By addressing these common issues promptly, vehicle owners can enhance performance, increase safety, and prolong the life of their automobiles.

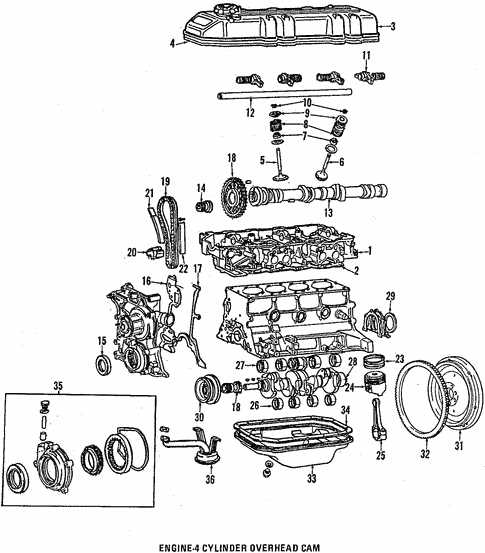

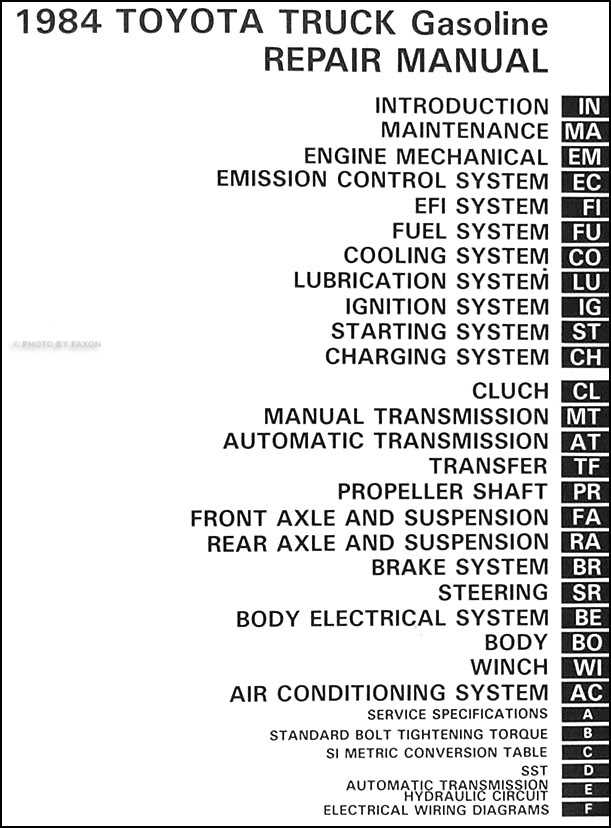

Engine Specifications and Maintenance

This section provides essential details regarding the powertrain, emphasizing its design, functionality, and care procedures. Understanding these elements is crucial for ensuring optimal performance and longevity of the vehicle’s engine.

Specifications Overview

The engine in question is a robust internal combustion unit, characterized by its displacement, number of cylinders, and configuration. With a typical inline layout, it delivers a balance of efficiency and power output, making it suitable for various driving conditions. Key specifications include:

- Displacement: 2.4 liters

- Cylinders: Four

- Compression Ratio: 9.0:1

- Horsepower: Approximately 116 hp

- Torque: 138 lb-ft

Maintenance Recommendations

Regular upkeep is vital for sustaining engine health. It is recommended to adhere to the following maintenance practices:

- Oil Changes: Change engine oil every 3,000 to 5,000 miles to ensure proper lubrication.

- Air Filter Replacement: Inspect and replace the air filter at least once a year to maintain airflow and efficiency.

- Coolant Checks: Regularly inspect the cooling system and replace coolant every two years to prevent overheating.

- Timing Belt Inspection: Check the timing belt for wear and replace it every 60,000 miles to avoid engine damage.

Transmission and Drivetrain Insights

The efficiency of any vehicle’s performance heavily relies on the synergy between its power transfer systems. Understanding these components is essential for optimizing functionality and longevity. This section delves into the intricacies of transmission and drivetrain elements, shedding light on their roles and maintenance considerations.

Key Components of the Drivetrain

The drivetrain comprises several critical parts that work together to deliver power from the engine to the wheels. Each component plays a vital role in ensuring smooth operation and enhancing vehicle handling. The following table summarizes these essential elements:

| Component | Function |

|---|---|

| Transmission | Modulates engine power and torque to the wheels |

| Driveshaft | Transmits rotational energy from the transmission to the axle |

| Differential | Distributes torque to the wheels, allowing them to rotate at different speeds |

| Axles | Support the weight of the vehicle and enable wheel rotation |

Maintenance Practices for Longevity

Regular upkeep of the transmission and drivetrain is crucial to avoid costly repairs and ensure optimal performance. Routine inspections and timely fluid changes can significantly enhance the lifespan of these systems. Keeping an eye on potential leaks, unusual noises, and performance issues will aid in early detection and prevention of major failures.

Electrical System Troubleshooting Guide

This section provides essential steps for diagnosing and resolving issues within the electrical framework of your vehicle. A reliable electrical system is crucial for the smooth operation of various components, including the ignition system, lights, and onboard accessories. Understanding how to systematically identify problems can save time and enhance the overall performance of the automobile.

Begin by examining the symptoms your vehicle exhibits, such as dim lights, malfunctioning instruments, or starting difficulties. These signs may indicate underlying electrical faults that require attention. Use the following table as a reference for common electrical problems and their potential causes:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Dim headlights | Weak battery or corroded connections | Check and clean battery terminals; test battery voltage |

| Instrument panel not functioning | Faulty fuse or wiring issues | Inspect fuses; test continuity of wiring harness |

| Engine won’t start | Defective starter or ignition switch | Test starter operation; check ignition circuit |

| Unresponsive electrical accessories | Blown fuse or malfunctioning relay | Replace blown fuses; test and replace relays if necessary |

| Frequent battery drain | Parasitic draw or aging battery | Perform a parasitic draw test; consider battery replacement |

By methodically following these guidelines and utilizing the table, you can effectively troubleshoot and resolve electrical issues in your vehicle. Always prioritize safety and consult a professional if you encounter complex problems beyond basic diagnostics.

Brake System Repair Procedures

This section outlines essential methods for maintaining and servicing the braking mechanism of a light utility vehicle. Proper attention to the braking system is crucial for ensuring optimal vehicle performance and safety. The following guidelines will assist in addressing common issues that may arise in the braking system, ensuring reliable operation and longevity.

Inspection and Diagnosis

Before proceeding with any maintenance tasks, a thorough inspection is necessary to identify potential problems. Follow these steps:

- Check the brake fluid level and condition.

- Inspect the brake pads for wear and damage.

- Examine the rotors for scoring or warping.

- Assess the condition of brake lines for leaks or corrosion.

- Listen for unusual noises during braking.

Maintenance Procedures

Once issues have been diagnosed, implement the following procedures to ensure proper functionality:

- Replace worn brake pads and ensure correct alignment.

- Resurface or replace rotors as needed to maintain even contact.

- Flush and replace brake fluid according to manufacturer specifications.

- Repair or replace any damaged brake lines to prevent fluid leaks.

- Regularly check the brake system components for signs of wear or failure.

Following these steps will help maintain the braking system’s efficiency and safety, providing peace of mind during operation.

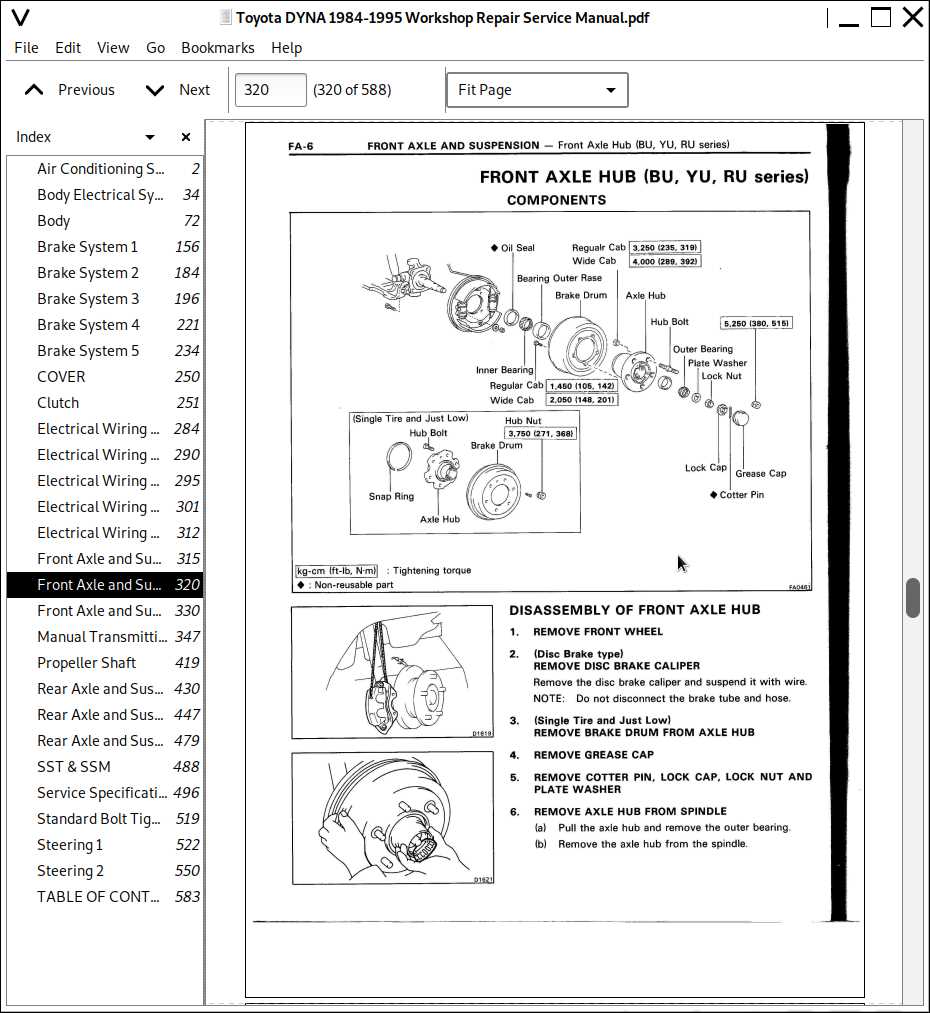

Suspension and Steering Adjustments

Ensuring optimal handling and ride comfort requires precise calibration of the suspension and steering systems. Proper adjustments can enhance vehicle stability, improve steering response, and extend the lifespan of crucial components.

Key aspects to consider during these adjustments include:

- Alignment: Ensuring that the wheels are parallel and correctly angled affects tire wear and handling.

- Shock Absorber Settings: Adjusting the damping characteristics can influence ride quality and stability, particularly on uneven surfaces.

- Spring Tension: Modifying the tension of springs can help achieve the desired ride height and load capacity.

To effectively make these adjustments, follow these steps:

- Start with a thorough inspection of the suspension and steering components.

- Utilize appropriate tools to measure and adjust wheel alignment.

- Consult specifications for shock absorber and spring settings, making modifications as necessary.

- Test drive the vehicle to assess changes and make additional adjustments if needed.

Regular attention to these systems not only improves performance but also contributes to safety and comfort during operation.

Body and Frame Restoration Techniques

Restoring the structure and chassis of a vehicle involves meticulous processes aimed at reviving its integrity and aesthetics. This endeavor requires an understanding of various techniques to ensure longevity and functionality while enhancing the overall appearance. Whether the goal is to bring an old classic back to life or to maintain a vehicle’s operational capabilities, employing the right methods is crucial.

Assessment and Planning

The initial stage involves a thorough evaluation of the body and frame. Identifying areas that require attention can significantly streamline the restoration process. Consider the following steps:

- Inspect for rust and corrosion.

- Check for structural damage, including bends or breaks.

- Evaluate the condition of body panels and components.

Restoration Methods

Once the assessment is complete, various techniques can be employed to restore the vehicle:

- Rust Removal: Utilize sandblasting or chemical rust removers to eliminate corrosion.

- Body Panel Replacement: When panels are beyond repair, sourcing new or used panels may be necessary.

- Frame Straightening: Use specialized equipment to correct any misalignment in the frame.

- Reinforcement: Consider adding reinforcements to strengthen weak areas.

- Finishing Touches: After structural repairs, refinishing with paint or protective coatings will enhance durability.

Applying these techniques diligently will ensure the successful restoration of both body and frame, resulting in a vehicle that not only looks great but also performs optimally.

Wiring Diagrams and Component Locations

Understanding the electrical framework and the placement of various elements is crucial for effective troubleshooting and maintenance. This section provides essential insights into the connectivity of the electrical system and identifies where key components are situated within the vehicle.

Proper wiring diagrams serve as a roadmap, illustrating how different parts are interconnected. This visual representation simplifies the diagnosis of electrical issues, ensuring that repairs can be made efficiently. Knowing the locations of critical components enhances the ability to access and replace faulty elements quickly.

- Main Fuse Box: Usually found under the dashboard on the driver’s side, this box houses fuses for various electrical systems.

- Battery: Located in the engine compartment, it provides power to the vehicle’s electrical components.

- ECU (Electronic Control Unit): Often situated near the steering column or under the dashboard, it manages engine functions.

- Ignition Coil: Typically mounted on or near the engine, responsible for generating the spark for ignition.

- Headlight Wiring: Routes through the front of the vehicle, connecting to the headlight assemblies.

Referencing the wiring diagrams and component locations can significantly reduce the time spent on repairs. Familiarity with these layouts helps in diagnosing problems more effectively, making the maintenance process smoother and more efficient.

Fluid Types and Replacement Intervals

Maintaining optimal performance of any vehicle requires careful attention to various essential liquids. Each fluid plays a vital role in ensuring smooth operation and longevity of components. Understanding the types of fluids used, along with their respective replacement schedules, is crucial for effective upkeep.

Engine Oil: This lubricant is critical for reducing friction and wear within the engine. Regular changes, typically every 3,000 to 5,000 miles, help maintain engine health. Always refer to the manufacturer’s recommendations for the appropriate viscosity grade.

Transmission Fluid: Essential for smooth shifting, this fluid should be replaced every 30,000 to 60,000 miles, depending on driving conditions. Checking the fluid level regularly can help prevent potential transmission issues.

Coolant: This fluid prevents overheating and protects against corrosion. It is advisable to flush and replace the coolant every 40,000 to 60,000 miles or every two years, whichever comes first, to ensure efficient engine temperature regulation.

Brake Fluid: Vital for safe stopping, this fluid should be inspected frequently. Replacement is typically recommended every two years, but it’s important to check the level regularly and top off if necessary.

By adhering to these guidelines for fluid types and their replacement intervals, vehicle owners can significantly enhance the reliability and performance of their vehicles.

Tools Required for Effective Repairs

Having the right equipment is crucial for successful maintenance tasks. Proper tools not only enhance efficiency but also ensure quality results when addressing various mechanical issues. A well-equipped workspace can significantly simplify the process, making it easier to tackle challenges as they arise.

Essential Hand Tools

- Wrenches: Adjustable and socket types for loosening and tightening bolts.

- Screwdrivers: A variety of sizes and types, including Phillips and flathead.

- Pliers: Needle-nose and standard for gripping and twisting wires.

- Hammers: A lightweight option for tapping components without causing damage.

Specialized Equipment

- Jack and Jack Stands: For safely lifting the vehicle and providing stability during work.

- Diagnostic Tools: OBD-II scanners for troubleshooting electronic systems.

- Torque Wrench: Ensures bolts are tightened to manufacturer specifications.

- Oil Filter Wrench: Simplifies the removal of oil filters during fluid changes.

Equipping oneself with these essential items can greatly enhance the ability to perform various tasks effectively. Investing in high-quality tools will contribute to a smoother workflow and longer-lasting results.

Tips for Enhancing Vehicle Performance

Improving the functionality and efficiency of a vehicle requires a combination of maintenance, tuning, and awareness of driving habits. By implementing specific strategies, drivers can maximize their vehicle’s potential, ensuring a smoother and more responsive ride.

Regular Maintenance Checks

Routine inspections are essential for maintaining peak performance. This includes checking fluid levels, replacing air filters, and monitoring tire pressure. A well-maintained vehicle operates more efficiently, ultimately enhancing fuel economy and overall performance.

Upgrading Components

Consider investing in high-quality aftermarket parts that can significantly improve your vehicle’s capabilities. Upgrading the exhaust system, intake manifold, or suspension can lead to increased power output and better handling. These modifications can provide noticeable improvements in driving experience.