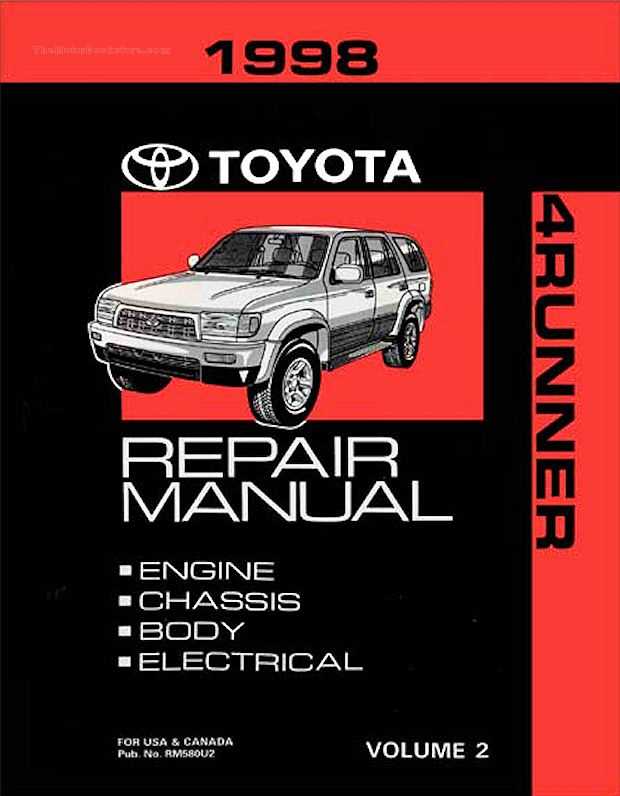

Comprehensive Repair Manual for the 1988 Toyota 4Runner

Owning a classic SUV comes with unique challenges and rewards. Understanding the intricacies of your vehicle is essential for ensuring its longevity and optimal performance. This section delves into essential procedures, troubleshooting techniques, and maintenance tips that can help you navigate the complexities of your model.

From routine check-ups to more complex repairs, having a thorough resource at your disposal can make a significant difference. This guide is designed to provide insights into common issues and their solutions, empowering you to take control of your automotive experience. Whether you’re a seasoned mechanic or a novice enthusiast, the information here will aid you in maintaining your vehicle with confidence.

Exploring the mechanics behind your vehicle is not only a practical necessity but also a rewarding journey. By familiarizing yourself with various components and systems, you can enhance your understanding of how everything works together. This knowledge will ultimately lead to more informed decisions when it comes to maintenance and repairs, ensuring your vehicle remains in top condition for years to come.

Overview of the 1988 Toyota 4Runner

This section provides a comprehensive look at a popular SUV known for its robust design and versatility. It combines functionality with a rugged aesthetic, making it a favored choice among outdoor enthusiasts and urban drivers alike.

Design and Features

The model showcases a distinctive exterior characterized by strong lines and a commanding presence on the road. Inside, the cabin is designed for comfort and utility, featuring ample space and various amenities that enhance the driving experience. Safety features and reliability are prominent, ensuring peace of mind for drivers and passengers.

Performance and Capabilities

Under the hood, this vehicle is equipped with a capable engine that delivers solid performance across various terrains. Its off-road capabilities are notable, allowing it to handle challenging landscapes with ease. The blend of power and efficiency makes it suitable for both daily commuting and adventurous excursions.

Common Issues and Troubleshooting Tips

When it comes to maintaining your vehicle, understanding prevalent complications and their solutions is essential for optimal performance. Various systems may exhibit specific symptoms, and being prepared can save time and resources.

- Engine Performance:

- Rough idling can indicate issues with spark plugs or fuel injectors.

- Reduced power may suggest a clogged air filter or exhaust restriction.

- Transmission Troubles:

- Slipping gears might be a sign of low transmission fluid or a failing torque converter.

- Delayed shifting can result from worn-out transmission bands or solenoids.

- Electrical Problems:

- Frequent blown fuses may indicate a short circuit or faulty components.

- Dim lights could signal a weak battery or alternator issues.

To effectively address these matters, regular inspections and maintenance checks are recommended. Keeping an eye on warning signs and addressing them promptly can lead to a smoother driving experience.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and reliability of any vehicle. Following a structured timeline for maintenance tasks helps to identify potential issues before they become significant problems, ultimately enhancing the overall driving experience.

Routine Inspections

Conducting frequent inspections is crucial for catching wear and tear early. Check fluid levels, brakes, and tires regularly. A detailed examination every few months will help maintain peak functionality and safety.

Service Intervals

Adhering to recommended service intervals is vital for preserving engine health and performance. Engine oil changes, air filter replacements, and spark plug checks should be scheduled according to manufacturer guidelines to ensure efficient operation.

Essential Tools for DIY Repairs

Undertaking vehicle maintenance requires a well-equipped toolkit to ensure efficiency and accuracy. Having the right instruments on hand not only simplifies the process but also enhances the overall quality of the work. This section outlines the fundamental tools that every automotive enthusiast should consider for successful projects.

Socket Set: A versatile socket set is crucial for loosening and tightening various fasteners. Look for a set that includes both metric and standard sizes to accommodate a range of applications.

Wrenches: Adjustable wrenches, combination wrenches, and torque wrenches are indispensable. They provide the leverage needed to handle stubborn bolts and ensure that fittings are secured to the proper specifications.

Screwdrivers: A selection of flathead and Phillips screwdrivers is essential for tasks involving screws. Magnetic tips can help with retrieving dropped hardware and make alignment easier.

Pliers: Needle-nose and slip-joint pliers offer versatility for gripping, bending, and cutting wires or small components. These tools are particularly useful in tight spaces.

Jack and Stands: Lifting equipment is vital for accessing the undercarriage. A reliable floor jack paired with jack stands ensures safety while working beneath the vehicle.

Multimeter: For electrical diagnostics, a multimeter is invaluable. It assists in measuring voltage, current, and resistance, allowing for effective troubleshooting of electrical systems.

By equipping yourself with these essential tools, you’ll be well-prepared to tackle a variety of tasks and enhance your automotive knowledge and skills.

Step-by-Step Guide to Engine Repairs

This section provides a comprehensive overview of the procedures involved in addressing engine issues. Following a systematic approach can help ensure that every aspect of the process is covered, from diagnosis to completion. Each step is designed to promote efficiency and accuracy, enabling individuals to tackle repairs with confidence.

Diagnosing the Problem

The first phase involves identifying the symptoms and understanding the underlying causes. Gather information about any unusual sounds, leaks, or performance issues. Conduct a thorough inspection and utilize diagnostic tools to pinpoint the exact problem, which will inform the subsequent repair steps.

Executing the Repair

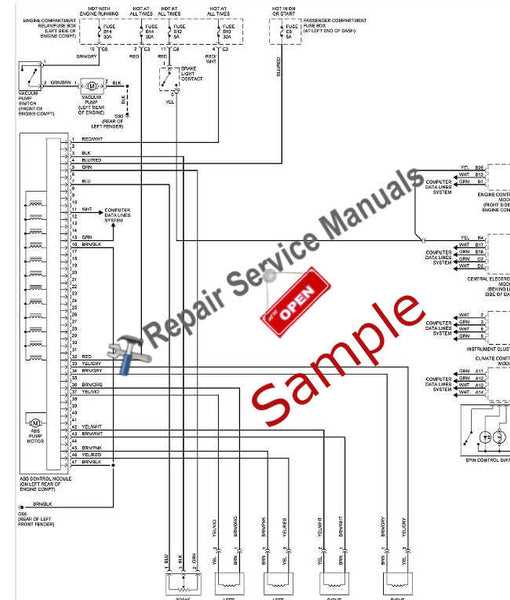

Electrical System Diagnostics and Fixes

This section provides a comprehensive approach to diagnosing and resolving issues within the electrical system of your vehicle. Understanding the components and their interconnections is crucial for effective troubleshooting and ensuring optimal performance.

Begin by systematically inspecting the battery, wiring harnesses, and electrical connections for signs of wear or corrosion. Utilize a multimeter to check voltage levels and continuity, which can help identify faulty components or wiring issues.

| Component | Common Issues | Diagnostic Steps | Fixes |

|---|---|---|---|

| Battery | Weak charge, corrosion | Check voltage with multimeter | Clean terminals, replace if necessary |

| Alternator | Insufficient power output | Test voltage while running | Replace faulty alternator |

| Fuses | Blown fuses | Inspect for damage | Replace with correct amperage |

| Wiring | Frayed or broken wires | Visual inspection, check continuity | Repair or replace damaged sections |

By following these guidelines and maintaining a methodical approach, you can effectively troubleshoot and resolve electrical system issues, ensuring your vehicle remains reliable and functional.

Transmission Service and Common Problems

Proper maintenance of the transmission system is crucial for ensuring optimal performance and longevity of a vehicle. Regular service can prevent many issues that may arise, leading to costly repairs and reduced functionality. Understanding the common problems associated with this system can help owners take proactive measures to keep their vehicles running smoothly.

| Common Issues | Symptoms | Potential Causes | Recommended Actions |

|---|---|---|---|

| Slipping Gears | Engine revs without acceleration | Low fluid levels, worn clutch | Check fluid levels, inspect clutch condition |

| Unusual Noises | Grinding or whining sounds | Worn bearings, low lubricant | Inspect for leaks, replace worn parts |

| Fluid Leaks | Puddles under the vehicle | Deteriorated seals, loose connections | Examine seals and gaskets, tighten connections |

| Warning Lights | Transmission warning indicator illuminated | Sensor failure, electrical issues | Diagnose with a scanner, check electrical connections |

By addressing these common issues promptly, vehicle owners can ensure their transmission operates efficiently and avoid more significant problems down the line. Regular inspections and fluid changes are key components of effective transmission maintenance.

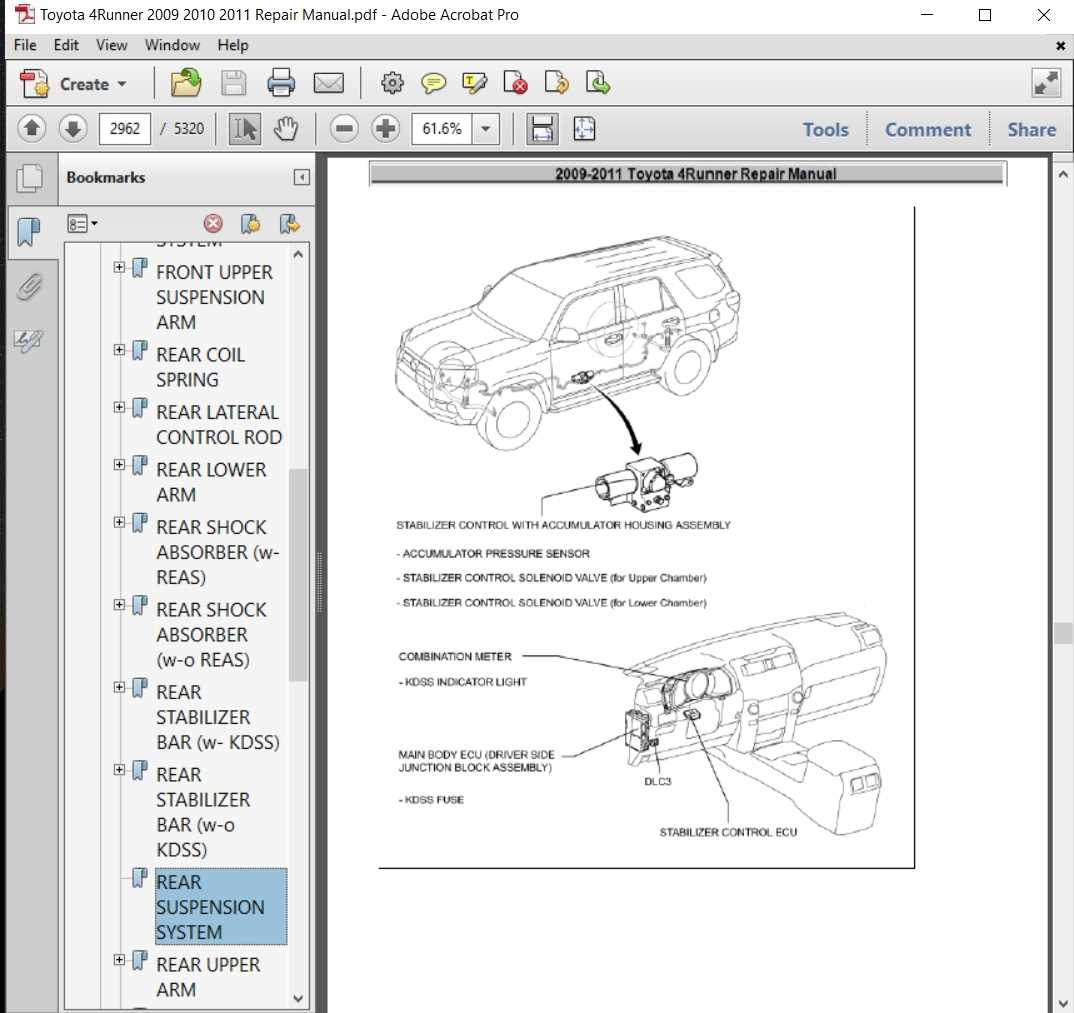

Suspension and Steering Maintenance Tips

Ensuring the longevity and optimal performance of your vehicle’s suspension and steering systems is crucial for a smooth and safe driving experience. Regular maintenance can help prevent premature wear and costly repairs while enhancing overall handling and stability.

1. Regular Inspections: Frequently check for any signs of wear, such as leaks in shock absorbers or struts. Look for uneven tire wear, which can indicate alignment issues. Promptly addressing these concerns can save you from more significant problems down the road.

2. Lubrication: Keep all moving parts adequately lubricated to minimize friction and wear. Focus on joints, bushings, and other components that experience regular movement. Using the correct lubricant is essential for ensuring long-lasting performance.

3. Tire Maintenance: Maintaining proper tire pressure and alignment is vital for the overall health of the steering and suspension systems. Rotate your tires regularly and ensure they are balanced to promote even wear and enhance handling.

4. Replace Worn Components: Be proactive in replacing any worn or damaged parts. Components like bushings, ball joints, and tie rods play a critical role in vehicle stability and responsiveness. Ignoring these can lead to compromised safety and performance.

5. Consult Professionals: When in doubt, consult a professional mechanic for comprehensive inspections and service. They can provide insights into specific issues and recommend maintenance practices tailored to your vehicle’s needs.

Brake System Inspection and Replacement

Ensuring optimal performance and safety of your vehicle requires regular examination and maintenance of the braking mechanism. This section outlines the essential steps for evaluating and replacing components within the brake assembly to maintain functionality and reliability.

Begin by visually inspecting the braking components for signs of wear or damage. Look for leaks in the hydraulic system, cracks in the brake pads, or corrosion on the rotors. Ensuring the integrity of these parts is crucial for effective braking performance.

| Component | Inspection Criteria | Replacement Interval |

|---|---|---|

| Brake Pads | Check for thickness; replace if less than 3mm. | Every 30,000 miles or as needed. |

| Brake Rotors | Inspect for grooves or warping; measure thickness. | Every 50,000 miles or as required. |

| Brake Lines | Look for leaks, cracks, and corrosion. | Every 2 years or as needed. |

| Brake Fluid | Check for contamination; test moisture content. | Every 2 years. |

If any component shows significant wear or is malfunctioning, immediate replacement is necessary. Utilizing high-quality parts and following manufacturer specifications during installation ensures the system operates effectively and enhances overall driving safety.

Body and Interior Repair Techniques

Maintaining the exterior and interior of a vehicle is crucial for both aesthetics and functionality. This section outlines various methods for addressing common issues that can arise in a vehicle’s body and cabin areas. By employing appropriate techniques, owners can enhance the longevity and appearance of their automobile.

Exterior Restoration Methods

When dealing with dents, scratches, or rust, several approaches can be utilized. It is important to assess the damage accurately before choosing a technique. Here are some common methods:

| Technique | Description |

|---|---|

| PDR (Paintless Dent Repair) | A method that uses specialized tools to massage the metal back into its original shape without damaging the paint. |

| Touch-Up Paint | Small containers of paint can be used to cover scratches and chips, restoring the vehicle’s appearance. |

| Rust Treatment | Applying rust-inhibiting agents and sealants to prevent further corrosion. |

Interior Maintenance Techniques

Interior care involves not only cosmetic improvements but also enhancing comfort and usability. Here are some recommended practices:

| Technique | Description |

|---|---|

| Upholstery Cleaning | Using appropriate cleaners and tools to remove stains and dirt from fabric surfaces. |

| Dashboard Restoration | Applying protectants to keep plastic and vinyl surfaces from fading and cracking. |

| Panel Replacement | Swapping out damaged or worn components with new or refurbished parts for a fresh look. |

Upgrading Components for Enhanced Performance

Improving vehicle efficiency and power often involves upgrading various parts to achieve a more dynamic driving experience. These enhancements can lead to better handling, increased horsepower, and improved fuel efficiency, making the vehicle not only more enjoyable to drive but also more reliable in various conditions.

One key area for enhancement is the suspension system. Upgrading to high-performance shock absorbers and springs can significantly improve ride quality and handling stability. Additionally, brake system upgrades, such as larger rotors and calipers, provide superior stopping power, ensuring safety without sacrificing performance.

Furthermore, attention to the engine components is essential. Installing a high-flow air intake and a performance exhaust system can enhance airflow, leading to increased horsepower. These modifications not only boost performance but also improve the overall sound of the engine, providing a more exhilarating driving experience.

Finally, considering the electrical system can also yield benefits. Upgrading to a high-output alternator and better battery can ensure that all components receive sufficient power, especially after other enhancements have been made. This holistic approach to upgrades guarantees that every part works in harmony, maximizing overall vehicle performance.