Ultimate Guide to 1990 Toyota Supra Repair Manual

Maintaining a classic vehicle requires a blend of knowledge, skill, and the right resources. Enthusiasts often seek comprehensive guides that illuminate the intricacies of their prized machines, ensuring that every component operates at its best. These resources serve not only as reference materials but also as a gateway to understanding the heart of a beloved automobile.

Whether tackling routine maintenance or addressing complex issues, having access to detailed instructions can make all the difference. From engine performance to electrical systems, the ability to troubleshoot effectively is paramount. As owners delve into the world of automotive care, they uncover the nuances that set their vehicles apart from the rest.

For those passionate about preserving and enhancing their driving experience, a well-structured guide becomes an invaluable tool. It empowers individuals to take charge of their vehicle’s upkeep, fostering a deeper connection to the machinery. This journey not only preserves the beauty and functionality of the car but also cultivates a sense of pride and accomplishment in every repair and modification undertaken.

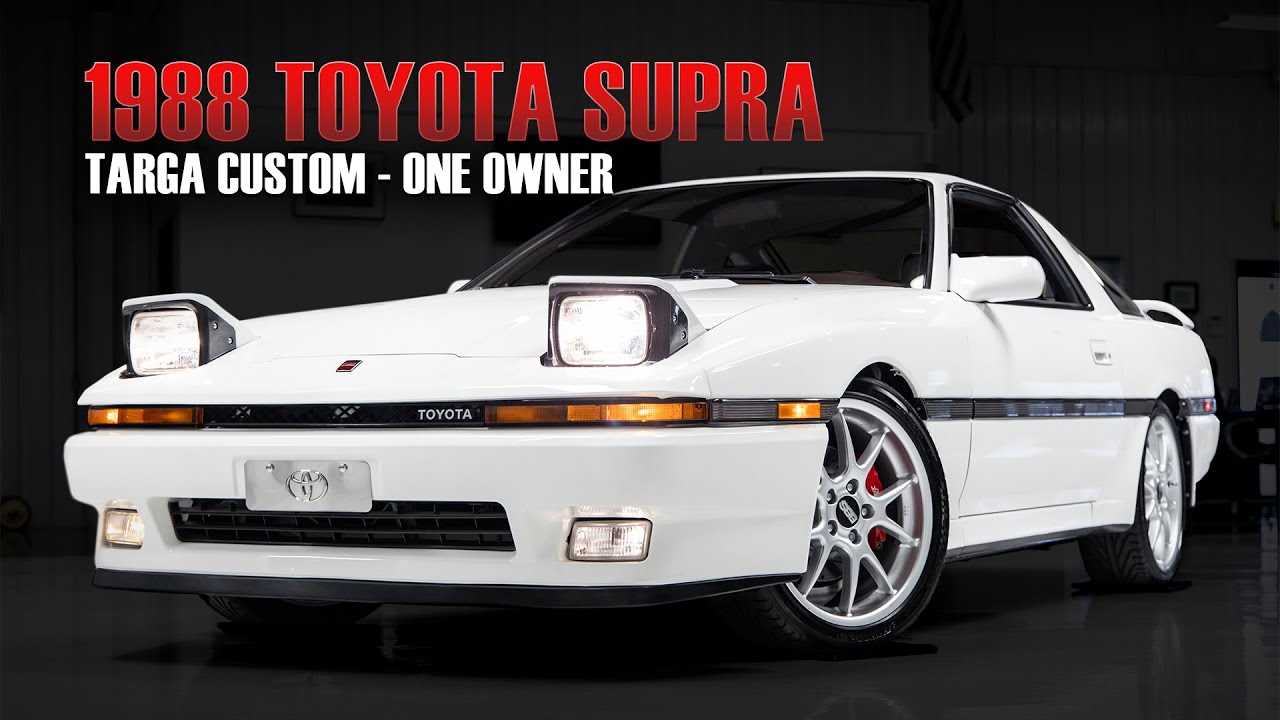

Overview of the 1990 Toyota Supra

This section provides a comprehensive look at a renowned model from the early ’90s, celebrated for its blend of performance and style. It captures the essence of engineering excellence, making it a sought-after vehicle among enthusiasts and collectors alike.

Design and Features

The aesthetic appeal of this automobile is matched by its innovative features. With a sleek silhouette and distinctive lines, it stands out on the road. Inside, the cabin is designed for comfort and functionality, offering a range of amenities that enhance the driving experience.

Performance Specifications

Under the hood, this model is powered by a robust engine that delivers impressive power and torque. Coupled with a well-engineered suspension system, it ensures a smooth ride and exceptional handling. Here’s a summary of its key specifications:

| Feature | Specification |

|---|---|

| Engine Type | Inline-6 |

| Horsepower | 200 hp |

| Torque | 196 lb-ft |

| Transmission | 5-speed manual / 4-speed automatic |

| 0-60 mph | 6.5 seconds |

Common Issues with the 1990 Model

The vehicle from this era is known for a range of mechanical and electrical challenges that owners often encounter. Understanding these common problems can help in maintaining the car and ensuring longevity. Issues may arise from wear and tear, age-related deterioration, and specific design flaws inherent to this model.

Engine Performance Problems

One prevalent issue involves engine performance, often characterized by rough idling or decreased acceleration. Drivers may notice unusual noises or vibrations, which can indicate problems with the ignition system or fuel delivery components. Regular checks and timely replacements can mitigate these concerns.

Transmission Difficulties

Transmission-related troubles are also frequent, with symptoms such as slipping gears or difficulty shifting. These issues can stem from low fluid levels or worn components within the transmission. Keeping an eye on fluid condition and ensuring proper maintenance can help alleviate these transmission woes.

Essential Tools for Repairs

When embarking on the journey of vehicle maintenance and restoration, having the right instruments at your disposal is crucial. The right equipment not only streamlines the process but also enhances safety and accuracy during the task at hand. From basic hand tools to specialized devices, each item plays a significant role in ensuring that repairs are executed with precision.

Basic Hand Tools: A well-equipped toolkit should include essential items such as wrenches, sockets, and screwdrivers. These tools form the foundation of any maintenance project, enabling you to tackle a variety of tasks with ease. Quality matters; investing in durable tools will pay off in the long run.

Diagnostic Equipment: In today’s automotive landscape, electronic systems are prevalent. Having diagnostic scanners can greatly assist in identifying issues quickly and accurately. This technology allows for effective troubleshooting, saving both time and resources.

Safety Gear: Always prioritize safety. Gear such as gloves, goggles, and protective clothing should be an integral part of your toolkit. These items not only protect you from potential hazards but also contribute to a more efficient working environment.

Specialized Tools: Depending on the specific tasks at hand, you may require specialized instruments such as torque wrenches, pullers, or compression testers. These tools are designed to handle particular tasks that general tools may not be able to perform effectively.

In summary, having a comprehensive collection of tools tailored to your needs will enhance your ability to carry out maintenance effectively. By ensuring that you are well-prepared, you can approach any task with confidence and skill.

Step-by-Step Maintenance Procedures

Regular upkeep of your vehicle is essential for ensuring optimal performance and longevity. Following systematic procedures can help identify potential issues before they escalate, enhancing the driving experience. Below are detailed guidelines that will assist you in performing routine maintenance tasks effectively.

Fluid Checks

Maintaining proper fluid levels is crucial for the efficient operation of your vehicle. Here are the key fluids to inspect:

- Engine Oil: Check the level and condition; replace as necessary.

- Coolant: Ensure it is at the recommended level to prevent overheating.

- Brake Fluid: Monitor the level to maintain braking efficiency.

- Transmission Fluid: Verify the level and inspect for any leaks.

Tire Maintenance

Proper tire care enhances safety and performance. Follow these steps for tire maintenance:

- Check tire pressure monthly; inflate to the recommended PSI.

- Inspect tread depth to ensure adequate traction.

- Rotate tires every 5,000 to 7,500 miles to promote even wear.

- Examine sidewalls for any signs of damage or wear.

Adhering to these maintenance procedures will not only improve your vehicle’s reliability but also contribute to a safer driving experience.

Engine Specifications and Troubleshooting

This section focuses on the critical aspects of the engine’s performance, offering insights into its specifications and common issues that may arise. Understanding these elements is essential for maintaining optimal functionality and addressing potential problems effectively.

Specifications Overview

The power unit features a robust design, with a displacement of approximately 3.0 liters and a dual overhead camshaft configuration. It employs a turbocharging system that enhances horsepower output significantly, making it a favored choice among enthusiasts. Key specifications include a compression ratio of around 8.0:1 and a maximum output of over 200 horsepower, coupled with a torque rating that ensures impressive acceleration.

Troubleshooting Common Issues

Identifying and resolving engine-related challenges is crucial for performance. Common symptoms such as unusual noises, reduced power, or erratic idling may indicate underlying issues. Regular checks on components such as spark plugs, fuel injectors, and the ignition system can prevent major breakdowns. Additionally, monitoring fluid levels and conducting routine diagnostics can help pinpoint problems early, ensuring the longevity of the engine.

Transmission Care and Adjustment

Maintaining optimal performance of the transmission system is crucial for the overall functionality of a vehicle. Regular inspection and fine-tuning can help ensure smooth gear shifting and prolong the lifespan of the transmission. This section outlines essential practices for upkeep and adjustment to enhance efficiency and reliability.

Routine Maintenance Checks

Conducting routine checks is vital for identifying potential issues before they escalate. Key components to inspect include fluid levels, filter condition, and linkage alignment. Ensuring that these elements are in good condition can prevent costly repairs and ensure seamless operation.

| Component | Maintenance Tip |

|---|---|

| Transmission Fluid | Check levels and top up if necessary; change every 30,000 miles. |

| Filter | Replace the filter during fluid changes to ensure clean operation. |

| Linkage | Inspect for proper alignment and lubrication to avoid shifting issues. |

Adjustment Techniques

If gear shifting is rough or hesitant, adjustments may be required. Common areas for fine-tuning include the shift linkage and the idle speed. Accurate settings can significantly improve performance and responsiveness.

Electrical System Diagnostics

The electrical system of a vehicle is crucial for its overall functionality, encompassing various components that work in harmony to ensure optimal performance. Diagnosing issues within this system requires a methodical approach to identify and resolve faults that can affect both operational efficiency and safety.

Begin the diagnostic process by visually inspecting the wiring harnesses, connectors, and fuses for any signs of damage or corrosion. A multimeter can be an invaluable tool for measuring voltage, resistance, and continuity throughout the circuit. Pay special attention to ground connections, as poor grounding can lead to a range of electrical malfunctions.

Next, it is essential to check the functionality of individual components, such as switches, relays, and sensors. Testing each part in isolation can help pinpoint the source of the problem. In some cases, a scan tool may be necessary to retrieve diagnostic trouble codes from the vehicle’s onboard computer, providing insight into specific issues affecting the electrical system.

Once faults are identified, repairing or replacing damaged components is the next step. Ensuring that all connections are secure and free from debris will help maintain a reliable electrical system. Regular maintenance and inspections can also prevent future problems, keeping the vehicle operating smoothly.

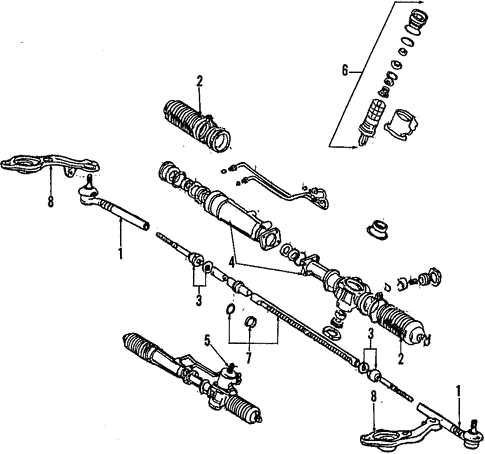

Suspension and Steering Maintenance

Proper upkeep of the suspension and steering systems is essential for ensuring a smooth and safe driving experience. Regular inspections and maintenance can prevent premature wear, enhance handling, and improve overall vehicle stability. Understanding the components involved and their functions is crucial for effective care.

The suspension system, comprising springs, shock absorbers, and control arms, plays a vital role in absorbing road irregularities and maintaining tire contact with the surface. Over time, these components can wear out or become damaged, leading to reduced performance and comfort. Regularly checking for leaks, unusual noises, and visible wear can help identify issues before they escalate.

Similarly, the steering system, which includes the steering wheel, column, and various linkages, is fundamental for directional control. Ensuring that these elements are in good condition promotes responsive handling. Common maintenance tasks include inspecting for play in the steering wheel, checking fluid levels, and ensuring proper alignment.

Routine maintenance not only prolongs the lifespan of these systems but also enhances safety and driving enjoyment. Keeping records of inspections and replacements can aid in maintaining optimal performance and preventing future complications.

Brake System Repair Techniques

The braking system is crucial for vehicle safety and performance. Proper maintenance and effective troubleshooting techniques are essential to ensure optimal functionality. This section outlines key methods for diagnosing issues and performing necessary interventions within the braking mechanism.

Diagnosing Brake Issues

Identifying problems in the braking system often starts with careful observation. Look for warning signs such as unusual noises, reduced responsiveness, or vibrations during braking. Visual inspections are also vital; check for leaks, wear on components, and the condition of brake pads. Utilizing a brake fluid tester can help assess fluid quality and moisture levels, which are critical for effective braking performance.

Maintenance and Component Replacement

Regular upkeep includes checking and replacing worn-out parts. Start with the brake pads; they should be changed when their thickness is below the manufacturer’s recommendation. The brake rotors also require attention; ensure they are not warped or excessively worn. Bleeding the brake lines is essential to remove air bubbles, which can compromise performance. Always consult specifications for torque settings and replacement intervals to maintain integrity and safety.

Upgrading and Modifying Your Supra

Enhancing the performance and aesthetics of your vehicle can lead to a more enjoyable driving experience. This process involves careful planning and selection of components that can elevate various aspects, from horsepower to handling and style. Whether you’re looking to boost power or refine appearance, understanding your options is crucial.

Performance Upgrades

- Engine modifications: Consider turbochargers or superchargers for increased power.

- Exhaust system: Upgrade to a high-performance exhaust to improve airflow and sound.

- Suspension enhancements: Invest in coilovers or sway bars for better handling.

- Braking system: Install larger rotors and calipers for improved stopping power.

Aesthetic Modifications

- Body kits: Add spoilers or side skirts for a sportier look.

- Wheels: Choose lightweight alloys for both style and performance.

- Interior upgrades: Replace seats or install custom dashboards for a personalized touch.

- Lighting: Consider LED upgrades for enhanced visibility and style.

Finding Quality Replacement Parts

When it comes to maintaining a vehicle, sourcing reliable components is crucial for optimal performance and longevity. The right parts ensure that your automobile runs smoothly and efficiently. However, the market is flooded with options, making it essential to identify trustworthy sources for quality replacements.

Identifying Reputable Suppliers

To find dependable parts, consider the following approaches:

- Research online reviews and ratings of suppliers.

- Join automotive forums and communities for recommendations.

- Check for certified dealers who specialize in your vehicle’s make.

- Ask for referrals from local mechanics or car enthusiasts.

Evaluating Parts Quality

Once you’ve identified potential suppliers, assess the quality of their offerings:

- Look for warranty information, which indicates confidence in the product.

- Examine materials and manufacturing standards of the components.

- Compare prices, but avoid opting for the cheapest option without researching.

- Seek out OEM (Original Equipment Manufacturer) parts when possible for guaranteed compatibility.

By following these guidelines, you can ensure that you acquire parts that will enhance the reliability and performance of your vehicle.