Comprehensive Guide to Repairing Your 1995 Toyota Celica

Understanding the intricacies of vehicle upkeep is essential for any car enthusiast or owner. With a solid foundation in vehicle care, individuals can ensure their automobiles run smoothly and efficiently. This knowledge not only enhances performance but also extends the lifespan of the machinery.

For those who appreciate the engineering behind their vehicles, delving into detailed documentation can be invaluable. Such resources provide step-by-step instructions, troubleshooting tips, and essential insights that empower owners to tackle a range of maintenance tasks. This approach fosters a deeper connection between the driver and their vehicle, transforming routine checks into rewarding projects.

Whether addressing minor issues or undertaking more significant repairs, having access to comprehensive information is crucial. It allows for informed decisions, helping to avoid common pitfalls and ensuring that every aspect of the vehicle is well cared for. Embracing this knowledge cultivates confidence and independence, making automotive maintenance not just a necessity, but also an engaging pursuit.

Overview of the 1995 Toyota Celica

This section provides a comprehensive look at a popular compact sports coupe from the mid-1990s. Renowned for its sleek design and spirited performance, this vehicle has garnered a dedicated following among enthusiasts and casual drivers alike.

Key characteristics include:

- Dynamic handling and responsive steering

- Attractive and aerodynamic exterior

- Various engine options catering to different performance preferences

- Comfortable interior with user-friendly features

The model stands out due to its balance between style and functionality, making it suitable for both daily commutes and spirited drives. Its engineering reflects a blend of practicality and sportiness, appealing to a wide range of consumers.

In terms of market positioning, it competes with other vehicles in the same class, offering a unique blend of features and affordability. Maintenance and care for this vehicle are crucial to ensure longevity and optimal performance, and many resources are available for owners seeking to understand their vehicle better.

Overall, this compact sports coupe remains a noteworthy option for those looking to combine everyday usability with an exhilarating driving experience.

Common Issues Faced by Owners

Many drivers encounter specific challenges with their vehicles, particularly as they age. Understanding these common problems can help in identifying symptoms early and preventing more severe issues down the line.

Frequent Mechanical Problems

- Engine performance issues, often characterized by rough idling or hesitation during acceleration.

- Transmission troubles, which may include slipping gears or difficulty shifting.

- Brake system concerns, such as squeaking or reduced responsiveness.

Electrical System Complaints

- Battery drainage, frequently due to parasitic draw or age-related wear.

- Malfunctioning lights, which can range from dim headlights to dashboard indicator failures.

- Starter issues, including a slow crank or complete failure to start.

Essential Tools for DIY Repairs

When it comes to maintaining and fixing your vehicle, having the right equipment is crucial. A well-equipped workspace can significantly simplify the process, making it easier to tackle various tasks. Whether you’re performing minor adjustments or more extensive overhauls, investing in the essential tools will help ensure that your projects are successful and efficient.

Here’s a list of indispensable items you should have in your toolkit:

- Socket Set: A comprehensive socket set is vital for loosening and tightening bolts in various sizes.

- Wrenches: Both open-end and box-end wrenches allow for better grip and leverage on nuts and bolts.

- Screwdrivers: A variety of screwdrivers, including flat-head and Phillips, are necessary for numerous fastening tasks.

- Pliers: These can be used for gripping, twisting, and cutting wires or other materials.

- Jack and Jack Stands: Essential for safely lifting your vehicle to access the undercarriage or perform tire changes.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for diagnosing electrical issues and ensuring proper voltage levels.

Having these tools on hand will not only enhance your ability to perform tasks but also provide you with the confidence to tackle any project that comes your way.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and performance of your vehicle. Following a systematic approach can help you address common issues, enhance reliability, and ultimately save on future repair costs. This section outlines detailed processes that every owner can undertake to keep their automobile in optimal condition.

1. Engine Oil Change

Begin by gathering the necessary tools, including an oil filter wrench, an oil catch pan, and a socket set. Warm up the engine slightly to help the oil drain smoothly. Once warm, turn off the engine and secure the vehicle on a level surface. Remove the oil drain plug and allow the old oil to fully drain into the pan. Replace the drain plug, then install a new oil filter. Finally, fill the engine with fresh oil through the designated opening.

2. Air Filter Replacement

Locate the air filter housing, typically found near the engine bay. Open the housing by unclipping or unscrewing it. Remove the old air filter, taking care to note its orientation. Insert the new filter in the same position, ensuring a snug fit, then close the housing securely.

3. Brake Inspection

Start by removing the wheel to access the brake components. Examine the brake pads for wear; if they appear thin, it’s time for replacement. Check the rotors for grooves or warping. Clean the brake components using a brake cleaner, and reassemble everything carefully. Ensure that all bolts are tightened to manufacturer specifications.

4. Tire Rotation

Regularly rotating tires promotes even wear and extends their lifespan. Lift the vehicle using a jack and remove the lug nuts to take off the wheels. Move the front tires to the back on the same side and the rear tires to the front, swapping sides. Reinstall the lug nuts and lower the vehicle. Tighten the nuts in a star pattern to ensure even pressure.

5. Battery Maintenance

Check the battery terminals for corrosion and clean them if necessary using a mixture of baking soda and water. Ensure that the battery is securely mounted and that all connections are tight. Test the battery voltage with a multimeter to confirm it’s holding a proper charge.

Following these straightforward procedures can significantly contribute to the overall health of your vehicle. Regular maintenance not only enhances performance but also provides peace of mind on the road.

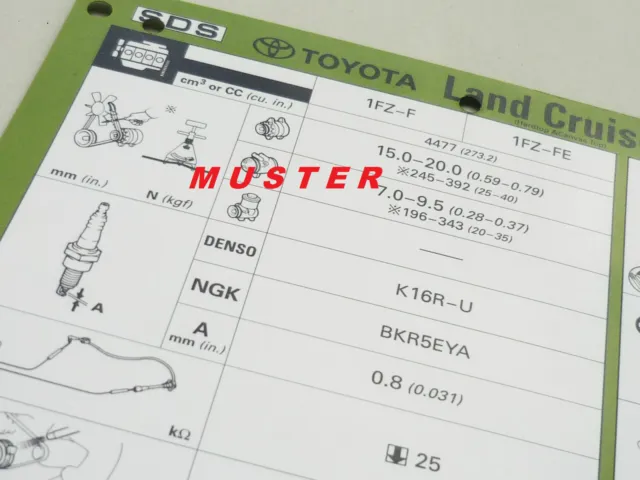

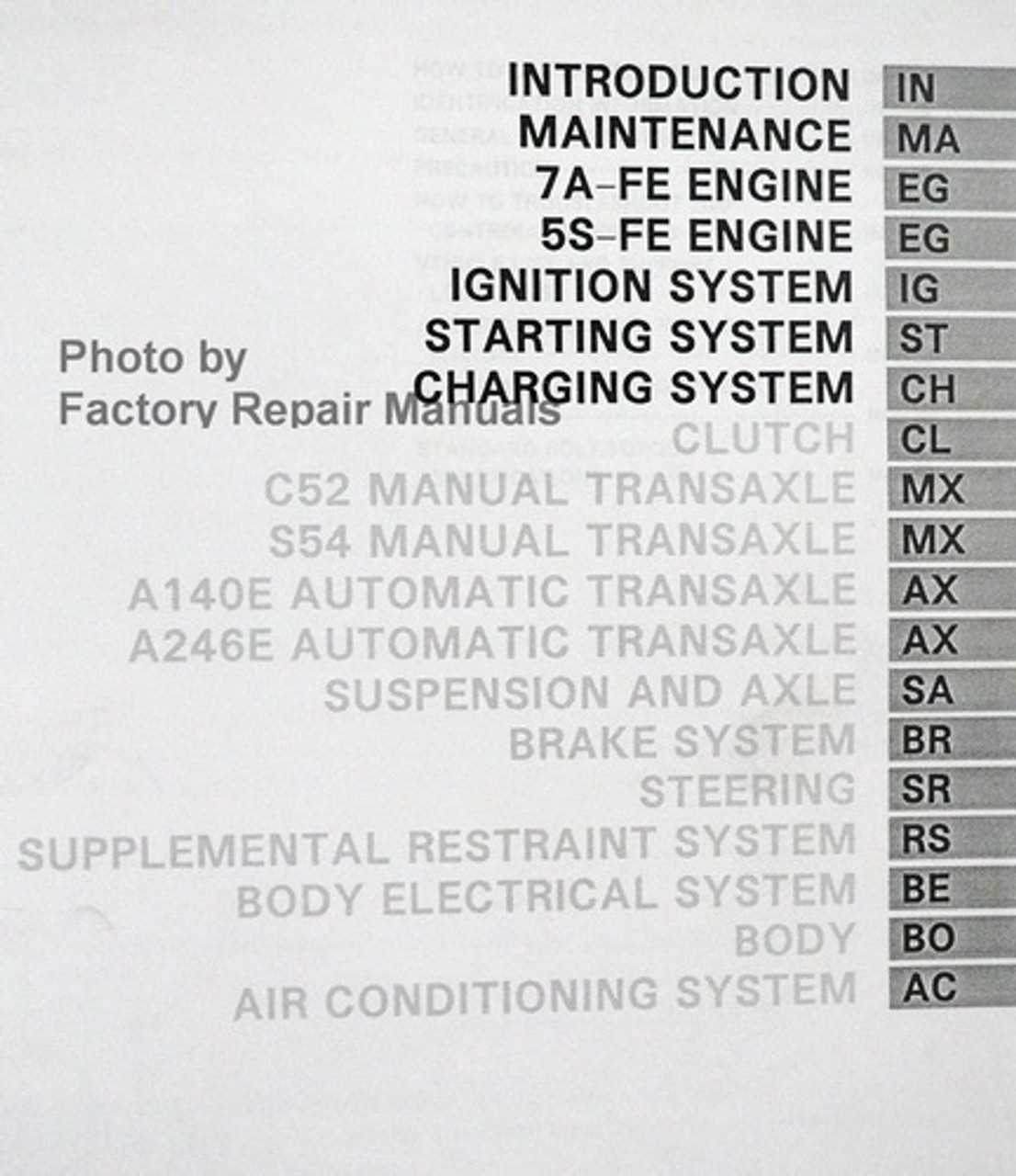

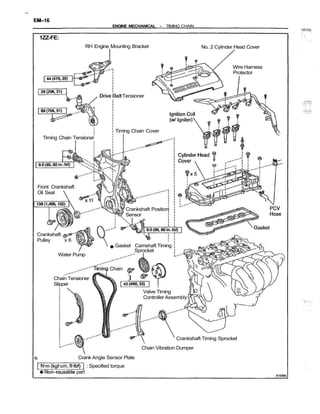

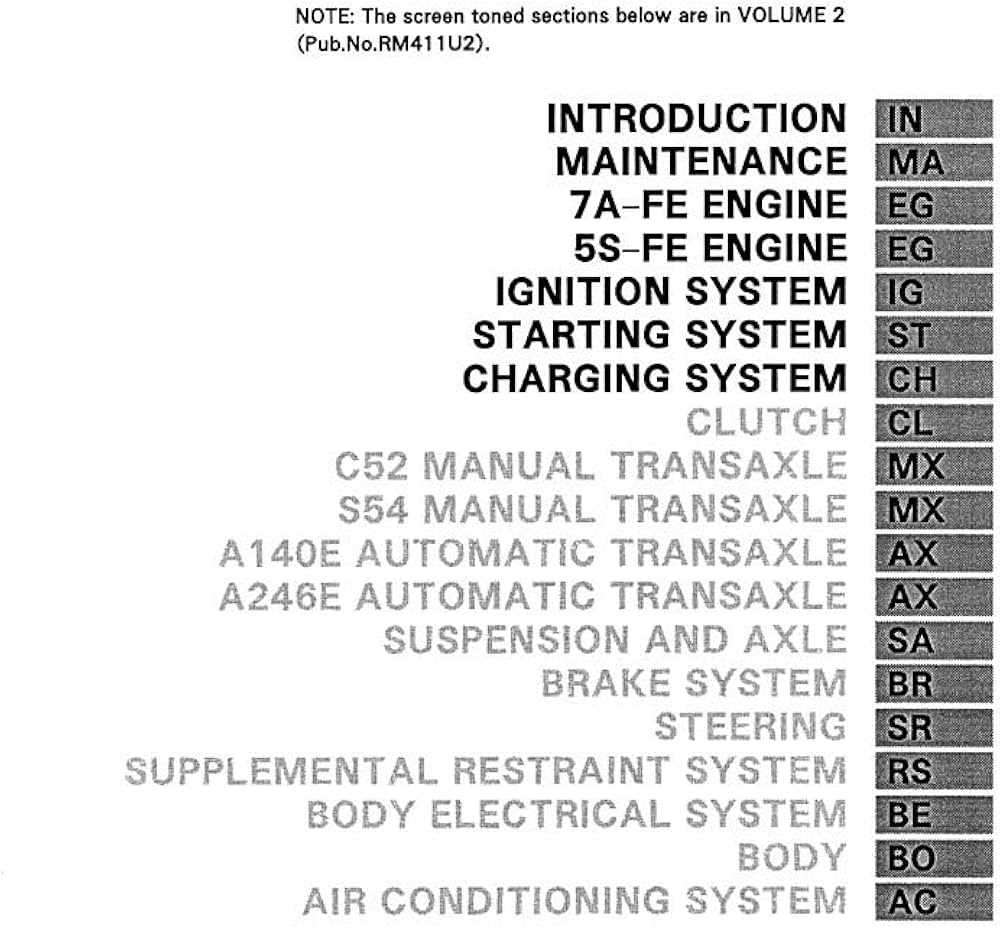

Engine Specifications and Troubleshooting

This section focuses on the key characteristics of the power unit, along with common issues and solutions. Understanding these elements is crucial for maintaining optimal performance and addressing any potential problems that may arise during operation.

Key Specifications

The engine is designed with a compact layout, featuring a 4-cylinder configuration that promotes efficiency and power. It has a displacement of approximately 2.2 liters, generating significant horsepower while maintaining fuel economy. The compression ratio is set at 9.5:1, ensuring a balance between power output and longevity. Notable components include a dual overhead camshaft (DOHC) design, which enhances airflow and efficiency.

Troubleshooting Common Issues

While routine maintenance is vital, occasional problems may occur. Common symptoms include difficulty starting, rough idling, or decreased acceleration. In such cases, first check the ignition system, including spark plugs and wires. Fuel delivery issues may also arise, often linked to a clogged fuel filter or failing fuel pump. Additionally, monitor for any unusual noises, which could indicate problems with the timing belt or internal components. For persistent issues, consulting a detailed guide can provide further insights into diagnosis and resolution.

Electrical System Diagnostics Explained

Understanding the intricacies of an automobile’s electrical framework is crucial for maintaining optimal performance and addressing issues effectively. This segment focuses on the methodologies employed to diagnose faults within the electrical components, ensuring a reliable and safe driving experience.

To embark on this diagnostic journey, one must familiarize themselves with the primary components involved:

- Batteries

- Alternators

- Wiring harnesses

- Fuses and relays

- Sensors and actuators

When diagnosing electrical systems, the following steps are commonly adopted:

- Visual Inspection: Begin with a thorough examination of the wiring and connections for signs of wear, corrosion, or damage.

- Testing Voltage: Use a multimeter to measure voltage levels at various points, ensuring they meet specified ranges.

- Continuity Check: Verify the integrity of circuits by checking for continuous electrical flow throughout the system.

- Component Testing: Assess individual components like the battery and alternator for proper functionality.

- Diagnostic Tools: Employ advanced diagnostic tools such as OBD-II scanners to identify trouble codes that indicate specific faults.

By following these procedures, technicians can effectively isolate and rectify issues within the electrical system, contributing to the vehicle’s overall reliability and safety.

Transmission Care and Repair Tips

Maintaining the functionality of your vehicle’s transmission is crucial for optimal performance and longevity. Regular checks and proper handling can prevent extensive issues and enhance driving experience. This section provides essential advice for keeping your gearbox in top shape and addressing common problems effectively.

Routine Maintenance Practices

Adopting a consistent maintenance routine is key to ensuring your transmission operates smoothly. Here are some fundamental practices to follow:

| Task | Frequency | Description |

|---|---|---|

| Fluid Check | Monthly | Inspect fluid levels and quality. Look for signs of contamination. |

| Fluid Change | Every 30,000 miles | Replace old fluid to maintain lubrication and cooling properties. |

| Filter Inspection | Every 15,000 miles | Check and clean or replace filters to ensure proper flow. |

Troubleshooting Common Issues

Recognizing and addressing problems early can save time and expenses. Here are some typical signs of transmission trouble:

- Unusual noises during gear shifts.

- Slipping gears or delayed engagement.

- Fluid leaks beneath the vehicle.

Address these symptoms promptly to avoid further complications and consult a professional if necessary. Keeping your transmission well-maintained not only enhances performance but also contributes to the overall lifespan of your vehicle.

Suspension System Maintenance Guide

Proper upkeep of the suspension system is crucial for ensuring a smooth ride and optimal handling characteristics. Regular maintenance can prevent issues that may lead to costly repairs and compromised safety. This guide outlines essential practices and checks to keep the suspension in peak condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Every 6 months | Check for signs of wear or damage, including cracks, leaks, and rust on components. |

| Shock Absorber Check | Every 12 months | Assess performance; replace if they show signs of leaking or excessive wear. |

| Wheel Alignment | Every 12 months or after impact | Ensure wheels are properly aligned to enhance tire life and driving stability. |

| Ball Joint Inspection | Every 12 months | Examine ball joints for play and lubrication; replace if necessary. |

| Suspension Bushings | Every 2 years | Inspect for cracks and deterioration; replace worn bushings to maintain performance. |

Incorporating these maintenance tasks into your routine will help extend the lifespan of the suspension system and enhance overall vehicle performance. Addressing minor issues promptly can prevent them from escalating into more significant problems.

Brake System Inspection and Replacement

Ensuring the functionality of the braking mechanism is crucial for vehicle safety. Regular checks and timely component replacements can prevent malfunctions that might lead to serious accidents. This section outlines essential procedures for assessing and renewing brake system parts, promoting optimal performance and reliability.

Inspection Procedures

Begin by visually examining the brake components, including pads, rotors, and calipers. Look for signs of wear, such as thinning brake pads or scoring on the rotors. Additionally, inspect the brake lines for any leaks or abrasions. Checking the brake fluid level is also important, as low fluid can indicate a problem within the system.

Replacement Guidelines

When it becomes necessary to replace any components, ensure you select high-quality parts that meet or exceed manufacturer specifications. For pad replacement, remove the wheel, and then detach the caliper to access the pads. Always replace pads in pairs to maintain even braking. After installation, bleed the brake lines to remove any air pockets, ensuring a firm pedal feel. Finally, test the system at low speeds to verify proper functionality before returning the vehicle to regular use.

Bodywork Repairs and Painting Techniques

This section focuses on essential methods for restoring vehicle exteriors and achieving a professional finish. Whether dealing with minor dents or extensive surface damage, understanding the correct approach can significantly enhance the vehicle’s appearance and longevity.

Common Body Damage Types

- Dents and dings from impacts

- Scratches and paint chips

- Rust and corrosion issues

- Misalignment from collisions

Painting Preparation Steps

- Clean the area thoroughly to remove dirt and grease.

- Sand the damaged surface to create a smooth foundation.

- Apply a primer to promote paint adhesion.

- Select the appropriate color match for the topcoat.

- Use multiple thin coats for an even finish.

- Allow sufficient drying time between each layer.

By following these techniques, vehicle owners can achieve high-quality results, ensuring that the bodywork not only looks great but also protects the underlying materials from further deterioration.

Resources for Obtaining Parts

When it comes to maintaining and restoring vehicles, sourcing the right components is crucial for optimal performance and longevity. A variety of channels exist for enthusiasts and professionals alike to find quality pieces, whether they seek original equipment or aftermarket alternatives.

Online Marketplaces

Many individuals turn to online platforms to find both new and used items. Websites such as eBay and Amazon provide extensive listings from sellers worldwide. These platforms often feature customer reviews and ratings, aiding buyers in making informed decisions. Furthermore, dedicated automotive parts sites can offer specialized components that may not be easily accessible elsewhere.

Local Auto Parts Stores

Brick-and-mortar stores remain a valuable resource for acquiring necessary items quickly. Local auto parts retailers often carry a range of components, from common replacements to more specific items. Establishing a relationship with knowledgeable staff can lead to valuable recommendations and even special orders for hard-to-find parts. Additionally, many of these stores provide the option to return items if they do not meet expectations, ensuring peace of mind during the purchasing process.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks on vehicles is paramount. Proper precautions not only protect the individual performing the work but also safeguard the vehicle from potential damage. A thoughtful approach can prevent accidents and promote a smoother, more efficient process.

Personal Protective Equipment

Wearing the appropriate personal protective gear is essential. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp edges and chemicals, and sturdy footwear to provide support and prevent slips. Additionally, employing hearing protection in noisy environments can prevent long-term damage to hearing.

Work Environment Safety

Maintaining a clean and organized workspace is crucial. Ensure that tools are easily accessible and that the area is free of clutter to reduce the risk of tripping or injury. Furthermore, adequate ventilation is important when working with substances that emit fumes. Always have a fire extinguisher nearby when dealing with flammable materials.