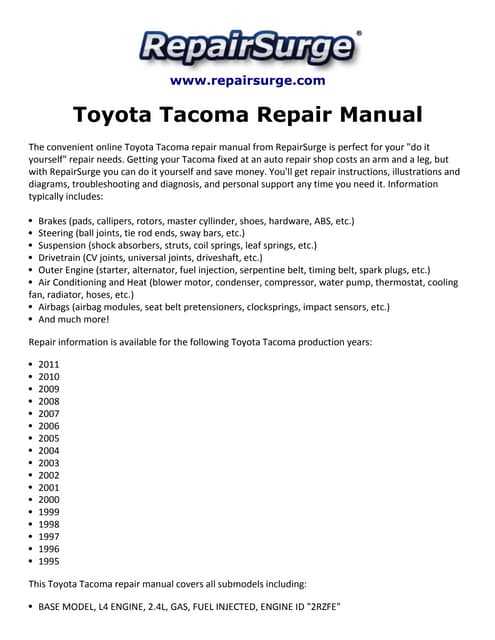

1995 Toyota Pickup Repair Guide for Easy Maintenance and Troubleshooting

Maintaining a dependable vehicle is essential for those who value both longevity and performance in their transportation. When the machinery operates smoothly, every journey becomes safer and more efficient. This guide delves into the essential practices for keeping various components in top condition, ensuring the vehicle’s reliability for years to come. From the basics of routine upkeep to handling specific issues, this resource covers the essential steps that can help extend the life of your vehicle.

Understanding Common Mechanical Challenges is critical for any vehicle owner aiming to avoid unexpected breakdowns. This guide focuses on diagnosing and resolving frequent issues associated with older models, offering both preventive measures and detailed approaches for addressing potential complications. Key sections highlight specific maintenance routines and provide insights on performing essential adjustments or replacements.

Whether you’re experienced in vehicle maintenance or just beginning to explore it, this guide offers invaluable insights to enhance both performance and durability. With step-by-step instructions and clear illustrations, vehicle owners gain the confidence to tackle a range of issues, ensuring safe and enjoyable driving experiences on the road.

Overview of 1995 Toyota Pickup Repairs

Maintaining this reliable vehicle involves a variety of tasks aimed at extending its performance and ensuring its dependability on and off the road. This guide provides insights into critical service areas, helping owners understand essential upkeep, from basic adjustments to more detailed overhauls.

Key Maintenance Areas

Keeping the vehicle in optimal condition starts with consistent inspections and attention to its core components. Engine tune-ups, fluid checks, and the replacement of aged parts are foundational practices that prevent common issues. Additionally, addressing wear on brakes, suspension, and exhaust systems promotes a smooth, safe driving experience.

Electrical System Essentials

The electrical system is another pivotal area requiring regular assessment. Essential elements like the battery, wiring, and lighting systems should be monitored for functionality. By performing routine checks, owners can avoid unforeseen malfunctions, ensuring that all components operate effectively and reliably.

Regular maintenance and proactive servicing can prolong the vehicle’s lifespan, making it a dependable companion for years to come. Inve

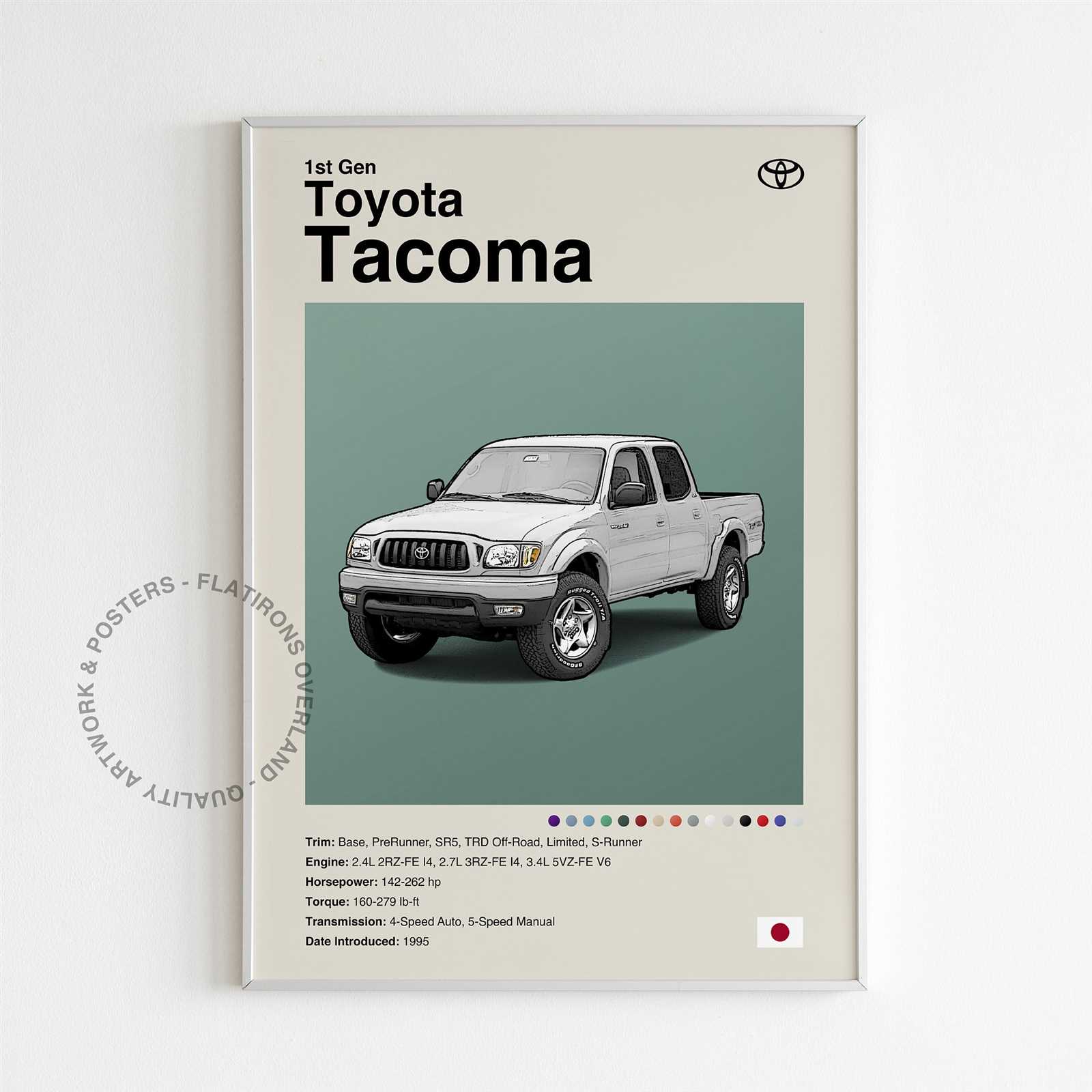

Key Components of the Mid-90s Compact Truck

This versatile vehicle, known for its durability and practical design, offers a range of components that contribute to its lasting popularity among compact trucks. Understanding the primary parts and systems can be beneficial for owners, whether for maintenance, tuning, or improving performance.

Engine and Powertrain

Under the hood, this model features a range of engines, each designed to deliver a balance between power and fuel efficiency. The powertrain includes options suited for various terrains, providing reliable performance in diverse driving conditions. This part of the truck is integral to achieving optimal efficiency and power output, ensuring the vehicle remains dependable over the years.

Suspension and Braking System

The suspension and braking systems are designed to handle both on-road and off-road conditions. A robust suspension setup provides stability, while the braking system offers

Common Mechanical Issues and Fixes

Over time, vehicles often encounter typical mechanical challenges that can affect performance and reliability. Understanding these issues and knowing how to address them can prevent further damage and maintain consistent functionality. This section highlights frequent concerns found in similar models, along with suggested solutions for each.

Engine Overheating: One of the most frequent concerns is the engine running hotter than usual. This can be due to worn-out coolant hoses, a malfunctioning thermostat, or insufficient coolant levels. Regular inspection of the cooling system components and timely replacement of worn parts can effectively manage overheating issues.

Brake Wear and Ineffectiveness: Brakes can exhibit reduced effectiveness or make squeaking noises, indicating wear. Inspecting brake pads, rotors, and fluid levels can address these issues, as replacing worn components is key to maintaining safety and optimal braking

Engine Maintenance Tips for Longevity

Ensuring the longevity of an engine requires regular and proactive maintenance. By focusing on essential care practices, you can enhance its performance, improve efficiency, and prevent issues that can lead to costly repairs over time.

Key Steps for Prolonged Engine Life

- Regular Oil Changes: Replace engine oil at the recommended intervals to ensure proper lubrication and reduce wear on internal components.

- Check Fluid Levels: Regularly inspect coolant, transmission fluid, and brake fluid levels. Proper fluid levels help prevent overheating and protect essential parts.

- Replace Filters: Change air and fuel filters as needed to maintain optimal fuel combustion and prevent contaminants from entering the engine.

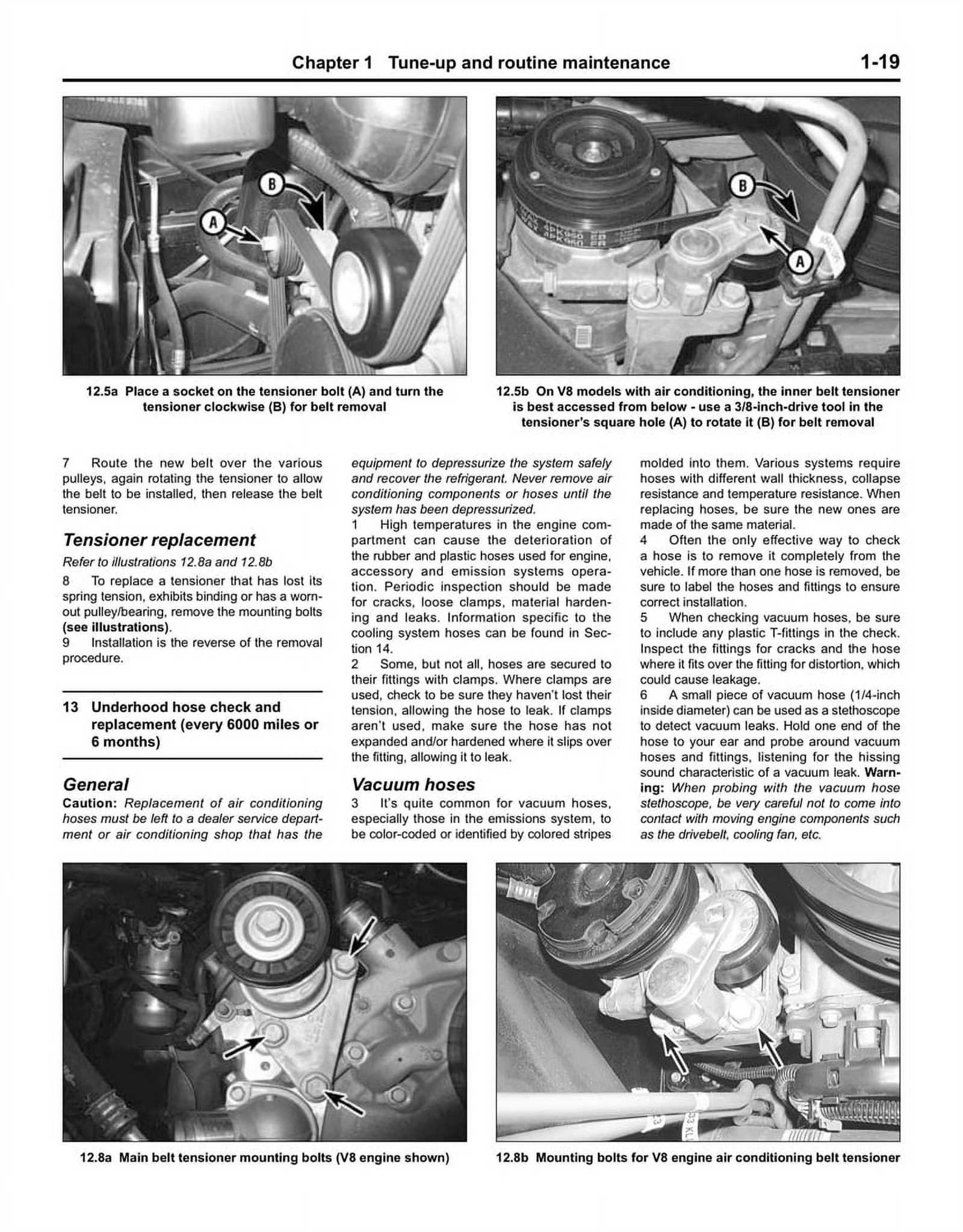

- Inspect Belts and Hoses: Look for signs of wear or cracking on belts and hoses. Replacing these parts promptly helps avoid sudden breakdowns.

Additional Recommendations

- Warm Up Before Driving: Allow the engine a few moments to reach operating temperature, especially in colder weather, to reduce stress on components.

- Monitor Engine Temperature: Watch for any signs of overheating and address any issues with the cooling system immediately.

- Drive Smoothly: Avoid rapid ac

Transmission Repair and Troubleshooting

Addressing transmission issues can significantly improve the performance and longevity of your vehicle’s drivetrain. Understanding the basic steps for diagnosing and fixing common transmission problems will aid in ensuring smooth and reliable operation. In this section, we will explore some common symptoms of transmission issues, potential causes, and effective methods to restore optimal function.

Common Transmission Issues

- Delayed Shifting: Hesitation in shifting gears often signals a need for fluid checks or adjustments in linkage or cable settings.

- Grinding or Shaking: This may indicate internal wear or damage, possibly due to low fluid levels or worn-out gears.

- Burning Smell: This odor could be a sign of overheating, often caused by fluid that’s breaking down and needs replacement.

- Leaking Fluid: Puddles under the vehicle can point to seals or gaskets that require inspection or replacement.

Troubleshooting Steps

- Start

Suspension System: Inspections and Adjustments

The suspension system plays a crucial role in ensuring a vehicle’s stability, comfort, and handling. Regular inspections and precise adjustments are essential to maintain optimal performance and safety. This section outlines key procedures for evaluating and fine-tuning the suspension components to enhance driving experience and prolong the life of the system.

Inspection Procedures

To effectively assess the suspension system, start by examining the shock absorbers and struts for any signs of leakage or physical damage. Check the bushings and mounts for wear or deterioration, as these can significantly impact ride quality. Additionally, inspect the springs for any signs of sagging or breakage, as well as the alignment of the wheels to ensure proper contact with the road surface.

Adjustment Techniques

After completing the inspections, necessary adjustments should be made to restore the suspension to its optimal state. This may include adjusting the ride height by altering spring preload or replacing worn components. Proper alignment of the wheels is also critical; utilize alignment specifications provided by the manufacturer to ensure accurate settings. Regular maintenance and timely adjustments will enhance both safety and vehicle performance.

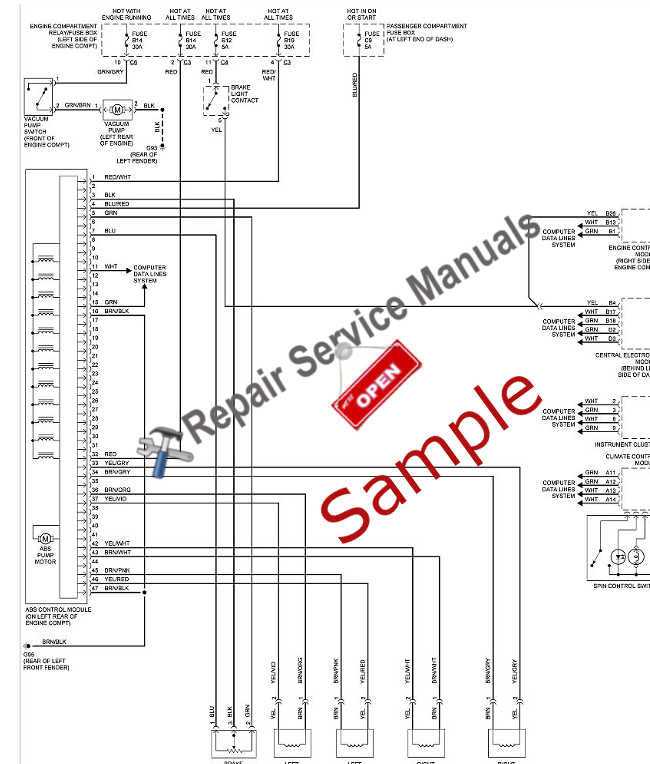

Electrical System Repair Essentials

The electrical system of a vehicle is crucial for its overall functionality, providing power to various components and ensuring smooth operation. Understanding the intricacies of this system is vital for effective troubleshooting and maintenance.

Key aspects to consider when addressing issues related to the electrical system include:

- Wiring Inspection: Regularly examine wiring for signs of wear, corrosion, or damage that could disrupt electrical flow.

- Battery Health: Ensure the battery is fully charged and connections are secure to prevent starting issues.

- Fuse Management: Check and replace any blown fuses, as they are essential for protecting circuits from overload.

- Component Testing: Use a multimeter to test switches, sensors, and other components to confirm they are functioning correctly.

- Ground Connections: Verify that ground connections are clean and secure to avoid electrical malfunctions.

Following these fundamental guidelines can enhance the reliability of the electrical system and prolong the lifespan of various components.

For effective maintenance, consider these additional practices:

- Keep the electrical connections clean and free from moisture.

- Utilize appropriate tools for repairs and replacements to avoid further damage.

- Refer to specifications for voltage and resistance to ensure components meet manufacturer standards.

- Stay informed about common electrical issues specific to your vehicle’s model.

By adhering to these essential practices, one can ensure a well-functioning electrical system, contributing to the overall performance and safety of the vehicle.

Brake System Maintenance Guide

The braking system is a crucial component of any vehicle, ensuring safety and performance on the road. Regular maintenance is essential for optimal functionality, preventing wear and tear that could lead to costly repairs or dangerous situations. This guide outlines essential practices to keep the braking system in top condition.

Key Maintenance Practices

Routine checks and services can significantly extend the life of the braking components. Here are some fundamental practices to follow:

Maintenance Task Frequency Description Inspect Brake Pads Every 6,000 miles Check for wear and replace if they are below the minimum thickness. Check Brake Fluid Level Monthly Ensure the fluid is at the recommended level and replace if contaminated. Examine Brake Lines Every 12,000 miles Look for leaks, corrosion, and cracks in the lines. Test Brake Performance Every 3 months Evaluate the responsiveness and effectiveness during driving. Signs of Trouble

Being aware of potential issues can prevent more significant problems down the line. Watch for these indicators:

- Squeaking or grinding noises when braking

- Vibration or pulsation in the brake pedal

- Dashboard warning lights related to the braking system

- Reduced braking responsiveness or longer stopping distances

Bodywork and Rust Prevention Techniques

Maintaining the exterior integrity of your vehicle is crucial for both aesthetics and longevity. Proper care can significantly reduce the risk of corrosion and damage, ensuring that your automobile remains in optimal condition over the years.

Here are some effective strategies for preserving the bodywork and preventing rust:

- Regular Washing: Frequent cleaning helps remove dirt, salt, and grime that can lead to rust formation.

- Waxing: Applying a high-quality wax creates a protective barrier against moisture and contaminants.

- Inspection: Regularly check for scratches, dents, and other imperfections. Addressing these issues promptly can prevent rust from developing.

- Sealing: Use sealants or protective coatings on vulnerable areas, such as seams and joints, to keep moisture out.

Additionally, consider the following methods for effective rust prevention:

- Undercoating: Apply an undercoating product to the underside of the vehicle to shield it from road salt and moisture.

- Touch-Up Paint: Use touch-up paint to cover any exposed metal areas that may have been damaged.

- Storage: When not in use, store the vehicle in a dry, sheltered location to minimize exposure to the elements.

By implementing these techniques, you can enhance the longevity of your automobile’s body and keep it looking its best for years to come.

Understanding the Fuel System Components

The fuel system in a vehicle plays a crucial role in ensuring optimal performance and efficiency. It is responsible for delivering the appropriate amount of fuel to the engine, allowing for smooth combustion and power generation. Understanding the various components involved in this system is essential for diagnosing issues and maintaining the vehicle’s overall functionality.

Key Components of the Fuel System

The primary elements of the fuel system include the fuel tank, fuel pump, fuel filter, fuel injectors, and fuel lines. The fuel tank serves as the storage unit for the fuel, while the fuel pump is responsible for transferring the fuel from the tank to the engine. A fuel filter ensures that impurities and debris do not enter the engine, protecting it from potential damage. Fuel injectors atomize the fuel and deliver it into the combustion chamber, where it mixes with air for ignition.

Importance of Regular Maintenance

Regular maintenance of the fuel system components is vital for enhancing vehicle performance and longevity. Clogged filters, worn pumps, or malfunctioning injectors can lead to decreased efficiency and power loss. By routinely inspecting and servicing these components, vehicle owners can prevent costly repairs and ensure a smooth driving experience.

Best Practices for Safe Repairs

Ensuring safety during maintenance tasks is essential for both the technician and the vehicle. By following established protocols, one can minimize risks and promote a secure working environment. This section highlights key strategies that should be adopted to enhance safety while conducting maintenance procedures.

Preparation and Planning

- Review relevant documentation and guidelines before starting work.

- Gather all necessary tools and parts to avoid interruptions.

- Assess the workspace for any potential hazards, ensuring it is clean and well-lit.

Personal Protective Equipment

- Always wear appropriate safety gear, including gloves, goggles, and steel-toed boots.

- Utilize ear protection when working with loud machinery.

- Ensure clothing is suitable for the task and does not pose a risk of entanglement.

By adhering to these best practices, individuals can foster a safer atmosphere, reducing the likelihood of accidents and promoting effective maintenance outcomes.