2002 Toyota Camry Repair Guide and Maintenance Tips

Vehicles often require a tailored approach to ensure longevity and optimal performance. This guide is designed for owners and enthusiasts who seek a deeper understanding of essential upkeep, from routine checks to specific troubleshooting techniques. By developing familiarity with core components and operational intricacies, you can effectively address issues as they arise, ensuring a smoother driving experience.

Covering a broad spectrum of maintenance tips, this guide delves into various systems, offering insights into both preventive care and problem-solving strategies. Whether you’re aiming to enhance efficiency or address specific mechanical concerns, this resource provides the knowledge needed to work confidently with key aspects of your car’s functionality.

Practical advice and clear instructions empower drivers to handle technical tasks with ease. By exploring fundamental details and actionable steps, you can gain the expertise needed to maintain vehicle integrity and reliability over time. Embrace this guide as your go-to resource for informed vehicle care, ensuring safe and smooth journeys ahead.

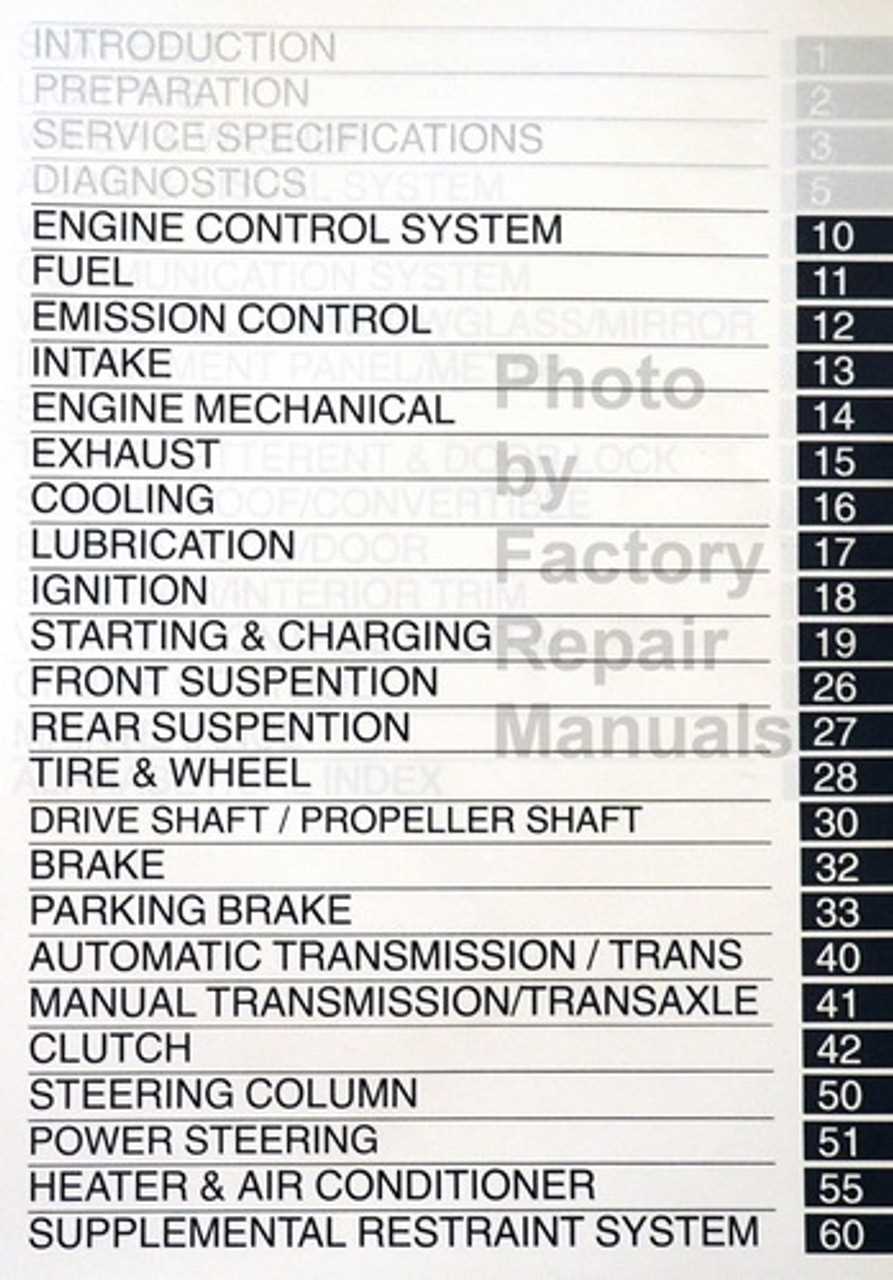

2002 Toyota Camry Repair Manual

This section provides a comprehensive guide for enhancing the maintenance and efficiency of this specific vehicle model. With detailed insights into various components and systems, users can understand core principles and implement effective solutions for improved performance and longevity.

- Step-by-step instructions for routine upkeep and essential services.

- Guidelines for troubleshooting common issues across electrical, mechanical, and interior systems.

- Detailed descriptions of parts involved in major systems like the engine, transmission, and braking, including optimal care techniques.

The guidance covers safe practices for handling different repairs and emphasizes the importance of regular checks and timely replacements. Through organized sections, readers gain valuable knowledge on diagnostics and part adjustments to ensure smooth operation and dependability.

- Inspection protocols for frequent maintenance.

- In-depth explanations for specialized tools and their usage.

- Recommendations for optimal replacements and compatible parts.

Engine Maintenance and Inspection

Regular upkeep of the engine is essential to ensure reliable operation, optimal performance, and longevity. A thorough inspection process helps in identifying early signs of wear or potential issues, allowing for timely interventions that prevent further complications. This section provides guidance on key areas of the engine to examine and maintain, promoting both efficiency and dependability.

Key areas for examination include fluid levels, belt conditions, and connections within the engine system. Regular checks and timely replacement of essential parts contribute significantly to overall functionality. The following table summarizes recommended inspection points and suggested maintenance intervals:

| Inspection Point | Description | Suggested Interval |

|---|---|---|

| Oil Level and Quality | Check oil level and quality to ensure proper lubrication. | Every 3,000 to 5,000 miles |

| Coolant Levels | Examine coolant to prevent overheating and ensure temperature regulation. | Monthly |

| Drive Belts | Inspect belts for wear or cracks, as they power essential engine components. | Every 30,000 miles |

| Battery Connections | Check terminals for corrosion and ensure secure connections for reliable starts. | Quarterly |

Transmission Troubleshooting Techniques

Effective transmission troubleshooting requires a systematic approach to identify and address common issues that may arise over time. In this section, we explore methods for diagnosing performance irregularities, providing guidance for detecting potential problem areas and understanding when certain checks are necessary.

Common Transmission Symptoms

- Delayed Shifting: Recognizable by a lag during gear shifts, often pointing to fluid issues or mechanical misalignments.

- Unusual Noises: Whining, grinding, or humming sounds can indicate component wear, especially if these noises arise during gear changes.

- Slipping Gears: Noticeable when the vehicle shifts unexpectedly, potentially due to worn clutches or insufficient fluid pressure.

- Fluid Leaks: Transmission fluid leaks are a common issue, visible as reddish stains beneath the vehicle, often due to deteriorated seals or gaskets.

Basic Diagnostic Steps

- Fluid Check: Inspect the fluid level and color. Low or discolored fluid is a primary indicator of potential issues and can often be resolved with a flush or refill.

- Electronic Scan: Utilize a diagnostic scanner to detect any stored fault codes that may highlight specific electronic malfunctions or sensor issues.

- Manual Testing: Manually shift through each gear and observe for delays, resistance, or irregularities. This can help pinpoint mechanical or hydraulic issues in the system.

Understanding these troubleshooting techniques can help diagnose and resolve transmission issues early, contributing to smoother vehicle operation and potentially reducing the need for major repairs.

Brake System Repair Essentials

Understanding the core aspects of maintaining and restoring a vehicle’s brake mechanism is essential for ensuring reliable performance and safety on the road. By examining critical parts and the steps involved in brake system upkeep, this section provides a foundation for effective maintenance practices.

| Component | Description | Inspection Frequency |

|---|---|---|

| Brake Pads | Designed to create the necessary friction to slow down and stop the vehicle, brake pads wear over time and require periodic assessment to ensure optimal function. | Every 10,000 miles |

| Brake Rotors | The rotors work in tandem with brake pads to create friction. Surface condition and thickness should be checked to prevent excessive wear. | Every 20,000 miles |

| Brake Fluid | A hydraulic fluid essential for transferring force from the pedal to the brake components. Fluid levels and quality must be monitored to avoid moisture contamination and performance loss. | Every 12 months |

| Calipers | These devices press the brake pads against the rotors to generate stopping power. Inspect for leaks or signs of corrosion. | Annually |

Electrical Components and Circuitry Guide

This section provides a comprehensive overview of the essential electrical elements and connections necessary for maintaining reliable vehicle performance. The guide highlights key components and their roles in the electrical network, supporting efficient troubleshooting and ensuring a consistent power flow across all systems.

| Component | Function | Location |

|---|---|---|

| Battery | Stores energy to power the starter motor and other electronic features when the engine is off. | Engine Compartment |

| Fuse Box | Contains fuses that protect various circuits from overloading and potential damage. | Under the Dashboard |

| Alternator | Generates electricity to recharge the battery and power electrical systems while the engine is running. | Attached to Engine Block |

| Ignition Coil | Transforms low battery voltage into the high voltage needed to create a spark for ignition. | Near Engine’s Spark Plugs |

| Starter Motor | Engages with the engine flywheel to start the engine when the ignition key is turned. | Mounted on the Transmission Housing |

Cooling System Servicing Tips

The maintenance of a vehicle’s cooling mechanism is crucial for ensuring optimal performance and preventing overheating. Proper care not only enhances the longevity of the engine but also improves overall efficiency. This section provides essential guidance on how to effectively manage this vital system.

Regular Inspections

Frequent evaluations of the cooling assembly are necessary to identify any potential issues before they escalate. Check for leaks, corrosion, and any signs of wear in the hoses and connections. Additionally, monitor the coolant levels to ensure they remain within the recommended range, as inadequate fluid can lead to overheating.

Fluid Replacement

Replacing the coolant at regular intervals is vital for maintaining the integrity of the cooling system. Over time, the fluid can become contaminated and lose its effectiveness. Follow the manufacturer’s guidelines for the appropriate type and mixture of coolant to use, and be sure to flush the system thoroughly to remove any debris or buildup.

Suspension and Steering Adjustments

This section delves into the intricacies of modifying the suspension and steering systems of vehicles. Proper adjustments are crucial for ensuring optimal handling, ride comfort, and overall vehicle performance. Understanding the various components involved and how they interact can lead to significant improvements in driving experience.

Key Components

The primary elements involved in suspension and steering adjustments include shock absorbers, struts, control arms, and tie rods. Each of these components plays a vital role in maintaining stability and control while driving. Regular inspection and precise calibration of these parts are essential for safe operation.

Adjustment Procedures

To achieve the best performance, follow these recommended procedures for adjustments:

| Component | Adjustment Type | Procedure |

|---|---|---|

| Shock Absorbers | Damping | Adjust settings according to manufacturer specifications for optimal ride quality. |

| Alignment | Toe, Camber, Caster | Utilize a professional alignment rack to achieve precise angles. |

| Steering Rack | Play Adjustment | Tighten or loosen the adjustment screw to eliminate excess play. |

| Control Arms | Height Adjustment | Adjust the height by modifying the suspension mounts as needed. |

Exterior and Bodywork Restoration

Restoring the outer appearance and structure of a vehicle is essential for maintaining its aesthetic appeal and functionality. This process encompasses various tasks that aim to rejuvenate the car’s exterior, addressing both cosmetic and structural issues. Proper care can extend the lifespan of components, enhance safety, and improve overall value.

Common Restoration Techniques

- Paint Correction: This involves removing imperfections such as scratches and swirl marks from the surface, often using polishing compounds.

- Rust Treatment: Identifying and treating rust spots is crucial to prevent further corrosion. Techniques may include sanding, applying rust inhibitors, and repainting.

- Panel Replacement: Damaged or bent panels may require replacement to restore the vehicle’s original shape and structural integrity.

Essential Tools and Materials

- Sanders and Buffers: Useful for smoothing surfaces and achieving a high-gloss finish.

- Rust Inhibitors: Chemicals designed to prevent rust from spreading and protect exposed metal.

- High-Quality Paint: Selecting the right color and finish is vital for a seamless restoration.

Interior Cleaning and Repair Methods

Maintaining the interior of a vehicle is essential for both aesthetic appeal and comfort. Regular cleaning and timely repairs can significantly enhance the overall experience for occupants. This section outlines effective techniques for cleaning and fixing various interior elements, ensuring a pleasant environment inside the vehicle.

To achieve optimal results, consider the following methods:

- Vacuuming: Begin by removing all floor mats and debris. Use a vacuum cleaner to thoroughly clean seats, carpets, and hard-to-reach areas.

- Surface Cleaning: Wipe down dashboards, door panels, and consoles with a microfiber cloth and a suitable cleaner to remove dust and grime.

- Upholstery Treatment: For fabric seats, use a steam cleaner or upholstery shampoo to eliminate stains and odors. Leather seats require a specific cleaner and conditioner to maintain suppleness.

- Carpet Shampooing: For deep cleaning, use a carpet shampooer or a foam cleaner. Make sure to allow sufficient drying time to prevent mildew.

- Odor Elimination: Utilize air fresheners or baking soda to absorb unwanted smells. Ensure good ventilation during and after cleaning to keep the air fresh.

In addition to cleaning, addressing minor repairs can improve the overall look and functionality:

- Replacing Bulbs: Check and replace any burned-out lights in the cabin to enhance visibility.

- Fixing Trim: Loose or damaged trim can be reattached with adhesive or replaced entirely to restore a neat appearance.

- Panel Alignment: Ensure that door and dashboard panels are properly aligned, adjusting clips or screws as necessary.

Implementing these practices will not only keep the interior in pristine condition but also contribute to the longevity and value of the vehicle.

Fuel System Diagnostics

Effective assessment of the fuel delivery mechanism is crucial for optimal engine performance. This section focuses on identifying potential issues that may arise within the system, allowing for prompt resolution and enhanced reliability. Understanding the components and their interactions will help in diagnosing and addressing faults efficiently.

Common Symptoms of Fuel System Issues

- Engine stalling or difficulty starting

- Poor acceleration or sluggish performance

- Decreased fuel efficiency

- Unusual noises from the fuel tank area

- Check engine light activation

Diagnostic Procedures

- Visual Inspection

- Examine fuel lines for leaks or damage.

- Check the condition of the fuel filter.

- Inspect the fuel pump for signs of wear.

- Pressure Testing

- Use a fuel pressure gauge to measure the system pressure.

- Compare readings against manufacturer specifications.

- Electrical Testing

- Test the fuel pump relay and fuses.

- Check for voltage at the fuel pump connector.

Battery Replacement and Care

Ensuring optimal performance and longevity of your vehicle’s power source is crucial for reliable operation. Proper maintenance and timely replacement of the energy unit can prevent unexpected breakdowns and enhance overall efficiency. This section provides essential guidelines for handling this vital component.

To effectively manage the power source, consider the following steps:

- Assessment: Regularly check the energy unit for signs of wear, corrosion, or leaks. Look for any physical damage that could affect performance.

- Replacement Timing: Follow manufacturer recommendations regarding lifespan. Generally, a power source should be replaced every three to five years, depending on usage and conditions.

- Choosing the Right Unit: Select a compatible energy unit that meets the specific requirements of your vehicle. Pay attention to specifications such as size, voltage, and capacity.

When replacing the energy unit, follow these steps:

- Ensure the engine is off and remove the key from the ignition.

- Disconnect the negative terminal first, followed by the positive terminal.

- Remove any securing mechanisms holding the power source in place.

- Carefully lift out the old unit and replace it with the new one, ensuring proper orientation.

- Reconnect the terminals, starting with the positive terminal followed by the negative terminal.

To maintain the health of the energy unit:

- Keep the terminals clean and free of corrosion by regularly inspecting and applying a suitable protector.

- Ensure secure connections to prevent power loss.

- Regularly check fluid levels if applicable, and top off as necessary.

By following these guidelines, you can enhance the reliability and performance of your vehicle’s energy source, contributing to a smoother driving experience.

Lighting and Signal Checks

Ensuring that illumination and signaling systems function correctly is vital for safety and compliance with regulations. Regular evaluations of these components help maintain visibility and communication with other road users, contributing to a safer driving experience. This section outlines the key aspects of assessing and verifying these essential systems.

To perform effective inspections, follow the outlined steps for each component. Utilize a systematic approach to identify any issues promptly. Below is a table summarizing the primary lights and signals, along with their respective checks:

| Component | Check Method | Notes |

|---|---|---|

| Headlights | Activate and observe brightness and alignment | Check for clear lens and proper focus |

| Turn Signals | Engage left and right indicators to confirm flashing | Ensure that both front and rear indicators operate |

| Brake Lights | Press brake pedal while observing at the rear | Verify that lights illuminate fully and uniformly |

| Reverse Lights | Shift into reverse and check activation | Must light up brightly for visibility |

| Fog Lights | Turn on to assess functionality in low visibility | Check for adequate spread of light |

Performing these evaluations regularly can prevent potential failures and ensure that the vehicle remains roadworthy. Always refer to detailed specifications for further guidance on the correct operation of each system.