Complete Guide to Repairing the 2002 Toyota Tacoma

For any automotive enthusiast or casual owner, understanding the intricacies of vehicle upkeep is essential. This document serves as a vital resource, illuminating the essential procedures and insights necessary to ensure longevity and optimal performance. Whether you’re tackling minor issues or preparing for significant overhauls, having access to detailed instructions is invaluable.

Within this guide, you will find a wealth of information covering a range of topics related to automotive care. From routine inspections to troubleshooting common problems, the content is designed to empower you with the knowledge required to maintain your vehicle effectively. Clear, step-by-step processes are presented to facilitate a deeper understanding of the mechanics at play.

Moreover, this resource is not just for those with extensive experience; it also caters to newcomers eager to learn the fundamentals. With straightforward explanations and helpful tips, you’ll gain confidence in your ability to address various maintenance tasks. Embrace the journey of automotive literacy and equip yourself with the tools needed for successful vehicle management.

Overview of the 2002 Toyota Tacoma

This section provides a comprehensive look at a popular compact pickup from the early 2000s. Renowned for its durability and versatility, this vehicle appeals to both everyday drivers and off-road enthusiasts. Its design balances functionality with comfort, making it suitable for a range of tasks, from commuting to weekend adventures.

Key Features and Specifications

This model is equipped with various engine options, offering a choice between performance and fuel efficiency. With a robust suspension system, it excels in handling rough terrains while maintaining a smooth ride on highways. The interior is designed with practicality in mind, featuring ample storage and user-friendly technology for an enhanced driving experience.

Performance and Handling

Common Issues with the Tacoma

Vehicles of this make and model often face several recurring problems that owners should be aware of. Understanding these issues can help in maintaining optimal performance and ensuring a smooth driving experience. From mechanical concerns to electronic malfunctions, being informed can save both time and money.

Engine Problems

One frequent complaint among drivers relates to engine performance. Symptoms can include rough idling, decreased power, or unusual noises. Regular maintenance checks can help identify potential issues early, such as worn spark plugs or fuel system irregularities, ensuring the engine runs smoothly.

Transmission Difficulties

Transmission-related issues are also commonly reported. Drivers may notice difficulties in shifting gears or delayed engagement. These problems can stem from low fluid levels or worn components, emphasizing the importance of routine inspections to catch any signs of wear before they escalate into more significant repairs.

Essential Tools for Repairs

Having the right equipment is crucial for successfully tackling maintenance and restoration tasks on your vehicle. A well-equipped workspace can significantly simplify the process and improve outcomes, ensuring that each job is completed efficiently and effectively. Below are some indispensable items that every automotive enthusiast should consider having on hand.

Basic Hand Tools

- Wrenches: A set of both metric and standard sizes is essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips options are necessary for various fasteners.

- Pliers: Needle-nose and slip-joint pliers are great for gripping and manipulating small parts.

- Ratchet and Socket Set: This allows for easier access to fasteners in tight spaces.

Specialized Equipment

- Jack and Jack Stands: These are crucial for safely lifting the vehicle off the ground.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Multimeter: Useful for diagnosing electrical issues and checking voltage levels.

- Diagnostic Scanner: Helps identify trouble codes and other issues in modern vehicles.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring optimal performance and longevity of your vehicle. Regular upkeep not only enhances reliability but also prevents costly repairs down the line.

Essential Tools and Supplies

- Wrench set

- Oil filter wrench

- Jack and jack stands

- Fluid containers

- Diagnostic scanner

Maintenance Checklist

- Check and change the oil regularly.

- Inspect and replace air filters as needed.

- Examine brakes for wear and tear.

- Monitor tire pressure and tread depth.

- Flush and refill coolant periodically.

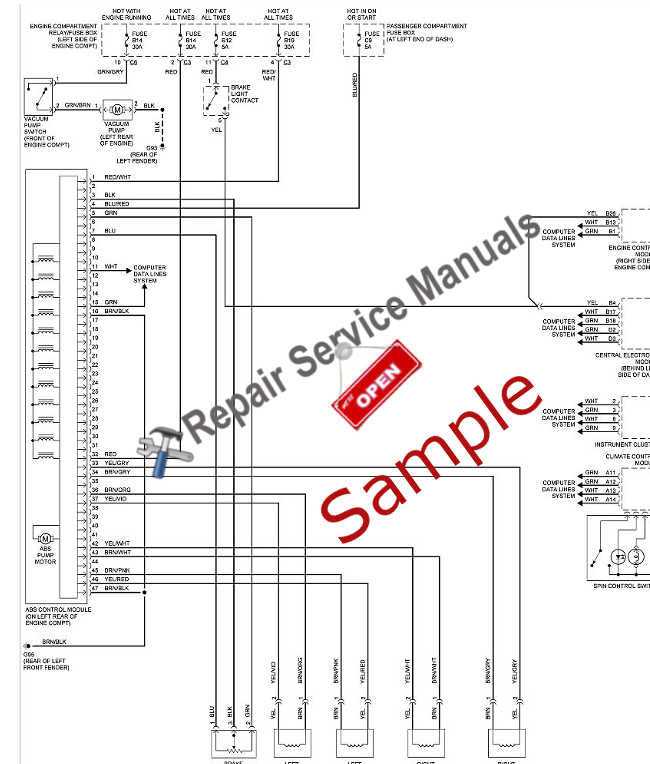

Electrical System Troubleshooting

This section focuses on diagnosing and resolving issues related to the vehicle’s electrical components. A systematic approach is essential to identify faults effectively and ensure proper functioning of the system.

Common Electrical Issues

Understanding typical electrical problems can help in pinpointing the cause of malfunctions. Below are some frequent issues encountered:

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Dead Battery | Engine won’t start, dim lights | Recharge or replace battery |

| Faulty Alternator | Battery warning light on, flickering lights | Test and replace alternator if needed |

| Blown Fuses | Inoperative accessories | Inspect and replace blown fuses |

Diagnostic Steps

To effectively troubleshoot the electrical system, follow these steps: begin with visual inspections of wiring and connections, use a multimeter to check voltage levels, and consult wiring diagrams for proper reference. By delving into these areas, you can uncover underlying issues that require attention.

Engine Specifications and Performance

This section delves into the intricate details of the powertrain, focusing on the specifications that define its capabilities. Understanding these elements is essential for optimizing performance and ensuring longevity. Key attributes include displacement, horsepower, torque, and fuel efficiency, all of which contribute to the overall driving experience.

Powertrain Details

The engine typically features a robust design, emphasizing reliability and power output. With a displacement of approximately 3.4 liters, it is engineered to deliver a balanced combination of performance and efficiency. The horsepower rating generally hovers around 190, while torque often peaks at about 220 lb-ft, providing ample thrust for various driving conditions.

Fuel Efficiency and Emissions

Efficiency plays a crucial role in modern automotive engineering. This powerplant is designed to offer competitive fuel economy, averaging around 17-21 miles per gallon, depending on driving habits and conditions. Additionally, the engine meets emission standards, contributing to a more sustainable driving experience without compromising on power.

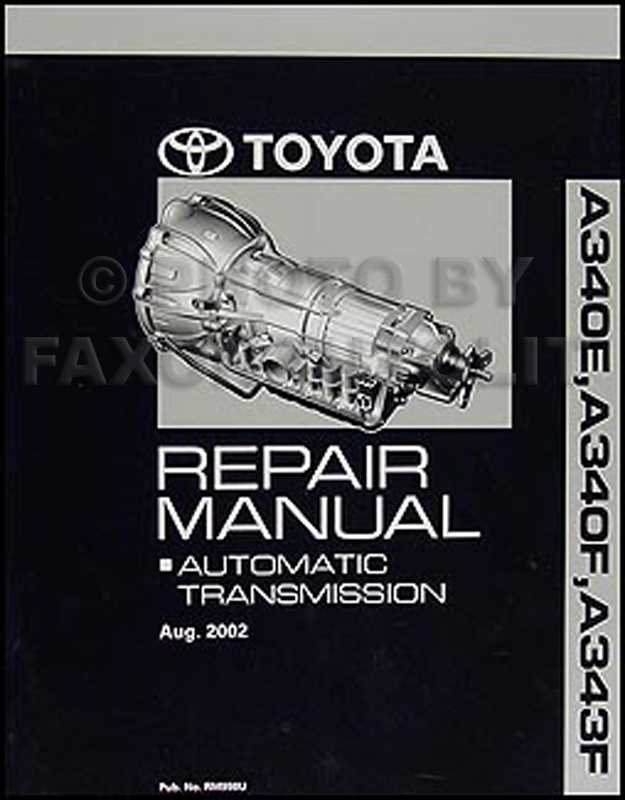

Transmission Repair Techniques

Effective maintenance and troubleshooting of gear systems are crucial for ensuring the longevity and performance of vehicles. Understanding various methodologies can aid in identifying issues early and executing corrective measures. This section explores essential strategies for addressing common transmission challenges.

Diagnostic Procedures

Accurate diagnosis is the foundation of successful transmission service. Utilizing specialized tools to assess fluid conditions, check for leaks, and perform electronic diagnostics can reveal underlying problems. Regular inspections and monitoring of performance metrics can prevent minor issues from escalating into major failures.

Component Replacement

When components exhibit wear or malfunction, timely replacement is essential. Identifying signs of damage, such as abnormal noises or slipping gears, allows for targeted intervention. Following manufacturer guidelines for part specifications ensures compatibility and optimal functionality, while proper installation techniques safeguard against future complications.

Brake System Inspection Procedures

Regular examination of the braking system is crucial for ensuring optimal performance and safety. This process involves a series of checks aimed at identifying any potential issues that could compromise the effectiveness of the brakes. By adhering to systematic inspection protocols, one can enhance both the reliability and longevity of the braking components.

Begin the inspection by visually assessing the brake pads and rotors for signs of wear or damage. Look for uneven wear patterns, cracks, or scoring on the rotor surface, as these can indicate underlying problems. Ensure that the pads have sufficient thickness; replacing them before they wear down completely can prevent further damage to the braking system.

Next, examine the brake fluid levels and quality. Low fluid levels may suggest leaks in the system, while contaminated fluid can lead to decreased braking performance. It is advisable to replace the brake fluid at regular intervals to maintain its efficacy.

Inspect the brake lines and hoses for any signs of deterioration, such as cracks, bulges, or leaks. Any compromised lines should be replaced immediately to prevent brake failure. Additionally, check the connections and fittings to ensure they are secure and free from corrosion.

Finally, test the braking system by conducting a functionality check. Engage the brakes at low speeds to listen for unusual noises, and pay attention to any vibrations or pulling sensations. These symptoms may indicate further issues that require attention. Regular inspections will help maintain the integrity of the braking system, ensuring a safer driving experience.

Suspension and Steering Adjustments

Proper adjustments to the suspension and steering systems are essential for maintaining vehicle stability and ensuring a smooth driving experience. These modifications not only enhance handling and comfort but also contribute to the longevity of the components involved. Understanding the various aspects of suspension and steering alignment can significantly improve performance and safety.

Key areas of focus include ride height, camber, caster, toe angles, and the overall balance of the vehicle. Regular inspections and adjustments can help identify wear or misalignment, preventing further issues down the line. Below is a table summarizing the key adjustments and their effects on vehicle handling:

| Adjustment Type | Description | Impact on Performance |

|---|---|---|

| Ride Height | Adjusts the distance between the vehicle body and ground. | Affects center of gravity and load distribution. |

| Camber | Angle of the wheels relative to vertical. | Influences tire wear and cornering stability. |

| Caster | Angle of the steering axis when viewed from the side. | Improves straight-line stability and steering feel. |

| Toe | Alignment of the wheels in relation to each other. | Impacts tire wear and handling response. |

In conclusion, regular adjustments to suspension and steering components are vital for optimal performance. Adhering to manufacturer specifications and conducting thorough inspections will ensure that the vehicle remains responsive and safe on the road.

Bodywork and Frame Repairs

Addressing issues related to bodywork and structural integrity is essential for maintaining vehicle safety and aesthetics. This segment focuses on common procedures involved in restoring exterior components and ensuring the chassis remains sound. Understanding the nuances of these repairs can enhance both functionality and appearance, providing a smoother driving experience.

Common Bodywork Issues

Vehicles often face various external damages, such as dents, scratches, and rust. Identifying the extent of the damage is crucial before proceeding with any restoration. Below is a summary of typical bodywork challenges and their respective solutions:

| Issue | Solution |

|---|---|

| Dents | Use a suction cup or specialized tools to pull out the dent or apply heat for better access. |

| Scratches | Sand the area, apply primer, and then repaint to blend with the surrounding surface. |

| Rust | Remove rust with a wire brush, apply a rust inhibitor, and repaint the affected area. |

Frame Integrity Assessment

Ensuring the frame is structurally sound is vital for overall vehicle performance. Common indicators of frame issues include misalignment or visible bends. Regular inspections can help identify these problems early on. Techniques for assessment include:

| Assessment Method | Description |

|---|---|

| Visual Inspection | Check for cracks, bends, or unusual wear patterns. |

| Measuring Tools | Utilize laser or traditional measuring tools to ensure proper alignment. |

| Professional Evaluation | Consult with specialists for thorough frame assessments and repairs. |

Replacement Parts and Sources

Finding the right components for vehicle maintenance is crucial for ensuring longevity and performance. This section focuses on various types of replacement items and the best sources for obtaining them.

When looking for parts, consider the following categories:

- OEM Parts: Original Equipment Manufacturer components guarantee compatibility and reliability.

- Aftermarket Options: These are alternatives that often come at a lower price, though quality can vary.

- Rebuilt or Remanufactured Parts: Ideal for those looking to save money while still receiving reliable performance.

- Used Parts: Salvaged components can be a budget-friendly option, but careful inspection is essential.

Here are some reliable sources for acquiring these items:

- Local Auto Parts Stores: Convenient for immediate needs and often provide expert advice.

- Online Retailers: Websites dedicated to automotive supplies offer a vast selection and competitive pricing.

- Dealerships: While typically more expensive, they ensure authenticity and access to the latest components.

- Junkyards: A treasure trove for used parts, often at a fraction of the cost of new ones.

Researching each option thoroughly will help in making informed choices that suit your vehicle’s needs and budget. Always prioritize quality to maintain performance and safety.

DIY vs. Professional Repairs

When it comes to maintaining your vehicle, there are two primary paths: tackling the job yourself or enlisting the help of an expert. Each approach has its own set of advantages and challenges, making the choice dependent on various factors including skills, resources, and time.

Advantages of DIY Repairs

- Cost Savings: Performing tasks independently can significantly reduce expenses related to labor.

- Learning Experience: Engaging in hands-on work enhances your understanding of automotive mechanics.

- Flexibility: You can work at your own pace and schedule, allowing for greater convenience.

- Customization: DIY projects can be tailored to your specific preferences and needs.

Benefits of Professional Services

- Expertise: Professionals bring specialized knowledge and experience to complex issues.

- Time Efficiency: Experienced technicians can often complete tasks more quickly than a novice.

- Warranty Protection: Work done by certified mechanics often comes with guarantees, offering peace of mind.

- Access to Equipment: Professionals utilize advanced tools and technology that may not be available to the average owner.

Ultimately, the decision between handling repairs yourself or seeking professional assistance hinges on your comfort level, the nature of the task, and the resources at your disposal. Weighing the pros and cons of each option can help you make an informed choice that best suits your situation.