Comprehensive Guide to Repairing the 92 Toyota Pickup

Maintaining a vintage vehicle requires a blend of knowledge, skill, and the right resources. For enthusiasts and owners of the 1992 utility model, having access to detailed information can make all the difference in preserving its performance and longevity. This section aims to provide essential insights into troubleshooting and upkeep, ensuring that your cherished automobile remains in optimal condition.

Whether you are tackling minor adjustments or major overhauls, understanding the intricacies of your vehicle’s systems is crucial. From the engine components to the electrical systems, every aspect plays a significant role in the overall functionality. With the right guidance, even those new to automotive care can navigate these challenges effectively.

Furthermore, equipping yourself with practical tips and best practices will not only enhance your skills but also foster a deeper appreciation for your vehicle. Embrace the journey of restoration and maintenance as an opportunity to connect with the craftsmanship of automotive engineering.

Overview of the 1992 Toyota Pickup

The 1992 model year marked a significant chapter in the evolution of compact utility vehicles. Renowned for its reliability and versatility, this vehicle appeals to both everyday drivers and enthusiasts alike. With a well-rounded design and a variety of configurations, it offers a balance of performance and practicality that suits various needs.

Design and Features

This model showcases a robust exterior that embodies a classic aesthetic, complemented by a functional interior. Drivers can expect a straightforward dashboard layout, with controls easily accessible for convenience. The seating is designed to provide comfort during long journeys, making it a suitable choice for both work and leisure activities.

Performance and Engine Options

Under the hood, this vehicle is equipped with a range of engine options that deliver commendable power and efficiency. The available drivetrain configurations allow for enhanced handling and adaptability to different terrains. Whether navigating city streets or venturing off-road, this model offers a driving experience that meets diverse expectations.

Overall, the 1992 iteration stands as a testament to quality engineering, making it a respected choice among its contemporaries in the automotive market.

Common Issues and Solutions

This section addresses frequent challenges encountered by owners of older utility vehicles, along with practical solutions to resolve them. By identifying typical problems, enthusiasts can enhance their driving experience and extend the life of their vehicles.

| Issue | Description | Solution |

|---|---|---|

| Engine Overheating | High engine temperatures can lead to serious damage if not addressed promptly. | Check coolant levels, inspect for leaks, and ensure the radiator is functioning properly. |

| Electrical System Failures | Malfunctions in the electrical system can cause issues with starting or running the vehicle. | Examine battery connections, replace fuses, and test alternator output. |

| Transmission Slipping | This issue may result in difficulty shifting gears or unexpected changes in gear engagement. | Check fluid levels, inspect for leaks, and consider fluid changes or professional servicing. |

| Suspension Problems | Worn or damaged components can lead to an uncomfortable ride and poor handling. | Inspect shocks and struts, and replace any worn bushings or joints. |

| Fuel System Issues | Problems in the fuel system can cause performance issues or difficulty starting. | Replace fuel filters, check for blockages, and inspect fuel injectors. |

Essential Tools for DIY Repairs

Engaging in self-service maintenance can be both rewarding and cost-effective. To successfully tackle various tasks, it’s important to have a selection of essential instruments at your disposal. This collection will not only simplify your efforts but also enhance the overall quality of your work.

Basic Hand Tools

Every enthusiast should start with a fundamental set of hand tools. This typically includes wrenches, screwdrivers, and pliers. These items are crucial for loosening and tightening components, allowing for easier access to internal parts. Additionally, consider adding a torque wrench to ensure that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

Specialized Equipment

As you delve deeper into your projects, specialized gear becomes increasingly valuable. A multimeter is essential for diagnosing electrical issues, while a jack and jack stands provide safe access to the underside of your vehicle. Investing in a mechanics tool set can also prove beneficial, as it typically includes a variety of sockets and extensions, enabling you to tackle a wider range of tasks with ease.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your vehicle in optimal condition. Regular upkeep is essential to ensure longevity and reliability. By following these systematic steps, you can enhance performance and avoid potential issues down the road.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace old oil with fresh oil to ensure smooth engine operation. |

| Air Filter Replacement | Every 15,000 miles | Change the air filter to maintain proper airflow and engine efficiency. |

| Tire Rotation | Every 6,000 miles | Rotate tires to promote even wear and extend tire life. |

| Brake Inspection | Every 10,000 miles | Check brake pads and discs for wear and replace as necessary. |

| Fluid Check | Monthly | Inspect and top off essential fluids, including coolant and brake fluid. |

| Battery Maintenance | Every 6 months | Clean terminals and check battery condition to prevent failures. |

By adhering to this structured maintenance schedule, you can significantly enhance the durability and performance of your vehicle, ensuring a safe and enjoyable driving experience.

Engine Specifications and Diagnostics

This section provides crucial information regarding the powertrain’s technical parameters and the processes involved in assessing its functionality. Understanding these details is essential for ensuring optimal performance and longevity of the vehicle.

Engine Type: The heart of the vehicle features a robust inline configuration that balances efficiency and power delivery. This design is favored for its simplicity and reliability.

Displacement: The engine boasts a displacement of approximately 2.4 liters, allowing it to generate sufficient torque for various driving conditions. This capacity strikes a balance between performance and fuel economy.

Compression Ratio: A compression ratio of 9.0:1 contributes to effective combustion and overall power output. This ratio is integral in maximizing efficiency while minimizing emissions.

Horsepower: The power output reaches around 105 horsepower at 4,600 RPM, providing ample acceleration for daily driving and off-road adventures alike.

Diagnostic Procedures: To maintain optimal engine health, regular diagnostics are essential. Utilizing an OBD-II scanner can reveal potential trouble codes, aiding in the identification of issues such as misfires or sensor failures.

Routine checks of fluid levels, ignition components, and exhaust systems are recommended to prevent larger mechanical problems. By adhering to these guidelines, owners can ensure their vehicle remains in peak condition.

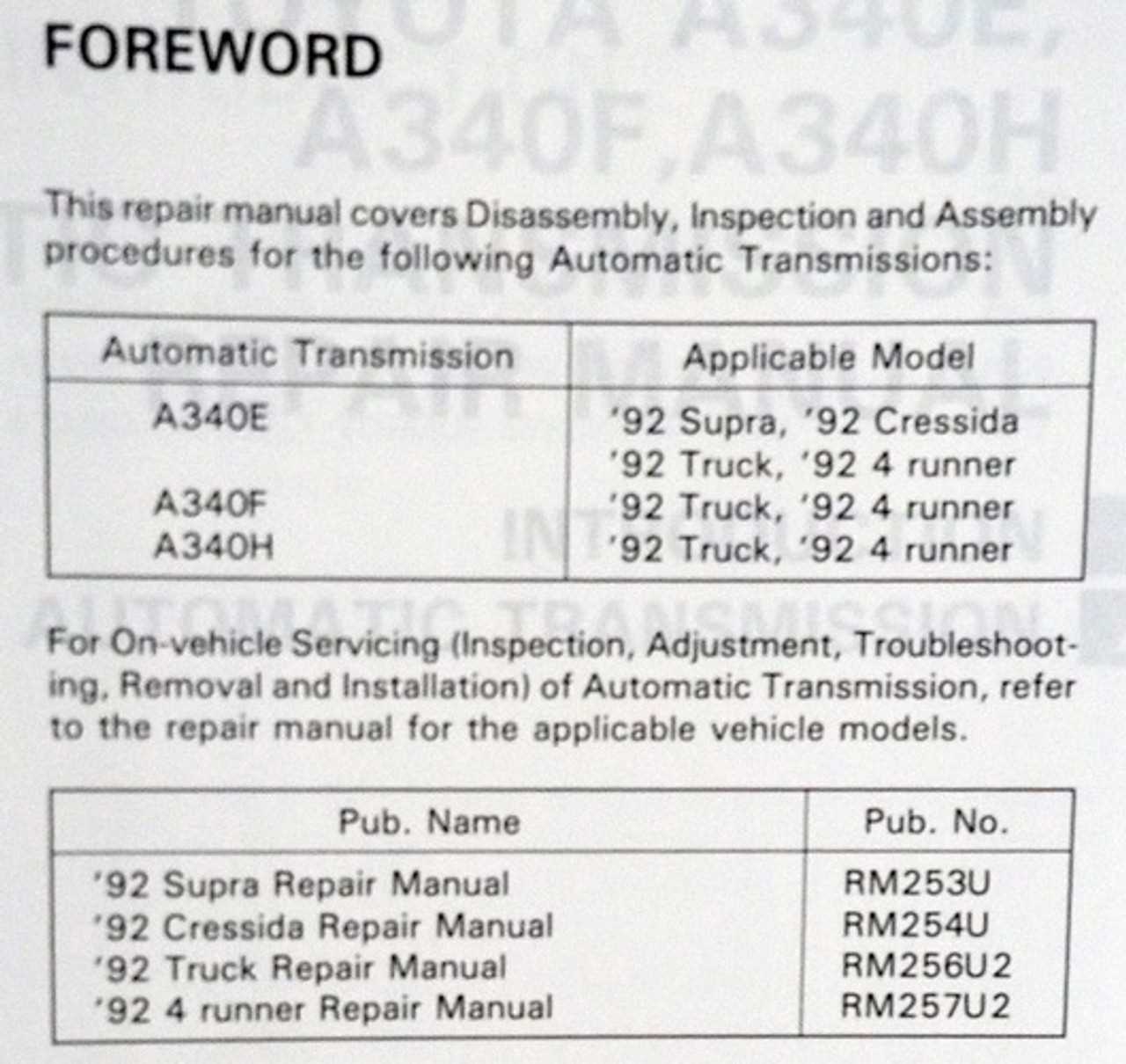

Transmission Troubleshooting Techniques

Addressing issues within the drivetrain can be a complex endeavor, requiring a systematic approach to identify and resolve problems effectively. Understanding the symptoms and utilizing appropriate diagnostic methods can significantly streamline the process of restoring functionality.

Common Symptoms of Transmission Issues

Recognizing the early signs of transmission trouble is crucial. The following table outlines frequent indicators and their potential implications:

| Symptom | Possible Cause |

|---|---|

| Slipping Gears | Low fluid levels or worn components |

| Delayed Engagement | Faulty solenoids or fluid contamination |

| Unusual Noises | Worn bearings or damaged gears |

| Fluid Leaks | Damaged seals or gaskets |

| Warning Lights | Electronic malfunctions or sensor issues |

Diagnostic Techniques

Employing effective diagnostic strategies is essential for pinpointing the root of transmission complications. Start by conducting a thorough inspection of fluid levels and quality. Following this, utilizing diagnostic tools such as OBD-II scanners can help detect error codes associated with the transmission system. Finally, performing road tests to evaluate the performance under various conditions can provide further insights into underlying issues.

Electrical System and Wiring Diagrams

The electrical framework of any vehicle is crucial for its overall functionality, ensuring that various components communicate effectively. Understanding the wiring layouts and circuitry is essential for diagnosing issues and performing maintenance. This section delves into the specifics of the electrical setup, providing a clear overview and necessary diagrams for reference.

Overview of the Electrical System

The electrical system consists of multiple interconnected parts, including the battery, alternator, starter, and various sensors and switches. Each component plays a vital role in the vehicle’s operation, contributing to everything from ignition to lighting. Familiarity with these elements and their configurations is important for troubleshooting and repairs.

Wiring Diagrams

Wiring diagrams serve as a visual representation of the electrical connections within the vehicle. They provide detailed layouts that help in understanding how different parts are linked, facilitating easier identification of potential faults. Below is a simplified representation of key components and their connections:

| Component | Function |

|---|---|

| Battery | Supplies electrical power to the system |

| Alternator | Recharges the battery while the engine runs |

| Starter Motor | Engages the engine during ignition |

| Fuses | Protects the circuit from overloads |

| Relays | Controls high-current circuits with low-current signals |

For successful troubleshooting, it is essential to reference these diagrams and understand the flow of electricity throughout the system. This knowledge empowers users to address issues confidently and maintain optimal performance.

Bodywork and Interior Repairs

This section focuses on the essential aspects of maintaining and restoring the external and internal components of your vehicle. Proper attention to these areas not only enhances the overall aesthetic but also ensures durability and comfort during use. Whether addressing minor dents, scratches, or interior wear, a systematic approach is key to achieving satisfactory results.

Common Exterior Issues

Vehicles often face various challenges related to their outer surfaces. From weather-related wear to accidental damage, understanding how to address these problems can greatly extend the lifespan of your vehicle’s body. Key repairs include:

| Issue | Solution |

|---|---|

| Dents | PDR (Paintless Dent Removal) |

| Scratches | Touch-up Paint or Polishing |

| Rust | Sand and Treat with Rust Inhibitor |

| Fading Paint | Buffing and Waxing |

Interior Maintenance

The inside of a vehicle plays a critical role in user experience. Regular upkeep can prevent damage and maintain a pleasant environment. Consider these common areas of concern:

| Issue | Solution |

|---|---|

| Stains on Upholstery | Steam Cleaning |

| Worn-out Dashboard | Conditioning and Repair Kits |

| Loose Panels | Reinforcement and Adhesive Solutions |

| Malfunctioning Controls | Component Replacement |

Suspension and Steering Components

The suspension and steering systems play a crucial role in ensuring vehicle stability, comfort, and handling. These components work together to absorb shocks, maintain tire contact with the road, and provide precise steering response. Understanding their function and maintenance is essential for any enthusiast aiming to enhance performance or address issues.

Key Suspension Elements

The primary components of the suspension system include shocks, struts, and springs. Each of these elements contributes to the overall ride quality by mitigating road imperfections. Shocks dampen the movement of the springs, while struts support the weight of the vehicle and absorb shocks simultaneously. Coil springs provide the necessary support and flexibility, allowing the wheels to move independently over uneven terrain.

Steering Mechanism Overview

The steering system comprises several critical parts, such as the rack and pinion, tie rods, and steering column. The rack and pinion setup translates the rotational motion of the steering wheel into lateral movement of the wheels. Tie rods connect the steering rack to the wheels, ensuring precise alignment and control. Regular inspection and maintenance of these components are vital for safe maneuverability and responsiveness.

Braking System Maintenance Tips

Proper upkeep of the braking system is crucial for ensuring safety and optimal performance on the road. Regular checks and timely interventions can prevent more significant issues and extend the lifespan of various components. This guide provides essential practices to help maintain this vital system effectively.

Regular Inspections

Conduct frequent assessments of the braking system to identify any wear and tear. Look for signs of damage, such as fluid leaks, worn pads, or corroded rotors. Inspect brake lines for cracks and ensure that the fluid levels are adequate. Addressing minor issues promptly can prevent costly repairs in the future.

Brake Fluid Maintenance

Brake fluid plays a critical role in the functionality of the braking system. Check the fluid regularly and replace it according to the manufacturer’s recommendations. Contaminated fluid can lead to brake failure, so it’s important to keep it clean and at the proper level. Always use the recommended type of fluid for optimal performance.

Upgrading Parts for Enhanced Performance

Improving your vehicle’s components can lead to significant gains in efficiency and power. By selecting high-quality alternatives and modifications, you can elevate your driving experience, whether it’s for daily commutes or off-road adventures. Understanding which areas to enhance can make all the difference in achieving the desired performance metrics.

Key Components to Consider

When looking to boost your vehicle’s capabilities, focus on critical elements such as the engine, suspension, and exhaust system. Upgrading the engine with a performance chip or aftermarket intake can optimize fuel efficiency and power output. Enhancing the suspension with upgraded shocks and springs provides better handling and stability, especially on uneven terrains.

Benefits of Quality Upgrades

Investing in superior parts not only improves functionality but also contributes to the longevity of your vehicle. High-performance components often withstand greater stress and wear, ensuring a reliable ride. Additionally, these modifications can enhance aesthetic appeal and resale value. Ultimately, the right upgrades create a more enjoyable and dynamic driving experience.

Safety Considerations During Repairs

Ensuring personal safety is paramount when undertaking maintenance tasks on vehicles. Adhering to best practices not only protects the individual but also helps prevent damage to the equipment. Awareness of potential hazards and preparation can significantly mitigate risks.

- Personal Protective Equipment (PPE): Always wear appropriate gear such as gloves, goggles, and steel-toed boots to shield against injuries.

- Ventilation: Work in a well-ventilated area to avoid inhaling harmful fumes or gases that can accumulate during the process.

- Stability: Ensure that the vehicle is securely supported using jack stands to prevent accidental collapse.

Preparation is crucial before starting any tasks. Reviewing the necessary procedures and gathering the right tools can streamline the process and enhance safety.

- Familiarize Yourself: Read relevant documentation to understand the vehicle’s systems and components.

- Organize Tools: Keep tools neatly arranged and within reach to reduce the risk of accidents.

- Work Methodically: Follow a step-by-step approach to avoid overlooking critical aspects of the task.

In case of emergencies, having a first aid kit readily available can be invaluable. It is also wise to know basic first aid procedures and contact numbers for local emergency services.

- Stay Alert: Avoid distractions and maintain focus while working.

- Seek Help: Don’t hesitate to ask for assistance when dealing with heavy or complex components.

By prioritizing safety, individuals can conduct maintenance activities more effectively and with greater confidence.