Complete Repair Manual for the 1999 Toyota Corolla

The journey of car ownership often includes the need for thorough understanding and upkeep of your vehicle. This particular guide focuses on a widely recognized model from 1999, offering valuable insights into its servicing and troubleshooting. By delving into the intricacies of this automobile, you can enhance its longevity and performance.

Within this resource, you will find a comprehensive collection of instructions and tips designed to assist you in addressing common issues and performing routine tasks. Emphasizing both practical advice and essential techniques, this guide is tailored for enthusiasts and everyday drivers alike. Embrace the knowledge that will empower you to take charge of your vehicle’s health.

Whether you are a seasoned mechanic or a novice owner, understanding the nuances of your car is crucial. This compilation aims to demystify the complexities involved, ensuring that you are well-equipped to handle maintenance challenges effectively. Let this be your companion in navigating the path to a well-maintained ride.

Overview of 1999 Toyota Corolla

The 1999 model of this compact vehicle is recognized for its reliability and practicality. Designed with the everyday driver in mind, it balances performance, comfort, and fuel efficiency, making it a popular choice for individuals and families alike.

Design and Features

This iteration boasts a streamlined exterior that emphasizes aerodynamics. The interior is user-friendly, featuring comfortable seating and straightforward controls. Standard amenities include air conditioning, a sound system, and ample storage space, enhancing the overall driving experience.

Performance and Efficiency

Equipped with a fuel-efficient engine, this vehicle offers a smooth ride while maintaining excellent mileage. The handling is responsive, making it suitable for both city commuting and longer journeys. Overall, it represents a well-rounded option for those seeking dependable transportation.

Common Issues with the 1999 Model

The 1999 model has garnered attention for several recurring challenges that owners may encounter. Understanding these common problems can aid in proactive maintenance and ensure a smoother driving experience.

One prevalent concern involves the transmission system. Many drivers report symptoms such as slipping gears or delayed engagement, which can indicate the need for adjustments or fluid changes.

Another frequent issue relates to the electrical system. Components such as the starter and alternator can fail, leading to difficulties in starting the vehicle or maintaining battery charge. Regular inspections can help mitigate these risks.

Additionally, the suspension may show signs of wear over time. Owners often notice excessive bouncing or noise when driving over bumps, signaling that shocks or struts may require replacement.

Finally, braking problems are also reported. Symptoms like squeaking or grinding sounds may indicate that brake pads are worn and should be checked to maintain optimal safety on the road.

Essential Tools for Repairs

Having the right equipment at hand is crucial for maintaining and fixing vehicles effectively. A well-equipped workspace not only streamlines the process but also enhances safety and efficiency. From basic hand tools to specialized instruments, understanding what is necessary can make any task more manageable.

Basic Hand Tools

Every enthusiast should start with a fundamental set of hand tools. Wrenches, screwdrivers, pliers, and sockets are essential for tackling a variety of tasks. Investing in a durable toolbox can help keep these tools organized and easily accessible, ensuring that you’re always prepared for any challenge that arises.

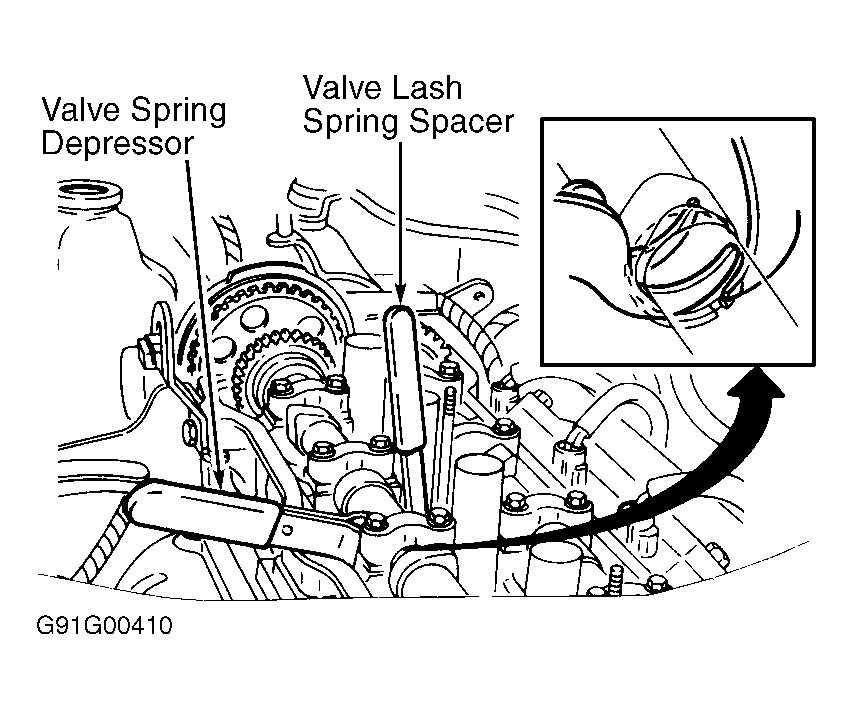

Specialized Equipment

In addition to basic tools, certain specialized equipment may be required for more intricate tasks. Items such as torque wrenches, diagnostic scanners, and jacks can greatly assist in performing specific functions accurately and safely. Familiarity with these tools enhances your ability to address a wider range of issues, making you a more proficient mechanic.

Step-by-Step Maintenance Guide

This section offers a comprehensive approach to vehicle upkeep, ensuring reliability and longevity. Regular attention to essential components can prevent costly issues and enhance performance. Following a systematic routine allows owners to tackle necessary tasks with confidence and clarity.

Start with regular oil changes, typically every 3,000 to 5,000 miles, to keep the engine running smoothly. Check the owner’s guide for the specific type of lubricant required. Additionally, inspect and replace the oil filter during each change to ensure contaminants do not circulate within the engine.

Next, examine the air filter. A clean air filter improves fuel efficiency and engine performance. Replace it every 15,000 to 30,000 miles, or more frequently if driving in dusty conditions. This simple task can significantly impact the vehicle’s overall efficiency.

Tire maintenance is equally crucial. Regularly check tire pressure and tread depth. Rotate tires every 5,000 to 7,500 miles to promote even wear. Additionally, ensure proper alignment to avoid uneven tire wear and enhance handling.

Brake system inspection is vital for safety. Regularly check brake fluid levels and inspect pads for wear. Replace pads as needed and have the entire system checked periodically to maintain optimal braking performance.

Lastly, pay attention to the battery. Inspect terminals for corrosion and ensure a secure connection. Replace the battery every 3 to 5 years, depending on usage, to prevent unexpected failures.

By adhering to these maintenance steps, vehicle owners can ensure their machines remain in top condition, ready to face any journey with reliability and efficiency.

Understanding the Engine Specifications

This section delves into the crucial aspects of engine characteristics that define performance, efficiency, and reliability. Familiarizing oneself with these specifications is essential for anyone looking to maintain or enhance the functionality of their vehicle.

Key Engine Components

Various components contribute to the overall performance of the power unit. Understanding these parts and their specifications allows for better decision-making regarding upgrades and maintenance.

| Component | Description |

|---|---|

| Cylinders | Indicate the number of combustion chambers, affecting power output and efficiency. |

| Displacement | Refers to the total volume of all cylinders, influencing torque and horsepower. |

| Compression Ratio | Determines the efficiency of fuel combustion, impacting performance and economy. |

| Fuel System | Describes the mechanism of fuel delivery, affecting both performance and emissions. |

Performance Metrics

Several performance metrics are vital for evaluating the engine’s capabilities. Understanding these figures can help in diagnosing issues and planning enhancements.

| Metric | Importance |

|---|---|

| Horsepower | Indicates the engine’s power output, crucial for acceleration and towing capacity. |

| Torque | Reflects the engine’s pulling power, important for heavy loads and off-road performance. |

| Miles Per Gallon (MPG) | Measures fuel efficiency, directly impacting running costs. |

| Emissions Rating | Assesses environmental impact, relevant for regulatory compliance. |

Electrical System Troubleshooting Tips

Tackling issues within an automobile’s electrical system can be challenging yet rewarding. Understanding common symptoms and employing systematic approaches can help diagnose and resolve problems effectively. Below are some useful strategies to aid in identifying electrical faults.

Check Battery Condition: A healthy battery is crucial for the overall functionality of the electrical network. Start by inspecting the battery terminals for corrosion and ensuring a secure connection. Use a multimeter to measure voltage; a reading below 12.4 volts indicates that the battery may require charging or replacement.

Inspect Fuses: Fuses protect the electrical components from overloads. If certain features are not functioning, check the fuse box for any blown fuses. Replace any faulty fuses with the appropriate amperage to restore power to affected circuits.

Examine Wiring and Connectors: Damaged or frayed wires can lead to intermittent issues. Look for signs of wear, such as cracks or exposed copper. Ensure all connectors are clean and securely attached, as loose connections can disrupt the flow of electricity.

Test Components: If specific electrical devices, like lights or sensors, are malfunctioning, individual testing can pinpoint the issue. Utilize a multimeter to check for continuity and proper voltage at various points in the circuit.

Ground Connections: Poor grounding can result in erratic behavior of electrical components. Inspect grounding points to ensure they are free from rust and securely fastened to the chassis.

By methodically addressing each aspect of the electrical system, issues can often be identified and resolved, ensuring reliable performance of the vehicle’s features.

How to Change Oil and Filters

Performing regular maintenance on your vehicle, particularly changing the oil and filters, is essential for ensuring optimal performance and longevity. This process helps to keep the engine clean and running smoothly, preventing potential issues down the line.

Tools and Materials Needed

- Oil filter wrench

- Socket set

- Drain pan

- New oil filter

- Engine oil (check specifications for type and quantity)

- Funnel

- Rags or paper towels

- Gloves

Step-by-Step Procedure

- Prepare the vehicle: Park on a level surface and turn off the engine. Allow it to cool if it has been running.

- Locate the oil drain plug: Refer to the owner’s guide for its location, typically found at the bottom of the oil pan.

- Place the drain pan: Position it under the drain plug to catch the old oil.

- Remove the drain plug: Use the socket wrench to unscrew the plug carefully, allowing the oil to drain completely.

- Replace the oil filter: Use the oil filter wrench to remove the old filter. Apply a small amount of new oil to the gasket of the new filter before installation.

- Install the new filter: Screw it in by hand until snug, then give it a slight turn with the wrench.

- Reinstall the drain plug: Once all oil has drained, replace and tighten the drain plug securely.

- Add new oil: Using a funnel, pour the new engine oil into the fill cap, checking the level with the dipstick as you go.

- Start the engine: Let it run for a few minutes, then check for leaks around the filter and drain plug.

- Dispose of old oil: Take the used oil and filter to a recycling center.

Following these steps will help maintain your vehicle’s engine health and performance. Regular oil changes can extend the life of your engine and improve efficiency.

Brake System Maintenance Procedures

Regular upkeep of the braking system is essential for ensuring safety and optimal performance of your vehicle. This section outlines the necessary steps to maintain and inspect the braking components effectively, promoting longevity and reliability.

Inspection of Brake Components

Begin by visually examining the brake pads, rotors, and calipers for signs of wear or damage. Look for uneven wear on the pads, deep grooves on the rotors, or leaks in the calipers. Regular checks help identify issues early, preventing costly repairs later.

Brake Pad Replacement

When the brake pads show significant wear, they should be replaced promptly. Ensure that you choose high-quality pads suited for your vehicle’s specifications. Always follow the manufacturer’s guidelines for installation to maintain proper function.

Rotor Maintenance

Rotors should be resurfaced or replaced if they are warped or excessively worn. Proper thickness is crucial for effective braking performance. Regularly check the rotor surface for any cracks or signs of overheating.

Fluid Replacement

The brake fluid should be changed at regular intervals, as it absorbs moisture over time, which can lead to corrosion and reduced braking efficiency. Always use the recommended fluid type and follow proper bleeding procedures to ensure air is removed from the system.

Testing the System

After completing maintenance tasks, conduct a thorough test of the braking system. This includes checking the pedal feel and response time. If any irregularities are detected, further inspection or adjustment may be necessary.

Replacing Worn Out Belts

Over time, the belts within your vehicle can become frayed or damaged, impacting performance and efficiency. Regular inspection and timely replacement of these components are crucial for maintaining optimal function. Neglecting this task may lead to more serious issues and costly repairs down the line.

Identifying Worn Belts is the first step in this process. Look for signs such as cracks, fraying, or unusual noises during operation. These indicators often signal that it’s time for a change. It’s advisable to check the belts during routine maintenance to ensure they are in good condition.

Gathering Necessary Tools is essential before beginning the replacement. You will typically need a set of wrenches, a socket set, and possibly a belt tension gauge. Having the right tools on hand will make the process smoother and more efficient.

Removing the Old Belt involves loosening the tensioner and carefully detaching the worn component. Take note of the routing path for the belt, as this will be critical when installing the new one. A diagram may be helpful for reference.

Installing the New Belt requires following the correct path as previously noted. Ensure that the belt is seated properly on all pulleys and that the tensioner is adjusted correctly. This step is vital for preventing slippage and ensuring longevity.

Finally, testing the Installation is crucial. Start the engine and listen for any abnormal sounds. If everything operates smoothly, you’ve successfully replaced the worn-out belt. Regular checks will help prolong the life of the new component and keep your vehicle running efficiently.

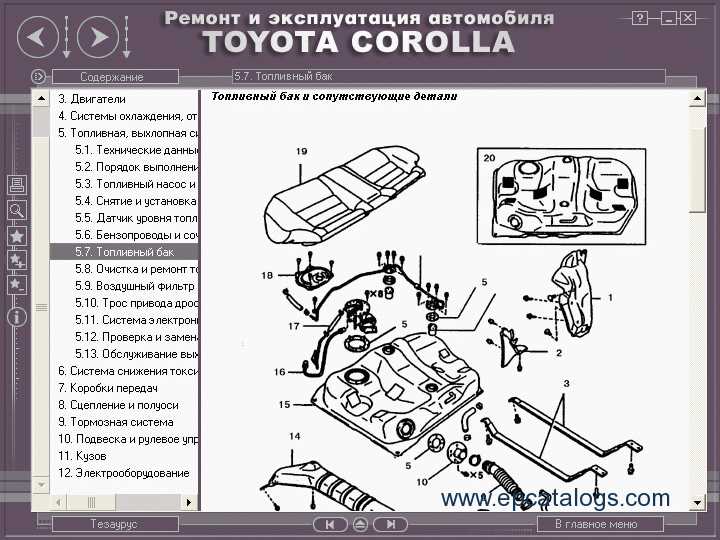

Body and Interior Repair Techniques

The maintenance and restoration of a vehicle’s exterior and interior play a crucial role in its overall longevity and appearance. Mastering various techniques not only enhances aesthetic appeal but also ensures functionality and safety. This section delves into essential methods for addressing common issues, ranging from minor dents to upholstery concerns.

Exterior Damage Solutions

When dealing with surface imperfections, such as scratches or dings, utilizing paintless dent removal is often the best approach. This technique preserves the original finish while effectively restoring the panel’s shape. For deeper scratches, color-matching touch-up paint can provide a seamless repair, maintaining the vehicle’s visual integrity.

Rust Prevention and Treatment

Rust can compromise the structure and aesthetics of a vehicle. To combat this, it is vital to regularly inspect for signs of corrosion. If detected, the area should be thoroughly cleaned, treated with a rust inhibitor, and properly painted to prevent further damage. Employing a protective sealant can also shield against future rust formation.

Interior Upkeep Methods

The interior requires just as much attention as the exterior. For fabric seats, regular vacuuming and spot cleaning can keep surfaces looking fresh. In cases of more significant stains, using a specialized upholstery cleaner can effectively restore the fabric’s appearance. For leather surfaces, conditioning products can prevent cracking and fading over time.

Dashboard and Trim Restoration

Faded or scratched dashboard surfaces can detract from the overall ambiance of the interior. Utilizing a gentle cleaner followed by a vinyl protectant can rejuvenate these areas. For deeper scratches, consider applying a trim restorer to enhance luster and protect against UV damage.

By mastering these techniques, vehicle owners can significantly extend the lifespan and maintain the aesthetic appeal of their cars, ensuring a pleasant driving experience for years to come.

Finding Genuine Parts for Repairs

When it comes to maintaining your vehicle, sourcing authentic components is crucial for ensuring longevity and optimal performance. Using original parts not only enhances reliability but also helps preserve the integrity of the machine, ultimately saving time and money in the long run.

To locate these genuine components, start by visiting authorized dealers or certified distributors. These establishments typically stock a comprehensive range of parts designed specifically for your model, ensuring compatibility and quality. Additionally, online platforms can be valuable resources, offering a wide selection of authentic pieces at competitive prices.

Another effective strategy is to connect with automotive enthusiasts or forums dedicated to your specific make. These communities often share insights on where to find trusted suppliers and may even offer leads on rare or hard-to-find items. It’s essential to do thorough research, as the quality of aftermarket parts can vary significantly.

Always verify the part numbers and cross-reference them with your vehicle’s specifications. This extra step can prevent potential issues down the line and ensure that the components you acquire meet the required standards for durability and safety.

In conclusion, investing time in finding genuine parts is an essential aspect of maintaining your vehicle’s performance and safety. By utilizing authorized dealers, online resources, and community networks, you can ensure that your machine remains in peak condition for years to come.

DIY vs. Professional Service Considerations

When it comes to maintaining and fixing your vehicle, choosing between self-service and hiring a professional can be a challenging decision. Each approach has its advantages and drawbacks, and understanding these can help you make an informed choice that suits your needs, budget, and skill level.

Advantages of DIY Repairs

- Cost Savings: Tackling issues on your own can significantly reduce expenses associated with labor.

- Learning Experience: Engaging in hands-on work enhances your mechanical knowledge and skills.

- Flexibility: You can work on your schedule without waiting for appointment slots.

- Satisfaction: Successfully completing a project can provide a sense of accomplishment.

Advantages of Professional Services

- Expertise: Professionals bring years of experience and specialized knowledge to their work.

- Time Efficiency: Skilled technicians can often complete repairs more quickly than a novice.

- Warranty Protection: Many shops offer warranties on their work, providing peace of mind.

- Advanced Tools: Professionals have access to specialized equipment that may not be affordable for individual use.

Ultimately, the choice between doing it yourself and seeking expert help depends on your comfort level with mechanical tasks, the complexity of the issue, and your available resources. Evaluating these factors will lead you to the best decision for your situation.