Toyota 1KD Engine Repair Guide

When it comes to the longevity and performance of your vehicle, understanding the intricacies of its power source is crucial. This section delves into the essential aspects of maintaining a specific type of internal combustion mechanism, focusing on the necessary steps for proper upkeep and troubleshooting.

Thorough knowledge of components and their functions can significantly enhance your ability to diagnose issues early and implement effective solutions. By following systematic approaches, enthusiasts and professionals alike can ensure optimal functionality and reliability.

From routine checks to more complex adjustments, this guide aims to equip you with the information needed to navigate common challenges. Whether you’re a seasoned mechanic or a dedicated car owner, having access to this information can make all the difference in maintaining peak performance.

This section provides a comprehensive overview of a widely used power unit known for its durability and efficiency. Understanding the fundamentals of this system is crucial for enthusiasts and professionals alike.

The following aspects are essential for grasping the characteristics and functionalities:

- Design and Specifications: This unit is engineered with precision to meet specific performance requirements.

- Common Applications: It is commonly utilized in various vehicles, showcasing its versatility.

- Performance Metrics: Key indicators of efficiency and power output are critical for assessing its capabilities.

Gaining insights into these areas not only enhances understanding but also aids in effective maintenance and troubleshooting. A thorough grasp of this unit’s attributes ensures optimal performance and longevity.

Common Issues and Symptoms

Identifying frequent problems and their manifestations is crucial for maintaining optimal performance of your vehicle’s power unit. Understanding these issues can help in early detection and prevent more significant complications in the future.

Overheating Concerns

One prevalent issue is overheating, which may arise from various factors such as coolant leaks or thermostat malfunctions. If the temperature gauge indicates unusually high readings, it is vital to investigate the cooling system.

Unusual Noises and Vibrations

Another common symptom involves unexpected sounds or vibrations during operation. These could signal internal wear or misalignment, potentially leading to severe damage if not addressed promptly. Regular monitoring of performance can aid in early identification.

Essential Tools for Repair

Having the right instruments is crucial for any maintenance task. This section will outline the key items that facilitate effective servicing and troubleshooting, ensuring a smooth workflow and optimal outcomes.

First and foremost, a comprehensive set of hand tools is indispensable. Wrenches, sockets, and screwdrivers in various sizes allow for efficient loosening and tightening of components. Investing in quality tools enhances durability and performance during challenging tasks.

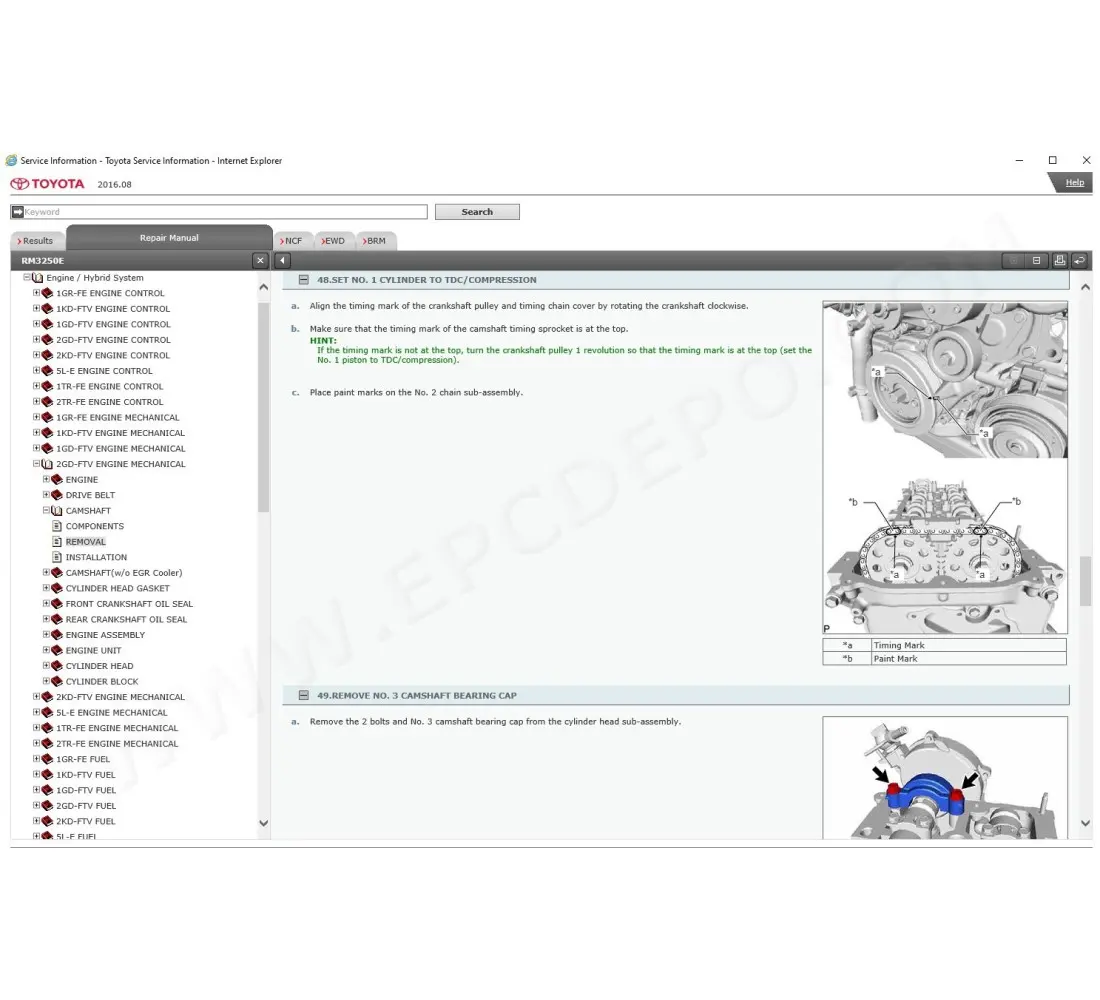

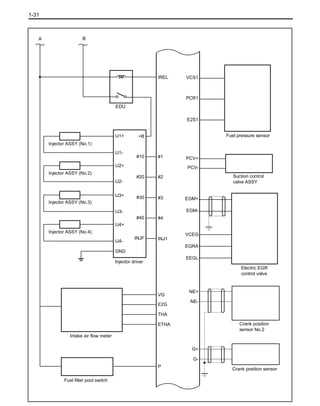

In addition to hand tools, specialized equipment such as diagnostic scanners plays a vital role in modern upkeep. These devices provide insights into system performance, helping to identify issues that may not be immediately visible. Their use streamlines the troubleshooting process, saving time and effort.

Finally, personal protective gear should not be overlooked. Items like gloves, safety glasses, and masks ensure a secure working environment, minimizing risks while handling potentially hazardous materials. Prioritizing safety contributes to a more effective and worry-free working experience.

Step-by-Step Disassembly Guide

This section outlines a systematic approach to disassembling a specific automotive power unit. Following these steps will ensure that each component is removed safely and efficiently, minimizing the risk of damage and facilitating a smooth reassembly process.

Begin by gathering the necessary tools, including wrenches, sockets, and pliers. Ensure that the workspace is clean and well-lit. Start with the removal of the outer casing, taking care to document the position of screws and clips for easy reinstallation.

Next, detach the intake and exhaust components, ensuring that any connections are properly labeled. Carefully remove any electrical connectors, being cautious not to damage wiring harnesses. As each part is taken off, inspect for wear and tear, noting any components that may need replacement.

Proceed to extract the main assembly, carefully loosening bolts in a crisscross pattern to avoid warping. Support the unit as it is lifted from its mountings. Once free, place it on a secure surface, ready for further inspection and maintenance.

Throughout the process, maintain an organized workspace to keep track of all removed parts. Following this detailed approach will aid in a successful disassembly, preparing the components for servicing or replacement.

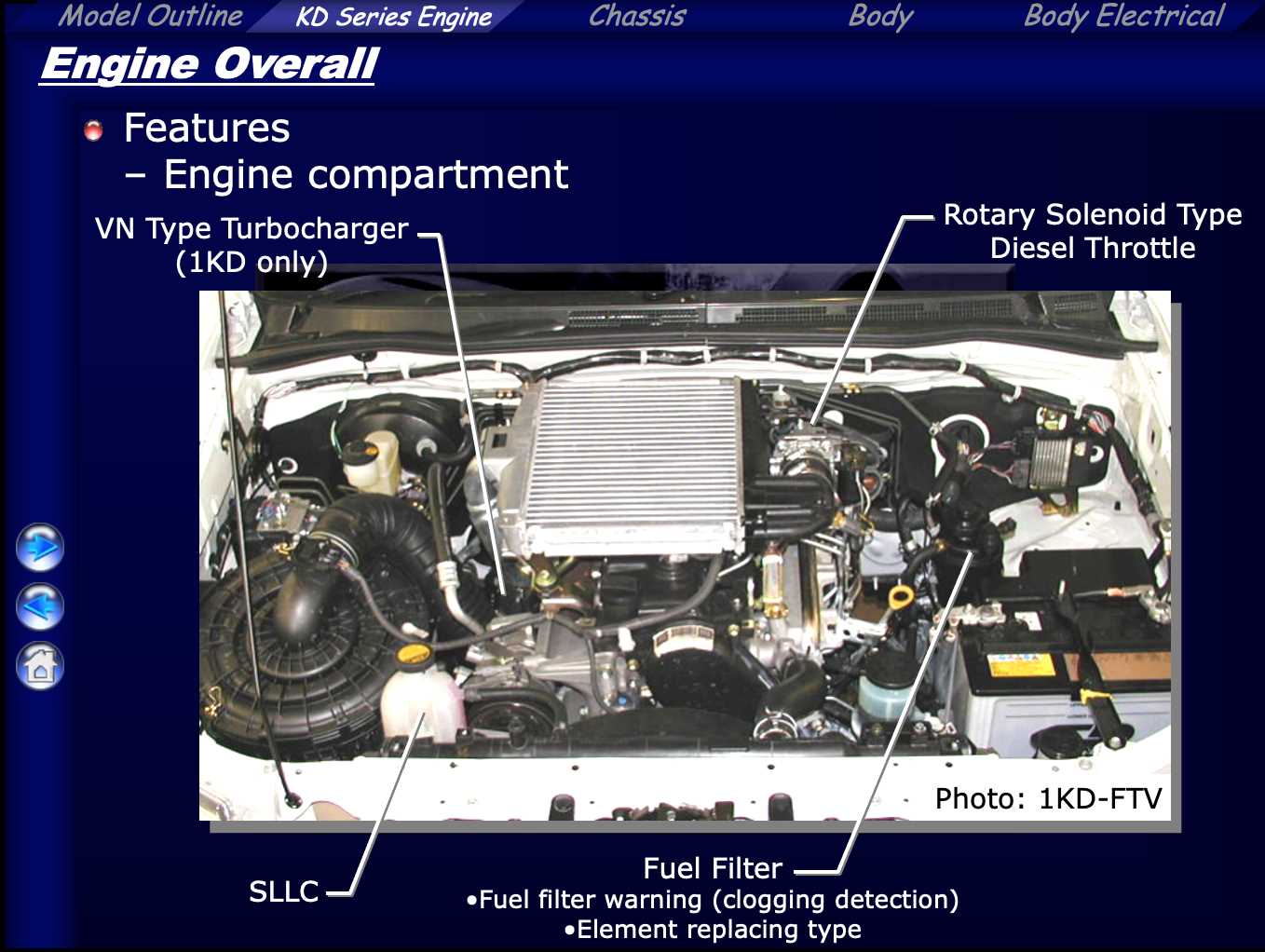

Components and Their Functions

This section delves into the various parts of the mechanical assembly and their respective roles in ensuring optimal performance. Understanding how each component interacts is crucial for effective maintenance and troubleshooting.

Core Elements

The core elements serve as the heart of the assembly, facilitating essential operations. These components are designed to work harmoniously, providing the necessary power and efficiency. Proper functioning of these parts is vital for the overall effectiveness of the system.

Auxiliary Systems

Auxiliary systems enhance the functionality of the main assembly, contributing to improved performance and reliability. These additional components often support critical processes such as cooling and lubrication, ensuring that the main elements operate smoothly under various conditions.

Reassembly Techniques for Efficiency

Ensuring a smooth reassembly process is crucial for optimal performance and longevity of mechanical systems. Implementing effective techniques can significantly enhance efficiency and reduce the likelihood of errors.

Consider the following strategies to streamline your reassembly efforts:

- Organize Components: Sort all parts by type and size, creating a clear workspace to minimize confusion.

- Use Reference Materials: Keep diagrams or documentation handy to guide you through the process.

- Label Parts: Clearly label components and fasteners to ensure proper placement during reassembly.

Utilizing tools designed for precision can further enhance your approach:

- Torque Wrenches: Ensure that all fasteners are tightened to the manufacturer’s specifications.

- Magnetic Trays: Use trays to keep small parts secure and easily accessible.

- Assembly Jigs: Consider using jigs to hold components in place during reassembly for added stability.

By adopting these techniques, you can improve your reassembly efficiency, leading to better overall functionality and reliability.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the long-lasting performance of your vehicle’s power unit. By adhering to a few simple guidelines, you can significantly enhance the durability and efficiency of the system, ultimately leading to a smoother driving experience.

Routine Inspections

Conducting frequent examinations of critical components is vital. Check fluid levels, belts, and hoses to identify any signs of wear or leaks. Addressing minor issues promptly can prevent more serious problems down the road.

Quality Fluids and Filters

Utilizing high-quality lubricants and filters is crucial for maintaining optimal functionality. Regularly replacing oil and air filters will not only improve performance but also contribute to the overall health of the unit. Always refer to specifications for the appropriate types and intervals for replacement.

Diagnosing Performance Problems

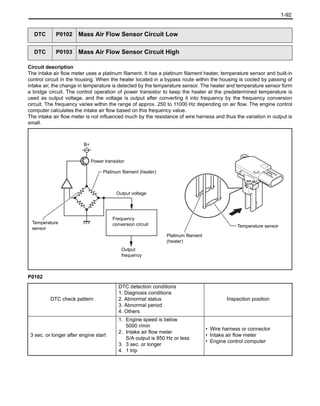

Identifying issues that affect the efficiency and functionality of a vehicle can be challenging. A systematic approach to troubleshooting can help pinpoint the root causes of various performance-related symptoms.

Common Symptoms to Observe

- Unusual noises during operation

- Decreased power output

- Poor fuel economy

- Excessive exhaust emissions

- Inconsistent acceleration

Steps for Troubleshooting

- Visual Inspection: Check for any obvious signs of wear or damage, including leaks, frayed belts, and loose connections.

- Diagnostic Tools: Utilize onboard diagnostic systems to retrieve error codes that may indicate specific faults.

- Fluid Levels: Ensure that all essential fluids, such as oil and coolant, are at appropriate levels.

- Performance Testing: Conduct tests under various conditions to observe changes in behavior and performance.

- Consultation: If issues persist, consider seeking expert advice for more in-depth analysis.

Resources for Further Learning

Enhancing your knowledge about vehicle maintenance and optimization can significantly improve your skills. This section provides a variety of materials that can help you deepen your understanding and expertise in this field.

- Online Forums: Participate in communities where enthusiasts and professionals share their experiences and insights.

- Technical Websites: Explore dedicated platforms that offer detailed guides, specifications, and troubleshooting tips.

- Books and Manuals: Consider purchasing comprehensive literature that covers a wide range of topics related to automotive systems.

- Video Tutorials: Utilize platforms like YouTube for visual learning, where step-by-step demonstrations are provided by experts.

- Workshops and Seminars: Attend local or online events to engage with instructors and gain hands-on experience.

Utilizing these resources can facilitate continuous learning and keep you updated with the latest advancements in automotive technology.