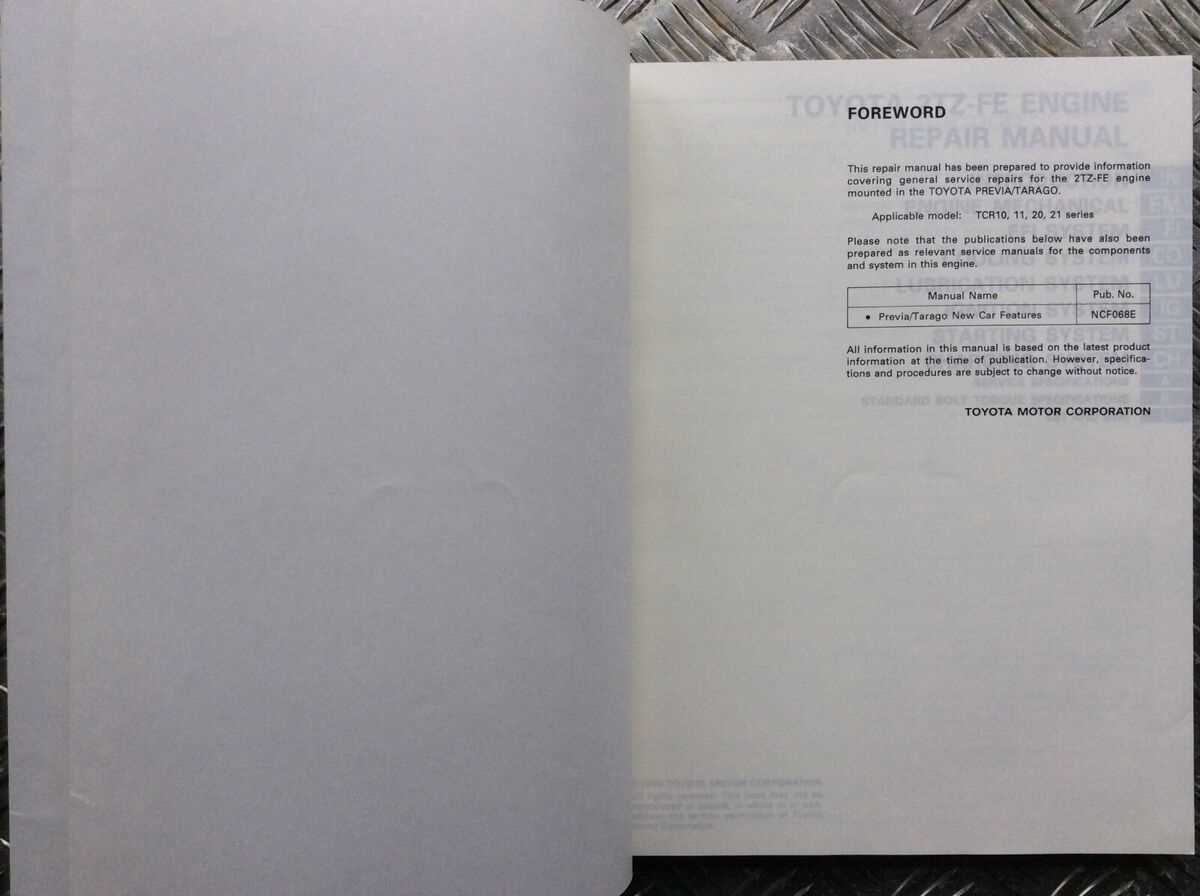

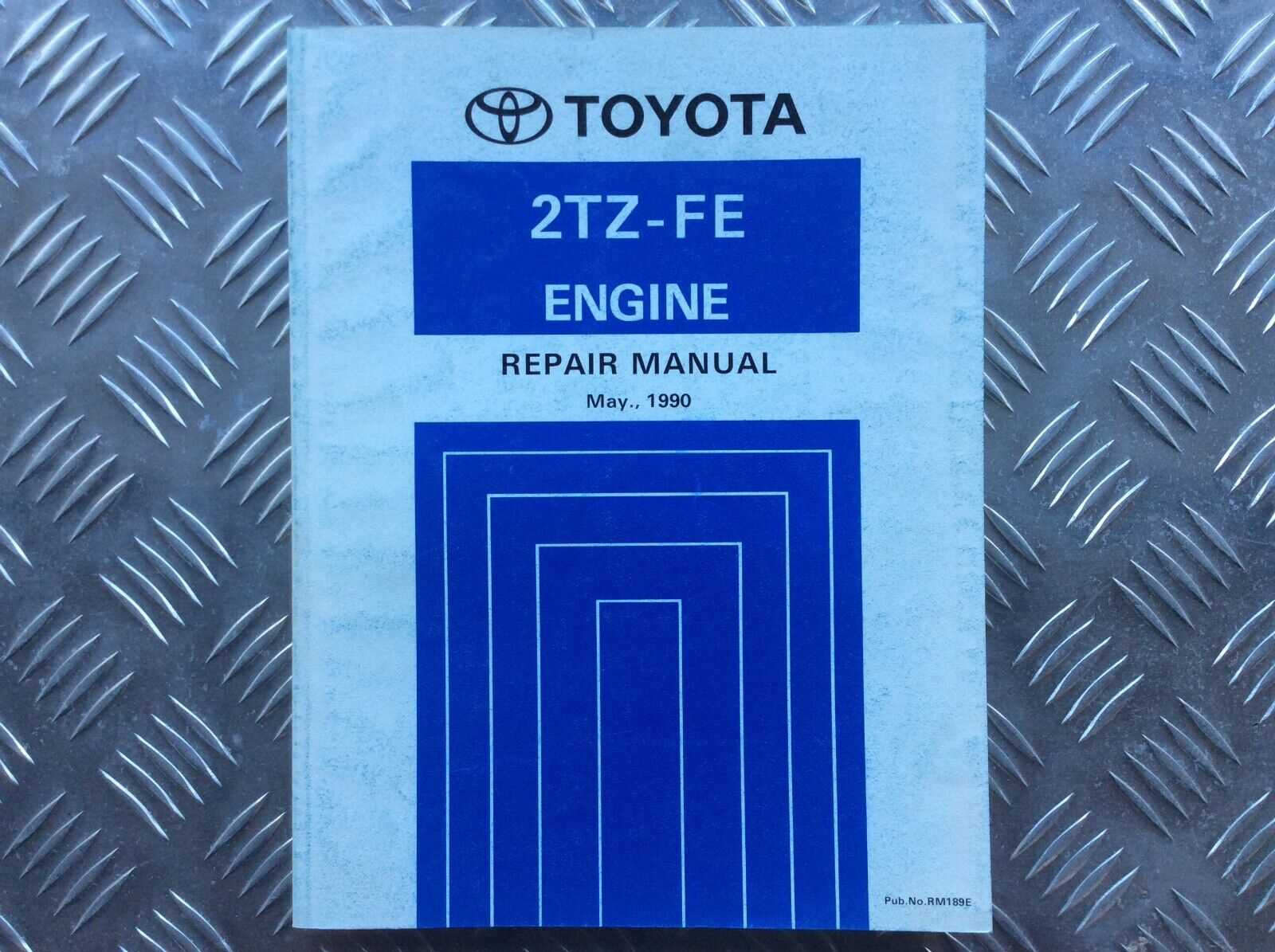

Comprehensive Guide to Repairing the Toyota 2TZ-FE Engine

The intricate world of automotive mechanics often presents enthusiasts and professionals alike with the challenge of understanding complex powertrains. This segment aims to demystify the essentials of maintaining and overhauling a specific type of propulsion unit, ensuring optimal performance and longevity. The following information serves as a valuable resource for those looking to deepen their knowledge and skills in this area.

Whether you’re facing issues with performance or simply conducting routine checks, familiarity with the key components and procedures is crucial. This guide will walk you through various aspects, from troubleshooting common problems to executing detailed servicing techniques. Each section is designed to equip you with the necessary tools and insights to tackle any task effectively.

By engaging with this resource, you will not only enhance your technical prowess but also gain a greater appreciation for the engineering behind these sophisticated machines. With diligence and the right approach, you can ensure that your vehicle remains reliable and efficient for years to come.

Toyota 2TZ-FE Engine Overview

This section provides a comprehensive insight into a specific power unit known for its reliability and performance. With a robust design and efficient functionality, this unit has become a preferred choice in various applications. Understanding its key features and specifications is essential for anyone looking to delve into maintenance or optimization.

Key Specifications

| Attribute | Details |

|---|---|

| Cylinder Configuration | Inline 4-cylinder |

| Displacement | 2.0 liters |

| Fuel System | Multi-Point Fuel Injection |

| Power Output | Approximately 130 hp |

| Torque | Approximately 180 Nm |

Notable Features

This power unit is characterized by its innovative design that maximizes efficiency while minimizing emissions. Its construction includes advanced materials that enhance durability and performance under various conditions. Regular maintenance ensures longevity, making it a dependable choice for both casual drivers and automotive enthusiasts.

Common Issues with 2TZ-FE Engines

When dealing with this specific power unit, various complications may arise, impacting performance and reliability. Understanding these frequent problems can aid in timely intervention and maintenance, ensuring longevity and efficiency.

Typical Problems

Many users encounter a range of issues that can hinder the optimal functioning of their machinery. The following table outlines some of the most commonly reported complications, their symptoms, and potential solutions.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Overheating | Temperature gauge rising, coolant leaks | Check coolant levels, inspect radiator, replace thermostat |

| Oil leaks | Oil spots under the vehicle, low oil levels | Inspect gaskets and seals, replace as necessary |

| Rough idle | Vibrations, inconsistent RPMs | Check spark plugs, clean or replace air filter |

| Loss of power | Difficulty accelerating, poor fuel efficiency | Inspect fuel system, check for clogged injectors |

Preventive Measures

Regular maintenance plays a crucial role in minimizing these issues. Routine checks and timely servicing can significantly reduce the likelihood of complications, ensuring smooth operation and enhancing overall performance.

Essential Tools for Engine Repair

When it comes to overhauling automotive machinery, having the right instruments is crucial for a successful outcome. A well-equipped workspace not only enhances efficiency but also ensures precision in every task. Below, we explore the fundamental devices required for tackling such intricate jobs.

Basic Hand Tools

- Wrenches: Various sizes and types (open-end, box-end, adjustable) are essential for loosening and tightening bolts.

- Screwdrivers: Flathead and Phillips varieties are necessary for securing or removing screws in different components.

- Pliers: Needle-nose and slip-joint pliers provide grip and leverage for various tasks.

- Torque Wrench: This tool is vital for applying the correct amount of torque to fasteners.

Specialized Equipment

- Compression Tester: Useful for checking the health of cylinders and ensuring optimal performance.

- Oil Filter Wrench: Designed specifically for removing oil filters with ease.

- Timing Light: Helps in adjusting ignition timing for improved efficiency.

- Diagnostic Scanner: Essential for identifying issues and reading error codes from the vehicle’s computer system.

Equipping yourself with these tools lays a solid foundation for any mechanical undertaking, facilitating both routine maintenance and more extensive interventions.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues related to your power unit. By following a structured methodology, you can systematically diagnose and resolve complications, ensuring optimal performance and longevity.

1. Preparation: Begin by gathering all necessary tools and materials. A clean workspace is essential for efficiency. Familiarize yourself with the layout and components involved, which will facilitate a smoother workflow.

2. Diagnosis: Identify the symptoms of the problem. Conduct visual inspections and utilize diagnostic tools to pinpoint the root cause. This step is crucial for determining the appropriate course of action.

3. Disassembly: Carefully dismantle the relevant components. Take notes and photographs to keep track of the order and orientation of parts, making reassembly easier.

4. Inspection: Examine each component for wear and damage. Look for signs of corrosion, cracks, or any irregularities. This will help you decide what needs replacement or refurbishment.

5. Replacement: Replace any defective parts with quality alternatives. Ensure that all components meet specified standards to maintain reliability and performance.

6. Reassembly: Following your documentation, reassemble the components with precision. Double-check the alignment and fit of each part to avoid issues later.

7. Testing: After reassembly, conduct thorough tests to verify functionality. Monitor for any unusual sounds or behaviors, addressing any concerns immediately.

8. Final Inspection: Once testing is complete, perform a final check to ensure everything is secure and properly installed. Clean up your workspace, ensuring that all tools and materials are accounted for.

By adhering to this structured process, you can effectively troubleshoot and restore your unit, enhancing its reliability and efficiency.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your vehicle requires consistent attention and care. Adopting best practices for upkeep not only enhances performance but also extends the lifespan of critical components. Here are some essential strategies to consider.

Regular Inspections

- Check fluid levels frequently, including oil, coolant, and transmission fluid.

- Inspect belts and hoses for wear and replace them as needed.

- Monitor tire pressure and tread depth to ensure optimal handling and safety.

Routine Servicing

- Change oil and filters at recommended intervals to keep the system clean.

- Replace air filters to maintain airflow and engine efficiency.

- Schedule periodic checks for the ignition system and replace spark plugs as necessary.

Implementing these maintenance tips can significantly contribute to the reliability and efficiency of your vehicle, ensuring that it remains in top condition for years to come.

Diagnosing Engine Performance Problems

Identifying issues related to vehicle performance requires a systematic approach. Various symptoms can indicate underlying problems, affecting efficiency and drivability. Understanding these signs and employing appropriate diagnostic techniques is essential for effective resolution.

Common Symptoms to Observe

Several indicators may suggest that the powertrain is not functioning optimally. These can include unusual noises, decreased acceleration, or irregular idling. Additionally, warning lights on the dashboard often signal that attention is needed. Observing these symptoms closely can provide valuable insights into potential malfunctions.

Diagnostic Techniques

Utilizing both visual inspections and electronic diagnostic tools can greatly enhance the troubleshooting process. Start by checking for visible leaks, wear, or loose connections. Following this, employing specialized equipment can help retrieve error codes, pinpointing specific areas requiring attention. A thorough examination of fuel delivery, air intake, and ignition systems is also crucial for a comprehensive assessment.

In conclusion, a methodical approach to diagnosing performance issues not only saves time but also ensures that problems are addressed efficiently and effectively.

Parts Replacement Guidelines

When maintaining a mechanical unit, knowing when and how to replace components is crucial for optimal performance and longevity. This section outlines essential practices for ensuring that parts are replaced effectively, minimizing the risk of malfunction and enhancing the overall functionality of the system.

Assessment of Component Condition

Before proceeding with any substitutions, it is vital to thoroughly assess the condition of each part. Look for signs of wear, such as cracks, discoloration, or excessive play. Regular inspections can help identify components that are nearing the end of their lifespan, allowing for timely replacements that prevent further damage to the assembly.

Selection of Replacement Parts

Choosing the right replacement components is essential for maintaining compatibility and efficiency. Always opt for high-quality, reliable parts that meet or exceed manufacturer specifications. Utilizing OEM (Original Equipment Manufacturer) components is often recommended to ensure a proper fit and function, although reputable aftermarket options can also be viable alternatives if they adhere to industry standards.

Understanding Engine Specifications

When delving into the intricacies of a vehicle’s power unit, it is essential to grasp the various parameters that define its performance and efficiency. These specifications encompass a wide array of details, ranging from dimensions and weight to fuel types and operational capabilities. By understanding these metrics, enthusiasts and professionals alike can make informed decisions regarding maintenance and upgrades.

Key Parameters to Consider

Several crucial aspects come into play when evaluating the characteristics of a power unit. Among these, displacement plays a vital role, indicating the total volume of the cylinders and influencing the output of power. Additionally, compression ratio affects both performance and fuel efficiency, determining how effectively the air-fuel mixture is utilized during combustion. Other factors, such as torque and horsepower, also provide insight into the overall capability and responsiveness of the machinery.

The Importance of Specifications

Understanding these specifications not only aids in troubleshooting and repairs but also enhances the overall driving experience. Knowledge of a power unit’s capabilities allows for better tuning and modifications, ensuring optimal performance. Furthermore, being aware of compatibility with various components can significantly impact the longevity and reliability of the entire system.

Upgrading Components for Better Performance

Enhancing various elements of a vehicle can lead to significant improvements in its overall functionality and responsiveness. By focusing on specific parts and making strategic modifications, enthusiasts can unlock the full potential of their machines, resulting in a more exhilarating driving experience.

Key Areas for Enhancement

- Intake System: Upgrading the intake can increase airflow, leading to improved combustion efficiency.

- Exhaust System: A high-performance exhaust can reduce back pressure and enhance power output.

- Fuel Delivery: Optimizing fuel injectors can ensure a more precise fuel-air mix, boosting performance.

- Ignition System: Advanced ignition components can provide a stronger spark, improving combustion timing and power.

Considerations Before Upgrading

- Compatibility: Ensure new parts are compatible with existing systems to avoid issues.

- Budget: Plan a budget that includes both parts and potential labor costs.

- Expert Guidance: Consult with professionals or experienced enthusiasts for recommendations.

- Regulations: Check local regulations regarding modifications to ensure compliance.

By carefully selecting and upgrading these components, owners can achieve noticeable gains in performance and driving enjoyment, creating a more dynamic and thrilling vehicle experience.

Resources for Further Learning

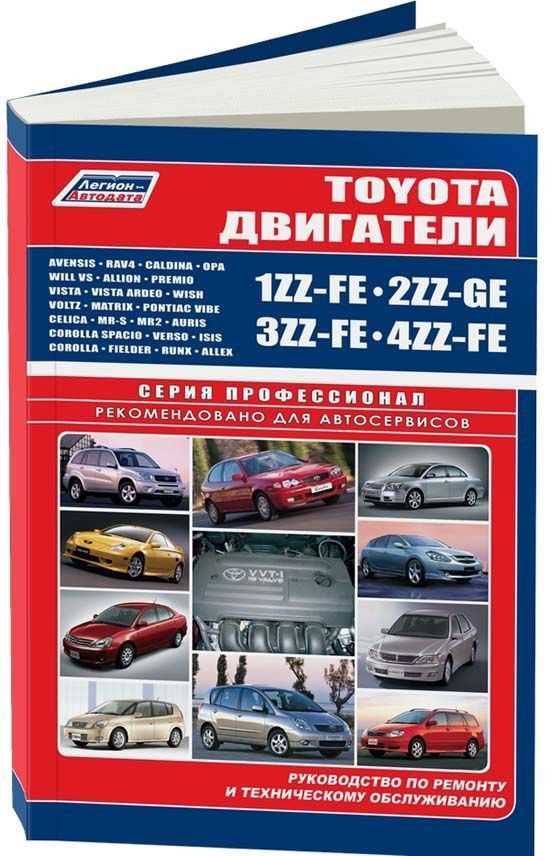

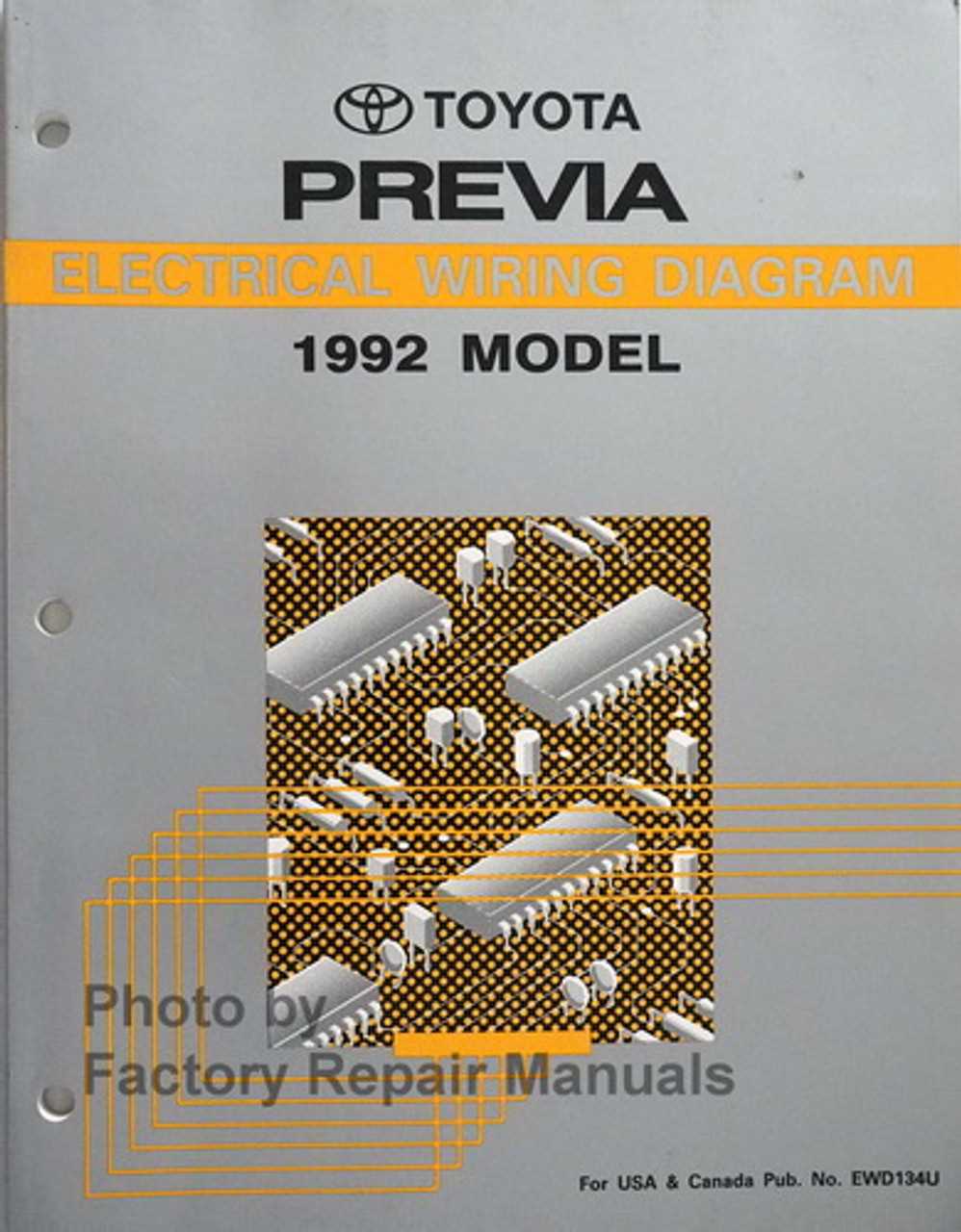

Expanding your knowledge in automotive maintenance and troubleshooting can significantly enhance your skills. There are various platforms and materials available that provide valuable insights into technical concepts and practical techniques.

Online Courses: Numerous websites offer specialized courses that cover a wide range of topics related to vehicle systems. These interactive sessions can provide you with both theoretical understanding and hands-on practice.

Books and eBooks: A wealth of literature exists, ranging from comprehensive guides to focused manuals. These resources often include illustrations, diagrams, and step-by-step instructions that make complex information more accessible.

Forums and Community Groups: Engaging with online communities allows you to share experiences and seek advice from fellow enthusiasts. These platforms often host discussions on troubleshooting, upgrades, and best practices.

Video Tutorials: Visual learners can benefit from a multitude of video resources available on platforms like YouTube. These tutorials often demonstrate procedures in real-time, making it easier to grasp intricate processes.

Workshops and Seminars: Attending local workshops or seminars can provide direct interaction with experts in the field. These events are great opportunities to learn new techniques and network with others who share your interests.

Utilizing these resources can greatly enhance your understanding and capability in the field, ensuring you stay informed about the latest advancements and practices.

Frequently Asked Questions

This section aims to address common inquiries regarding the maintenance and troubleshooting of a specific automotive power unit. Below, you will find a compilation of frequently asked questions, designed to provide clarity and assistance for enthusiasts and professionals alike.

| Question | Answer |

|---|---|

| What are the common symptoms of issues in this power unit? | Common symptoms include unusual noises, decreased performance, and unexpected leaks. Regular checks can help identify these issues early. |

| How often should routine maintenance be performed? | It is generally recommended to perform maintenance every 5,000 to 7,500 miles, depending on usage and manufacturer guidelines. |

| What tools are essential for basic upkeep? | Essential tools include wrenches, screwdrivers, oil filters, and a diagnostic scanner for electronic issues. |

| Can I perform repairs myself? | Yes, many individuals choose to conduct their own repairs. However, understanding the complexity of the task is crucial, and professional help may be advisable for significant repairs. |

| What should I do if I encounter a warning light? | If a warning light appears, it’s important to consult the manual for guidance. Many lights indicate specific issues that require prompt attention. |