Toyota 3Y Engine Repair Guide for DIY Enthusiasts

For enthusiasts and professionals alike, understanding the intricacies of a specific power unit can enhance performance and longevity. This section delves into the essential components and techniques needed to maintain and restore optimal functionality in a well-regarded mechanical system.

The process of rejuvenating such a unit involves a systematic approach, emphasizing both preventative measures and corrective actions. Detailed instructions and insights are crucial for ensuring that every aspect, from minor adjustments to major overhauls, is executed with precision.

Whether you’re tackling a simple tune-up or a complete disassembly, familiarity with the parts and procedures will empower you to achieve your desired outcomes. This guide aims to provide valuable knowledge, helping you navigate the complexities and nuances of maintaining this remarkable power source.

Toyota 3Y Engine Overview

This section provides a comprehensive look at a widely utilized power unit known for its reliability and performance in various applications. The design emphasizes durability, efficiency, and ease of maintenance, making it a popular choice among enthusiasts and professionals alike.

The unit features a robust configuration, typically equipped with a carburetor or fuel injection system, allowing for smooth operation across different conditions. Its construction includes a strong block and head, which contribute to the longevity and effectiveness of the overall system.

In terms of specifications, this model generally offers a balance between power output and fuel economy, catering to both commercial and personal use. Its adaptability to various vehicles and machinery highlights its versatility in the automotive landscape.

Understanding the components and functions of this unit is crucial for anyone looking to maximize its potential. A thorough knowledge of its parts and maintenance requirements can lead to enhanced performance and prolonged service life.

Common Issues with the 3Y Engine

In the realm of automotive mechanics, certain power units are known for recurring challenges that can affect performance and reliability. Understanding these prevalent problems is crucial for maintaining optimal functionality and extending lifespan.

One of the frequent concerns involves overheating. This can stem from various factors, including a malfunctioning cooling system or a clogged radiator. Over time, excessive heat can lead to significant damage, impacting overall efficiency.

Another common issue relates to oil leaks. Such leaks can occur due to worn gaskets or seals, resulting in reduced lubrication and potential wear on internal components. Regular inspections can help identify these leaks early, preventing further complications.

Fuel delivery problems are also notable. Clogged filters or failing fuel pumps can lead to inadequate fuel reaching the combustion chamber, causing performance issues such as rough idling or poor acceleration. Addressing these components promptly ensures smooth operation.

Finally, issues with the ignition system, such as faulty spark plugs or coils, can disrupt the firing process. This may manifest as misfires, which not only affect power output but can also lead to increased emissions and reduced fuel efficiency. Routine checks of these components can mitigate such problems.

Essential Tools for Repairing 3Y

When working on a specific mechanical unit, having the right instruments at your disposal is crucial for achieving optimal results. This section outlines the necessary equipment to effectively tackle maintenance and restoration tasks. Each tool plays a vital role in ensuring precision and efficiency throughout the process.

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Torque Wrench | To apply the correct torque to fasteners. |

| Screwdriver Set | For driving various types of screws. |

| Wrenches | For gripping and turning nuts and bolts. |

| Pliers | For holding and manipulating small components. |

| Feeler Gauge | To measure gap widths accurately. |

| Oil Filter Wrench | For easy removal of oil filters. |

| Inspection Mirror | To view hard-to-reach areas. |

Utilizing these tools ensures that every task is approached with the necessary skill and precision, making the overall process smoother and more effective.

Step-by-Step Disassembly Process

This section outlines a systematic approach to dismantling complex machinery components. Each stage is designed to ensure careful removal and organization of parts, facilitating efficient reassembly. Following these steps will help maintain integrity and prevent damage to crucial elements.

1. Preparation: Begin by gathering all necessary tools and equipment. Ensure that your workspace is clean and organized, providing easy access to components as they are removed.

2. Documentation: Take detailed notes and photographs of the assembly prior to disassembly. This documentation will serve as a valuable reference during reassembly.

3. Drain Fluids: Before starting, drain any fluids from the system to avoid spills. Use appropriate containers to collect and dispose of fluids safely.

4. Disconnect Accessories: Remove any attached accessories or components that may hinder access. This may include belts, wires, and other attachments.

5. Remove Fasteners: Systematically remove bolts, screws, and clips securing the parts. Keep these fasteners organized, labeling them if necessary to simplify reinstallation.

6. Separate Components: Gently separate the main components, taking care to avoid unnecessary force that could cause damage. Utilize appropriate tools to assist in the separation process.

7. Inspect Parts: As each component is removed, inspect it for wear or damage. Document any findings that may require attention during reassembly.

8. Clean Components: Once disassembled, clean each part to remove debris or buildup. This will promote better performance when reassembling the unit.

9. Organize Parts: Store all components in a labeled container or tray, ensuring they are protected and easily accessible for future assembly.

10. Review: Before proceeding to the next phase, review all documentation and ensure all parts are accounted for. This step is critical to avoid any missing elements during reassembly.

Inspecting Engine Components Effectively

Thorough examination of mechanical parts is crucial for maintaining optimal performance and longevity. A systematic approach ensures that any potential issues are identified early, reducing the risk of costly failures. By utilizing proper techniques and tools, one can gain valuable insights into the condition of each component, facilitating informed decision-making for maintenance or replacement.

Begin the assessment by visually inspecting each part for signs of wear, corrosion, or damage. Look for unusual stains or residues that may indicate leaks or other problems. Pay close attention to critical areas such as seals and gaskets, as these often reveal early signs of deterioration. Ensure that all connections are secure and free from debris that could impair functionality.

Utilize measuring instruments to check tolerances and alignments. Gauges and calipers can help verify whether components are within specified limits, while alignment tools ensure that moving parts function harmoniously. Regularly monitor performance metrics, as deviations may signal underlying issues that require immediate attention.

Lastly, maintain detailed records of your findings. Documentation provides a valuable reference for future inspections and helps track the health of components over time. By adopting a proactive inspection routine, you can enhance reliability and prevent unexpected breakdowns, ultimately extending the lifespan of your machinery.

Reassembly Techniques for the 3Y

Proper reassembly of the 3Y is crucial for ensuring optimal performance and longevity. This process involves meticulous attention to detail and adherence to specific protocols to guarantee that all components fit together seamlessly. Following the right techniques can prevent future issues and enhance the overall functionality of the unit.

Essential Steps in Reassembly

To ensure a successful reassembly, follow these key steps:

| Step | Description |

|---|---|

| 1 | Thoroughly clean all parts to remove any debris or old lubricants. |

| 2 | Inspect all components for wear and replace if necessary. |

| 3 | Carefully align all parts during assembly to avoid misalignment. |

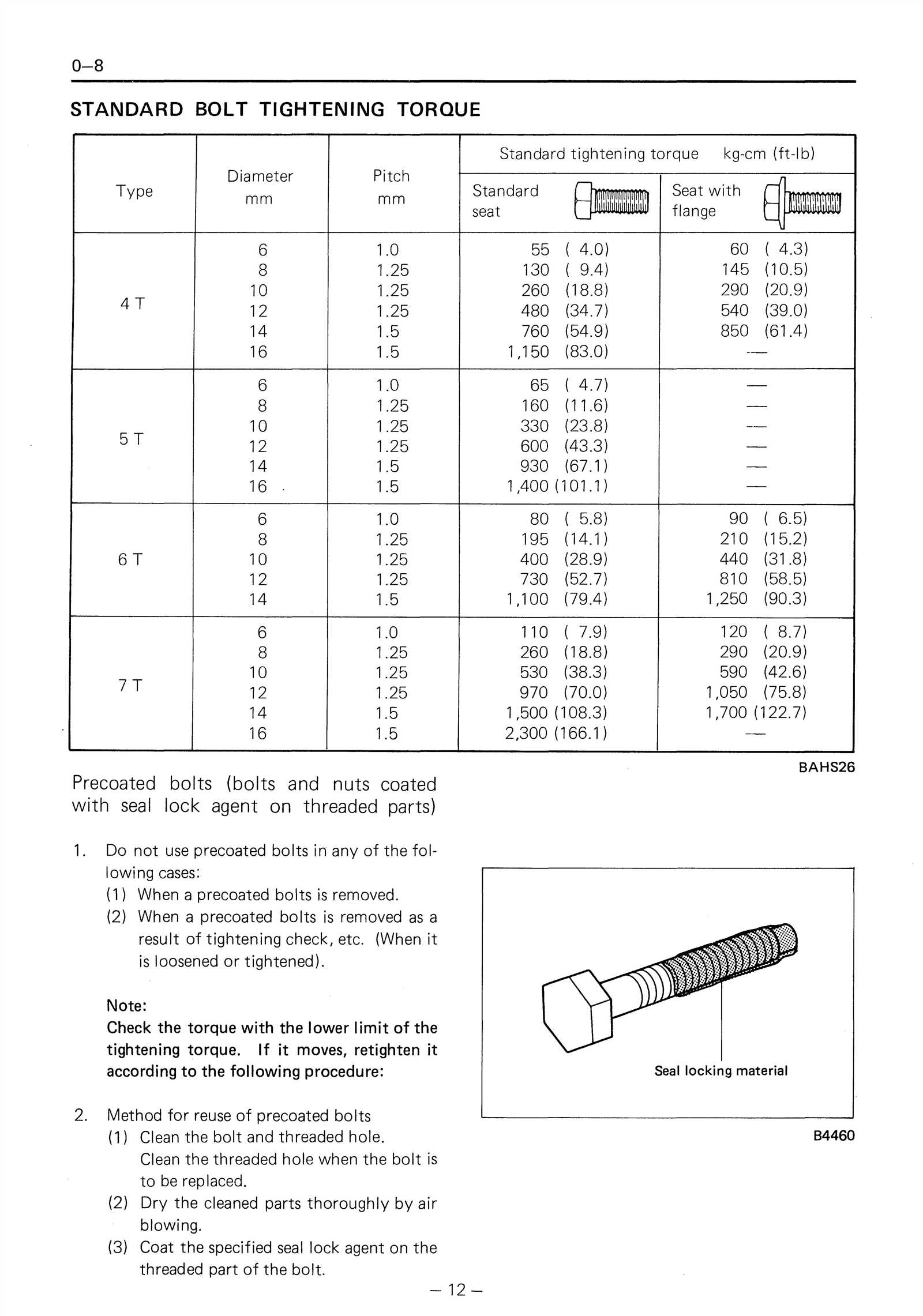

| 4 | Use proper torque specifications to secure fasteners. |

| 5 | Double-check all connections and seals to prevent leaks. |

Tips for Success

In addition to the essential steps, consider the following tips for effective reassembly:

- Utilize a clean workspace to avoid contamination.

- Keep track of all components using a systematic labeling method.

- Consult reliable resources for specifications and torque values.

Recommended Lubricants and Fluids

Ensuring optimal performance and longevity of your mechanical unit requires the use of appropriate lubricants and fluids. The selection of high-quality substances plays a crucial role in maintaining efficiency, minimizing wear, and preventing potential damage. This section provides guidelines on the most suitable options for different components.

Engine Oil

For the best protection and efficiency, select a premium-grade oil that meets the specified viscosity requirements. Synthetic options often provide superior performance under varying temperature conditions, ensuring smooth operation and extended service intervals.

Cooling System Fluid

A reliable coolant is essential for regulating operating temperatures and preventing overheating. Look for a mixture designed to resist corrosion and scale buildup, enhancing the lifespan of the cooling system components. Always adhere to the recommended dilution ratios for optimal results.

Timing Belt Replacement Guidelines

Replacing the timing belt is a crucial maintenance task that ensures optimal performance and longevity of your vehicle’s components. This process involves several steps that must be followed meticulously to avoid potential damage and ensure proper functioning.

Preparation Steps

- Gather necessary tools, including wrenches, sockets, and a timing belt kit.

- Consult the specifications for the correct timing belt and any associated parts.

- Ensure the workspace is clean and well-lit for efficiency and safety.

Replacement Procedure

- Disconnect the battery to prevent any electrical issues.

- Remove components obstructing access to the timing assembly, such as the air intake and covers.

- Align the timing marks on the pulleys to ensure correct positioning.

- Loosen the tensioner and remove the old timing belt carefully.

- Install the new timing belt, ensuring it is properly tensioned according to specifications.

- Reassemble any removed components and reconnect the battery.

- Start the vehicle and check for proper operation, listening for any unusual noises.

Following these guidelines will help maintain the efficiency and reliability of your vehicle’s operation. Always refer to specific documentation for detailed procedures and specifications related to your model.

Diagnosing Electrical Problems

Identifying issues within the electrical system can be a daunting task, yet it is crucial for optimal performance. A systematic approach is necessary to uncover the root causes of malfunctions.

- Start by inspecting visible connections for signs of corrosion or damage.

- Utilize a multimeter to measure voltage, resistance, and continuity.

- Check for blown fuses and replace them as needed.

Following these steps can help isolate problems effectively. If issues persist, consider these advanced techniques:

- Review wiring diagrams to understand circuit pathways.

- Test relays and switches to ensure they function correctly.

- Employ diagnostic tools for comprehensive analysis.

By following this structured approach, you can delve into the complexities of the electrical system and identify the ultimate solutions to restore functionality.

Cooling System Maintenance Tips

Maintaining the cooling mechanism of your vehicle is essential for optimal performance and longevity. A well-functioning cooling system prevents overheating and ensures that all components operate efficiently. Here are some effective practices to keep this system in top condition.

Regular Inspections

Consistent checks can help identify issues before they escalate. Focus on the following areas:

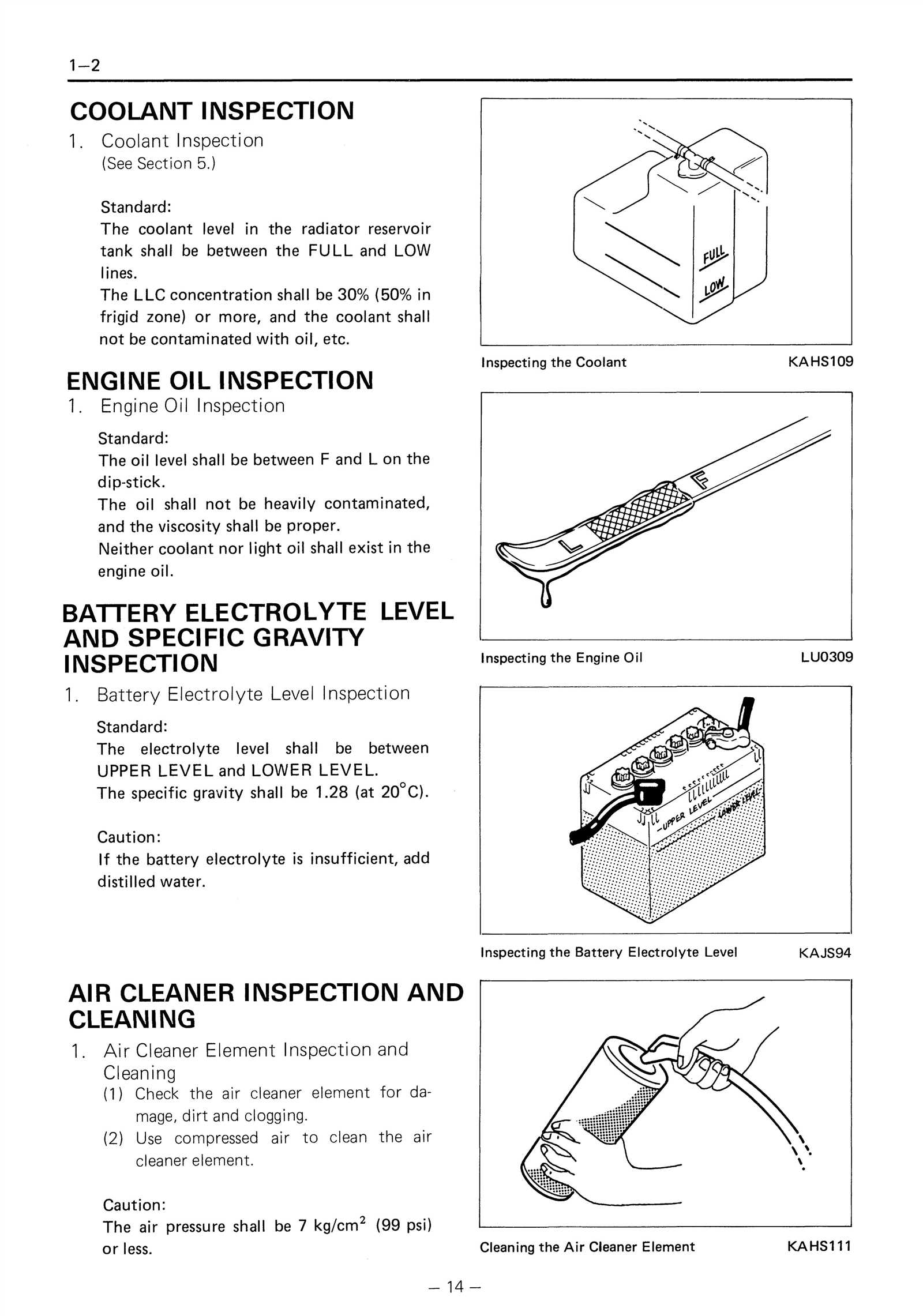

- Coolant Level: Regularly check the coolant level and top it off if necessary.

- Leaks: Look for any signs of leakage around hoses, the radiator, and the water pump.

- Hoses and Clamps: Inspect for wear and ensure all clamps are secure.

Flushing the System

Periodic flushing can remove contaminants and buildup, enhancing system efficiency. Follow these steps:

- Consult your vehicle’s specifications for recommended intervals.

- Drain the existing coolant completely.

- Flush the system with clean water or a specialized flushing solution.

- Refill with fresh coolant according to manufacturer guidelines.

By adhering to these maintenance tips, you can ensure your cooling system remains in excellent condition, contributing to the overall health of your vehicle.

Enhancing Performance of the 3Y

Boosting the capabilities of the 3Y requires a combination of thoughtful modifications and careful maintenance. By implementing certain upgrades and adjustments, enthusiasts can significantly improve responsiveness, efficiency, and overall driving experience.

Here are some effective strategies to enhance performance:

- Upgrade the Intake System:

- Install a high-flow air filter to increase airflow.

- Consider a performance intake manifold for better air distribution.

- Exhaust System Modifications:

- Replace the stock exhaust with a performance system to reduce backpressure.

- Install a larger diameter exhaust pipe for improved exhaust flow.

- Fuel Delivery Improvements:

- Upgrade the fuel pump for increased fuel flow.

- Consider high-performance fuel injectors for better fuel atomization.

- Tuning the Management System:

- Utilize a performance chip to optimize fuel maps and ignition timing.

- Regularly update software for best performance outputs.

- Regular Maintenance:

- Perform routine checks on spark plugs and ignition systems.

- Keep the cooling system well-maintained to prevent overheating.

Implementing these enhancements can lead to a noticeable improvement in power delivery and responsiveness, providing a more enjoyable driving experience. Regular evaluation and maintenance will ensure these modifications continue to perform at their best.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial for both the technician and the vehicle. Adopting safety measures minimizes the risk of accidents and injuries, creating a smoother workflow. Proper preparation and awareness can significantly enhance the overall experience and effectiveness of the job.

Personal Protective Equipment

Utilizing personal protective gear is essential when engaging in maintenance activities. Items such as gloves, safety goggles, and sturdy footwear provide necessary protection against hazardous materials and potential injuries. Ensure that all equipment fits properly and is in good condition to maximize safety.

Work Area Organization

A well-organized workspace can prevent accidents and facilitate efficient work. Keep tools and materials neatly arranged and within reach. Remove any unnecessary clutter that could pose a tripping hazard. Additionally, ensuring adequate lighting and ventilation will further enhance safety during tasks.

FAQs About the 3Y Engine

This section addresses common inquiries related to the 3Y power unit, providing clear and concise answers to enhance understanding and facilitate maintenance. Whether you are a novice or experienced user, these FAQs will assist you in navigating potential challenges and optimizing performance.

General Questions

- What is the typical lifespan of this power unit?

The longevity largely depends on maintenance practices, driving conditions, and usage. With regular care, many units can exceed 200,000 miles.

- What are common symptoms of issues?

Symptoms may include unusual noises, decreased performance, excessive vibrations, or warning lights on the dashboard.

Maintenance Tips

- How often should oil changes be performed?

It is advisable to change the oil every 5,000 to 7,500 miles to ensure optimal performance and longevity.

- What type of coolant is recommended?

A high-quality, ethylene glycol-based coolant is generally recommended to prevent overheating and corrosion.