Comprehensive Guide to Repairing the 5R Engine

This section provides valuable insights into the upkeep and troubleshooting of a specific type of power unit commonly found in various vehicles. A thorough understanding of its components and functionality is essential for ensuring optimal performance and longevity.

In the following paragraphs, we will explore essential techniques and methods to address common challenges. Emphasis will be placed on practical solutions, enhancing efficiency, and maintaining the integrity of the system. Mastering these concepts will empower users to confidently navigate any issues that may arise.

Toyota 5R Engine Repair Guide

This section provides valuable insights into the maintenance and restoration of a specific power unit commonly found in various vehicles. Understanding the essential components and procedures can greatly enhance the longevity and performance of this unit, ensuring optimal functionality and reliability.

Key aspects to consider during the maintenance process include regular inspections, appropriate lubrication, and timely replacement of worn parts. Proper care will minimize the risk of unexpected failures and extend the lifespan of the unit.

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 5,000 miles | Replace old lubricant with fresh oil to ensure smooth operation. |

| Filter Inspection | Every 10,000 miles | Check and replace filters as needed to maintain efficiency. |

| Component Check | Monthly | Inspect key parts for signs of wear and tear to prevent issues. |

By following these guidelines and conducting regular assessments, owners can ensure their machinery remains in peak condition, ultimately leading to enhanced performance and reliability on the road.

Common Issues and Solutions

This section addresses frequent challenges faced by users and provides effective resolutions. Understanding these common problems can enhance overall performance and longevity.

Frequent Challenges

- Overheating

- Oil leaks

- Starting difficulties

- Unusual noises

Effective Solutions

- Ensure the cooling system is functioning properly and check coolant levels regularly.

- Inspect seals and gaskets to identify and repair leaks promptly.

- Examine the battery and starter connections for corrosion or damage.

- Conduct a thorough inspection to identify the source of any strange sounds and address them accordingly.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for efficient maintenance tasks. These implements not only facilitate smoother processes but also enhance the overall effectiveness of your work. A well-equipped workspace can significantly reduce time spent on various projects.

Basic Hand Tools

Common hand tools are fundamental for any maintenance activity. Wrenches, pliers, and screwdrivers form the backbone of your toolkit. Each tool serves a specific purpose, making it easier to address different components and achieve optimal results.

Advanced Equipment

In addition to basic tools, certain advanced equipment can greatly improve your capabilities. Items such as diagnostic devices and specialized measuring tools provide insights into performance and ensure precision in adjustments. Investing in quality gear can lead to better outcomes and prolonged functionality.

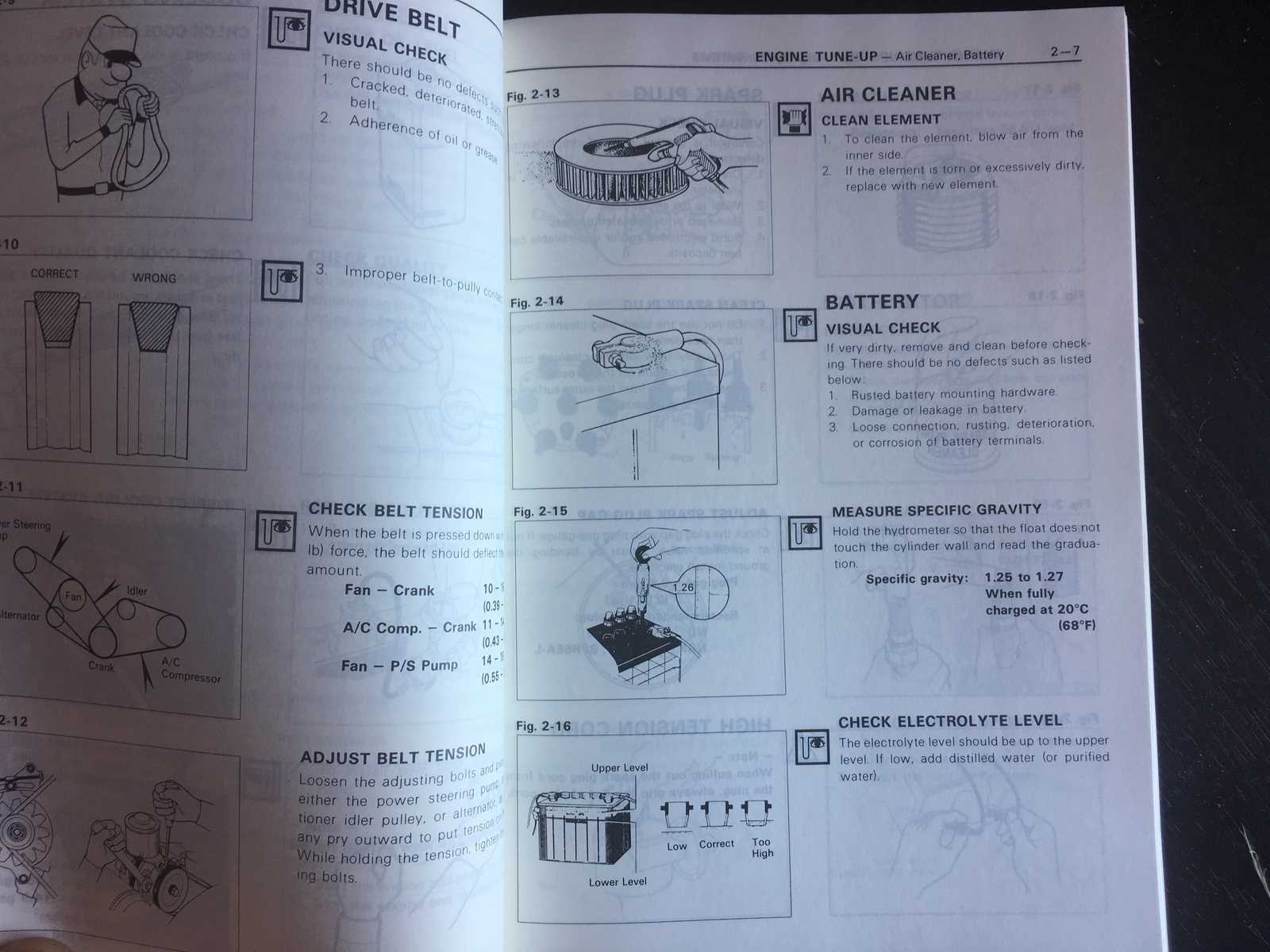

Step-by-Step Maintenance Procedures

This section outlines essential tasks for ensuring optimal performance and longevity of your vehicle’s components. Following these systematic approaches will help maintain functionality and prevent potential issues over time.

Preparation and Tools Required

Before starting the maintenance tasks, gather the necessary tools and materials. This preparation is crucial for a smooth process. Here is a list of common tools and their purposes:

| Tool | Purpose |

|---|---|

| Wrench Set | Tightening and loosening bolts |

| Screwdriver Set | Adjusting screws |

| Jack | Elevating the vehicle for access |

| Oil Pan | Collecting fluids during changes |

| Filter Wrench | Removing filters |

Step-by-Step Procedure

1. Safety First: Ensure the vehicle is on a level surface and secure it with wheel chocks.

2. Fluid Checks: Inspect all essential fluids, including coolant, oil, and transmission fluid. Top off or replace as necessary.

3. Filter Replacement: Change the air and oil filters according to the service schedule. This promotes better efficiency and performance.

4. Belt Inspection: Examine belts for wear and tension. Replace any that show signs of cracking or fraying.

5. Brake System Review: Inspect brake pads and rotors for wear. Ensure that the brake fluid is at the correct level.

6. Tire Maintenance: Check tire pressure and tread depth. Rotate tires as recommended to ensure even wear.

7. Final Checks: After completing all tasks, start the vehicle and listen for any unusual noises. Take it for a short drive to confirm everything is functioning properly.

Diagnosing Engine Performance Problems

Identifying issues that affect the functionality of your vehicle is essential for ensuring optimal performance. This section covers various strategies for recognizing and addressing common symptoms that may indicate underlying concerns. Proper diagnostics not only aids in enhancing efficiency but also extends the lifespan of the machinery.

Common Symptoms to Observe

Several indicators can suggest that something is amiss. Look out for irregular noises, changes in acceleration, or unusual vibrations. Additionally, variations in fuel consumption can be telling signs. Monitoring these aspects is crucial for early detection of potential issues.

Utilizing Diagnostic Tools

Employing specialized instruments can significantly aid in pinpointing the root causes of performance problems. Tools such as onboard diagnostics can provide valuable data, allowing for more accurate assessments. Regular use of these devices can streamline the troubleshooting process, making it easier to maintain high performance.

Overhauling the Toyota 5R Engine

Rebuilding a specific power unit involves several critical steps aimed at restoring its optimal performance. This process requires careful disassembly, inspection, and replacement of worn components to ensure longevity and reliability. Proper techniques and tools are essential for achieving the best results in revitalizing the machinery.

Disassembly Process

The initial phase involves taking apart the assembly systematically. It’s vital to keep track of each component and its orientation to facilitate reassembly. Utilizing a clean workspace and organized storage for parts can greatly enhance efficiency during this stage.

Inspection and Replacement

After disassembly, a thorough examination of each part is crucial. Look for signs of wear, damage, or corrosion. Components such as seals, gaskets, and bearings may require replacement to prevent future issues. Utilizing high-quality materials during this phase can contribute to the overall performance and durability of the rebuilt unit.

Replacing Engine Components Safely

When undertaking the task of swapping vital parts in your vehicle, it is essential to prioritize safety and efficiency. Proper preparation and understanding of the procedures involved can significantly enhance the outcome and minimize risks. Ensuring that the right tools and protective equipment are at hand is fundamental to a successful operation.

Essential Safety Precautions

Before initiating any work, make sure to disconnect the power source to avoid accidental starts. Wearing gloves and safety goggles will protect you from potential injuries. Additionally, organizing your workspace and having a clean area will reduce the chances of mishaps during the process.

Steps for Component Replacement

Begin by consulting detailed guides or schematics to understand the layout and connection of the components. Carefully detach each part, paying attention to how they are connected. When installing new components, ensure they are secured properly and aligned correctly. Regularly check for any abnormalities or signs of wear in surrounding areas to maintain overall functionality.

Preventative Maintenance Tips

Regular upkeep is essential for enhancing the longevity and efficiency of your vehicle. By following a structured approach to maintenance, you can prevent potential issues and ensure smooth operation over time.

- Routine Inspections: Check vital components periodically, including fluids, belts, and hoses.

- Fluid Levels: Regularly monitor and top off engine oil, coolant, brake fluid, and transmission fluid.

- Air Filters: Change or clean air filters to maintain optimal airflow and efficiency.

- Tire Care: Inspect tire pressure and tread depth regularly, and rotate tires to ensure even wear.

- Battery Maintenance: Clean battery terminals and check for corrosion to avoid starting issues.

- Brake System: Regularly check brake pads and rotors for wear and replace as necessary.

- Light Functionality: Ensure all exterior and interior lights are functioning properly for safety.

Implementing these practices can help you avoid costly repairs and keep your vehicle in optimal condition for years to come.

Understanding Engine Specifications

Comprehending the technical details of a power unit is crucial for effective maintenance and performance enhancement. Familiarity with these parameters helps in making informed decisions regarding adjustments and upgrades, ensuring optimal functionality.

Key characteristics include aspects such as displacement, compression ratios, and fuel requirements. These elements influence power output, efficiency, and overall behavior of the system. Knowing these specifications allows for better alignment with specific operational needs and can lead to improved performance and longevity.

Additionally, understanding tolerances and recommended lubricants is essential for smooth operation. Proper fluid selection and regular monitoring contribute significantly to the reliability of the unit, reducing the likelihood of premature wear and failure.

Fuel System Troubleshooting

Identifying issues within the fuel delivery system is crucial for ensuring optimal performance. This section outlines common problems and methods for diagnosing them effectively.

- Insufficient Fuel Supply: Check for clogged filters or fuel lines that may restrict flow.

- Fuel Leakage: Inspect all connections and hoses for signs of dripping or wetness.

- Inconsistent Engine Performance: Evaluate injectors for proper function; clean or replace as necessary.

- Unusual Noises: Listen for sounds that may indicate a failing pump or other components.

Utilizing the right diagnostic tools can simplify the process of pinpointing specific issues. Regular maintenance can prevent many common complications associated with the fuel system.

Cooling System Maintenance Practices

Regular attention to the cooling mechanism is essential for ensuring optimal performance and longevity of the vehicle. This process involves a series of steps that help maintain the integrity and efficiency of the system, preventing overheating and potential damage.

Routine Inspections: Periodically checking the various components of the cooling system, such as hoses, radiators, and reservoirs, is crucial. Look for signs of wear, leaks, or corrosion that could lead to failures.

Fluid Levels: Maintaining proper fluid levels is vital for effective temperature regulation. Regularly check and top off coolant as necessary, ensuring the right mix to prevent freezing or boiling.

Flushing the System: Over time, debris and contaminants can accumulate, hindering performance. Flushing the system periodically removes these impurities, promoting efficient heat transfer.

Thermostat Functionality: The thermostat plays a key role in regulating the engine temperature. Ensure that it is functioning correctly to prevent overheating or inefficient operation.

Professional Servicing: While many tasks can be handled independently, enlisting professional help for complex issues or major maintenance can ensure thorough and effective service.