Toyota Collision Repair Guide

When it comes to the intricacies of vehicle refurbishment, having a thorough understanding of the processes involved is essential. This section aims to equip you with the knowledge needed to navigate through various repair techniques and standards that ensure optimal performance and safety of your automobile.

By delving into the specifics of structural adjustments and component replacements, you will gain insights that enhance your ability to handle damage effectively. This guide emphasizes the importance of following established protocols, ensuring that every aspect of the restoration is executed with precision and care.

In this exploration, we will cover critical methodologies and practical tips that empower you to undertake complex restoration tasks confidently. Emphasizing both skill development and knowledge acquisition, this resource serves as a valuable companion for anyone looking to elevate their expertise in automotive servicing.

Toyota Collision Repair Overview

This section provides a comprehensive insight into the processes involved in restoring vehicles to their original condition following an incident. It emphasizes the importance of following established guidelines and utilizing specialized techniques to ensure the integrity and safety of the automobile after damage.

Understanding the key components of the restoration process is crucial for achieving optimal results. The following table outlines the essential stages involved:

| Stage | Description |

|---|---|

| Assessment | Evaluation of the vehicle’s damage to determine necessary actions. |

| Disassembly | Careful removal of damaged parts to access underlying issues. |

| Repair | Utilization of specialized techniques to fix or replace affected components. |

| Reassembly | Putting the vehicle back together following repairs, ensuring proper fit and finish. |

| Quality Control | Final inspection to verify that all repairs meet safety and quality standards. |

Each phase is essential for achieving a high-quality outcome, ensuring that the vehicle not only looks great but also performs safely on the road.

Importance of Accurate Repair Techniques

Precision in restoration methods is crucial for ensuring safety and longevity in vehicles. When techniques are applied correctly, they not only enhance the structural integrity of the automobile but also optimize its performance on the road. Inadequate methods can lead to severe consequences, both mechanically and in terms of safety.

Enhancing Vehicle Safety

Accurate methods are essential for maintaining the safety features of a vehicle. Proper execution of these techniques ensures that all components function as intended, reducing the risk of failure during operation. This attention to detail is vital for protecting both the driver and passengers.

Preserving Vehicle Value

Utilizing precise techniques also plays a significant role in retaining the vehicle’s value. A well-maintained automobile, which has undergone meticulous restoration, is more likely to command a higher resale price. Buyers are often more inclined to invest in a vehicle that reflects quality craftsmanship.

Common Types of Vehicle Damage

Understanding the various forms of harm that can occur to a vehicle is essential for maintaining its longevity and performance. Different incidents can lead to a wide range of issues, impacting both aesthetics and functionality.

- Body Damage: This includes dents, scratches, and paint chipping resulting from collisions or minor accidents.

- Frame Damage: The vehicle’s structural integrity can be compromised if the frame is bent or misaligned, often requiring specialized assessment.

- Glass Damage: Cracks or chips in windshields and windows can impede visibility and pose safety risks, often necessitating replacement.

- Mechanical Damage: Components like the engine, transmission, or suspension may suffer due to impacts, leading to decreased performance.

- Electrical Damage: Wiring and electronic systems can be affected, causing malfunctions in critical features such as lighting and sensors.

Recognizing these common types of damage can aid vehicle owners in making informed decisions regarding maintenance and potential restoration efforts.

Essential Tools for Repair Process

In any vehicle restoration or damage correction endeavor, having the right set of instruments is crucial for achieving high-quality results. A well-equipped workspace allows technicians to effectively address issues, ensuring both safety and efficiency throughout the procedure.

One of the most important categories of instruments includes hand tools. These typically comprise wrenches, pliers, and screwdrivers, which are essential for disassembling and reassembling various components. Additionally, power tools, such as drills and grinders, significantly expedite the process, allowing for quicker adjustments and modifications.

Another vital group is measuring instruments. Tools like calipers and gauges enable precise assessments, ensuring that all parts align correctly and function optimally after adjustments. Furthermore, specialized equipment, including frame straighteners and pullers, plays a key role in restoring structural integrity.

Lastly, having access to a comprehensive safety gear is essential. Protective eyewear, gloves, and other safety equipment not only safeguard the technician but also promote a secure working environment. With the right tools and precautions in place, the entire process can be conducted smoothly and effectively.

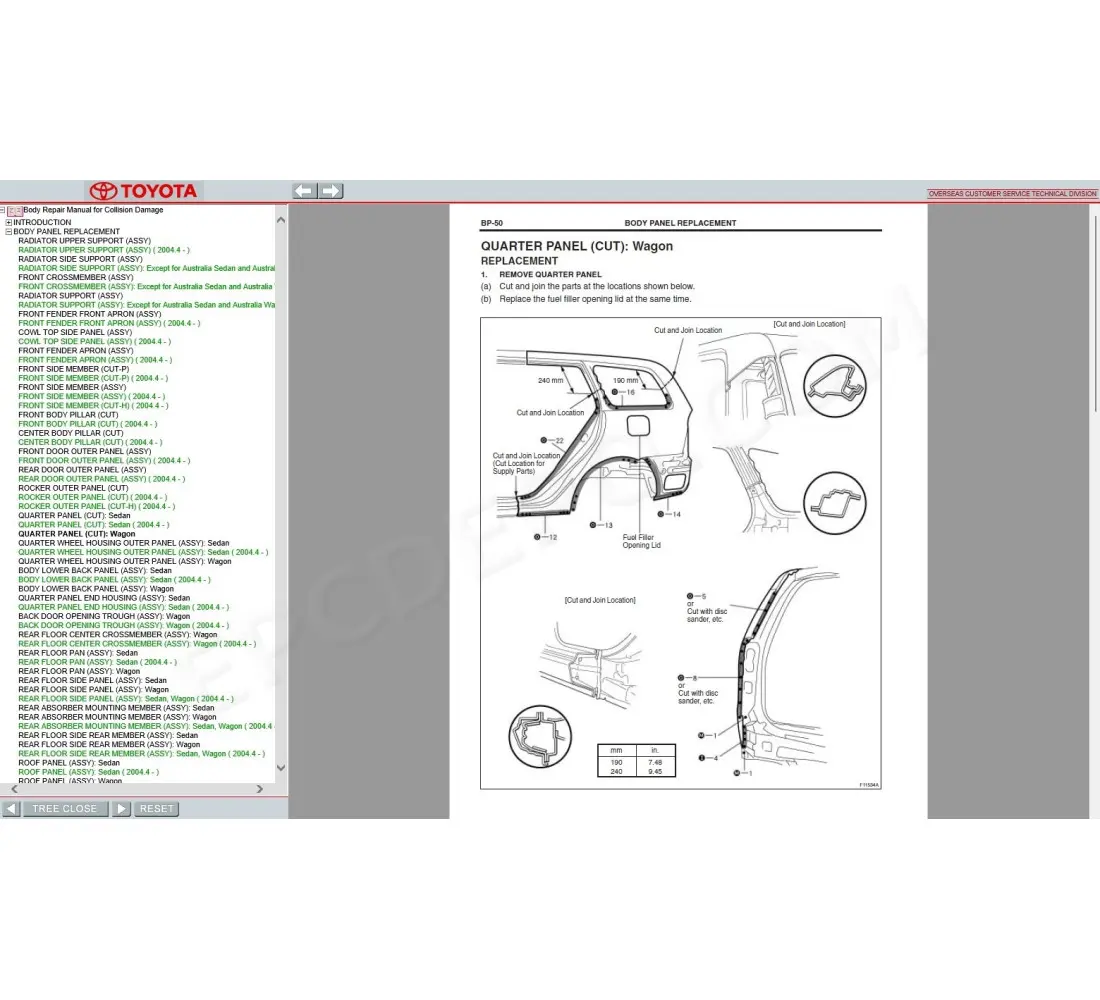

Step-by-Step Repair Procedures

This section outlines the essential processes to effectively restore vehicles following damage. Following these structured guidelines ensures that repairs are completed efficiently and to a high standard.

- Assessment:

Begin with a thorough examination of the vehicle to identify all areas requiring attention. Document any visible damages and take necessary measurements.

- Preparation:

Gather all tools and materials needed for the task. Ensure the workspace is organized and free from hazards.

- Disassembly:

Carefully remove affected components. Keep track of all fasteners and parts for reinstallation.

- Repair/Replacement:

Address damages through appropriate methods, such as straightening, welding, or replacing parts. Follow manufacturer guidelines for specific procedures.

- Reassembly:

Reattach all components securely, ensuring alignment and proper fit. Refer to the initial documentation for accurate placement.

- Finishing:

Perform final checks to ensure everything is functioning correctly. Clean the workspace and dispose of waste responsibly.

Following these steps methodically will contribute to restoring vehicles effectively, ensuring both safety and quality.

Understanding Structural Integrity Standards

Ensuring the durability and safety of a vehicle involves adhering to specific benchmarks that dictate how its components withstand various stresses and impacts. These criteria are essential for maintaining the overall robustness of the structure, which directly influences performance and occupant protection.

Key aspects of structural integrity standards include:

- Material Quality: The choice of materials plays a significant role in determining how well a structure can endure forces. High-grade metals and advanced composites are often utilized.

- Design Specifications: Engineers establish design protocols that optimize strength while minimizing weight, creating a balance that enhances efficiency without compromising safety.

- Manufacturing Processes: Techniques used in fabrication must ensure precise tolerances and fit, which are crucial for maintaining the intended performance characteristics.

- Testing Procedures: Rigorous assessments are conducted to verify that structures meet or exceed established standards. This includes simulations and physical tests that mimic real-world conditions.

By comprehensively understanding these standards, manufacturers and technicians can ensure that vehicles are not only compliant with regulations but also capable of providing the necessary safety and reliability expected by consumers.

Diagnostic Tools and Their Usage

In the automotive field, precise evaluation of vehicle issues is crucial for effective solutions. Various instruments assist technicians in identifying malfunctions and ensuring optimal performance. These tools are designed to facilitate thorough assessments, ultimately leading to informed decisions during the service process.

Types of Diagnostic Instruments

Diagnostic devices come in multiple forms, each serving specific functions. They range from basic tools that read error codes to advanced systems that provide comprehensive data analysis. Below is a table outlining some common diagnostic tools and their primary uses:

| Tool Type | Primary Function |

|---|---|

| OBD-II Scanner | Reads and clears trouble codes from the vehicle’s computer. |

| Multimeter | Measures electrical values such as voltage, current, and resistance. |

| Compression Tester | Evaluates the engine’s compression levels to assess health. |

| Diagnostic Oscilloscope | Analyzes electrical signals for in-depth examination of components. |

Utilization Techniques

Effective usage of these diagnostic tools requires both knowledge and experience. Technicians must be familiar with the operation of each device and understand the significance of the data it provides. Regular training and staying updated with technological advancements are essential for maximizing the potential of these instruments.

Choosing Quality Replacement Parts

When it comes to restoring a vehicle to its original condition, selecting high-quality components is crucial. The longevity and performance of the automobile largely depend on the parts used during the restoration process. Making informed choices ensures safety, reliability, and overall satisfaction.

There are various factors to consider when choosing replacement components:

| Factor | Description |

|---|---|

| Compatibility | Ensure that the parts are specifically designed for the make and model of the vehicle to guarantee proper fit and function. |

| Material Quality | Opt for components made from durable materials that withstand wear and tear, enhancing the vehicle’s lifespan. |

| Manufacturer Reputation | Choose parts from reputable manufacturers known for their reliability and adherence to industry standards. |

| Warranty | Look for components that come with a warranty, providing assurance against defects and premature failure. |

| Cost | While budget considerations are important, prioritize quality over the lowest price to avoid future issues. |

By carefully evaluating these factors, individuals can ensure that their vehicles are equipped with the best possible components, leading to a safer and more enjoyable driving experience.

Paint Matching and Finishing Techniques

Achieving a seamless appearance after a vehicle has undergone bodywork is crucial for restoring its original aesthetics. This section delves into the methods used to ensure that the applied finish closely resembles the surrounding surfaces, resulting in a flawless integration.

Color Identification and Mixing

Identifying the correct hue is the first step in the finishing process. Utilizing a color spectrophotometer can greatly assist in determining the precise shade needed for a perfect match. Once the color is identified, it is essential to mix the paint properly, considering factors like base type and additives, to achieve an optimal consistency and durability.

Application Techniques

When applying the paint, using the right technique is vital for a smooth and even finish. Employing methods such as spray application or airbrush can provide control over the layering process. Additionally, allowing sufficient drying time between coats and utilizing clear coats can enhance the depth and gloss of the final appearance, ensuring a professional-quality outcome.

Safety Measures During Repairs

Ensuring a secure environment while conducting maintenance on vehicles is crucial for both the technician and the equipment involved. Implementing appropriate safety protocols can significantly reduce the risk of accidents and injuries, promoting a more efficient workflow.

Personal Protective Equipment

Utilizing personal protective gear is essential. This includes items such as gloves, goggles, and protective clothing. Gloves shield hands from harmful substances, while goggles protect eyes from flying debris and chemicals. Proper attire not only safeguards against physical harm but also enhances overall comfort during prolonged tasks.

Workspace Organization

Maintaining an orderly workspace contributes to safety. Ensuring that tools and materials are neatly arranged minimizes the chances of tripping hazards and accidental spills. Clear pathways allow for swift movement, which is vital in emergency situations. Regularly inspecting equipment for any signs of wear or malfunction can prevent unexpected issues, further enhancing a secure working atmosphere.

Estimating Repair Costs Effectively

Accurately determining the expenses associated with vehicle restoration is crucial for both professionals and owners. A comprehensive approach involves considering various factors that contribute to the final price, ensuring transparency and avoiding unexpected financial burdens.

Several key elements play a role in estimating costs:

| Factor | Description |

|---|---|

| Parts | The cost of new or used components needed for the restoration process. |

| Labor | Wages for skilled technicians performing the necessary work, often calculated per hour. |

| Supplies | Materials such as paint, adhesives, and protective gear required for the job. |

| Inspection | Fees for assessments to identify underlying issues not visible during the initial evaluation. |

| Timeframe | The estimated duration of the work, which can affect overall costs, especially if additional repairs are identified. |

By thoroughly evaluating these aspects, individuals can create a realistic budget that reflects the true costs of vehicle restoration, facilitating better decision-making throughout the process.

Insurance Claims and Repair Documentation

When a vehicle sustains damage, navigating the process of securing financial compensation and ensuring proper restoration can be challenging. Effective communication between vehicle owners, insurance providers, and service professionals is crucial for a smooth resolution. This section outlines the essential steps and documentation needed to facilitate claims and guarantee quality work.

Documentation is Key

Maintaining thorough records of the incident is vital. This includes photographs of the damage, police reports, and any witness statements. These documents provide clear evidence to support the claim, helping to establish the extent of the damage and the necessary actions for recovery.

Estimate and Invoice

After an assessment by a qualified technician, an estimate detailing the expected costs for the necessary services should be provided. This estimate, along with the final invoice, is critical for the claims process, as insurance companies often require detailed breakdowns of expenses for reimbursement.

Communication with Insurers

Staying in contact with your insurance representative is essential. Regular updates and prompt submission of all required documentation can help expedite the claims process. Ensure that all communications are documented to create a clear trail of information shared.

Final Approval

Once all evaluations and repairs are completed, obtaining final approval from the insurance company is necessary before concluding the process. This step confirms that all expenses align with the initial agreement and that the vehicle meets safety and quality standards post-repair.

Ongoing Maintenance After Repairs

Ensuring the longevity and performance of a vehicle following restorative work is crucial. Continuous care not only enhances safety but also preserves the value of the automobile. Implementing a consistent maintenance schedule can significantly reduce the likelihood of future issues.

Regular checks and servicing play a vital role in maintaining the integrity of the vehicle’s systems. It is important to adhere to the recommended guidelines to ensure optimal functionality. Below is a table outlining key maintenance tasks and their suggested intervals:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 5,000 miles or 6 months |

| Tire Rotation | Every 6,000 to 8,000 miles |

| Brake Inspection | Every 10,000 miles |

| Fluid Levels Check | Monthly |

| Battery Check | Every 6 months |

By following these practices, vehicle owners can ensure their automobile remains in excellent condition, minimizing the chances of unexpected problems down the line.