Comprehensive Repair Guide for the 2006 Toyota RAV4

This section provides essential information for maintaining and servicing a particular model of an automotive vehicle, focusing on practical advice and troubleshooting techniques. Understanding the intricacies of your vehicle’s systems is vital for ensuring optimal performance and longevity.

In this guide, you will find detailed insights into the various components that require regular attention, along with step-by-step instructions to address common issues. Whether you are a seasoned enthusiast or a novice, this resource aims to empower you with the knowledge needed for effective vehicle upkeep.

Furthermore, the emphasis will be placed on safety measures and recommended practices, ensuring that you can confidently tackle any task related to your vehicle. This information serves as a reliable reference for those looking to enhance their skills and understanding of automotive maintenance.

Toyota RAV4 2006 Overview

This section provides a comprehensive examination of a popular compact sport utility vehicle known for its versatility and practicality. Designed to cater to diverse driving needs, this model combines a robust structure with advanced technology, making it an ideal choice for both urban commuting and outdoor adventures.

Performance and Handling

The vehicle is equipped with a dynamic powertrain that offers a balance of efficiency and responsiveness. Its handling capabilities ensure a smooth ride, while the suspension system enhances stability on various terrains. With options for both front-wheel and all-wheel drive, it caters to drivers seeking adaptability in their journeys.

Interior Features and Comfort

Inside, the cabin is designed with user comfort in mind, featuring ample space for passengers and cargo. The layout is intuitive, with accessible controls and high-quality materials. Enhanced entertainment systems and safety features ensure a pleasant and secure driving experience.

Essential Tools for DIY Repairs

Engaging in automotive maintenance and upgrades requires a set of fundamental instruments to ensure effectiveness and safety. Whether addressing minor adjustments or undertaking extensive modifications, having the right equipment is crucial for achieving optimal results. This section outlines key items that every enthusiast should consider having in their toolkit for successful endeavors.

| Tool | Description |

|---|---|

| Socket Set | A comprehensive assortment of sockets and ratchets, essential for loosening and tightening fasteners. |

| Wrench Set | Includes various sizes of wrenches, crucial for working with nuts and bolts in confined spaces. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage from over-tightening. |

| Screwdriver Set | Consists of various types and sizes of screwdrivers, vital for accessing different components. |

| Pliers | Useful for gripping, bending, and cutting wires or other materials during the process. |

| Jack and Stands | Essential for lifting the vehicle safely, allowing access to the underside for maintenance tasks. |

| Multimeter | Instrument for measuring electrical properties, ideal for diagnosing electrical systems. |

Common Issues and Solutions

Vehicles often encounter a variety of problems that can affect performance, comfort, and safety. Understanding these common challenges and their respective remedies is essential for maintaining optimal functionality. This section aims to highlight prevalent concerns and provide effective solutions for each situation.

Engine Performance Problems: Many drivers report issues such as reduced power or stalling. These symptoms can arise from a clogged air filter, faulty spark plugs, or fuel delivery problems. Regular maintenance, including filter replacements and spark plug checks, can help mitigate these issues.

Electrical System Failures: Malfunctions in the electrical system may manifest as problems with the battery, lights, or starting mechanism. These issues are often linked to a weak battery or corroded connections. Checking the battery condition and cleaning terminals can resolve these concerns.

Suspension and Steering Complaints: Uneven tire wear, vibrations, or a bumpy ride may indicate suspension or steering issues. Worn-out components such as struts or shocks are common culprits. Regular inspections and timely replacements can enhance ride quality and safety.

Transmission Difficulties: Shifting problems, unusual noises, or fluid leaks can indicate transmission trouble. Regular fluid changes and prompt attention to leaks are essential for preventing costly repairs. If issues persist, a thorough inspection by a professional is recommended.

Cooling System Overheating: Overheating can lead to serious engine damage. Common causes include low coolant levels, a faulty thermostat, or a damaged radiator. Regular checks of coolant levels and system integrity can prevent overheating incidents.

By being aware of these issues and implementing the suggested solutions, vehicle owners can ensure a smoother driving experience and extend the lifespan of their automobile.

Routine Maintenance Checklist

Regular upkeep is essential to ensure optimal performance and longevity of your vehicle. A comprehensive checklist serves as a valuable tool to monitor key aspects that contribute to the overall health of your automobile. This section outlines crucial tasks that should be performed consistently to keep your vehicle running smoothly.

Engine and Fluid Checks

Begin with inspecting the engine oil level and quality. Change the oil as recommended by the manufacturer to maintain engine efficiency. Additionally, check the coolant, brake fluid, and transmission fluid levels, topping them off as necessary. Replacing air filters at specified intervals is also vital for maintaining good airflow and enhancing fuel efficiency.

Tire Maintenance

Tires are critical for safe handling and fuel economy. Regularly examine tire pressure, ensuring it aligns with the manufacturer’s specifications. Rotate tires every 5,000 to 7,500 miles to promote even wear. Don’t forget to check tread depth and inspect for any signs of damage or irregular wear patterns. Proper alignment and balancing can further enhance performance.

Engine Specifications and Troubleshooting

This section provides a comprehensive overview of the engine characteristics and potential issues that may arise during operation. Understanding these aspects is crucial for effective maintenance and problem resolution.

The power unit in question typically features a robust design, incorporating advanced technology to enhance performance and efficiency. Key parameters include displacement, horsepower, and torque ratings, which collectively contribute to the vehicle’s dynamic capabilities.

When encountering difficulties, it is essential to systematically diagnose the root cause. Common symptoms may include unusual noises, decreased power, or irregular fuel consumption. Utilizing diagnostic tools can aid in pinpointing specific faults, such as sensor malfunctions or ignition system failures.

Regular inspections and timely interventions can prevent minor issues from escalating into significant repairs. By adhering to maintenance schedules and staying alert to performance changes, drivers can ensure the longevity and reliability of their vehicle.

Electrical System Diagnosis Guide

This section provides a comprehensive overview of troubleshooting procedures for diagnosing electrical issues in vehicles. Understanding the fundamentals of the electrical system is crucial for identifying faults and ensuring optimal functionality. Accurate diagnosis can save time and prevent unnecessary repairs.

Step 1: Initial Inspection

Begin by visually inspecting the wiring harness and connectors for signs of wear or damage. Look for frayed wires, corrosion, or loose connections that may disrupt the electrical flow. A thorough examination is vital for identifying potential problems early on.

Step 2: Utilizing Diagnostic Tools

Employ diagnostic equipment such as multimeters and scanners to assess the system’s performance. A multimeter can measure voltage, current, and resistance, helping to pinpoint issues in the circuit. Scanners can provide valuable information from the vehicle’s onboard computer, aiding in the identification of error codes.

Step 3: Testing Components

Test individual components, such as fuses, relays, and sensors, to verify their functionality. Replace any faulty components to restore proper operation. It’s important to consult the specifications for each part to ensure they meet the required standards.

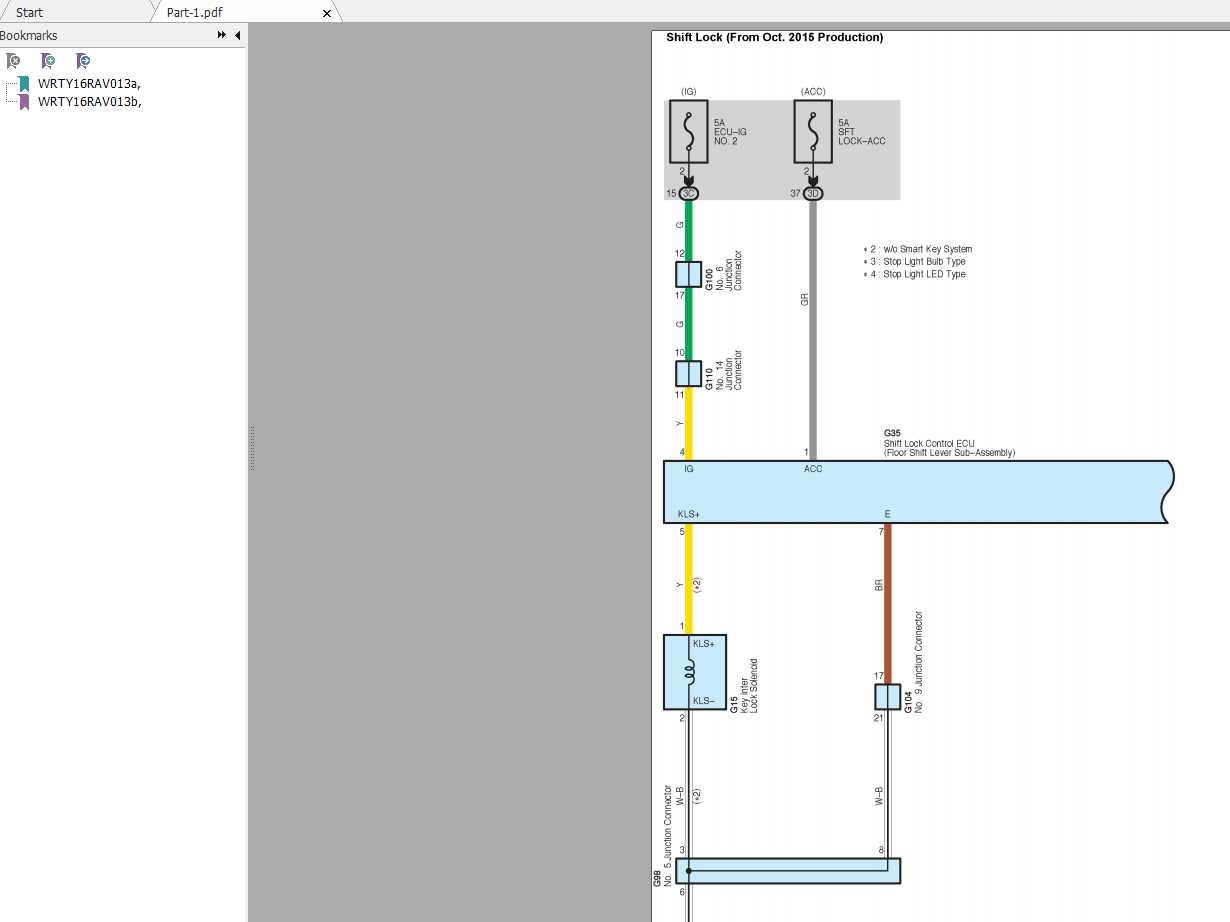

Step 4: Wiring Diagram Reference

Refer to the wiring diagram to understand the relationships between different electrical components. This visual guide will assist in tracing circuits and identifying potential short circuits or open circuits that may affect the system.

Step 5: Final Verification

After completing the diagnostic process and making necessary repairs, conduct a final verification to ensure everything is functioning correctly. Test all electrical systems thoroughly to confirm that the issues have been resolved and the vehicle is operating as intended.

Brake System Inspection Process

Ensuring optimal performance of the braking mechanism is crucial for vehicle safety. Regular evaluations help identify potential issues before they escalate, contributing to a reliable driving experience. This section outlines the essential steps involved in assessing the braking system to maintain its efficiency and functionality.

Visual Examination

The initial phase of the inspection involves a thorough visual assessment of the braking components. This includes checking for wear and tear, leaks, and any visible damage that may hinder performance. Pay particular attention to the following parts:

| Component | Inspection Points |

|---|---|

| Brake Pads | Thickness, wear patterns, and cracking |

| Brake Rotors | Surface condition, warping, and scoring |

| Brake Lines | Leaks, corrosion, and secure connections |

| Master Cylinder | Fluid levels and any signs of leakage |

Functional Testing

After the visual inspection, the next step is to conduct functional tests. These assessments ensure that all components work as intended and that the braking force is applied uniformly. Key tests include:

| Test | Purpose |

|---|---|

| Brake Fluid Check | To ensure proper hydraulic function |

| Brake Response Test | To assess the immediate engagement of brakes |

| Noise Assessment | To identify abnormal sounds indicating potential issues |

Suspension and Steering Adjustments

The proper calibration of the suspension and steering systems is essential for maintaining optimal handling and ride comfort. Ensuring that these components are correctly aligned and adjusted not only enhances vehicle performance but also contributes to overall safety. This section will explore the key considerations and procedures involved in fine-tuning these crucial systems.

Importance of Alignment

Alignment plays a vital role in the performance of both the suspension and steering systems. Misalignment can lead to uneven tire wear, reduced fuel efficiency, and compromised handling. Regular checks and adjustments can mitigate these issues, allowing for a smoother driving experience and prolonging the lifespan of the vehicle’s components.

Adjusting Steering Components

Fine-tuning steering elements is critical for achieving accurate vehicle control. Adjustments may include the positioning of tie rods, steering gear, and other related components. Ensuring these parts are set to manufacturer specifications helps maintain responsive handling and reduces strain on the steering system during operation.

Cooling System Maintenance Tips

Regular upkeep of the cooling system is crucial for ensuring optimal engine performance and preventing overheating issues. A well-maintained cooling system helps extend the lifespan of the engine and maintains its efficiency. This section outlines essential practices to keep the cooling system in top condition.

Firstly, it’s important to routinely check the coolant levels and ensure they are within the recommended range. Low coolant levels can lead to engine overheating, so topping up or replacing the fluid as needed is essential. Additionally, inspecting for leaks around hoses and connections can prevent potential problems.

Furthermore, flushing the cooling system at specified intervals helps remove debris and contaminants that can hinder performance. This process involves draining the old coolant and replacing it with fresh fluid to ensure effective heat transfer. Always refer to the manufacturer’s guidelines for the appropriate type of coolant and flushing frequency.

Finally, pay attention to the condition of the radiator and its components. Cleaning the radiator fins and ensuring they are free from debris enhances airflow, which is vital for cooling efficiency. Regularly inspecting the water pump and thermostat also contributes to a reliable cooling system. By following these tips, you can maintain the performance and longevity of your vehicle’s engine.

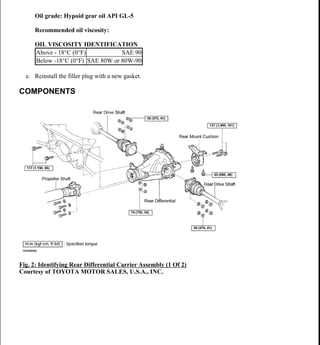

Transmission Service Recommendations

Proper maintenance of the drivetrain system is essential for ensuring optimal performance and longevity. Regular service can prevent potential issues, enhance efficiency, and provide a smoother driving experience. Following specific guidelines for fluid changes, inspections, and adjustments is crucial in keeping the transmission in top condition.

Fluid Change Intervals

Regularly replacing the transmission fluid is vital for maintaining the internal components’ health. It is recommended to check the fluid levels frequently and replace the fluid according to the manufacturer’s specifications. Over time, transmission fluid can degrade and lose its lubricating properties, leading to wear and tear on gears and seals.

Routine Inspections

Conducting periodic inspections of the transmission system can help identify signs of potential problems early. Look for leaks, unusual noises, or performance issues during operation. Addressing any abnormalities promptly can save on costly repairs in the future and ensure the system operates smoothly.