Comprehensive Guide to 09A Transmission Repair

This section provides an in-depth exploration of the intricacies involved in overhauling automotive gear systems. It aims to equip readers with essential knowledge and techniques to effectively manage the complexities associated with these components. Understanding the underlying principles can significantly enhance maintenance practices and extend the lifespan of the vehicle.

Through a detailed examination of various processes and methodologies, enthusiasts and professionals alike will gain insights into best practices for ensuring optimal functionality. From diagnosing common issues to executing corrective measures, this guide is designed to empower individuals to tackle challenges confidently and competently.

Whether you are a seasoned mechanic or a curious DIY enthusiast, this resource will serve as a valuable reference. By delving into the nuances of gearbox assembly and disassembly, you will be better prepared to navigate the technical demands of the task at hand, fostering a deeper appreciation for the engineering behind automotive performance.

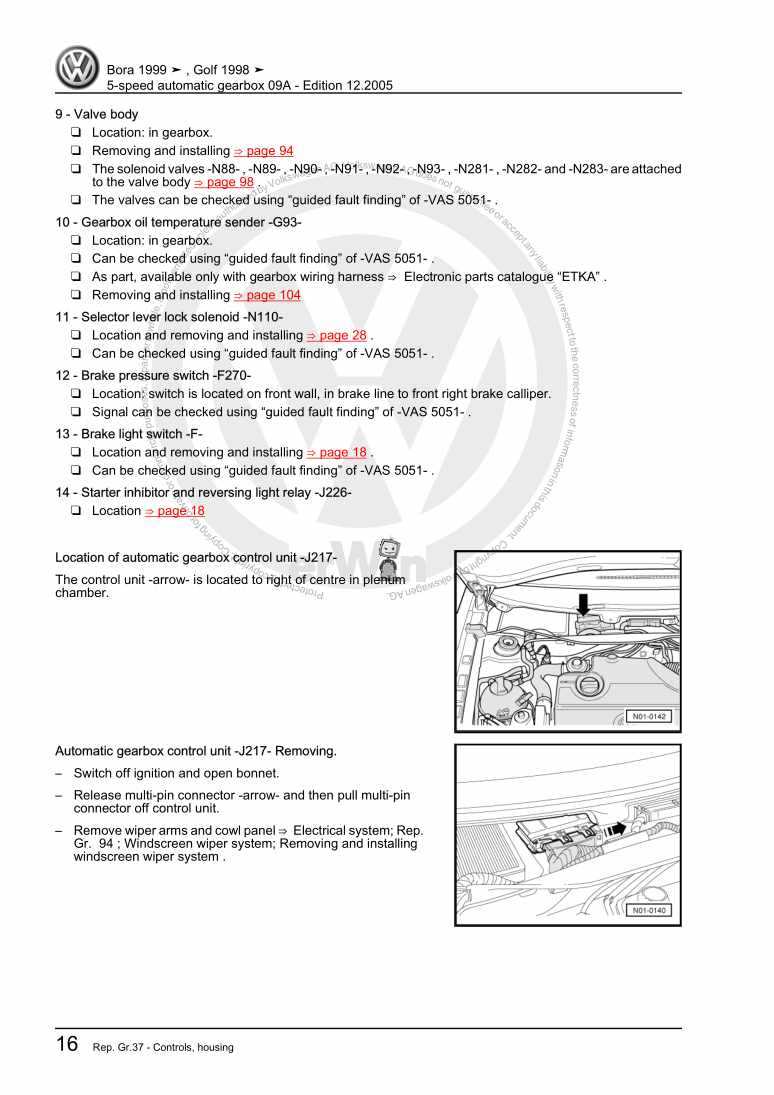

This section provides an overview of the crucial components and functionalities associated with a specific vehicle system. Understanding these elements is essential for effective troubleshooting and maintenance. This knowledge aids in diagnosing issues and ensuring optimal performance.

Key Components of the System

The system comprises various integral parts, each serving a unique purpose. Familiarity with these components is vital for effective management and service. Here are some primary elements:

| Component | Function |

|---|---|

| Gear Set | Facilitates gear shifting for varying speeds. |

| Fluid Pump | Maintains hydraulic pressure for operation. |

| Clutch Assembly | Engages and disengages power transfer. |

| Control Module | Manages system operations and diagnostics. |

Importance of Proper Maintenance

Common Issues with 09A Transmissions

When dealing with certain automotive systems, several recurring challenges can emerge, impacting performance and reliability. Understanding these typical problems is essential for effective troubleshooting and maintenance.

Frequent Malfunctions

Among the most reported difficulties are unexpected slippage and shifting delays. These issues can arise from various sources, including wear and tear on internal components or fluid contamination.

Fluid Contamination Risks

Maintaining clean and adequate fluid levels is crucial for optimal function. Contaminated or low fluid can lead to severe complications, such as overheating or complete failure.

| Issue | Description | Possible Solutions |

|---|---|---|

| Slippage | Unexpected loss of power during gear changes. | Check fluid levels, replace worn components. |

| Shifting Delays | Delayed engagement between gears, causing unresponsiveness. | Inspect and replace damaged sensors, flush and refill fluids. |

| Overheating | Excessive heat leading to system failure. | Ensure adequate cooling, inspect for leaks. |

Essential Tools for Repairs

When tackling intricate mechanical tasks, having the right equipment is crucial for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures safety during the process. Various instruments cater to different aspects of maintenance, allowing for precise adjustments and thorough inspections.

Key items include wrenches, sockets, and pliers, which facilitate the loosening and tightening of components. Specialized gauges and diagnostic devices play a vital role in assessing performance and identifying issues. Additionally, utilizing a sturdy workbench and adequate lighting can significantly improve visibility and comfort while working.

Investing in quality tools may seem daunting initially, but their reliability and durability can save both time and effort in the long run. By assembling a comprehensive toolkit, enthusiasts can confidently tackle any challenge that arises in the realm of mechanical maintenance.

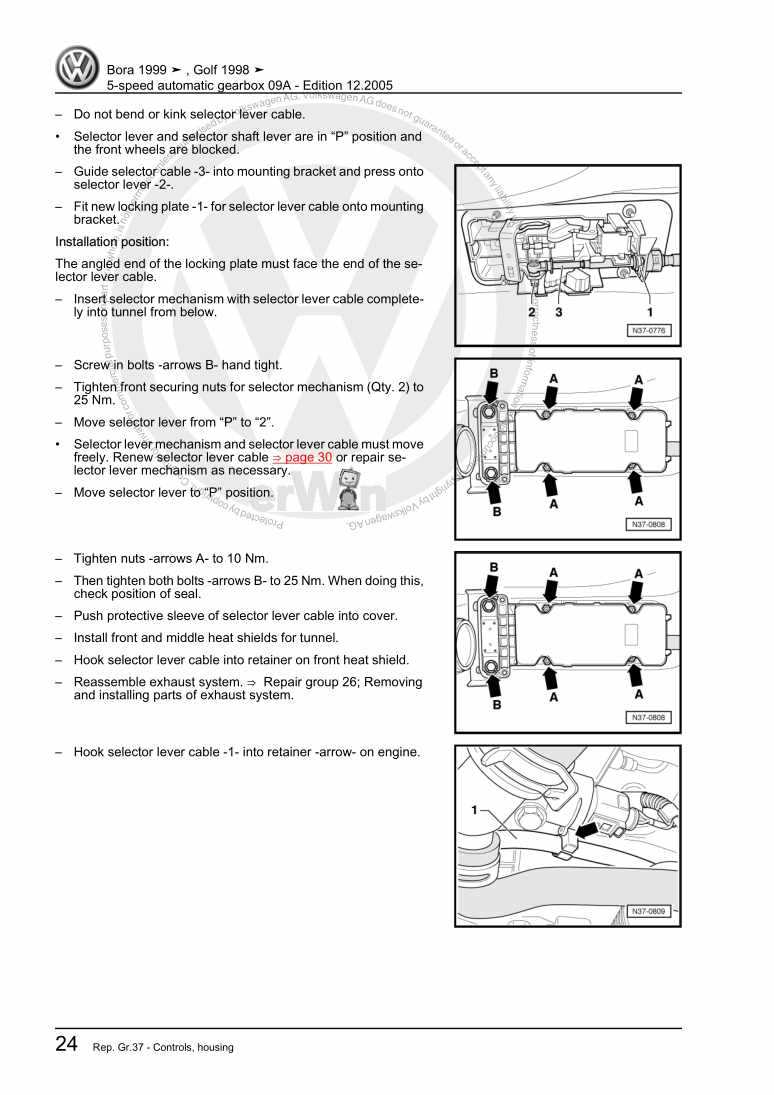

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues related to a specific automotive component. By following a systematic procedure, one can effectively troubleshoot and resolve common challenges, ensuring optimal performance and longevity.

-

Initial Assessment: Begin with a thorough inspection to identify symptoms and potential problems.

-

Preparation: Gather necessary tools and parts, ensuring everything is ready for the process.

-

Disassembly: Carefully remove components while documenting each step to facilitate reassembly.

-

Inspection: Examine the removed parts for wear and damage, noting any replacements needed.

-

Replacement: Install new or refurbished components as required, ensuring proper fit and alignment.

-

Reassembly: Reconstruct the unit by reversing the disassembly steps, double-checking each connection.

-

Final Testing: Conduct tests to ensure everything operates correctly and safely before concluding.

Following this structured methodology will help achieve successful outcomes and enhance the overall functionality of the vehicle.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s components is essential for optimal performance and efficiency. By following a few straightforward practices, you can significantly extend the lifespan of critical systems, preventing costly issues down the road.

Regular Inspections

Conducting routine checks on various elements can help identify wear and tear before they escalate into major problems. Look for signs of leaks, unusual noises, or irregular behavior during operation.

Fluid Changes

Maintaining proper fluid levels and replacing them according to the manufacturer’s recommendations is vital. Clean fluids not only enhance performance but also protect internal mechanisms from damage.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Check | Monthly | Ensure all fluids are at proper levels. |

| Fluid Replacement | Every 30,000 miles | Follow specific guidelines for different fluids. |

| Visual Inspection | Every 6 months | Look for leaks and damage. |

Signs of Transmission Failure

Identifying issues with your vehicle’s shifting system early can save you from extensive damage and costly repairs. Recognizing the warning signs is crucial for maintaining performance and safety on the road.

Common Indicators

- Unusual noises during gear changes, such as grinding or clunking sounds.

- Slipping gears, where the vehicle unexpectedly changes gears or loses power.

- Delayed or harsh shifting, causing a rough transition between gears.

- Warning lights illuminated on the dashboard, particularly the check engine light.

- Fluid leaks under the vehicle, often appearing red or brown.

Behavioral Changes

- Decreased fuel efficiency, as the engine works harder to compensate for inefficiencies.

- Unresponsive acceleration, where the vehicle fails to respond as expected when pressing the gas pedal.

- Overheating, which may occur due to excessive friction in the system.

Replacing Fluid Safely

Ensuring the proper maintenance of your vehicle’s fluid system is crucial for optimal performance and longevity. This section will guide you through the necessary steps to safely replace the fluid, helping to avoid common pitfalls and maintain the integrity of your machinery.

Essential Tools and Materials

Before beginning the process, gather the following tools and materials:

| Tool/Material | Description |

|---|---|

| Fluid Pump | Used for transferring new fluid into the system. |

| Fluid Catch Pan | Helps collect old fluid to prevent spills. |

| Wrench Set | Needed for loosening and tightening fittings. |

| Safety Gloves | Protects hands from chemicals and hot fluid. |

Step-by-Step Process

Follow these steps to ensure a safe and effective fluid change:

- Park the vehicle on a flat surface and engage the parking brake.

- Allow the engine to cool if it has been running.

- Locate the fluid reservoir and the drainage plug.

- Place the catch pan under the drainage plug to collect the old fluid.

- Remove the drainage plug carefully, allowing the old fluid to drain completely.

- Replace the drainage plug securely once the old fluid is drained.

- Use the fluid pump to fill the reservoir with the appropriate new fluid.

- Check the levels using the dipstick, if available, and add more fluid as necessary.

Following these guidelines will help you perform the fluid replacement effectively, contributing to the overall health of your vehicle’s systems.

Upgrading Your Transmission System

Enhancing the performance of your vehicle’s shifting mechanism can lead to significant improvements in overall efficiency and responsiveness. This process involves implementing advanced components and techniques to optimize gear changes and power delivery.

One effective method is to replace outdated elements with high-performance alternatives. Utilizing upgraded gears, clutches, and hydraulic systems can drastically enhance the vehicle’s handling and acceleration. Additionally, modern electronic controls can offer greater precision, allowing for smoother shifts and better adaptation to driving conditions.

Regular maintenance is equally essential in ensuring the longevity of your enhanced system. Keeping components clean and properly lubricated will prevent premature wear and potential failures. Moreover, it is advisable to consult with professionals who specialize in these upgrades to ensure the best results.

Investing in improvements not only boosts your vehicle’s capabilities but also elevates your driving experience. By prioritizing quality and innovation, you can achieve remarkable gains in both performance and reliability.

Cost Considerations for Repairs

When facing the need for vehicle service, understanding the financial implications is crucial. Various factors can influence the overall expenses associated with fixing issues, and being informed can help in making better decisions.

Factors Influencing Expenses

- Parts Quality: The choice between OEM and aftermarket components can significantly affect costs.

- Labor Rates: Different workshops have varying hourly rates, which can influence the total bill.

- Type of Issue: Some malfunctions are more complex and time-consuming, resulting in higher charges.

Budgeting for Maintenance

Planning for routine upkeep can mitigate unexpected financial burdens. Consider allocating a specific percentage of your budget towards ongoing maintenance to avoid larger costs down the line.

Professional vs. DIY Repairs

When faced with mechanical issues, individuals often grapple with the decision of whether to seek expert assistance or to tackle the problem themselves. This choice can significantly impact both the outcome and the overall experience of resolving the issue.

Benefits of Professional Services

- Expertise: Professionals possess specialized knowledge and experience, ensuring effective solutions.

- Warranty: Many services offer warranties on their work, providing peace of mind.

- Time-Saving: Entrusting the task to an expert can save valuable time for individuals.

- Advanced Tools: Professionals have access to sophisticated equipment that may not be available to the average person.

Advantages of DIY Approaches

- Cost-Effective: Handling repairs personally can reduce expenses associated with labor costs.

- Learning Opportunity: Engaging in self-repair allows for skill development and knowledge enhancement.

- Control: DIY repairs provide individuals with complete oversight of the process.

- Flexible Timing: Working at one’s own pace enables a more adaptable schedule.

Resources for Further Learning

Expanding your knowledge in automotive systems can greatly enhance your understanding and skills. Whether you are a beginner or an experienced enthusiast, numerous resources are available to deepen your insights.

Online Courses: Various platforms offer structured programs focusing on automotive mechanics, covering topics from basic principles to advanced diagnostics. Engaging in these courses can provide valuable hands-on experience.

Books and Guides: Consider investing in comprehensive texts that delve into the intricacies of vehicle mechanics. These publications often contain detailed explanations and illustrations, making complex concepts more accessible.

Forums and Communities: Participating in online forums allows you to connect with fellow learners and professionals. These communities often share tips, troubleshooting advice, and personal experiences that can be incredibly beneficial.

Videos and Tutorials: Visual learners may find instructional videos particularly useful. Many experienced mechanics share their knowledge through tutorials, providing practical demonstrations and insights into various techniques.

By utilizing these resources, you can enhance your skills and stay informed about the latest developments in the automotive field.