4R44E Transmission Repair Manual Guide for Effective Maintenance and Troubleshooting

Understanding how to effectively maintain and restore a vehicle’s core mechanical components is essential for every car owner. This guide covers in-depth insights on handling issues and optimizing performance in one of the most intricate parts of your vehicle. For those looking to address specific challenges or to extend the life of key components, this will be an invaluable resource.

In this section, you’ll find practical advice, detailed steps, and common solutions related to keeping essential gear mechanisms in top shape. Learn the best methods to diagnose issues, perform preventative upkeep, and make adjustments to improve functionality. From tackling unusual sounds to addressing shifting problems, our guide aims to help you handle various scenarios effectively.

Whether you’re a seasoned mechanic or a dedicated car enthusiast, this material will support you in honing your technical skills. By following our structured approach, you’ll gain the knowledge to identify and resolve issues safely, ensuring long-lasting reliability and smoother operation for your vehicle’s essential systems.

4R44E Transmission Repair Manual

This guide provides a comprehensive overview for vehicle enthusiasts and mechanics aiming to address common component issues in certain automatic systems. The section highlights essential steps and crucial components, making it easier for users to navigate the process and ensure a smoother function in their vehicle’s mechanism. Through clear instructions and practical insights, readers will gain valuable knowledge for successful restoration and adjustment.

Main Parts and Common Challenges

To achieve optimal performance, it’s essential to understand the primary elements involved in the reconditioning process. The table below lists some of the critical components and potential obstacles you may encounter during the maintenance procedures, alongside tips for effective handling.

| Component | Common Issue | Solution Tips |

|---|---|---|

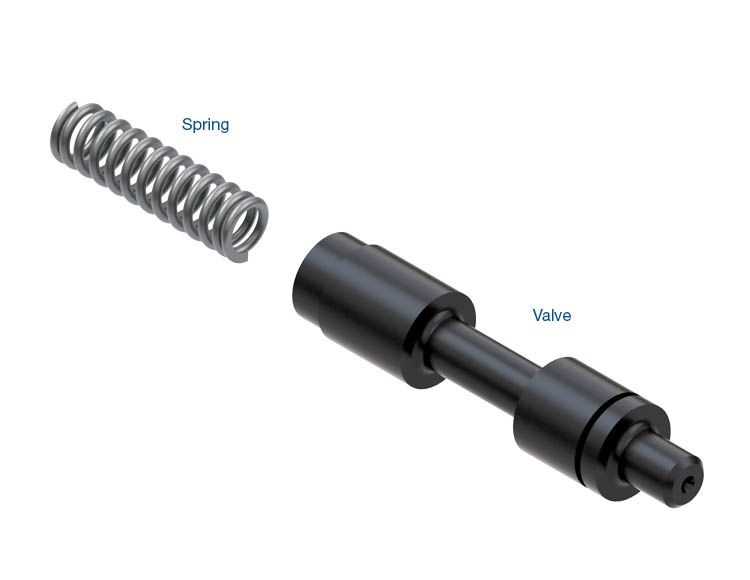

| Valve Body | Clogging due to debris | Clean thoroughly and inspect for wear |

| Fluid Pump | Low pressure output | Replace or rebuild pump components |

| Seals and Gaskets | Leakage from aging or wear | Ensure proper sealing and consider replacement |

| Clutch Plates | Slipping during operation | Check for wear and replace as necessary |

Testing and Final Adjustments

Upon completing the reconditioning process, testing and calibration are essential to confirm functionality. Adjustments to pressure and proper alignment of parts play a crucial role in achieving seamless operation. Careful observation during test runs can reveal minor issues that may need further tuning to ensure durability and efficiency.

Understanding the 4-Speed Automatic Gearbox

The inner workings of this 4-speed unit demonstrate a blend of efficiency and durability designed to handle varying road conditions. Known for its versatility, this system uses a combination of hydraulic and electronic controls to deliver smooth shifting and optimal power distribution. Its compact design allows for reliable integration into various vehicle models, supporting both day-to-day driving and more demanding applications.

Key Components and Functions

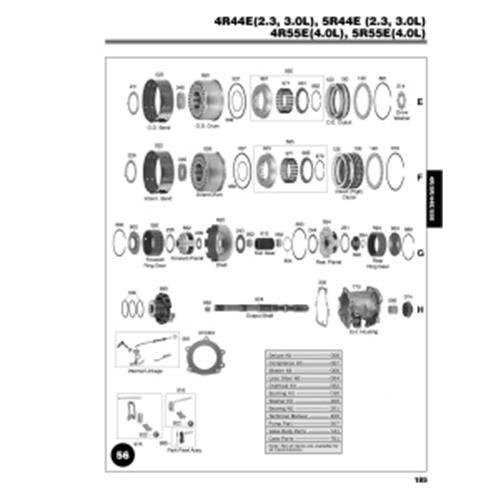

At the core of the mechanism are several primary elements, including a torque converter, planetary gears, and a valve body. The torque converter replaces a traditional clutch and enables smooth acceleration and deceleration by managing the engine’s rotational force. Planetary gears, in turn, provide multiple gear ratios, allowing the system to adjust seamlessly to speed and load changes. The valve body acts as the control center, directing hydraulic fluid to various components for precise gear engagement.

Benefits of Electronic Control

One notable advantage of this model is its electronic management system, which adjusts shifting patterns based on input from vehicle sensors. This adaptive approach enhances fuel efficiency and provides a smoother ride by tailoring the gear changes to driving conditions and performance demands. The electronic control also enables quicker diagnostics, allowing for timely adjustments that maintain the unit’s longevity.

Common Issues and Symptoms

This section outlines typical problems and warning signs that can indicate mechanical or operational inconsistencies in vehicle systems. Understanding these signs early on can be crucial for maintaining overall functionality and preventing further complications.

Unusual Sounds

One of the most noticeable indicators of internal issues is the presence of strange sounds. Drivers may hear grinding, whining, or humming noises, especially during gear shifts or while the vehicle is in motion. These sounds often suggest internal wear or improper alignment within the system, warranting immediate attention.

Performance Irregularities

Another common symptom includes unusual performance shifts, such as delayed engagement, erratic gear changes, or a sudden loss of response while driving. These irregularities can affect acceleration and handling, often becoming more apparent at specific speeds or under increased load.

Diagnosing Transmission Problems

Identifying issues in a vehicle’s power-shift system involves careful observation of performance and behavior during operation. These systems are crucial for smooth and efficient motion, and any inconsistency can signal underlying mechanical or electronic faults. By examining specific symptoms and conditions, drivers can pinpoint whether adjustments, maintenance, or further investigation are needed.

One common sign of potential issues is unusual noises, such as grinding or whining sounds, often heard during acceleration or deceleration. These sounds can indicate wear in internal components or a need for lubrication adjustments. Observing how the system engages and disengages can also be insightful, as delays or irregular shifts may reflect internal imbalances or fluid pressure concerns.

Another key indicator is unexpected vibrations or shudders when the vehicle changes speed or direction. Such vibrations can suggest alignment issues, component wear, or malfunctioning valves. Monitoring system responsiveness can reveal if further diagnostics are required to assess internal wear levels and pinpoint specific areas needing attention.

Fluid inspection is another essential diagnostic step. Observing fluid color, consistency, and level can often reveal system health. Dark, burnt-smelling fluid may suggest overheating, while low levels can lead to performance irregularities. Routine checks ensure that the system remains lubricated and that any leaks or contaminations are identified early.

Overall, paying attention to these warning signs can guide effective diagnostics, helping prevent minor issues from becoming costly repairs. A proactive approach with regular assessments enables better performance, safety, and longevity for the entire driving system.

Essential Tools for Repair

When it comes to mechanical maintenance, having the right set of equipment is fundamental for effective and efficient work. These tools not only streamline the process but also ensure each task is performed with precision and safety. This section will outline key equipment that every mechanic or enthusiast should consider to make challenging tasks simpler and to improve results.

Basic Hand Tools

Basic hand tools are a must-have in any toolkit, as they’re needed for a wide range of tasks. Consider having the following essentials on hand:

- Wrenches: Adjustable, box-end, and open-end wrenches are useful for gripping and turning bolts and nuts of different sizes.

- Screwdrivers: Both flathead and Phillips screwdrivers in multiple sizes are essential for assembling and disassembling various components.

- Pliers: Pliers come in different types, such as needle-nose and slip-joint, providing a strong grip for handling small parts and difficult-to-reach places.

- Torque Wrench: This tool is necessary to apply a specific torque to bolts and nuts, helping avoid over-tightening or damage.

Advanced Diagnostic and Specialty Tools

While basic tools are crucial, certain specialized tools make more technical work easier and more accurate.

- Diagnostic Scanner: Useful for identifying issues electronically and providing quick insights into underlying problems.

- Hydraulic Jack: A sturdy jack with sufficient lifting capacity is essential for safely elevating vehicles to access underside areas.

- Measuring Instruments: Calipers and micrometers help in precise measurements, ensuring parts fit perfectly and meet required specifications.

- Pry Bars: Used to apply leverage on various parts during removal or adjustment, making disassembly easier.

Equipping yourself with these tools can significantly enhance your ability to handle both routine maintenance and more intricate work, allowing for a more seamless and professional experience.

Removing the Transmission Safely

When it comes to detaching the power transfer system from your vehicle, ensuring safety is paramount. This process requires careful planning and execution to prevent accidents or damage to components. Following a systematic approach will help achieve a successful removal while safeguarding both yourself and the vehicle.

Before beginning, gather the necessary tools and equipment. Here are some crucial steps to consider:

- Prepare the Workspace:

- Ensure the area is well-lit and free of obstacles.

- Have adequate ventilation to avoid inhaling fumes.

- Use appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Disconnect the Battery:

- Remove the negative terminal first to prevent electrical shorts.

- Secure the cable away from the terminal to avoid accidental reconnection.

- Support the Vehicle:

- Use jack stands to securely elevate the vehicle.

- Ensure the vehicle is on a flat, stable surface to prevent slipping.

- Drain Fluids:

- Locate and drain any fluids from the system to prevent spills.

- Dispose of fluids according to local regulations.

- Disconnect Components:

- Carefully detach any linkage, wiring, and mounts connecting the power unit to the chassis.

- Label connections to ensure correct reassembly later.

- Remove the Assembly:

- Use a hoist or transmission jack for support while removing.

- Ensure all connections are free before attempting to lift the unit.

By adhering to these guidelines, you can ensure a safe and efficient detachment of the power transfer unit, setting the stage for further servicing or replacement as needed.

Inspecting Internal Components

Evaluating the inner elements of an automotive system is crucial for ensuring optimal performance and longevity. A thorough examination helps identify wear, damage, or misalignment that could affect functionality.

Key areas to focus on during the inspection include:

- Gear Sets: Check for signs of wear or scoring on the gears.

- Shafts: Inspect for bends, cracks, or other imperfections.

- Bearings: Look for signs of wear and ensure they rotate smoothly.

- Seals and Gaskets: Examine for leaks or degradation that could lead to fluid loss.

To conduct a comprehensive evaluation, follow these steps:

- Disassemble the unit carefully to avoid damaging components.

- Clean all parts thoroughly to remove any debris or contaminants.

- Use precise measuring tools to assess tolerances and clearances.

- Document any findings, noting specific areas of concern for further attention.

By diligently inspecting the internal elements, one can effectively maintain and enhance the overall functionality of the system.

Replacing Worn-Out Parts

When components begin to show signs of fatigue, their replacement is crucial to maintain optimal functionality and performance. Over time, the wear and tear on various elements can lead to inefficiencies and potential failures. Addressing these issues promptly not only enhances the overall efficiency but also prolongs the lifespan of the entire system.

Identifying worn-out components is the first step in the process. Common indicators include unusual noises, decreased performance, and visible signs of damage. Once identified, removing these outdated parts requires careful disassembly. It is essential to use the appropriate tools and follow the recommended procedures to prevent any additional damage.

After successfully extracting the obsolete parts, the next step involves sourcing high-quality replacements. Opt for components that meet or exceed the original specifications to ensure compatibility and reliability. Installing the new parts should be executed with precision, adhering to the manufacturer’s guidelines to guarantee proper fitment and function.

Finally, conducting a thorough inspection after installation is vital. This ensures that everything operates as intended and that no additional adjustments are necessary. Regular maintenance checks will help in identifying potential issues early, allowing for timely interventions that can save time and resources in the long run.

Transmission Fluid Types and Tips

Understanding the various types of fluid used in vehicle gear systems is essential for maintaining optimal performance and longevity. The right selection can enhance shifting quality, prevent wear, and ensure smooth operation. In this section, we will explore the different categories of these essential fluids and provide practical advice for their use.

Types of Fluids

Different formulations are available, each designed to meet specific performance requirements. Here’s a summary of the main types:

| Type | Description | Use Case |

|---|---|---|

| Conventional | Standard formulation, suitable for older models. | Basic vehicles with simple gear systems. |

| Synthetic | Engineered for high performance, offers superior protection. | Modern cars and heavy-duty applications. |

| Multi-Vehicle | Compatible with a variety of makes and models. | Useful for owners with multiple vehicles. |

Usage Tips

To ensure optimal functioning, consider the following tips:

- Check fluid levels regularly to avoid overheating.

- Follow the manufacturer’s recommendations for fluid change intervals.

- Use the correct type of fluid as specified in the vehicle’s documentation.

- Monitor for signs of contamination, such as unusual color or smell.

Reassembly and Installation Guide

This section provides detailed instructions for the proper reassembly and installation of your unit. Following these guidelines will ensure optimal performance and longevity. Careful attention to each step is crucial to avoid any issues that may arise during or after the process.

Preparation: Before you begin, ensure that all components are clean and free of debris. Gather all necessary tools and parts to streamline the reassembly process.

Step-by-Step Reassembly:

- Start by aligning the major components, ensuring that all parts fit together smoothly.

- Secure each piece using the appropriate fasteners, adhering to the specified torque values.

- Inspect all seals and gaskets for damage; replace if necessary to prevent leaks.

- Carefully connect any electrical components, ensuring proper alignment and secure connections.

Final Checks: After assembly, double-check all connections and fasteners. Verify that moving parts operate freely without obstruction. Make sure that fluid levels are appropriate before proceeding to the installation phase.

Installation: Position the unit back into its designated location, ensuring that all brackets and mounts align correctly. Tighten all securing hardware to the specified torque values. Reconnect any necessary hoses, wiring, or linkages, confirming that everything is securely in place.

Following this guide will help achieve a successful reassembly and installation, contributing to the overall reliability and functionality of your system.

Testing the Repaired Transmission

After addressing the issues within the drivetrain component, it is crucial to verify its functionality to ensure optimal performance. This evaluation process involves a series of steps designed to assess the efficiency and reliability of the system after modifications have been made. Proper testing not only confirms that previous faults have been rectified but also guarantees that the assembly operates smoothly under various conditions.

Initial Check-Up

Begin by inspecting the installation of the unit to ensure all connections are secure. Look for any signs of leaks or irregularities in the fluid levels. Ensuring that all components are properly fitted will lay the groundwork for a successful evaluation.

Road Test

Conduct a controlled drive to monitor how the assembly performs under real-world conditions. Pay attention to shifting patterns, noise levels, and any unusual vibrations. It is essential to evaluate the unit under different loads to ascertain that it meets the required performance benchmarks. Any irregularities detected during this phase should be addressed promptly to avoid further complications.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle’s drivetrain components. By implementing a few straightforward practices, you can avoid potential issues and enhance reliability over time.

1. Regular Fluid Checks: Periodically examine the fluid levels and quality. Clean and fresh fluids facilitate smooth operation, while contaminants can lead to wear and failure.

2. Schedule Routine Inspections: Arrange for comprehensive assessments of your vehicle at regular intervals. This proactive approach helps identify wear and potential failures before they escalate.

3. Monitor Driving Habits: Pay attention to your driving style. Smooth acceleration and deceleration can significantly reduce stress on the components, prolonging their lifespan.

4. Keep Components Clean: Maintain cleanliness around critical areas. Dirt and debris can contribute to malfunctioning parts, so regular cleaning is vital.

5. Use Quality Parts: When replacements are necessary, opt for high-quality components. Investing in superior materials can prevent premature failures and improve overall performance.

By following these guidelines, you can effectively extend the life of your vehicle’s drivetrain and minimize the chances of unexpected issues.