Guide to Repairing the 5L40E Transmission

This section delves into the intricacies of maintaining and restoring automotive gear systems. Understanding the inner workings of these components is essential for any vehicle owner or enthusiast aiming to ensure optimal performance and longevity.

Proper guidance can significantly enhance your ability to address common issues and undertake necessary adjustments. With the right approach and knowledge, you can effectively tackle various challenges associated with these complex mechanisms.

In this resource, we will explore essential techniques and best practices that empower you to engage in successful interventions. Gaining insights into this process will not only enhance your skills but also elevate your confidence when faced with mechanical difficulties.

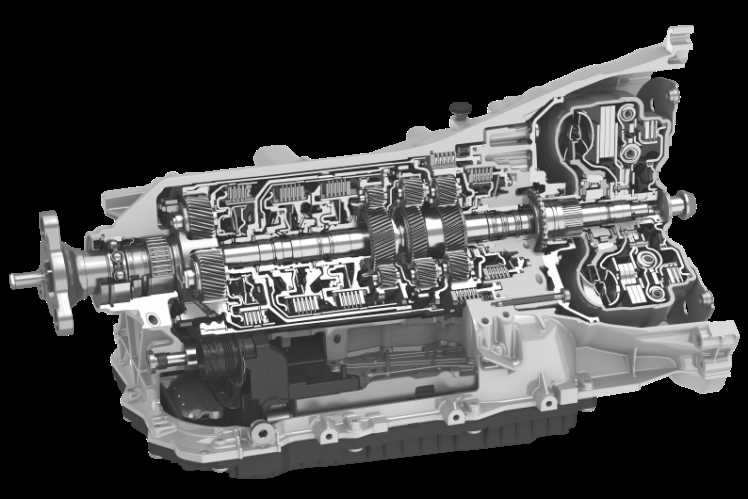

5L40E Transmission Overview

This section provides a comprehensive understanding of a specific automatic gearbox widely used in various vehicles. This system is designed to facilitate smooth power transfer from the engine to the wheels, ensuring optimal performance and efficiency.

Key Features

- Compact design for versatile applications

- Advanced gear shifting technology for improved acceleration

- Integrated electronic controls for enhanced reliability

Common Applications

- Sports utility vehicles (SUVs)

- Light trucks

- Some performance-oriented cars

Understanding the characteristics and applications of this gearbox helps in appreciating its role in modern automotive engineering.

Common Issues with 5L40E

This section discusses frequent problems encountered with a specific automatic gearbox often found in various vehicles. Understanding these issues can help in identifying symptoms and addressing them promptly to ensure optimal performance.

Drivers may experience a variety of challenges, which can range from minor inconveniences to significant malfunctions. Below are some of the most commonly reported problems:

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Slipping | Delayed acceleration, engine revving without speed increase | Low fluid levels, worn clutches |

| Overheating | Warning lights, unusual smells | Fluid contamination, blocked cooler |

| Rough shifting | Harsh transitions between gears | Low fluid levels, damaged solenoids |

| Fluid leaks | Puddles under the vehicle, low fluid levels | Worn seals, damaged pan |

Awareness of these issues can guide users in maintaining their gearbox effectively, prolonging its lifespan and enhancing vehicle reliability.

Tools Needed for Repair

When undertaking the process of fixing automotive components, having the right tools is essential for achieving optimal results. A well-equipped workspace ensures that the task can be completed efficiently and safely, reducing the risk of errors and facilitating a smoother workflow.

Essential Equipment

To get started, certain fundamental instruments are necessary. These tools not only aid in disassembly and assembly but also ensure that all parts are handled correctly. Below is a list of essential items to have on hand:

| Tool | Description |

|---|---|

| Socket Set | A variety of sockets for loosening and tightening bolts of different sizes. |

| Torque Wrench | Used to apply a specific torque to fasteners, ensuring they are tightened to manufacturer specifications. |

| Oil Filter Wrench | Specialized tool for removing and installing oil filters easily. |

| Fluid Pump | Helpful for transferring fluids without mess. |

Additional Tools

In addition to the basic tools, there are several other instruments that can enhance the efficiency of the process. These may include diagnostic equipment and specialized gadgets tailored for specific tasks.

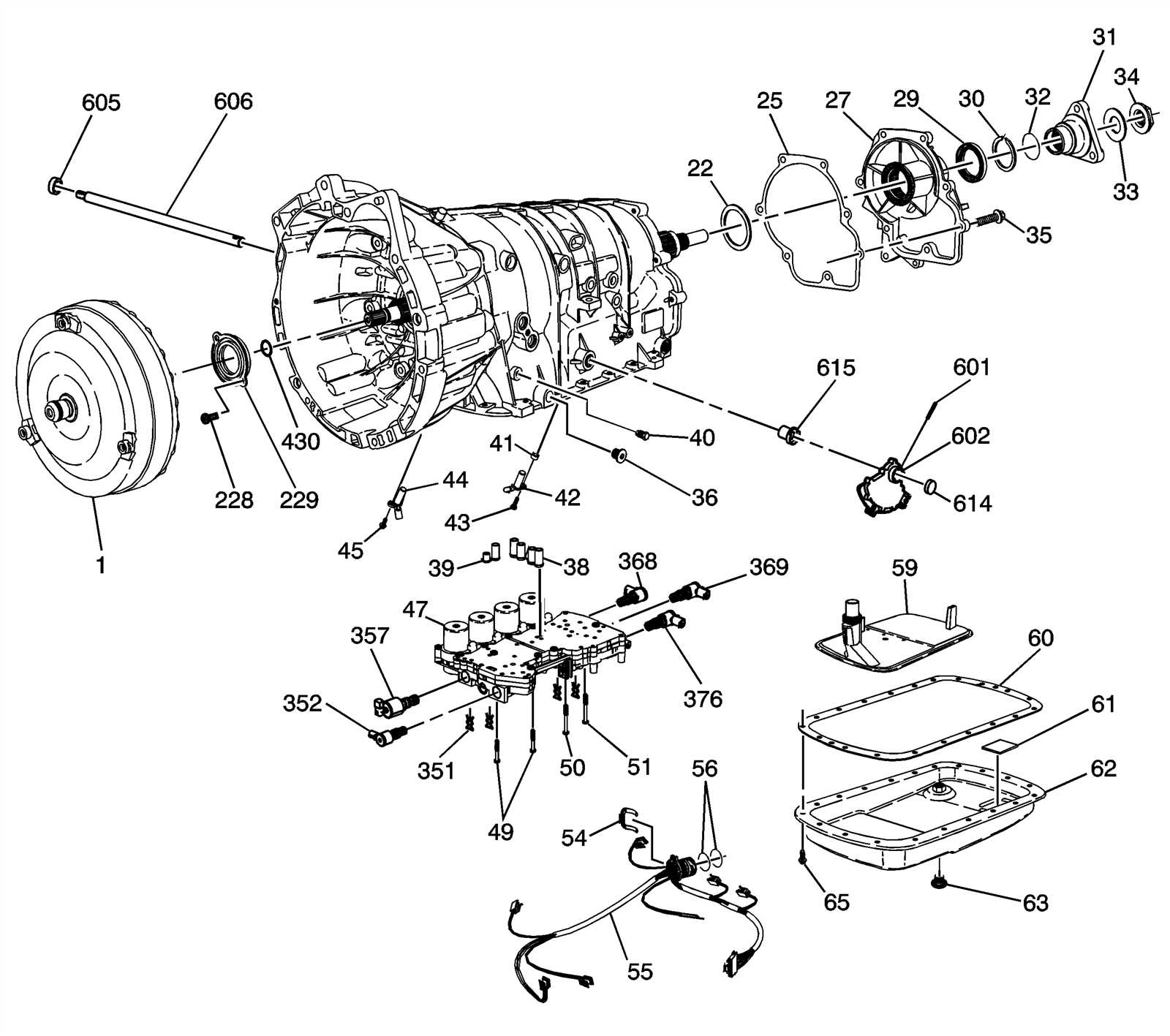

Step-by-Step Disassembly Process

This section outlines the systematic approach to taking apart the mechanical assembly. Understanding the sequence and technique involved is crucial for effective maintenance and troubleshooting. Proper disassembly ensures that components can be assessed and serviced without damage.

Follow these steps for an organized disassembly:

- Prepare the workspace:

- Ensure all necessary tools are available.

- Clear the area to avoid any distractions.

- Take notes or photos of the assembly for reference.

- Label each component as it is removed.

- Loosen screws and bolts carefully.

- Keep track of all fasteners.

- Start with smaller parts, working systematically towards larger assemblies.

- Handle each piece gently to prevent wear or breakage.

- Look for signs of wear, damage, or debris.

- Clean parts as necessary for better visibility.

By adhering to this structured process, one can effectively dismantle the assembly for further examination and servicing.

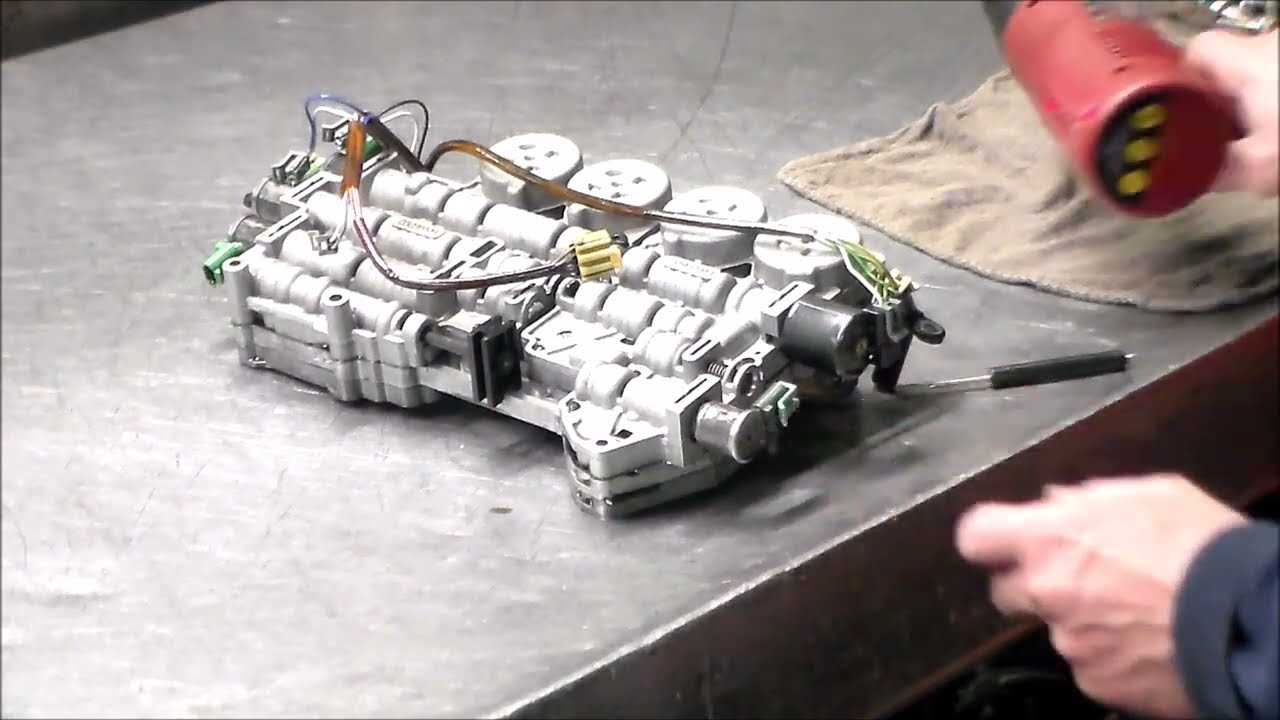

Inspecting Internal Components

When examining the internal elements of a vehicle’s power transfer unit, it is crucial to identify any signs of wear or damage. Thorough inspections can prevent future issues and ensure optimal performance. This process involves a systematic approach to assess each component’s condition.

Visual Inspection

The first step in the assessment involves a detailed visual check. Look for:

- Cracks or fractures in the housing

- Discoloration indicating overheating

- Fluid leaks around seals and gaskets

Component Assessment

After the visual inspection, focus on individual parts to evaluate their functionality:

- Check gears for proper meshing and any signs of pitting.

- Inspect bearings for smooth rotation and any unusual noises.

- Assess clutches and bands for wear and proper engagement.

Reassembly Techniques and Tips

Successful reassembly of complex mechanisms requires careful attention to detail and a systematic approach. This section focuses on effective methods and practical advice to ensure all components fit together seamlessly, enhancing the overall functionality of the unit.

Preparation and Organization

Before starting the reassembly process, it is crucial to organize all parts and tools. Create a clean workspace and utilize containers to keep small items secure. This not only minimizes the risk of losing components but also facilitates a more efficient assembly process. Reviewing any diagrams or documentation beforehand can also provide valuable insights into the proper arrangement of parts.

Step-by-Step Assembly

During reassembly, follow a step-by-step method to ensure that each component is placed correctly. Begin with larger parts and progressively add smaller pieces. Pay special attention to alignment; even minor misalignments can lead to operational issues. Using lubricants where necessary can help reduce friction and ease the assembly of moving parts. Remember to perform periodic checks to confirm that everything is progressing as planned.

Incorporating these techniques will not only enhance the reassembly experience but also contribute to the longevity and performance of the assembled unit.

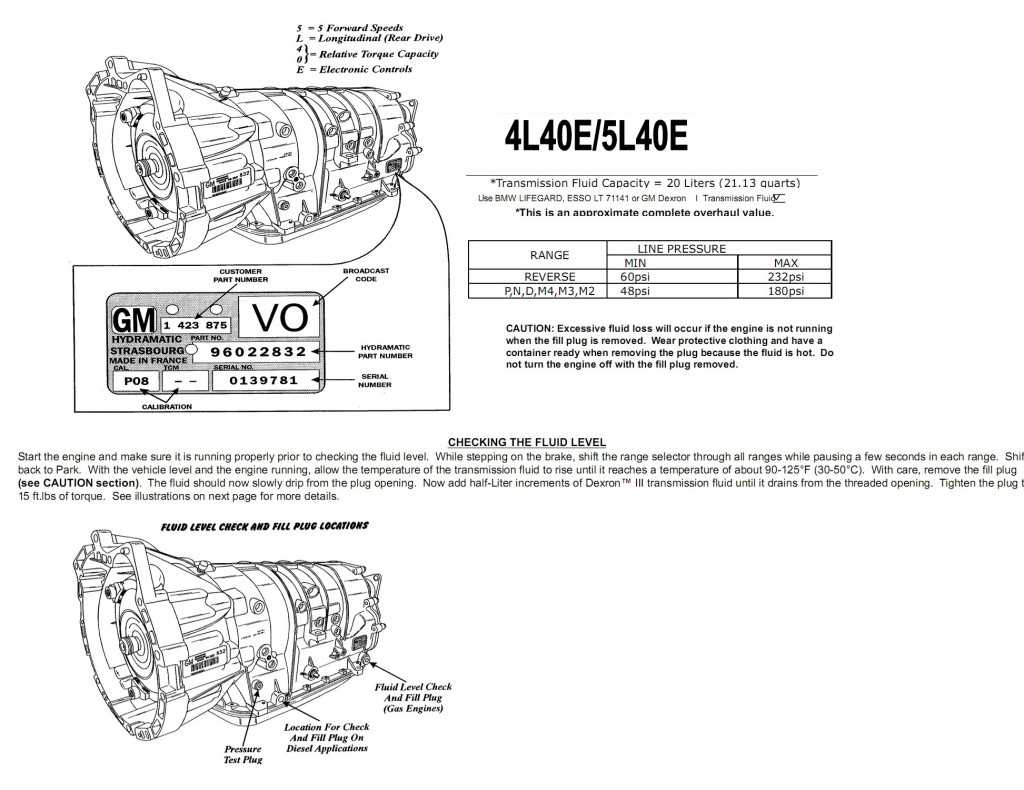

Fluid Requirements and Maintenance

Ensuring optimal performance of any vehicle’s power delivery system requires attention to fluid specifications and regular upkeep. The right type of lubricant is essential for maintaining efficiency and extending the lifespan of the components involved. Proper care not only enhances functionality but also prevents potential issues that could arise from neglecting these crucial elements.

It is vital to use the recommended type of lubricant that meets the manufacturer’s specifications. The right fluid ensures smooth operation and minimizes wear and tear on the internal parts. Regular checks and changes of the lubricant are equally important. Over time, contaminants can accumulate, leading to reduced effectiveness and potential damage. Routine maintenance schedules should be established to monitor fluid levels and quality.

Additionally, attention to the seals and gaskets is essential to prevent leaks, which can compromise the entire system. Keeping a close eye on these components can help avoid costly repairs in the future. Regular inspections and adherence to maintenance guidelines will contribute significantly to the longevity and reliability of the power delivery system.

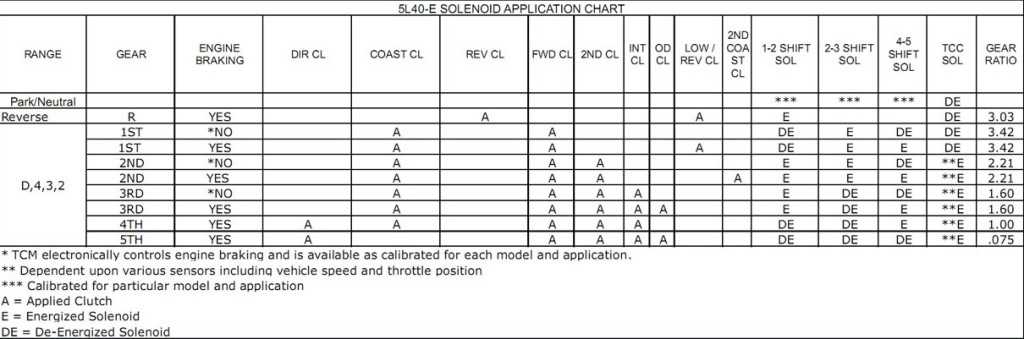

Diagnostic Procedures for Transmission

Accurate identification of issues within a vehicle’s shifting mechanism is essential for effective maintenance and troubleshooting. This section outlines systematic approaches to assess performance, pinpoint malfunctions, and ensure optimal functioning of the system.

Visual Inspection

Begin by examining the external components for any obvious signs of wear or damage. Key areas to focus on include:

- Fluid leaks around seals and connections

- Physical wear on casing and mounts

- Condition of electrical connections and wiring

Fluid Condition Analysis

The state of the hydraulic fluid can provide significant insights into the overall health of the mechanism. Consider the following:

- Check for discoloration or burnt smell, indicating overheating

- Assess fluid level and consistency; low or contaminated fluid can affect performance

- Perform a fluid change if contamination is detected to prevent further damage

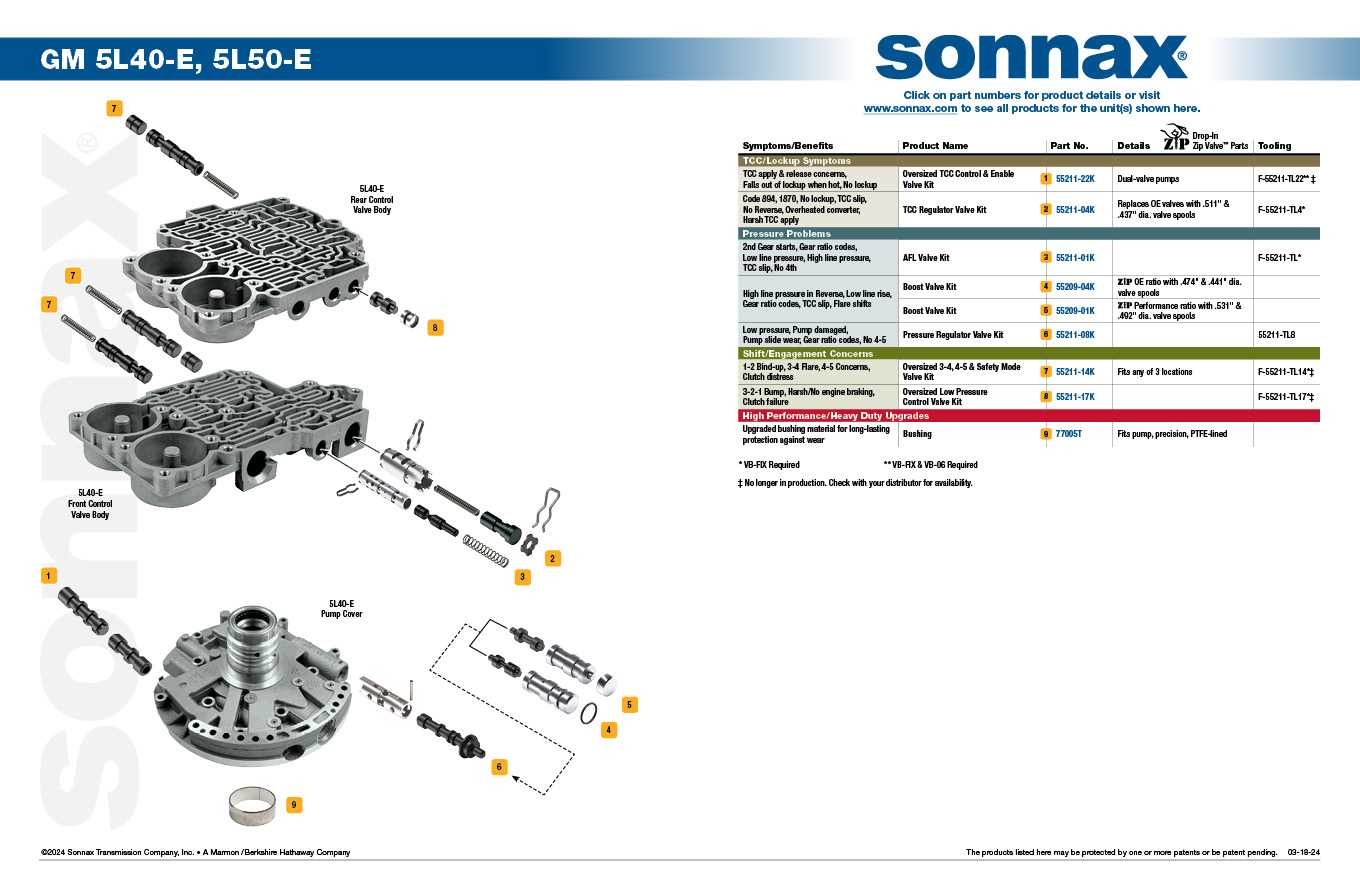

Upgrading 5L40E Performance

Enhancing the efficiency and responsiveness of an automatic power transfer system can significantly improve vehicle performance. By implementing various modifications, enthusiasts can achieve better acceleration, increased durability, and a more engaging driving experience.

One effective approach involves the installation of high-performance components that can handle greater power levels. Upgrading the fluid pump can lead to improved lubrication and cooling, while enhanced valve bodies can provide more precise control over gear shifts. Additionally, utilizing stronger clutches and bands will ensure that the system can withstand increased torque without failure.

Another critical aspect is recalibrating the electronic control unit. Adjusting the settings allows for optimized shift points and quicker response times, which results in a more dynamic driving experience. Moreover, fine-tuning the programming can adapt the system to match individual driving styles and performance expectations.

Finally, regular maintenance and monitoring of the fluid quality are essential for sustained performance. Utilizing high-quality fluids and filters will help maintain optimal functioning, reducing wear and extending the lifespan of the system. Overall, these upgrades not only enhance performance but also contribute to a more enjoyable driving experience.

Common Mistakes to Avoid

When undertaking complex mechanical tasks, certain pitfalls can hinder the process and lead to undesirable outcomes. Understanding these common errors can greatly improve the chances of a successful project. Below are some key mistakes to watch out for when addressing vehicle transmission issues.

| Error | Description |

|---|---|

| Neglecting Preparation | Failing to gather all necessary tools and components can lead to interruptions and frustration during the process. |

| Ignoring Manufacturer Guidelines | Disregarding specific instructions provided by the manufacturer can result in improper handling and potential damage. |

| Overlooking Safety Measures | Forgetting to implement safety precautions can pose serious risks to personal safety and equipment integrity. |

| Rushing the Process | Attempting to complete tasks too quickly may lead to mistakes and oversights that could compromise the entire operation. |

| Insufficient Testing | Failing to thoroughly test the system after modifications can leave undetected issues that may lead to further complications. |

Testing the Repaired Transmission

After completing the necessary modifications to the gear system, it is crucial to conduct thorough evaluations to ensure optimal performance. This phase focuses on verifying that all adjustments have been successful and that the mechanism operates smoothly under various conditions.

To effectively assess the functionality, follow these essential steps:

- Conduct a visual inspection to identify any visible issues.

- Check fluid levels and ensure there are no leaks.

- Perform a static test to assess responsiveness without driving.

- Engage the system in different gears to evaluate shifting quality.

- Take the vehicle for a test drive, monitoring for unusual noises or behavior.

During the test drive, pay attention to:

- Smoothness of gear transitions

- Acceleration and deceleration responses

- Any warning indicators on the dashboard

- Overall driving comfort and performance

If any irregularities arise, further investigation may be necessary to address potential concerns. Consistent testing ensures reliability and enhances the longevity of the system.

Warranty and Service Considerations

When dealing with vehicle powertrain components, understanding the coverage and support options available is essential for ensuring long-term reliability. Proper knowledge of warranty terms and service guidelines can significantly enhance the ownership experience.

Coverage typically varies based on manufacturer policies, and it’s crucial to be aware of what is included in the warranty. Regular maintenance plays a vital role in preserving these components and may influence warranty validity. It’s advisable to follow recommended service intervals and use appropriate fluids and parts to maintain performance standards.

| Aspect | Consideration |

|---|---|

| Warranty Period | Understand the duration and coverage limits for repairs. |

| Service Requirements | Adhere to recommended maintenance schedules to keep coverage valid. |

| Authorized Service Centers | Utilize certified facilities for repairs to maintain warranty status. |

| Documentation | Keep all service records and receipts to support any warranty claims. |

By paying attention to these factors, vehicle owners can ensure optimal performance and reliability, minimizing unexpected costs associated with powertrain issues.

Resources for Further Learning

Exploring the intricacies of automotive systems can greatly enhance your understanding and skills. There are various avenues available for those looking to deepen their knowledge, whether through books, online courses, or community forums.

Books and Guides

- Comprehensive automotive handbooks

- Detailed guides focused on specific systems

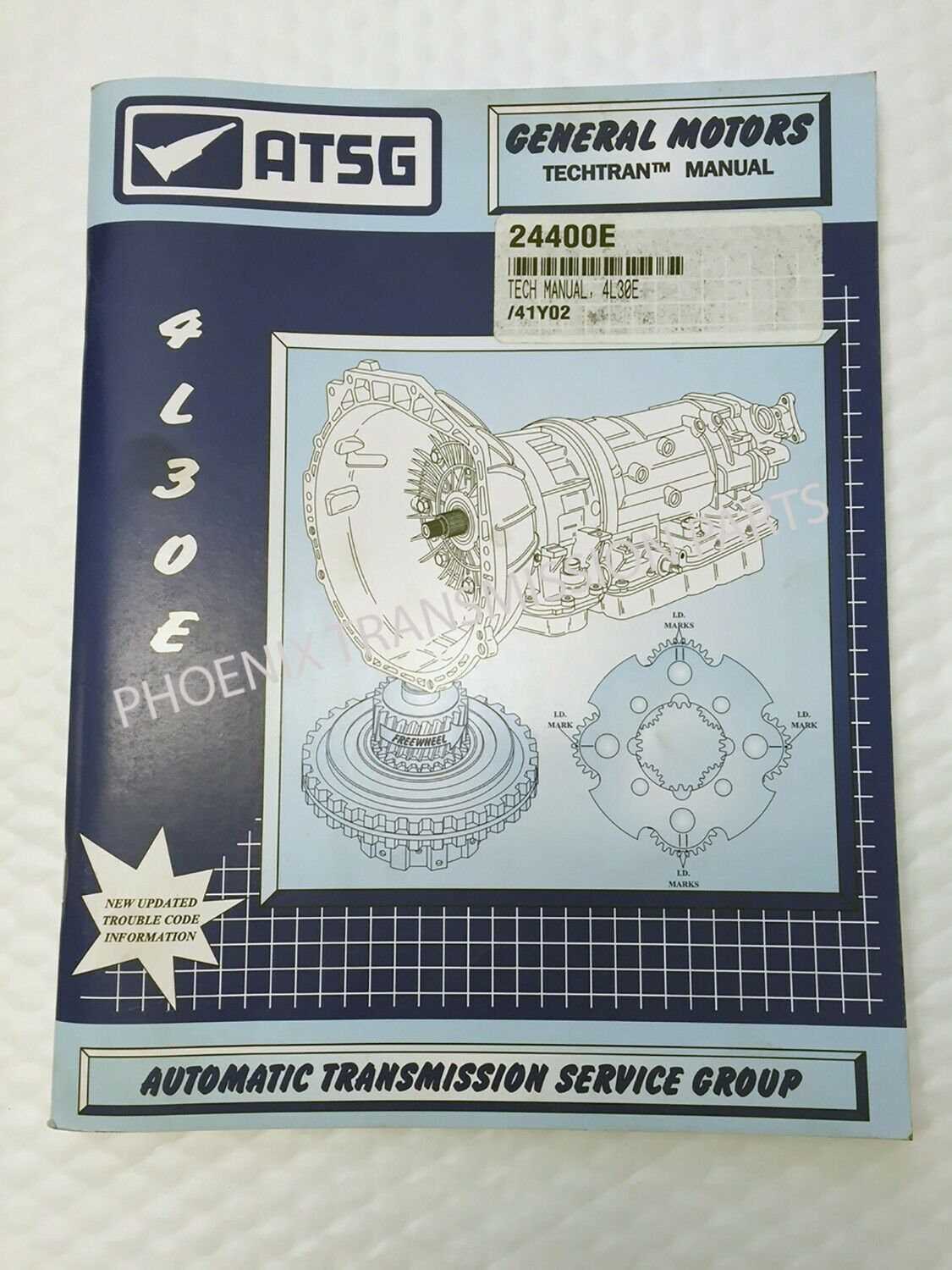

- Technical manuals from reputable publishers

Online Learning Platforms

- Video tutorials on specialized websites

- Interactive courses offered by automotive schools

- Webinars featuring industry experts

Engaging with these resources can provide valuable insights and practical skills necessary for tackling various automotive challenges.