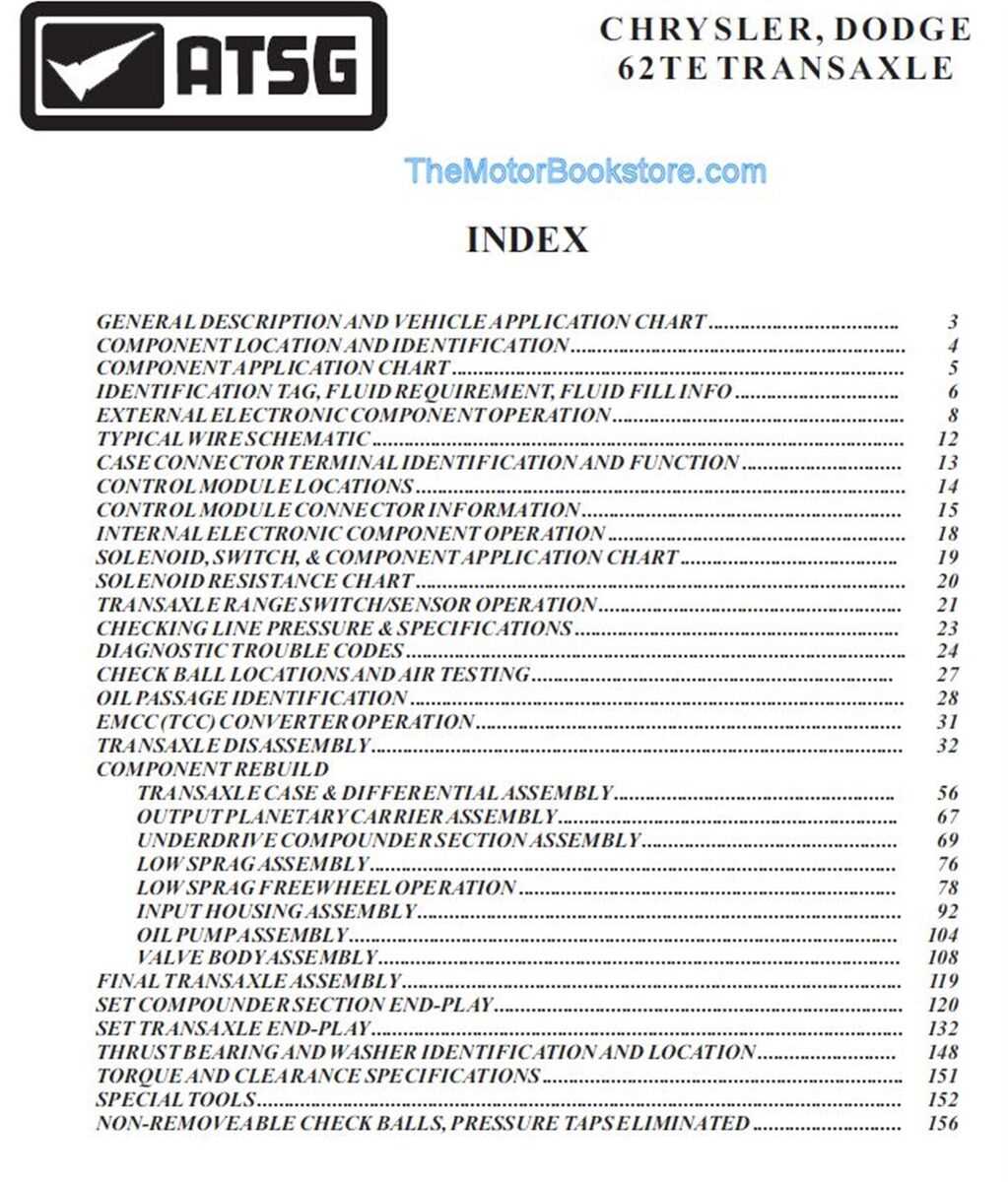

Comprehensive Guide to 62TE Transmission Repair

Understanding the intricacies of automotive power delivery systems is essential for anyone involved in vehicle maintenance or enhancement. These complex mechanisms play a crucial role in ensuring that power from the engine is effectively transferred to the wheels, providing the performance and efficiency that drivers expect. This section delves into the vital components and functions, offering insights into diagnostics, service procedures, and troubleshooting techniques.

Proper knowledge of these systems can significantly extend the lifespan of your vehicle and enhance its performance. Whether you are a seasoned technician or a dedicated car enthusiast, familiarizing yourself with the specific nuances can help you tackle common challenges with confidence. We will explore essential aspects that contribute to the overall functionality, ensuring you are well-prepared for any situation.

Moreover, understanding these systems can empower you to make informed decisions regarding maintenance and potential upgrades. By mastering the details, you can optimize both the reliability and efficiency of your vehicle, ensuring a smooth and responsive driving experience. This guide aims to equip you with the necessary tools and insights to navigate this intricate world with ease.

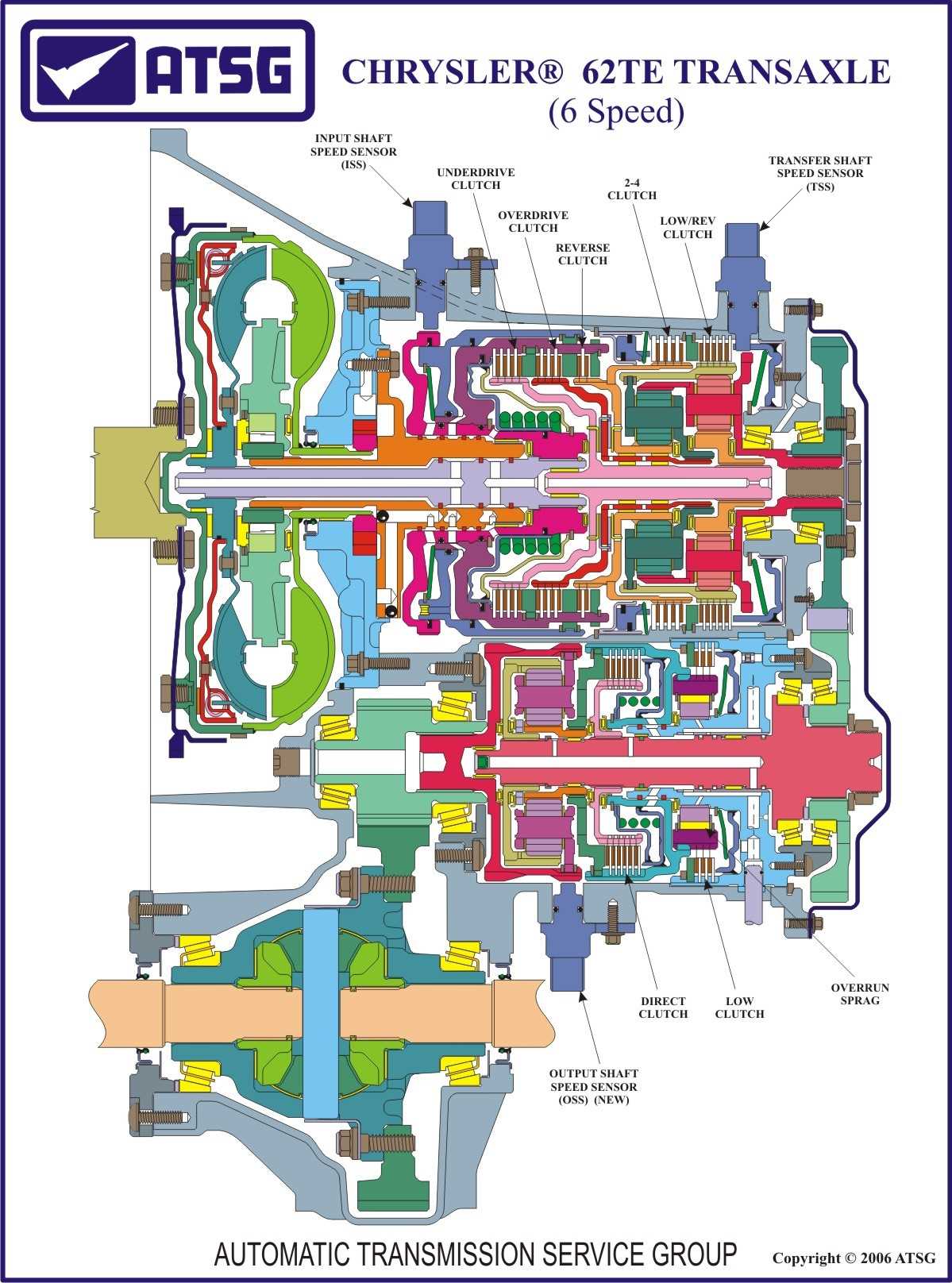

Understanding the 62TE Transmission

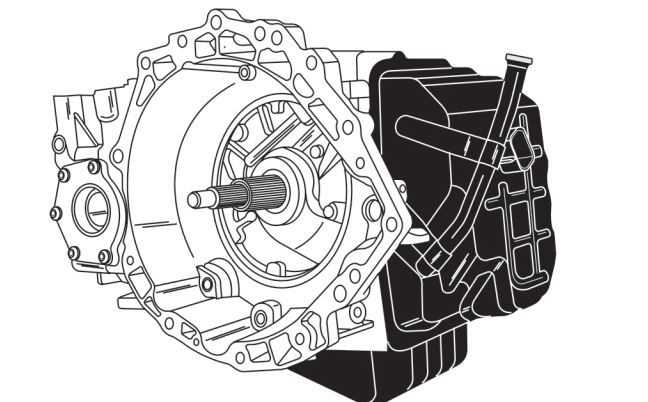

The 62TE system is a vital component in many vehicles, serving as a bridge between the engine and the wheels. This mechanism ensures optimal power delivery while maintaining efficiency. Understanding its workings is essential for anyone looking to maintain or enhance vehicle performance.

At its core, this assembly is designed to manage the shifting of gears automatically, adapting to driving conditions and the driver’s behavior. By utilizing hydraulic pressure and sophisticated electronic controls, it provides smooth transitions that enhance both comfort and control during operation.

One key feature of this setup is its ability to respond to various driving situations. For instance, it can adjust shift points based on factors such as speed, load, and throttle position. This adaptability contributes to better fuel economy and improved overall performance, making it a crucial element in modern automotive engineering.

Regular maintenance and awareness of potential issues can prolong the lifespan of this complex system. Understanding its components and how they interact can help vehicle owners diagnose problems early, ensuring safe and reliable operation.

In conclusion, familiarity with this essential assembly not only empowers drivers but also enhances their ability to manage their vehicle’s performance effectively. Whether for personal use or professional endeavors, knowledge of its functionality can lead to better decision-making and greater satisfaction on the road.

Common Issues with the 62TE

Many vehicle owners encounter a variety of challenges related to their automatic gearbox, which can significantly affect driving performance. Understanding these frequent problems can help in identifying symptoms early and seeking appropriate solutions.

Frequent Problems

- Slipping: This often manifests as a noticeable delay in acceleration, causing the engine to rev higher than usual without corresponding vehicle speed increase.

- Shifting Delays: A lag between pressing the accelerator and the vehicle responding can indicate internal issues.

- Fluid Leaks: Transmission fluid leaks can lead to low fluid levels, which may result in overheating and further damage.

- Unusual Noises: Grinding or whining sounds while the vehicle is in gear may signal mechanical wear or failure.

Diagnosis and Prevention

- Regular Maintenance: Adhering to a strict maintenance schedule can help catch potential issues before they escalate.

- Fluid Checks: Regularly inspect fluid levels and quality, replacing it as necessary to ensure smooth operation.

- Professional Inspections: Consulting a qualified technician for periodic evaluations can help identify underlying problems early on.

Essential Tools for Repairs

When tackling mechanical challenges, having the right instruments is crucial for achieving successful outcomes. A well-equipped workspace enhances efficiency and ensures that each task is performed with precision. Below is a compilation of indispensable tools that every enthusiast or professional should consider for their toolkit.

Basic Hand Tools

- Wrenches: Adjustable and fixed varieties to handle various fasteners.

- Screwdrivers: A set of both flathead and Phillips to accommodate different screws.

- Pliers: Needle-nose and slip-joint options for gripping and bending.

- Sockets: A socket set allows for easy loosening and tightening of nuts and bolts.

Specialized Instruments

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

- Oil Filter Wrench: Designed for easy removal and installation of filters.

- Diagnostic Scanner: Helps identify issues through electronic system analysis.

- Fluid Transfer Pump: Useful for moving liquids in a clean and efficient manner.

Equipping yourself with these essential tools will not only streamline your workflow but also enhance the overall quality of your projects. A comprehensive set of instruments prepares you for any task, big or small.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues in the drivetrain system of vehicles. By following a structured sequence of actions, individuals can effectively diagnose and resolve common challenges. Each stage is crucial for ensuring optimal performance and longevity of the equipment.

Preparation and Diagnosis

Before diving into the hands-on work, it’s essential to gather the necessary tools and materials. Conducting a thorough assessment will help pinpoint the problem areas. This phase sets the foundation for a successful intervention.

Disassembly and Inspection

Once the diagnosis is clear, the next step involves carefully dismantling the components. Attention to detail during this stage is vital to prevent damage. Inspect each part for wear or malfunction, as this will inform the subsequent actions required for restoration.

| Component | Common Issues | Recommended Actions |

|---|---|---|

| Gear Set | Worn teeth | Replace or recondition |

| Seals | Leaks | Replace with new seals |

| Fluid | Contamination | Flush and refill |

| Clutch Assembly | Slippage | Inspect and replace worn components |

Fluid Maintenance and Replacement

Regular upkeep of fluids is crucial for the longevity and efficiency of your vehicle’s components. Proper management of these essential liquids helps to prevent wear and tear, ensuring optimal performance. Neglecting this aspect can lead to significant issues, including overheating and mechanical failure.

Importance of Fluid Changes

Over time, fluids can become contaminated with debris and lose their effectiveness. Routine changes are necessary to maintain proper viscosity and lubrication, which directly impacts the overall functionality of various systems. By adhering to a consistent schedule for replacement, you can avoid costly repairs and extend the lifespan of your vehicle.

Fluid Replacement Schedule

Below is a recommended timeline for fluid changes to keep your vehicle operating smoothly:

| Fluid Type | Recommended Change Interval |

|---|---|

| Engine Oil | Every 5,000 – 7,500 miles |

| Coolant | Every 30,000 – 50,000 miles |

| Brake Fluid | Every 2 years |

| Power Steering Fluid | Every 50,000 miles |

| Differential Fluid | Every 30,000 – 60,000 miles |

By adhering to these guidelines, you can significantly enhance the reliability and performance of your vehicle, ensuring a safer driving experience.

Diagnostic Techniques for Transmission Problems

Identifying issues within a vehicle’s shifting mechanism requires a systematic approach. Proper diagnostics can help pinpoint the root cause of performance anomalies, enabling effective solutions. Utilizing a combination of observational skills and technical knowledge enhances the accuracy of the diagnostic process.

Observation and Initial Assessment

Begin by conducting a thorough visual inspection. Check for fluid leaks, worn components, and any signs of damage. Pay attention to unusual sounds during operation, as these can indicate underlying mechanical issues. Documenting symptoms is crucial for a clear understanding of the problem and will aid in communicating with professionals if needed.

Diagnostic Tools and Techniques

Utilize specialized equipment to gather data on performance. Scan tools can provide valuable information by reading error codes from the vehicle’s computer system. Performing a road test allows for real-time observation of shifts and responsiveness. Additionally, pressure tests can reveal potential problems with hydraulic systems, while fluid analysis can indicate wear and contamination. Combining these methods leads to a more comprehensive diagnosis, facilitating effective intervention.

Upgrading Components for Better Performance

Enhancing the efficiency and responsiveness of your vehicle often involves upgrading various components that play a crucial role in its overall functionality. By carefully selecting and replacing specific parts, you can achieve significant improvements in power delivery, handling, and durability. This section delves into the benefits and considerations associated with component enhancements.

One of the most impactful areas to focus on is the drivetrain, where optimized gears and improved fluid dynamics can lead to a more agile and powerful experience. Additionally, investing in higher-quality materials can enhance strength and longevity, reducing the likelihood of future issues. Evaluating performance parts that offer better thermal management can also prevent overheating and ensure consistent operation under demanding conditions.

Another critical aspect is electronic systems. Upgrading to advanced control modules or sensors can enhance responsiveness and adaptability, providing a smoother driving experience. These technologies can also allow for finer tuning of performance parameters, enabling personalized settings that suit individual driving styles.

Ultimately, a well-rounded approach to upgrading components not only enhances performance but also contributes to the overall enjoyment and reliability of your vehicle. Careful planning and selection of high-quality upgrades can lead to remarkable transformations, making every journey more exhilarating.

Safety Precautions During Repairs

When engaging in complex mechanical tasks, prioritizing safety is crucial to prevent accidents and injuries. Understanding the inherent risks involved in hands-on work helps ensure a secure environment for both the technician and the vehicle. Adhering to proper protocols not only protects individuals but also enhances the overall efficiency of the process.

Always begin by wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This gear acts as a first line of defense against potential hazards. Additionally, maintaining a clean and organized workspace minimizes the risk of tripping or mishandling tools and components.

Before commencing any work, disconnect the vehicle’s battery to avoid electrical shocks and short circuits. It’s also advisable to consult relevant guidelines and specifications to familiarize yourself with the task at hand. If lifting heavy parts, utilize jacks and supports designed for this purpose, ensuring stability to prevent collapse.

Furthermore, keeping a fire extinguisher nearby can be beneficial, especially when working with flammable materials. Always remain vigilant and avoid distractions during the process. Being mindful of these precautions contributes to a safer and more effective working atmosphere.

Comparing 62TE to Other Transmissions

This section explores the unique characteristics and performance aspects of a specific automatic gearbox in relation to other similar systems available in the automotive market. Understanding these differences is crucial for enthusiasts and professionals alike, as it sheds light on the advantages and potential drawbacks of various designs.

Design and Efficiency

The examined system boasts a distinct design that enhances fuel efficiency and smooth shifting. Compared to conventional systems, it employs advanced technology to optimize power delivery, which can result in improved driving dynamics. Many alternatives may not offer the same level of responsiveness, making this option particularly appealing for those seeking a balance between performance and economy.

Durability and Maintenance

When assessing longevity, this unit demonstrates remarkable durability under various driving conditions. While some competitors may require more frequent upkeep, this system is engineered to withstand wear and tear, ultimately leading to lower maintenance costs over time. Such resilience can be a deciding factor for users looking for reliability in their vehicles.

Cost Estimates for Repair Services

Understanding the financial implications of vehicle servicing is crucial for informed decision-making. Various factors influence the overall expenses associated with fixing complex systems within automobiles. This section provides an overview of potential costs, helping vehicle owners anticipate their budgetary needs.

Factors Influencing Costs

The pricing for service interventions can vary widely based on several elements. Labor rates are often dictated by the region and the expertise of the technicians involved. Additionally, the type of issue being addressed significantly impacts the final bill; more intricate problems typically require more time and specialized skills. Furthermore, the availability of parts and their associated costs can also sway the total expenditure.

Average Cost Ranges

On average, customers can expect to pay anywhere from $500 to $3,000 for comprehensive service. Basic issues may cost less, while extensive repairs could lead to higher fees. It’s advisable to obtain multiple estimates to ensure competitive pricing and fair assessments of the required work.

Owner Maintenance Tips and Tricks

Regular upkeep of your vehicle’s components is essential for longevity and optimal performance. This section offers valuable insights to help you maintain the functionality of your system, ensuring it runs smoothly and efficiently over time. With a few proactive steps, you can enhance the reliability of your machine and potentially avoid costly issues down the line.

Routine Checks

Conducting frequent inspections is vital. Start by monitoring fluid levels and ensuring they are clean and at the appropriate levels. This includes checking for leaks and looking for signs of wear in hoses and seals. Pay attention to unusual noises or vibrations during operation, as these can indicate underlying problems that may require further investigation.

Best Practices for Longevity

To extend the life of your system, consider adopting best practices. Regularly scheduled fluid changes can significantly enhance performance, while using high-quality products tailored for your specific needs will provide additional protection. Additionally, avoid heavy loads when possible and drive smoothly to minimize strain. These habits contribute to a healthier operating environment and reduce the likelihood of premature failures.

Resources for Further Learning

Expanding your knowledge in the field of automotive mechanics can significantly enhance your skills and confidence. Whether you’re a novice or a seasoned enthusiast, numerous resources are available to deepen your understanding and expertise.

Online Courses and Tutorials

Websites such as Udemy and Coursera offer comprehensive courses that cover various aspects of vehicle systems. These platforms provide video tutorials, quizzes, and community support, making learning interactive and engaging. Consider exploring topics related to automotive technology to gain a broader perspective.

Books and Publications

Reading material is invaluable for grasping complex concepts. Look for books that focus on automotive engineering and diagnostics, which can provide detailed insights and practical applications. Automotive Technology: A Systems Approach is a recommended read for anyone looking to delve deeper into this field.