Comprehensive Guide to 6T40 Transmission Repair

Understanding the intricacies of a vehicle’s power transfer system is essential for ensuring optimal performance. This guide aims to provide comprehensive insights into the components and mechanisms involved in these complex systems. With a focus on practical solutions, it serves as a valuable resource for both novice and experienced enthusiasts.

Whether facing minor issues or undertaking significant overhauls, familiarity with the specific elements can greatly enhance the efficiency of the process. Detailed descriptions and step-by-step instructions will aid in diagnosing problems and implementing effective solutions. Empowering oneself with knowledge is the first step toward achieving successful outcomes.

As technology evolves, so too do the methods of addressing mechanical challenges. This guide emphasizes modern techniques and tools that streamline the maintenance process. By prioritizing precision and attention to detail, readers can confidently navigate the tasks at hand, ensuring their vehicle remains in peak condition.

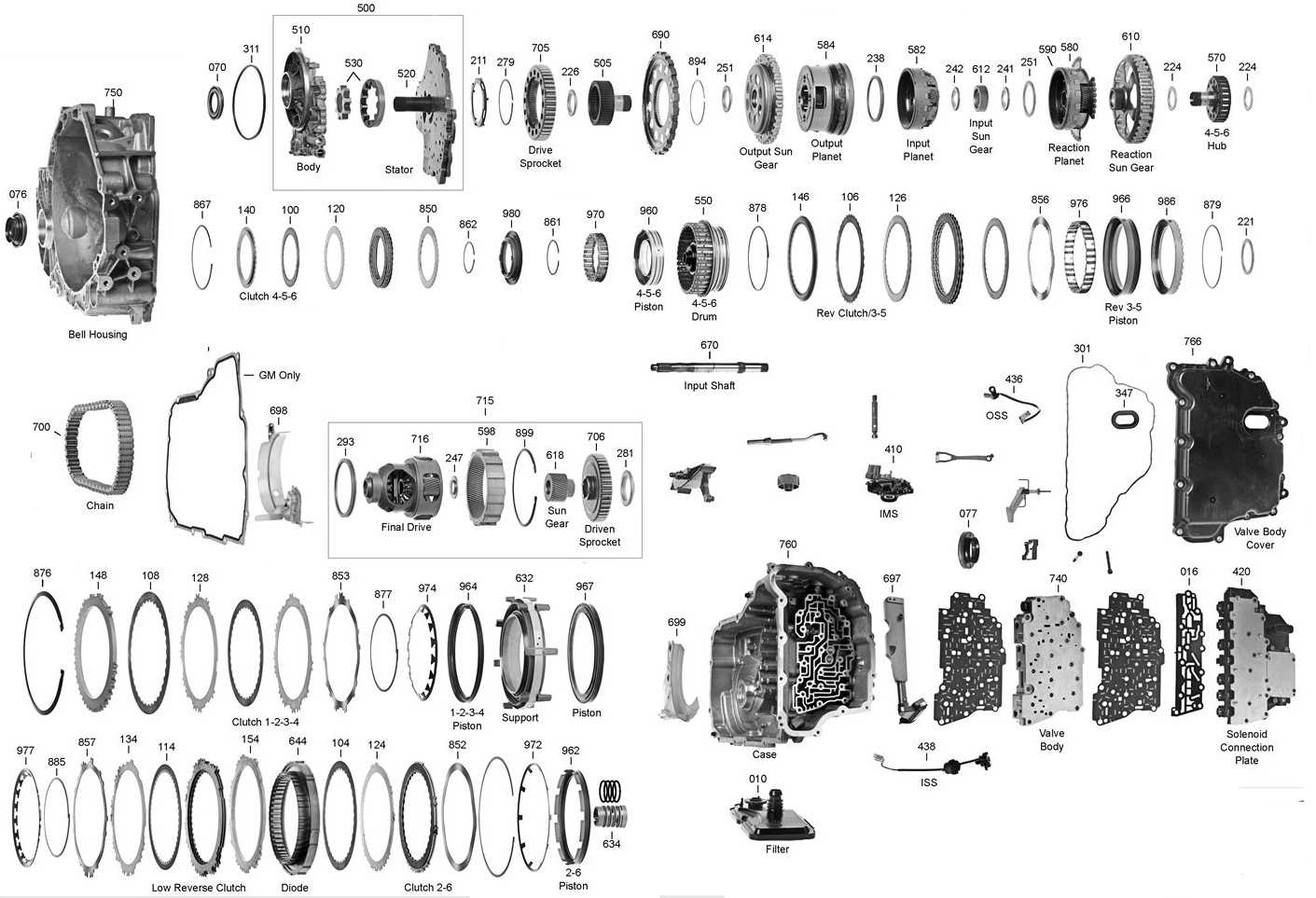

This section aims to provide a comprehensive understanding of a specific automatic gear mechanism commonly used in various vehicles. By exploring its fundamental components and functions, readers will gain insights into its design and operational principles.

The following points outline the key aspects to be covered:

- Basic Structure: Discuss the main elements that comprise this mechanism and how they interact.

- Functionality: Explain the primary roles of each component in facilitating smooth vehicle operation.

- Common Issues: Identify frequent complications that may arise during usage, along with potential indicators of malfunction.

- Maintenance Tips: Provide practical advice on how to ensure longevity and optimal performance of the mechanism.

Through this outline, readers will be equipped with the knowledge necessary to comprehend the intricacies of this automatic gear system.

Common Issues and Symptoms

Understanding the typical challenges that can arise in an automotive gearbox system is crucial for maintaining optimal performance. Drivers may experience various signs indicating that something is amiss, often leading to more significant problems if left unaddressed.

Identifying Common Problems

Several issues can surface during the operation of these complex systems:

- Slipping Gears: This occurs when the gears fail to engage properly, resulting in a loss of power.

- Unusual Noises: Grinding, whining, or clunking sounds can signify internal wear or damage.

- Fluid Leaks: Any visible fluid under the vehicle may indicate a seal or gasket failure.

- Delayed Engagement: Hesitation when shifting from park to drive can point to mechanical faults.

Symptoms to Watch For

Drivers should remain vigilant for the following symptoms:

- Check Engine Light: An illuminated warning can indicate issues with the gearbox.

- Vibration: Unusual shaking during operation often signifies misalignment or wear.

- Poor Acceleration: Difficulty in gaining speed may suggest problems within the gear system.

- Inconsistent Shifting: Erratic changes between gears can be a red flag for underlying issues.

Essential Tools for Repair

When addressing complex mechanical issues, having the right instruments is crucial for effective troubleshooting and maintenance. A well-equipped workspace can significantly enhance efficiency and precision during the process. Below are some indispensable tools that facilitate effective diagnostics and adjustments.

Basic Hand Tools

These tools form the foundation of any toolkit. They are versatile and essential for a wide range of tasks, making them indispensable in any mechanical setting.

| Tool | Purpose |

|---|---|

| Wrenches | Tightening and loosening bolts and nuts |

| Screwdrivers | Fastening and removing screws |

| Pliers | Gripping and manipulating various components |

Diagnostic Instruments

To accurately assess issues, specific diagnostic tools are necessary. These instruments help in identifying problems efficiently, ensuring that repairs can be performed correctly.

| Instrument | Function |

|---|---|

| Multimeter | Measuring voltage, current, and resistance |

| Pressure Gauge | Checking fluid pressure levels |

| OBD Scanner | Reading fault codes from electronic systems |

Step-by-Step Disassembly Guide

This section outlines a systematic approach to disassembling a complex mechanical assembly, ensuring clarity and precision at each stage. By following these steps, you will gain insights into the internal components and their configurations, allowing for effective assessment and maintenance.

Preparation and Safety Measures

Before beginning the disassembly, ensure that you have the necessary tools and a clean workspace. Wear appropriate safety gear to protect against any sharp edges or moving parts. Organize the components as they are removed to facilitate easier reassembly.

Disassembly Process

Start by removing any external covers or shields that may obstruct access to the internal elements. Carefully detach the connectors and fasteners, noting their locations. As you proceed, document each step with photographs or notes to aid in reassembly. Maintain a methodical approach to avoid losing or damaging critical parts.

Once all components are detached, you can further examine individual elements for wear or damage, setting the stage for effective service or refurbishment.

Inspecting Key Components

Thorough examination of essential parts is crucial for ensuring optimal performance and longevity of any mechanical system. Each element plays a vital role in overall functionality, and recognizing signs of wear or damage can prevent future complications.

Visual Assessment

Start with a visual inspection of accessible components. Look for signs of leakage, corrosion, or unusual wear patterns that may indicate underlying issues.

Functional Testing

After visual checks, perform functional tests to assess the performance of critical elements. This helps identify discrepancies in operation that could lead to failure.

| Component | Inspection Criteria | Common Issues |

|---|---|---|

| Gear Set | Check for pitting and abnormal wear | Excessive noise, slippage |

| Seals | Look for cracks and wear | Fluid leaks |

| Fluid Pump | Test pressure output | Inadequate pressure, noise |

Reassembly Procedures Explained

The process of reassembling a complex mechanical assembly requires precision and attention to detail. Each component must be meticulously positioned to ensure optimal functionality and longevity. Understanding the proper sequence and techniques is essential for achieving a successful outcome.

Begin by gathering all necessary parts and tools, ensuring that everything is clean and free from debris. This initial step helps prevent contamination that could lead to future issues. Follow the manufacturer’s specifications for the correct order of assembly, paying close attention to torque settings and alignment markings.

As you reassemble the unit, regularly check that each component fits snugly and operates smoothly. It’s advisable to test functionality incrementally as sections are completed, allowing for easier identification of any potential problems. Remember to consult any relevant documentation for specific instructions or tips unique to the assembly.

Finally, once the entire assembly is complete, perform a thorough inspection before sealing it. This final check helps ensure that every aspect is functioning as intended, setting the stage for reliable performance in the long run.

Fluid Change and Maintenance Tips

Proper upkeep of the hydraulic system is essential for optimal performance and longevity. Regular fluid replacement and routine care help prevent potential issues, ensuring smooth operation. Here are some essential tips for maintaining and changing the fluid effectively.

Fluid Change Process

Follow these steps to successfully change the hydraulic fluid:

- Gather the necessary tools and materials, including a fluid pump, catch basin, and new fluid.

- Warm up the system slightly to help the fluid flow out easily.

- Locate the drain plug and carefully remove it to allow old fluid to drain completely.

- Replace the drain plug securely once all fluid has been removed.

- Fill the system with the appropriate new fluid through the designated fill port.

- Run the system briefly to circulate the new fluid and check for leaks.

- Dispose of the old fluid responsibly at a recycling center.

Maintenance Recommendations

To ensure the system remains in top condition, consider the following maintenance practices:

- Inspect fluid levels regularly and top off as needed.

- Check for any signs of leaks or discoloration in the fluid.

- Follow the manufacturer’s guidelines for fluid change intervals.

- Monitor system performance and address any unusual noises or behaviors promptly.

- Consider using a fluid analysis service to assess the condition of the hydraulic fluid.

Diagnosing Electrical Problems

Identifying issues within the electrical system of a vehicle’s drivetrain requires a systematic approach. Various components work together to ensure optimal performance, and any malfunction can lead to significant operational challenges. Understanding the common signs of electrical faults is crucial for effective troubleshooting.

Begin by observing any warning lights on the dashboard. These indicators often provide initial clues about underlying problems. A thorough inspection of wiring harnesses and connectors can reveal signs of wear or damage, which may disrupt communication between components.

Utilizing diagnostic tools is essential for pinpointing specific faults. Scanning the vehicle’s onboard computer can generate error codes that help technicians identify the source of the issue. Once codes are retrieved, a comprehensive analysis of the affected systems will assist in isolating the malfunction.

Furthermore, testing the voltage and ground connections is vital. Inconsistent readings may suggest an issue with the power supply or a poor ground, leading to erratic performance. By methodically checking each component, one can effectively narrow down the potential causes of electrical malfunctions.

Performance Enhancements and Upgrades

Improving the efficiency and responsiveness of a vehicle’s powertrain is a common pursuit among enthusiasts. Various enhancements can significantly elevate performance levels, providing a more dynamic driving experience. By focusing on specific areas, owners can achieve notable gains in power output, shifting smoothness, and overall reliability.

Common Upgrades

Several modifications can be implemented to boost performance. Below are popular enhancements that many consider when looking to optimize their systems:

| Upgrade Type | Description | Benefits |

|---|---|---|

| ECU Remapping | Adjusting the engine’s electronic control unit for optimal performance. | Increased horsepower and torque. |

| High-Performance Clutch | Installing a more robust clutch to handle increased power. | Improved durability and engagement. |

| Cooling System Upgrade | Enhancing the cooling components to prevent overheating. | Consistent performance under stress. |

Considerations for Enhancements

While upgrades can provide significant benefits, careful consideration is essential. Factors such as compatibility, installation complexity, and overall vehicle goals should guide decisions. A well-planned approach will ensure that enhancements not only improve performance but also maintain the integrity and longevity of the vehicle.

Preventive Measures for Longevity

Maintaining the functionality of your vehicle’s power transfer system is essential for ensuring its performance and durability. By implementing strategic practices, you can significantly extend the lifespan of these components and enhance overall efficiency.

Regular Maintenance: Frequent inspections and servicing are vital. Ensure that all fluid levels are adequate and that any signs of wear are addressed promptly. This proactive approach minimizes the risk of major issues arising unexpectedly.

Quality Fluids: Utilizing high-quality lubricants and fluids tailored to your system can improve performance. These substances reduce friction and wear, promoting smoother operation and preventing premature damage.

Driving Habits: Adopting gentle driving practices can greatly influence the longevity of your vehicle’s power delivery system. Avoiding rapid acceleration and heavy braking can help maintain its integrity over time.

Temperature Control: Keeping an eye on operating temperatures is crucial. Excessive heat can lead to accelerated wear and failure, so ensure that cooling systems are functioning properly to dissipate heat effectively.

By integrating these preventive measures into your vehicle care routine, you can enhance the reliability and lifespan of its essential components, ensuring a smoother and more enjoyable driving experience.

Troubleshooting Common Failures

Understanding the typical issues that arise in complex systems can significantly aid in effective diagnosis. By recognizing the signs and symptoms associated with various malfunctions, individuals can implement targeted solutions, ultimately restoring functionality and performance.

Identifying Symptoms

Common indicators of underlying problems include:

- Unusual noises during operation

- Delayed engagement or responsiveness

- Fluid leaks beneath the vehicle

- Warning lights illuminated on the dashboard

Steps for Diagnosis

To systematically approach troubleshooting, consider the following steps:

- Begin with a thorough visual inspection for leaks and damages.

- Check fluid levels and quality, ensuring they meet required standards.

- Utilize diagnostic tools to retrieve error codes from the onboard computer.

- Assess the performance under various conditions to pinpoint specific issues.

By adhering to these guidelines, individuals can enhance their troubleshooting efforts and address common failures with confidence.

Recommended Replacement Parts

When addressing issues within a vehicle’s shifting system, selecting high-quality components is crucial for restoring optimal performance. This section highlights essential parts that should be considered for replacement to ensure reliability and longevity of the assembly.

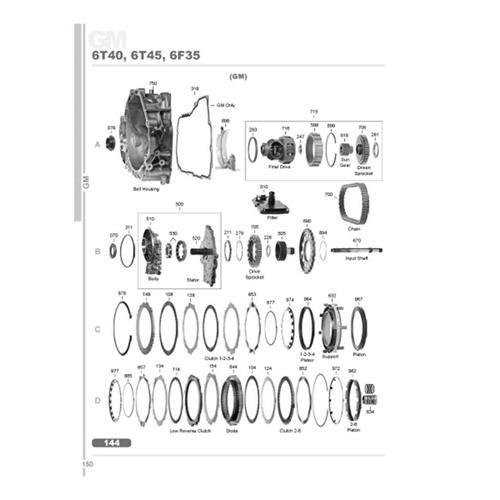

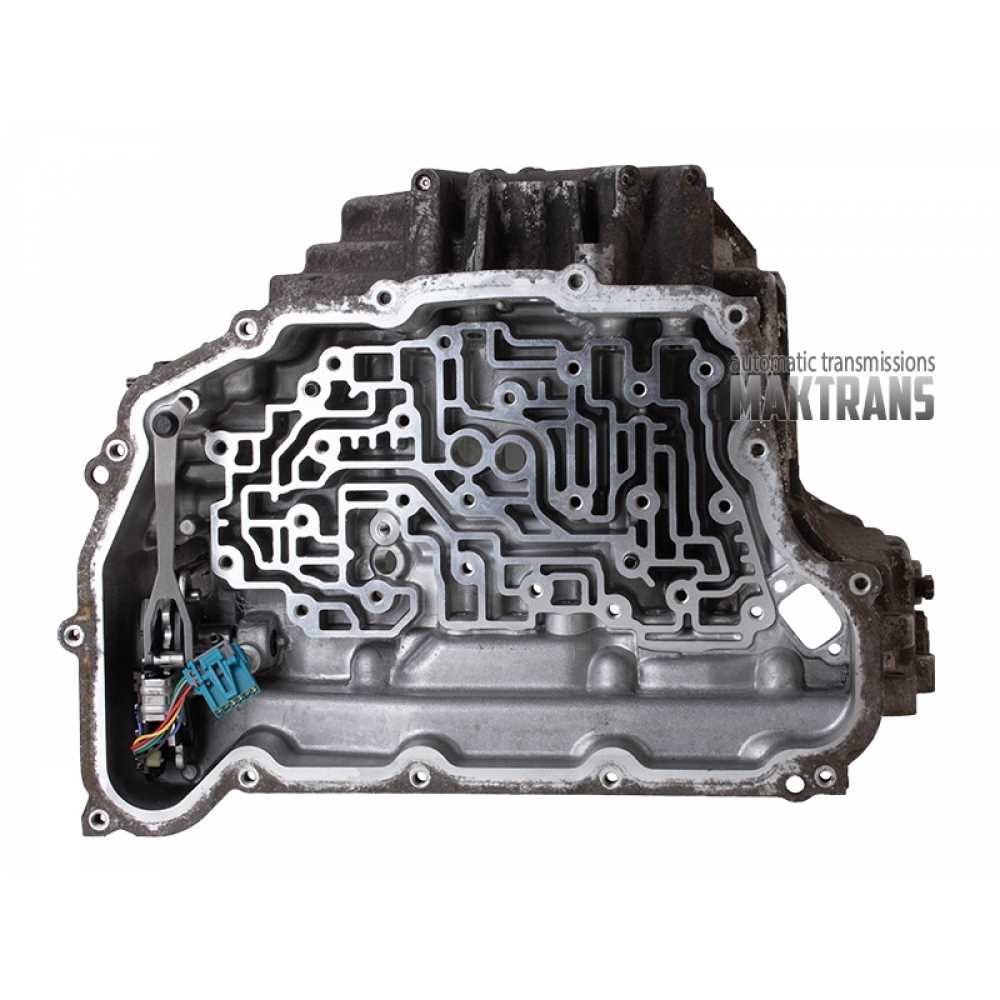

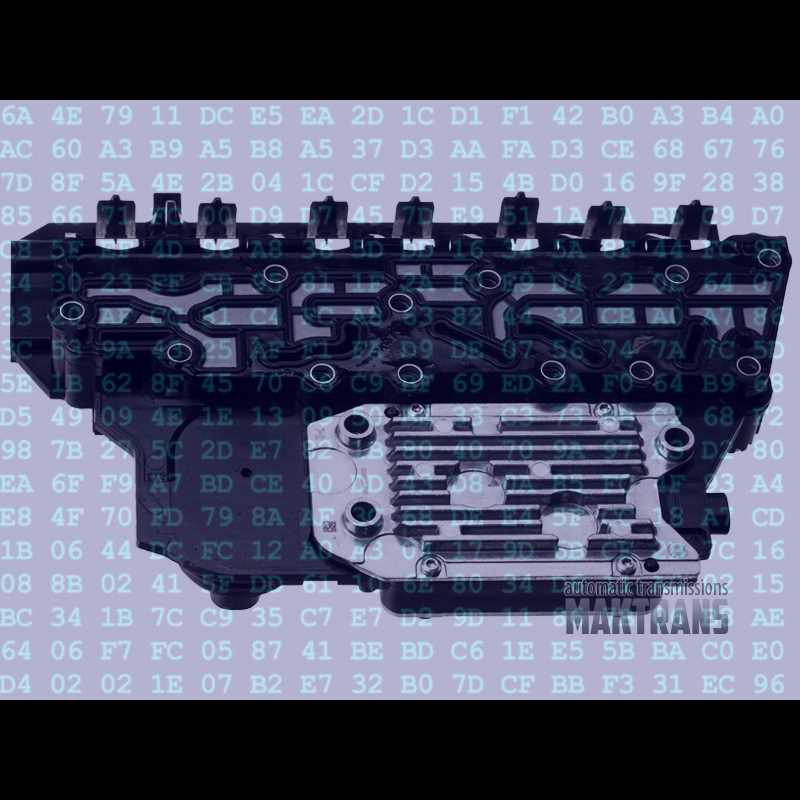

Key Components

Among the vital elements are the valve body and solenoids. These parts play a significant role in controlling fluid flow and pressure, directly impacting gear changes. Investing in durable and efficient replacements can enhance the overall functionality of the system.

Additional Considerations

Other notable parts include clutches and seals, which are necessary for maintaining proper engagement and preventing leaks. Utilizing reputable brands for these components not only ensures compatibility but also contributes to the durability of the overall assembly. Proper selection and installation of these parts can lead to a smoother operation and extend the lifespan of the entire unit.

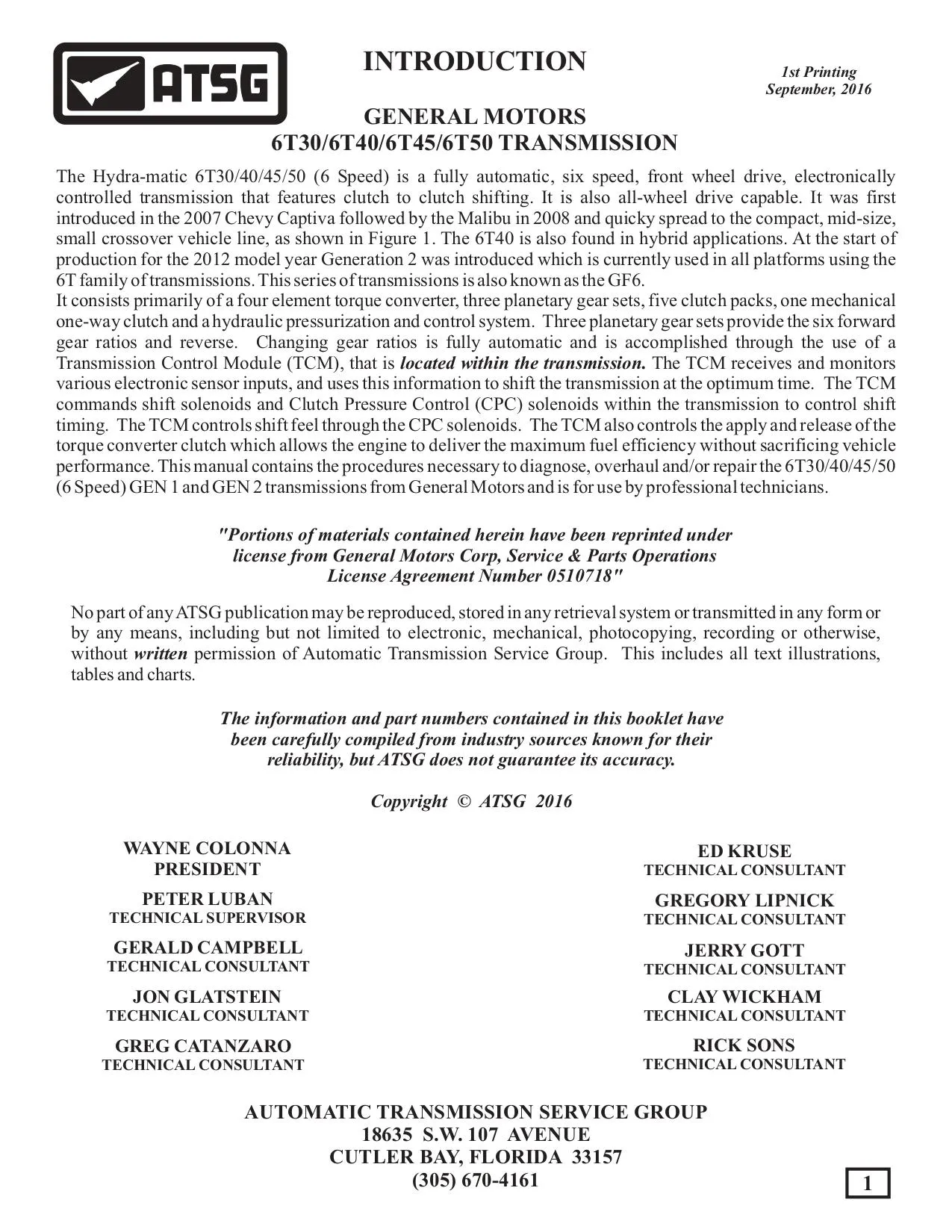

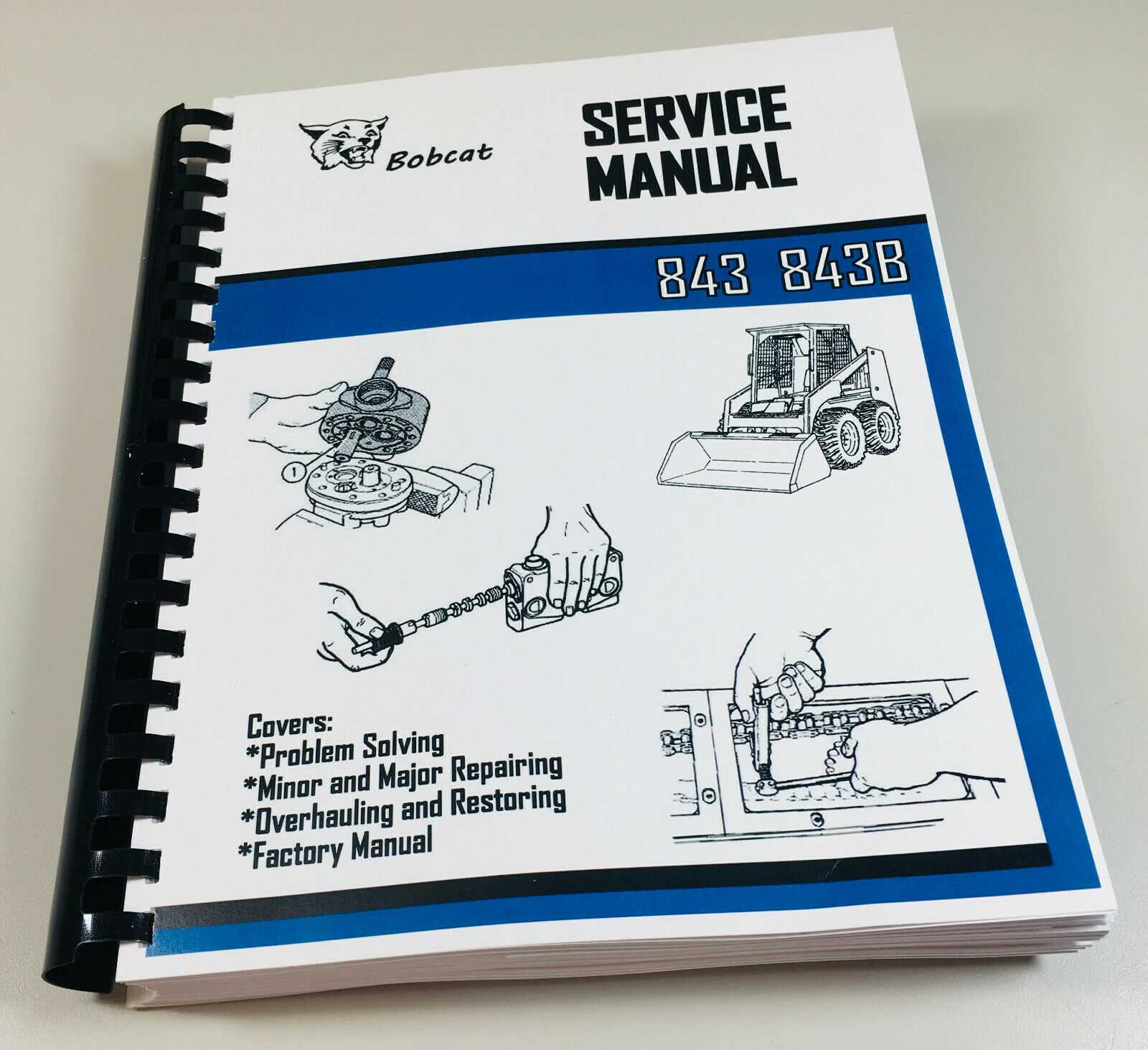

Resources for Further Learning

Expanding your knowledge on automotive systems and their intricacies is essential for enthusiasts and professionals alike. Various resources are available to deepen your understanding, offering insights into functionality, troubleshooting, and enhancement techniques. Below are some recommended avenues for further exploration.

Online Courses and Tutorials

Numerous platforms provide comprehensive courses focused on vehicle mechanics and electronic systems. Websites like Coursera and Udemy offer structured programs, while YouTube hosts countless video tutorials, making complex topics accessible through visual learning.

Books and Publications

Investing in specialized literature can significantly enhance your expertise. Look for technical books that cover automotive engineering, system diagnostics, and performance upgrades. Automotive magazines also provide valuable insights, reviews, and case studies, keeping you updated on industry trends.