Comprehensive Guide to 700R4 Transmission Repair

The proper functioning of an automatic gear system is crucial for optimal vehicle performance. Understanding the intricacies of these complex assemblies can lead to improved longevity and reliability. This section aims to provide essential insights into maintaining and troubleshooting these essential components.

Knowledge of the internal mechanics and potential issues can empower vehicle owners to make informed decisions. By exploring various techniques and best practices, one can enhance the overall efficiency and durability of the gear system. This guide serves as a comprehensive resource for anyone looking to delve deeper into the nuances of automatic gear systems.

Through a systematic approach to care and maintenance, it is possible to mitigate common problems and extend the lifespan of these vital components. Each segment will address key aspects of upkeep, ensuring that users are equipped with the knowledge to handle any challenges that may arise.

tags and avoids repetition. Understanding 700R4 Transmission Basics”>

tags and avoids repetition. Understanding 700R4 Transmission Basics”>

This section aims to provide a comprehensive overview of a specific vehicle component, focusing on its functionalities, potential issues, and maintenance strategies. By exploring various aspects, readers can gain insights into optimal practices for handling this crucial element in automotive systems.

Understanding how this part operates is essential for effective troubleshooting and maintenance.

Identifying typical problems can help in early detection and prevention of further damage.

Having the right tools is vital for successful upkeep and repairs.

A systematic approach can simplify the process and ensure thorough inspections.

The choice of fluids significantly impacts performance and longevity.

Knowledge of specifications aids in making informed decisions during repairs.

Upgrading can enhance performance and adapt the component to specific needs.

Electrical problems can often be overlooked but are crucial to address.

Implementing best practices can extend the lifespan of this vital component.

Insider tips can make the repair process more manageable and efficient.

Being informed about warranties can provide peace of mind for owners.

Looking ahead, staying updated on advancements can ensure optimal performance.

Common Issues with 700R4 Transmissions

Understanding the frequent problems associated with this specific gearbox can greatly aid in timely diagnostics and effective solutions. Many users encounter issues that may lead to performance degradation or complete failure if not addressed promptly.

Shifting Difficulties

One prevalent concern is related to shifting. Users often report harsh or delayed gear changes, which can stem from a variety of causes, including low fluid levels or worn internal components. Regular maintenance and fluid checks are essential to prevent these complications.

Overheating Concerns

Another common problem involves overheating. Excessive heat can result from towing heavy loads or driving under extreme conditions. Installing an external cooler can help manage temperatures and extend the life of the system. Monitoring fluid temperatures regularly is advisable to avoid significant damage.

Tools Required for Repair

When undertaking the task of servicing a specific automotive component, having the right tools is essential for achieving optimal results. This section outlines the necessary equipment to ensure a smooth process and effective troubleshooting.

- Socket Set: A complete set with various sizes will facilitate the removal and installation of bolts.

- Wrenches: Both open-end and box-end wrenches are crucial for accessing tight spaces.

- Screwdrivers: A variety of flathead and Phillips screwdrivers will help with different fasteners.

- Pliers: Needle-nose and locking pliers can be useful for gripping and manipulating components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Fluid Pump: Assists in adding or removing fluids efficiently.

- Inspection Mirror: Allows for visual checks in hard-to-reach areas.

- Work Light: Provides adequate lighting for a clear view of the workspace.

Having these tools at hand will greatly enhance the efficiency and effectiveness of the service process, leading to successful outcomes and improved performance.

Step-by-Step Repair Process

This section outlines a comprehensive procedure for addressing issues within a specific automotive component. The approach consists of multiple stages, ensuring thorough examination and restoration to optimal functionality.

| Step | Description |

|---|---|

| 1 | Begin by disconnecting the electrical systems and removing any obstructing parts. |

| 2 | Carefully extract the unit from the vehicle, noting the connections for reassembly. |

| 3 | Inspect all components for wear, damage, or failure, documenting any findings. |

| 4 | Replace any defective parts with new or refurbished items, ensuring compatibility. |

| 5 | Reassemble the unit, following the documented connections to maintain integrity. |

| 6 | Reinstall the assembly into the vehicle, reconnecting all necessary systems. |

| 7 | Conduct tests to verify proper operation, making adjustments as needed. |

Replacing Fluid Effectively

Changing the fluid in your vehicle’s drivetrain system is essential for maintaining optimal performance and longevity. Regularly refreshing this vital substance helps to ensure smooth operation and prevents potential damage caused by contaminants and breakdown of the fluid over time.

Begin the process by safely elevating the vehicle and ensuring it is stable. Drain the old fluid by locating the appropriate valve and allowing it to flow completely into a suitable container. After draining, remove the filter, which may require specific tools for proper access. Clean the area around the filter thoroughly to avoid introducing debris.

Next, install the new filter securely and replace any gaskets to prevent leaks. Fill the system with fresh fluid according to the manufacturer’s specifications. It is crucial to use the correct type to ensure compatibility and performance. After filling, start the engine and let it idle for a few minutes, allowing the new fluid to circulate properly throughout the system.

Finally, check the fluid level once more, adding more if necessary, and inspect for any leaks around the filter and drain plug. Proper maintenance of this aspect of your vehicle will enhance its reliability and efficiency on the road.

Identifying Worn Components

Recognizing damaged or degraded parts is essential for ensuring optimal performance in any mechanical system. Regular inspection can help pinpoint issues that may lead to failure or inefficiency.

Visual Examination: Begin by inspecting visible components for signs of wear, such as cracks, discoloration, or excessive corrosion. Components should have a uniform appearance; any irregularities can indicate potential problems.

Physical Testing: Manual checks, such as wiggling or turning parts, can reveal looseness or unusual resistance. Components should operate smoothly without any unexpected stiffness or play.

Performance Assessment: Monitor the overall functionality during operation. Unusual noises, vibrations, or changes in responsiveness often suggest that some parts may need replacement. Timely intervention can prevent further damage and enhance longevity.

Adjusting Transmission Bands

Proper adjustment of the bands is crucial for optimal performance of the shifting mechanism. This process ensures that the components work harmoniously, contributing to smoother gear transitions and extending the lifespan of the system.

Tools Required

To begin, gather the necessary tools, including a torque wrench, socket set, and appropriate measuring instruments. These will help achieve precise adjustments for the bands.

Adjustment Process

Start by identifying the adjustment points on the assembly. Carefully loosen the lock nuts before making any changes. Use the torque wrench to tighten the bands to the specified pressure, ensuring each band is calibrated correctly. Finally, recheck the tightness of the lock nuts to maintain the adjustments.

Upgrading 700R4 Performance Parts

Enhancing the efficiency and capability of your vehicle’s power delivery system involves selecting high-quality components that can significantly improve overall performance. Upgrades can lead to better acceleration, smoother shifts, and increased durability, ensuring your system operates at its best.

| Component | Benefits |

|---|---|

| High-Performance Torque Converter | Improves stall speed and enhances throttle response. |

| Upgraded Valve Body | Offers firmer shifts and reduces shift time. |

| Improved Clutch Packs | Increases holding capacity for added power. |

| Shift Kit | Optimizes shift points for better performance. |

Investing in these components can greatly enhance your vehicle’s overall driving experience, providing the performance boost you desire. Proper selection and installation of these parts are crucial for maximizing effectiveness and ensuring compatibility with your setup.

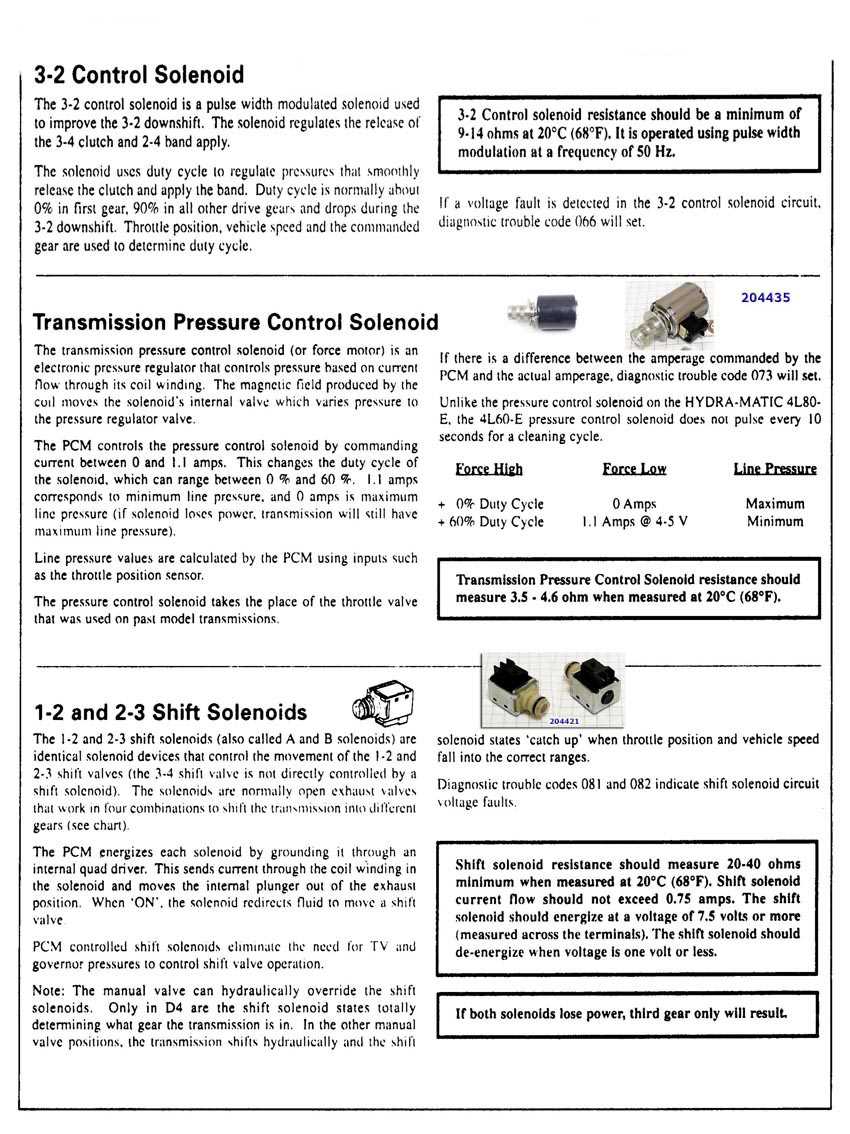

Troubleshooting Electrical Connections

Identifying and resolving issues with electrical links is crucial for optimal functionality in automotive systems. Understanding the common problems that can arise will help ensure reliability and efficiency.

Here are key steps to consider when diagnosing electrical connections:

- Visual Inspection: Check for frayed wires, loose connections, and corrosion.

- Testing Voltage: Use a multimeter to measure voltage at various points to ensure proper flow.

- Continuity Check: Verify that the circuit is complete by testing continuity across connections.

- Grounding Issues: Ensure all grounds are secure and free of rust or dirt that may impede performance.

By systematically assessing these areas, one can effectively pinpoint and address electrical issues, enhancing the overall system performance.

Maintaining 700R4 Transmission Longevity

Ensuring the durability of your vehicle’s gear system involves regular attention and care. Proper maintenance practices can significantly enhance the lifespan of these critical components, ultimately leading to a more reliable driving experience.

Regular Fluid Checks

Rebuilding vs. Repairing

When addressing issues with automotive components, it’s essential to distinguish between two approaches: rebuilding and repairing. Each method has its own implications, benefits, and ideal use cases.

Rebuilding involves disassembling the unit entirely, replacing worn or damaged parts, and restoring it to a like-new condition. This process often includes:

- Thorough inspection of all components

- Replacement of seals and gaskets

- Reconditioning of critical parts

- Upgrades to enhance performance

On the other hand, repairing typically focuses on fixing specific problems without a complete overhaul. This method may involve:

- Identifying and correcting faults

- Limited component replacements

- Quick fixes for immediate issues

- Cost-effectiveness for minor malfunctions

Choosing between rebuilding and repairing often depends on factors such as the extent of damage, budget considerations, and long-term goals for the vehicle’s performance.

Safety Precautions During Repair

Ensuring a safe working environment is essential when undertaking maintenance tasks on automotive systems. Adhering to specific safety measures can significantly reduce the risk of accidents and injuries.

Before beginning any work, it is crucial to wear appropriate protective gear, including gloves, goggles, and sturdy footwear. This gear shields against potential hazards such as sharp components and harmful fluids.

Additionally, maintaining a clean workspace helps prevent accidents. Remove any clutter and ensure that tools are organized to avoid trips and falls. It is also advisable to work in a well-ventilated area to minimize exposure to harmful fumes.

When lifting heavy parts, always use the correct equipment, such as jacks or hoists, to avoid strain or injury. Be mindful of the weight and stability of components being handled.

Finally, familiarize yourself with the specific procedures and risks associated with the task at hand. Understanding the machinery involved can help anticipate potential dangers, allowing for a safer and more efficient working process.