A Comprehensive Guide to ATSG 6L80E Transmission Repair

The intricacies of modern vehicle gear systems require a thorough understanding for effective upkeep. This section delves into essential techniques and insights that enhance the longevity and performance of these complex mechanisms. Whether you are a seasoned professional or a novice enthusiast, mastering these skills is vital for ensuring optimal functionality.

From diagnostics to practical procedures, this guide provides a wealth of information to navigate the challenges associated with maintaining these systems. Each component plays a crucial role, and recognizing their interdependencies is key to successful servicing. Emphasizing precision and attention to detail, this resource equips readers with the knowledge to tackle various issues that may arise during routine checks or overhauls.

With a focus on step-by-step methodologies, users will find practical advice tailored to the specific needs of each system. Understanding the underlying principles not only facilitates effective troubleshooting but also promotes best practices in maintenance. Engage with the material to develop a comprehensive skill set that will prove invaluable in the realm of automotive mechanics.

Atsg 6l80e Transmission Repair Manual

This section offers essential guidance for those involved in the maintenance and troubleshooting of a specific automotive component. The objective is to empower individuals with the knowledge needed to effectively address issues, ensuring optimal performance and longevity of the system.

Understanding Common Issues

When dealing with this particular system, it’s vital to recognize frequent challenges that may arise. Symptoms like slipping, overheating, or unusual noises can indicate underlying problems. Proper diagnosis and timely intervention can prevent further complications.

Key Maintenance Practices

Regular upkeep is crucial for enhancing the durability of the assembly. Key practices include fluid level checks, filter replacements, and monitoring for leaks. Keeping detailed records of maintenance activities can also aid in tracking performance over time.

Understanding the 6l80e Transmission

This section delves into the complexities of an advanced gear-shifting mechanism commonly found in modern vehicles. With its intricate design and multiple components, this system plays a crucial role in enhancing vehicle performance and fuel efficiency. By understanding its functionality, one can appreciate the engineering marvel that contributes to smoother acceleration and effective power distribution.

Key Features of the Mechanism

One notable aspect of this system is its electronic control unit, which optimizes gear changes based on various driving conditions. This feature not only improves responsiveness but also aids in maintaining optimal engine performance. Additionally, the incorporation of adaptive learning technology allows the system to adjust its behavior according to the driver’s habits, ensuring a customized driving experience.

Common Issues and Solutions

Despite its advanced engineering, this assembly can encounter several challenges over time. Frequent symptoms include harsh shifting or slipping between gears, often stemming from fluid issues or worn components. Regular maintenance and timely diagnostics are essential to prevent significant problems. Proper servicing and attention to detail can extend the lifespan of this critical system, ensuring it remains in peak condition.

Common Issues and Symptoms

Understanding the frequent problems that may arise in vehicle systems can significantly aid in early detection and troubleshooting. Awareness of specific indicators can help identify underlying complications before they escalate.

Symptoms to Watch For

- Unusual noises during operation, such as grinding or whining sounds.

- Shifting delays or rough transitions between gears.

- Fluid leaks under the vehicle.

- Warning lights illuminated on the dashboard.

- Slippage while accelerating or inconsistent speed changes.

Potential Issues

- Worn components that may require replacement.

- Contaminated or low fluid levels impacting performance.

- Faulty sensors leading to erratic behavior.

- Electrical problems causing operational failures.

- Overheating due to improper cooling or airflow.

Tools Required for Repairs

When tackling complex vehicle systems, having the right equipment is essential for successful maintenance and restoration. Utilizing the proper tools not only enhances efficiency but also ensures that each component is handled correctly, minimizing the risk of damage.

To begin, a comprehensive toolkit should include ratchets and socket sets, which are vital for loosening and tightening bolts. Additionally, wrenches in various sizes will facilitate access to tight spaces. An impact wrench can also be beneficial for those stubborn fasteners.

Next, diagnostic tools such as OBD-II scanners can aid in identifying issues by reading error codes. Furthermore, a reliable multimeter is crucial for testing electrical systems, ensuring all components function as intended.

For disassembly and assembly tasks, pliers, scrapers, and hook tools will prove invaluable. Lastly, always keep a set of torque wrenches handy to ensure that all connections are secured to the manufacturer’s specifications.

Disassembly Process Overview

The disassembly of a complex mechanical assembly is a critical step in the maintenance and troubleshooting of its internal components. This process involves carefully separating various parts to assess their condition and identify any potential issues that may require attention. Proper techniques and precautions must be observed to ensure the integrity of the components during this phase.

Before beginning, it is essential to gather the necessary tools and equipment. The following table outlines the key tools typically required for an effective disassembly:

| Tool | Purpose |

|---|---|

| Socket Set | To remove bolts and screws |

| Screwdriver Set | For various screw types |

| Pry Bar | To separate tightly fitted components |

| Torque Wrench | To ensure proper reassembly torque |

| Parts Tray | To organize removed components |

Following the necessary preparations, the disassembly can commence, focusing on systematic removal and careful handling of each part to avoid damage. This ensures a smooth transition into the subsequent evaluation and potential reconditioning stages.

Rebuilding the 6l80e Unit

Revamping this particular assembly involves a detailed process aimed at restoring its functionality and enhancing performance. Understanding the essential components and their roles is crucial for ensuring a successful overhaul.

The initial step in the refurbishment process is to disassemble the unit carefully. This allows for a thorough inspection of each part, identifying any wear or damage that may need addressing. Once disassembled, it’s important to clean all components meticulously to eliminate any debris or residues that could affect operation.

Next, assessing the integrity of critical elements such as clutches, bands, and seals is essential. Replacing worn parts with high-quality replacements can significantly improve the longevity and efficiency of the system. Each component should be re-evaluated to ensure it meets the required specifications for optimal performance.

After replacing necessary parts, reassembly should be approached methodically. Following the correct torque specifications and assembly sequence is vital to prevent future issues. Finally, performing a series of tests post-assembly is crucial to verify that the unit operates smoothly and effectively, ensuring all systems function as intended.

Essential Replacement Parts

When it comes to maintaining optimal performance in your vehicle’s gear system, having the right components on hand is crucial. Regular upkeep often requires the replacement of specific parts to ensure longevity and reliability. This section will outline key components that should be considered for replacement to keep the system functioning efficiently.

- Seals and Gaskets: These parts are vital for preventing fluid leaks, which can lead to decreased efficiency and potential damage.

- Filters: Clean filters are essential for maintaining fluid cleanliness, ensuring that the system operates smoothly.

- Clutch Packs: Worn or damaged clutch packs can result in shifting issues, making their replacement necessary for optimal performance.

- Solenoids: These electrical components control fluid flow and pressure, making them critical for proper gear engagement.

- Planetary Gear Sets: Damaged gears can lead to significant operational problems, necessitating replacement to restore function.

Investing in high-quality replacement parts will not only enhance the performance of your system but also extend its lifespan. Proper maintenance and timely component replacement are key to avoiding costly repairs in the future.

Torque Specifications and Guidelines

Proper torque application is crucial for ensuring the longevity and optimal performance of automotive components. Adhering to specific guidelines helps to prevent mechanical failures and enhances the efficiency of the assembly process. In this section, we will discuss the necessary torque specifications that should be followed during assembly and maintenance procedures.

When tightening fasteners, it is essential to utilize a calibrated torque wrench to achieve accurate measurements. Different components require varying torque levels; therefore, referring to a comprehensive chart that outlines these specifications is advisable. For instance, the torque applied to bolts should be consistent with the manufacturer’s recommendations, as this helps maintain the integrity of the unit.

In addition to using the correct torque settings, it is important to follow a specific tightening sequence, especially for multi-bolt assemblies. This practice ensures even distribution of force and minimizes the risk of distortion. It is also recommended to inspect the condition of fasteners regularly, replacing any that show signs of wear or damage.

Finally, always consider the application of lubrication on threaded fasteners, as this can significantly affect the torque readings. Properly prepared threads can lead to more accurate torque values and improve the overall performance of the assembly. By adhering to these torque specifications and guidelines, you can ensure the reliability and efficiency of your automotive components.

Fluid Types and Capacity

Understanding the various liquids used in an automotive gearbox is crucial for optimal performance and longevity. Different types of fluids offer unique properties that can affect the efficiency and reliability of the system. Proper maintenance of these fluids is essential for ensuring smooth operation and preventing premature wear.

Types of Fluids

There are several kinds of liquids suitable for use in gear mechanisms. Each type has specific characteristics that cater to different operational needs.

| Fluid Type | Characteristics |

|---|---|

| ATF (Automatic Transmission Fluid) | Provides lubrication, heat transfer, and assists in hydraulic functions. |

| Full Synthetic Fluid | Offers superior performance and resistance to breakdown under high temperatures. |

| Mineral-Based Fluid | Traditional option with adequate lubrication but may require more frequent changes. |

Fluid Capacity

Each system has a designated capacity that must be adhered to for optimal functioning. Overfilling or underfilling can lead to serious issues, including overheating and erratic performance. Always refer to the specifications to ensure the right amount is used during service.

Testing the Transmission Functionality

Evaluating the performance of a vehicle’s shifting system is crucial for ensuring optimal operation. This process involves a series of assessments that help identify any underlying issues, ensuring smooth gear changes and enhancing overall efficiency.

To effectively assess the functionality, follow these essential steps:

- Initial Inspection:

- Check fluid levels and condition.

- Inspect for leaks around seals and connections.

- Examine electrical connections and wiring for damage.

- Diagnostic Scanning:

- Utilize a compatible diagnostic tool to retrieve any error codes.

- Analyze codes for insights into performance issues.

- Road Test:

- Drive the vehicle to evaluate shifting behavior under various conditions.

- Listen for unusual noises during gear changes.

- Monitor responsiveness and accuracy of shifts.

- Performance Assessment:

- Check for slipping or harsh engagement during shifts.

- Observe any delayed response or failure to engage gears.

By systematically executing these evaluations, you can accurately determine the operational state of the shifting mechanism and address any identified problems effectively.

Common Misdiagnoses to Avoid

When dealing with complex automotive issues, accurate diagnosis is crucial to effective resolution. Misinterpretations can lead to unnecessary repairs and increased costs. Understanding common pitfalls in diagnostics can save time and resources, ensuring that the actual problem is identified and addressed promptly.

One frequent error is attributing electrical failures solely to battery issues. While a weak battery can cause various symptoms, it is essential to check the entire electrical system, including wiring and fuses, to rule out other potential faults. Additionally, overlooking software updates in modern vehicles may result in malfunctions that mimic hardware problems.

Another common misconception is assuming that fluid leaks always indicate a failing component. While leaks can indeed signify issues, they may also arise from simple causes, such as loose fittings or seals. Thorough inspection is necessary to determine the exact source of any leakage before jumping to conclusions.

Lastly, misjudging noise sources can lead to wasted effort. Sounds emanating from different areas may be misattributed to specific components. Conducting a detailed analysis of noise can help pinpoint the actual source, preventing unnecessary disassembly and repairs.

Maintenance Tips for Longevity

Ensuring the durability and performance of your vehicle’s power delivery system requires regular care and attention. By following key practices, you can extend the lifespan and enhance the efficiency of these complex components, ultimately saving time and resources in the long run.

First, regular fluid checks and changes are essential. Using high-quality lubricants helps reduce friction and wear, promoting smoother operation. Pay attention to the manufacturer’s recommendations regarding service intervals to avoid potential issues.

Additionally, keep an eye on temperature levels during operation. Overheating can lead to significant damage, so it’s wise to monitor gauges and ensure the cooling system is functioning correctly. Regular inspections can help identify any cooling system problems before they escalate.

Lastly, practicing gentle driving habits can greatly impact the longevity of your vehicle’s drivetrain. Avoiding rapid acceleration and heavy loads can reduce stress on the components, allowing them to perform optimally over time. By adopting these habits, you contribute to a healthier performance profile.

Troubleshooting Electrical Components

Diagnosing issues within electronic systems is crucial for maintaining optimal performance. Identifying faults in electrical elements can prevent further complications and ensure efficient operation. This section outlines essential steps for effectively troubleshooting these components.

Step 1: Visual Inspection

Begin by examining all accessible parts for signs of wear, corrosion, or damage. Look for loose connections, frayed wires, or burnt terminals. Any visible anomalies can indicate underlying problems that require attention.

Step 2: Testing Continuity

Utilize a multimeter to check for continuity in circuits. Set the device to the appropriate mode and probe each section of the circuit. A lack of continuity may suggest a break or short in the wiring, necessitating further investigation.

Step 3: Voltage Testing

Measure voltage levels at various points to ensure components are receiving adequate power. A significant drop in voltage can signify a malfunctioning part or a poor connection. Compare readings with manufacturer specifications to determine if they fall within acceptable ranges.

Step 4: Analyzing Sensor Inputs

Inspect the functionality of sensors that provide crucial data to the system. Verify that each sensor is operating correctly by checking input and output signals. Malfunctions in sensors can lead to erroneous readings and system performance issues.

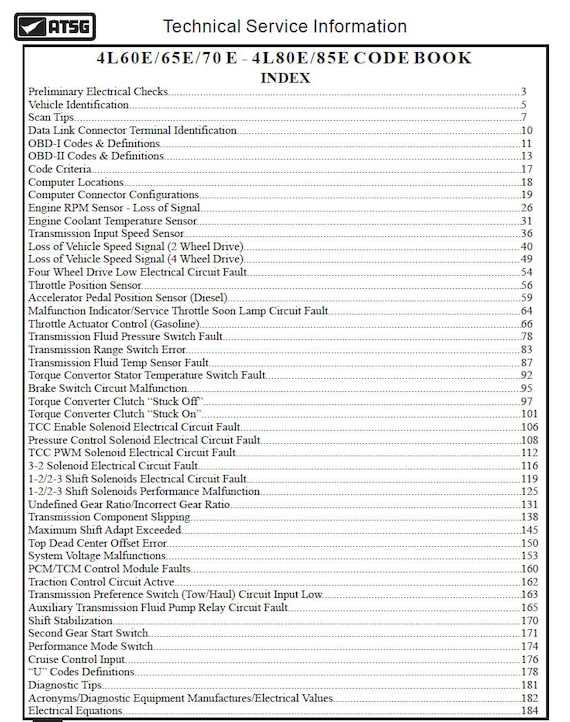

Step 5: Reviewing Diagnostic Codes

If available, use a diagnostic tool to retrieve error codes from the control module. These codes can offer valuable insights into specific problems within the electrical network. Address any identified issues systematically to resolve the underlying causes.

By following these steps, you can effectively troubleshoot and resolve issues related to electrical components, ensuring reliable and smooth operation.