Austin Manual Transmission Repair Guide

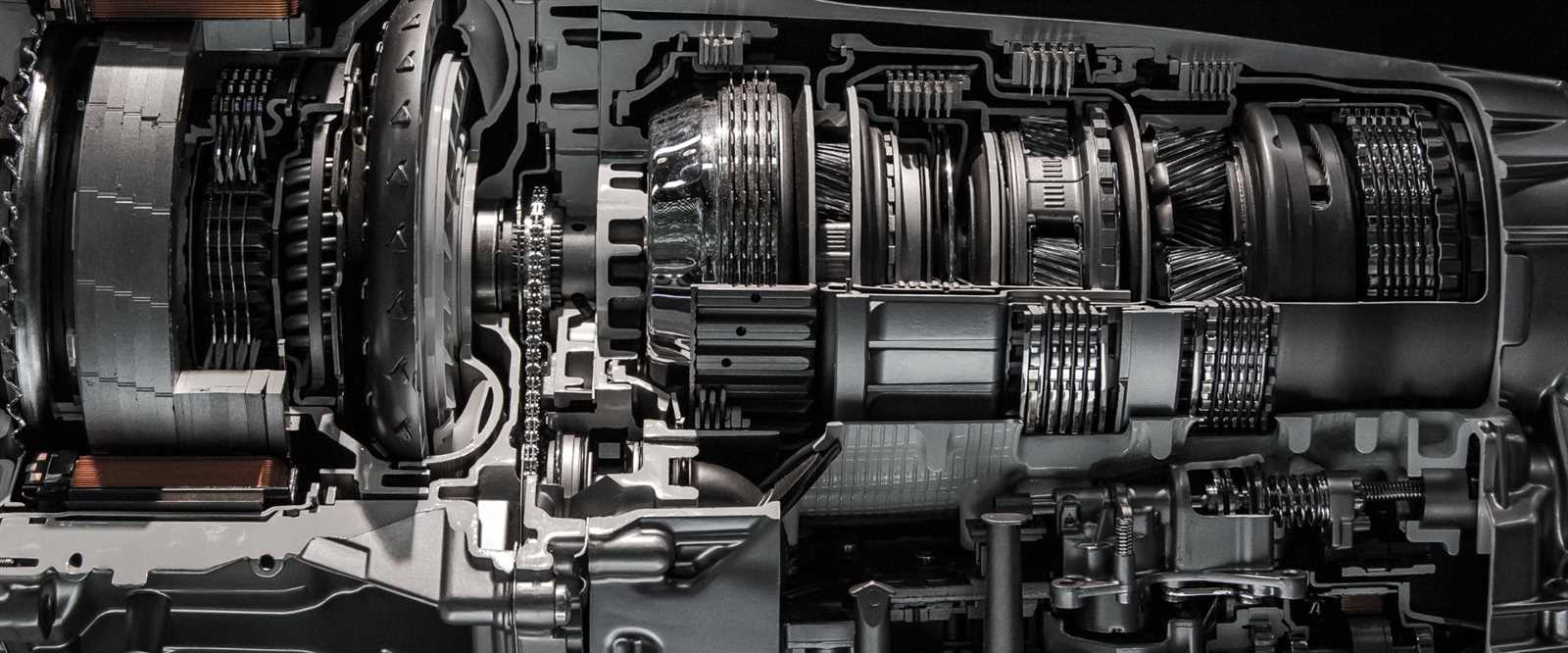

Understanding the intricacies of gear systems is essential for ensuring optimal performance in vehicles. Regular attention to these mechanisms can prevent issues that might arise from wear and tear over time. Proper maintenance not only extends the lifespan of these components but also enhances driving efficiency.

In this section, we will explore various techniques and tips for effectively maintaining gear systems. By applying the recommended practices, one can achieve smoother operation and avoid costly disruptions. Engaging with these processes empowers vehicle owners to take control of their machinery and make informed decisions regarding upkeep.

Knowledge and awareness are crucial in this field. By familiarizing oneself with the workings of these systems, individuals can better address challenges as they arise and ensure that their vehicles remain in top condition.

Austin Manual Transmission Repair Guide

This section provides essential information for maintaining and fixing the gear-shifting system of specific vehicles. Understanding the workings of this component can enhance the performance and longevity of the automobile, ensuring a smoother driving experience.

Common Issues and Solutions

Several problems can arise with the gear engagement system, leading to a decline in functionality. Here are typical issues and their corresponding solutions:

| Issue | Solution |

|---|---|

| Difficulty shifting gears | Inspect the linkage for adjustments or damage. |

| Unusual noises while shifting | Check for worn components or low fluid levels. |

| Fluid leaks | Identify and seal any leaking seals or gaskets. |

Maintenance Tips

Regular maintenance can prevent many common issues. Here are some practical tips:

- Consistently check fluid levels and replace as necessary.

- Inspect linkage and components for signs of wear.

- Ensure the vehicle is parked on a level surface during checks.

Common Issues with Manual Transmissions

When dealing with vehicle gear systems, various challenges can arise that affect performance and functionality. Understanding these common difficulties can help in identifying symptoms early, preventing further complications and ensuring smooth operation.

1. Difficulty Shifting Gears

One prevalent issue involves trouble engaging or disengaging gears. This can be caused by a variety of factors, including worn components or insufficient fluid levels. Proper maintenance is essential to avoid this problem.

2. Unusual Noises

Uncommon sounds such as grinding, whining, or clunking may indicate underlying issues. These noises can signal that parts are misaligned or deteriorating, necessitating closer inspection.

3. Slipping Gears

A situation where the vehicle unexpectedly changes gears can be disconcerting. This often results from worn clutch plates or other components, highlighting the need for prompt attention.

4. Fluid Leaks

Detecting fluid leaks beneath the vehicle is a warning sign that should not be ignored. Low fluid levels can lead to overheating and increased wear on internal parts, compromising overall functionality.

5. Burning Smell

A noticeable burning odor may indicate overheating due to excessive friction or worn parts. Addressing this issue quickly is crucial to prevent severe damage.

Essential Tools for Repairing Transmissions

When it comes to addressing issues within gear systems, having the right equipment is crucial for achieving successful outcomes. Certain instruments can significantly streamline the process and enhance efficiency, ensuring that tasks are performed with precision and care.

Basic Hand Tools

Every enthusiast should start with a solid set of hand tools. Wrenches, screwdrivers, and pliers form the foundation of any toolkit. These essentials allow for easy access to components and facilitate adjustments as needed. Investing in high-quality hand tools can make a substantial difference in performance and longevity.

Specialized Equipment

In addition to basic hand tools, specialized equipment is necessary for more intricate procedures. Gear pullers and alignment tools are among the key instruments that can aid in disassembly and assembly tasks. Utilizing these tools not only simplifies complex processes but also minimizes the risk of damaging sensitive parts.

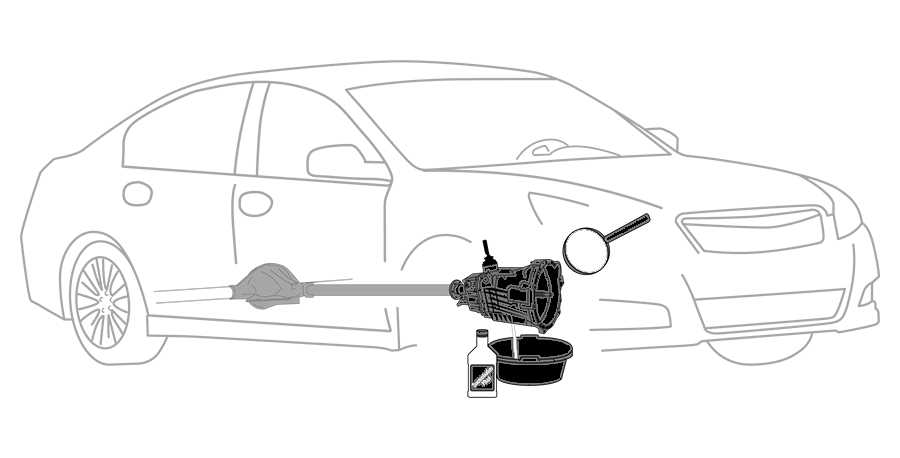

Step-by-Step Repair Process Overview

This section provides a comprehensive guide to the systematic approach required for addressing issues related to the gear-shifting mechanism in vehicles. Understanding each phase of the process is essential for achieving effective results and ensuring longevity in performance.

Preparation Phase

- Gather necessary tools and equipment.

- Ensure a clean workspace to facilitate smooth operations.

- Review the vehicle’s service manual for specific guidelines.

Disassembly Steps

- Remove the protective casing to access the internal components.

- Carefully detach the various parts, noting their arrangement for reassembly.

- Inspect each component for wear and damage.

Following these initial steps sets a solid foundation for addressing the underlying issues and proceeding with the subsequent phases of the process.

Identifying Symptoms of Transmission Failure

Recognizing signs of a performance issue is crucial for maintaining vehicle functionality. Various indicators can signal that something is amiss, requiring prompt attention to avoid further complications.

- Unusual Noises: Listen for grinding, whining, or clunking sounds while shifting gears.

- Slipping Gears: If the vehicle unexpectedly changes gears or has difficulty staying in gear, this may be a warning sign.

- Delayed Engagement: A noticeable lag between pressing the accelerator and the vehicle responding can indicate a problem.

- Fluid Leaks: Any signs of fluid pooling under the vehicle may suggest a leak that needs investigation.

- Warning Lights: Pay attention to dashboard indicators that signal issues related to vehicle operation.

Monitoring these signs can help ensure timely intervention and maintain the overall health of the vehicle.

How to Adjust Clutch Systems

Fine-tuning the components that control engagement and disengagement of the driving mechanism is crucial for optimal performance. A well-adjusted system ensures smooth transitions and prevents unnecessary wear on parts.

Follow these steps to achieve proper adjustment:

| Step | Description |

|---|---|

| 1 | Locate the adjustment mechanism, typically found near the pedal or under the vehicle. |

| 2 | Inspect the cable or linkage for any signs of wear or damage that could affect performance. |

| 3 | Loosen the lock nut and adjust the tension until you achieve the desired free play. |

| 4 | Tighten the lock nut securely, ensuring that no further movement occurs. |

| 5 | Test the system by pressing the pedal and confirming smooth operation. |

Regular checks and adjustments can enhance longevity and functionality, contributing to an overall better driving experience.

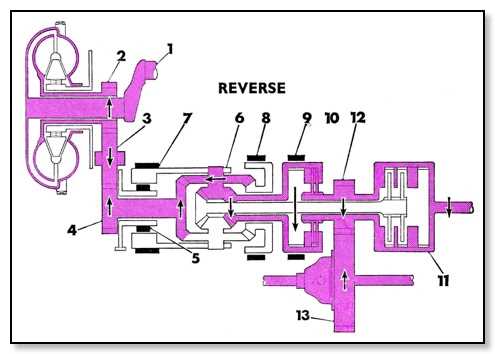

Inspecting Gears and Synchronizers

Examining the components responsible for gear engagement and smooth shifting is crucial for optimal vehicle performance. Understanding the wear patterns and potential issues can prevent future complications and enhance the overall driving experience.

Common Signs of Wear

When assessing the operational efficiency of these components, look for indicators such as:

- Difficulty in shifting

- Unusual noises during engagement

- Grinding sensations

Inspection Process

The evaluation of these elements involves several key steps, including visual inspections and tactile assessments. A thorough examination may include:

| Step | Description |

|---|---|

| Visual Check | Inspect for chips, cracks, or discoloration on surfaces. |

| Physical Feel | Test for smooth operation and resistance during movement. |

| Measurement | Use precision tools to check dimensions against specifications. |

Regular assessments can help maintain efficiency and prolong the lifespan of these vital components.

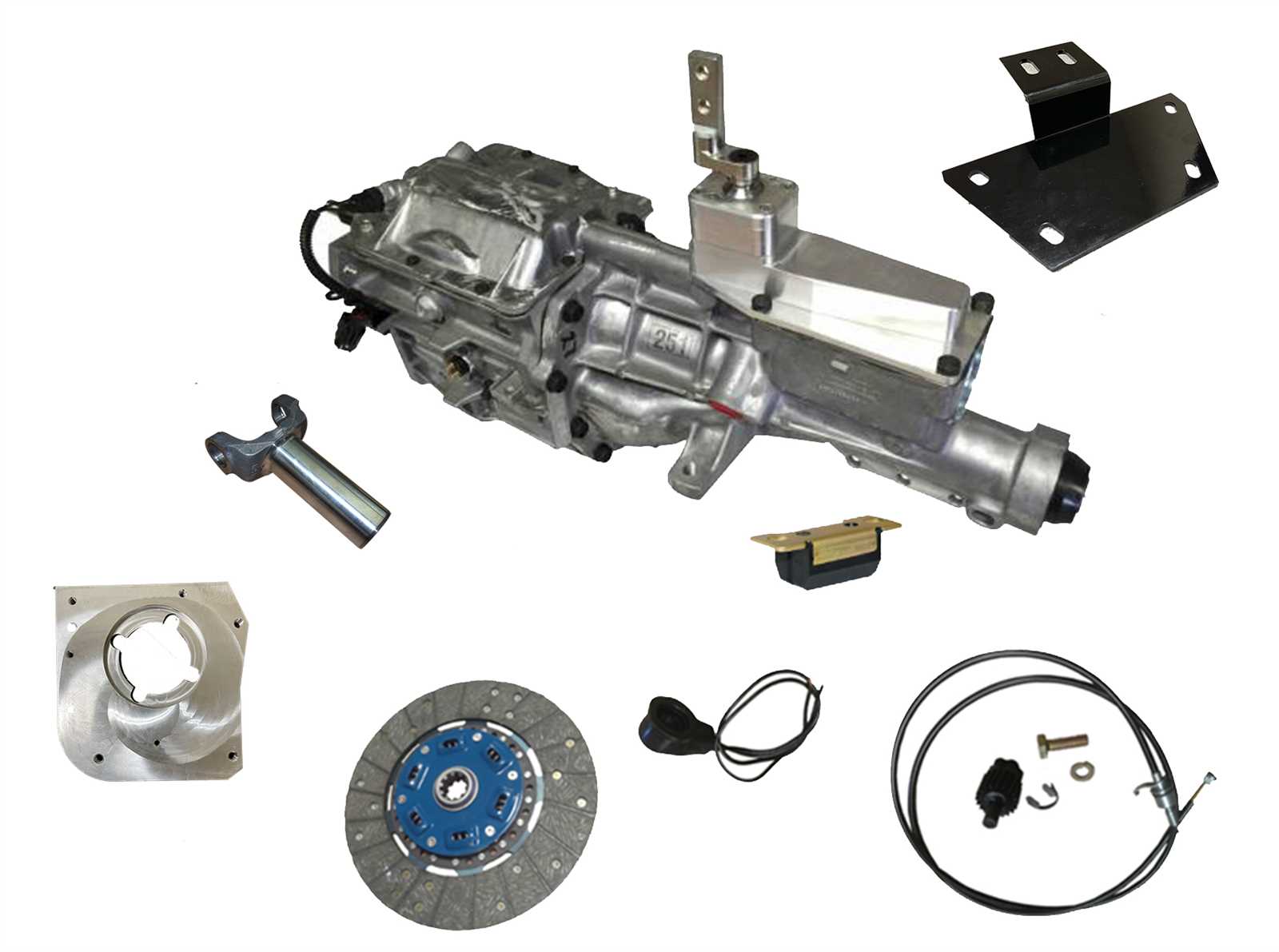

Replacing Worn Out Components

Over time, certain elements of your vehicle’s system may exhibit signs of fatigue or deterioration. Addressing these issues promptly is crucial for maintaining optimal performance and ensuring a smooth driving experience. Recognizing the right moments to replace these components can prevent further complications and enhance overall reliability.

Common parts that often require attention include gears, bearings, and seals. Each of these elements plays a vital role in the system’s functionality, and their wear can lead to decreased efficiency and potential failure. Replacing them with high-quality alternatives ensures that your vehicle operates smoothly and efficiently.

Before undertaking the replacement process, it is essential to gather the necessary tools and components. Following a systematic approach will facilitate a smoother transition, allowing you to complete the task with minimal hassle. Always consult appropriate guides or manuals to ensure proper techniques and safety precautions are observed during the replacement process.

Fluid Types and Maintenance Tips

Proper care and selection of liquids are essential for optimal performance and longevity of your vehicle’s components. Understanding the different categories of fluids available can greatly enhance functionality and minimize wear over time.

Types of Fluids

When it comes to vehicle operation, various liquids serve distinct purposes. Each type is formulated to meet specific requirements, ensuring smooth functioning. Common categories include:

- Engine Oil: Vital for lubrication, it reduces friction between moving parts.

- Gear Oil: Specifically designed to protect gear systems, preventing wear and tear.

- Hydraulic Fluid: Essential for the proper operation of hydraulic systems, providing necessary pressure.

Maintenance Recommendations

Regular maintenance is crucial for ensuring the effectiveness of these liquids. Here are some tips to keep in mind:

- Check fluid levels frequently to prevent any issues related to low amounts.

- Change fluids as per manufacturer guidelines to ensure optimal performance.

- Inspect for leaks, as they can lead to significant problems if not addressed promptly.

Safety Precautions During Repairs

Ensuring a safe environment is essential when undertaking mechanical work. Proper precautions can prevent accidents and injuries, allowing for a smoother and more efficient process. Familiarizing oneself with potential hazards and necessary safety measures is crucial before beginning any tasks.

First and foremost, wearing appropriate protective gear is vital. This includes safety goggles, gloves, and sturdy footwear to safeguard against flying debris and heavy components. Additionally, ensuring that the workspace is well-lit and organized can help avoid unnecessary mishaps.

Before starting any procedure, it is important to disconnect the power source to prevent accidental activation of tools or machinery. Employing proper lifting techniques and using tools designed for specific tasks can also minimize the risk of strain or injury.

Finally, staying focused and aware of the surroundings while working is key. Distractions can lead to errors, so maintaining concentration and following established protocols will enhance safety throughout the process.

Cost Factors in Transmission Repair

The expenses associated with fixing a vehicle’s gear system can vary significantly based on several key elements. Understanding these factors is crucial for anyone considering maintenance or restoration of their automobile’s shifting mechanism.

Labor Expenses

Labor costs often represent a substantial portion of the overall expenditure. The hourly rates charged by skilled technicians can fluctuate depending on their experience, the complexity of the task, and the geographic location of the service center. It is advisable to obtain multiple quotes to gauge the market rate.

Parts Quality

The quality of replacement components plays a vital role in determining the final cost. Higher-quality parts, while potentially more expensive upfront, may offer greater durability and longevity, ultimately saving money in the long run. Conversely, opting for lower-cost alternatives could lead to additional expenses due to premature failure.

Choosing a Professional Mechanic

Finding a skilled technician is essential for ensuring your vehicle operates smoothly. The right professional can provide the necessary expertise to address any issues, enhancing both performance and longevity.

Key Qualities to Look For

- Experience: Look for a mechanic with a solid background and experience in handling various automotive challenges.

- Certifications: Verify that the technician holds relevant certifications, which indicate a commitment to quality and ongoing education.

- Reputation: Research customer reviews and ask for recommendations to gauge the mechanic’s reliability and trustworthiness.

Questions to Ask

- What is your experience with vehicles similar to mine?

- Can you provide references or testimonials from previous clients?

- What kind of warranty do you offer on your work?

By considering these factors, you can confidently select a professional who will meet your automotive needs effectively.