Cvt Transmission Repair Guide

The world of automotive engineering features a diverse array of mechanisms designed to optimize vehicle performance. Among these, one type of gear system stands out due to its innovative approach to power delivery. This section delves into the intricacies of these advanced systems, shedding light on their unique characteristics and operational principles.

Maintaining the efficiency and longevity of such systems is crucial for any vehicle owner. Familiarity with common challenges and solutions can empower individuals to tackle issues proactively. This discussion aims to provide insights into the essential practices necessary for preserving functionality and ensuring seamless operation.

By exploring the underlying concepts and offering practical advice, readers will gain a deeper understanding of how to address potential complications effectively. Whether for personal knowledge or professional application, mastering these principles is invaluable for anyone engaged in the automotive field.

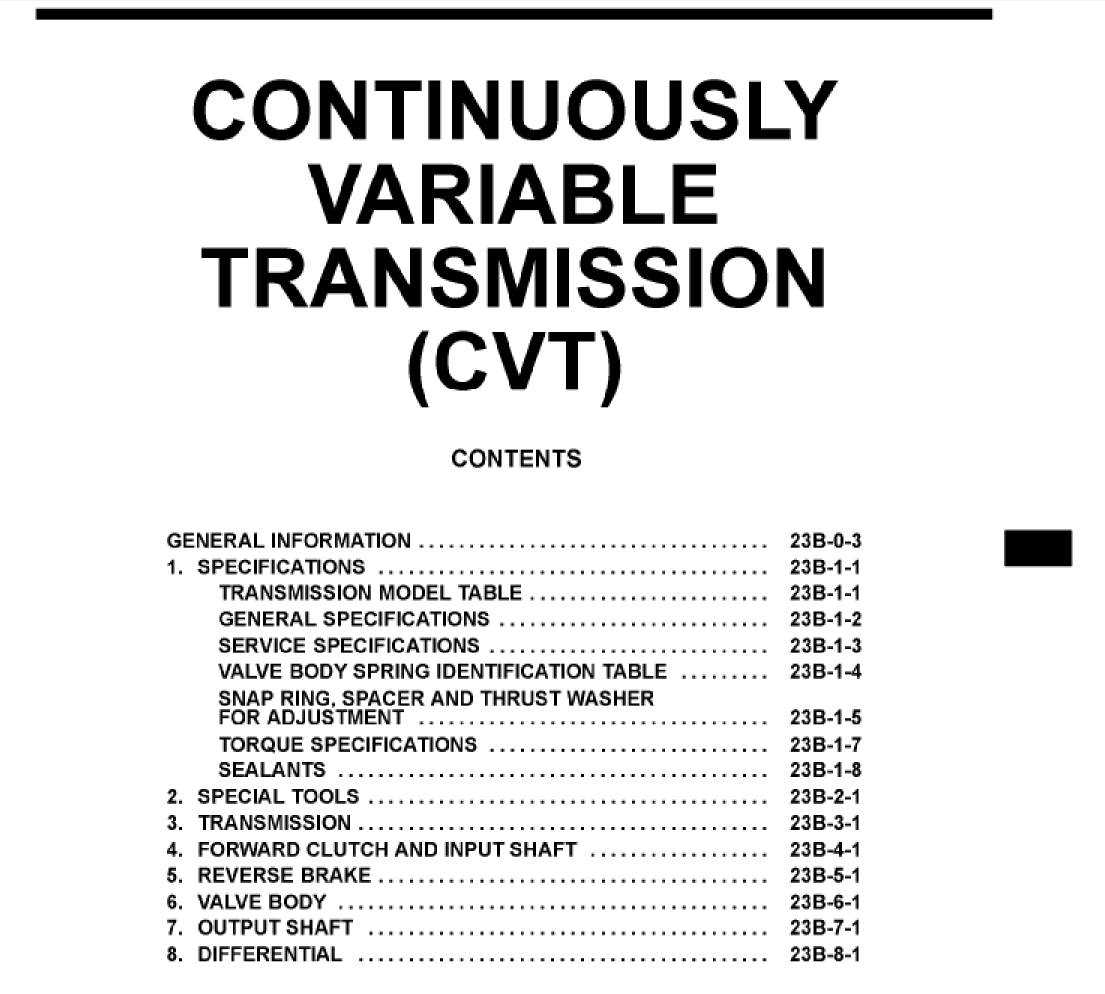

This section aims to provide a foundational understanding of the continuous variable system used in modern vehicles. By grasping the core principles behind its functionality, readers will be better equipped to delve into more complex aspects related to its maintenance and troubleshooting.

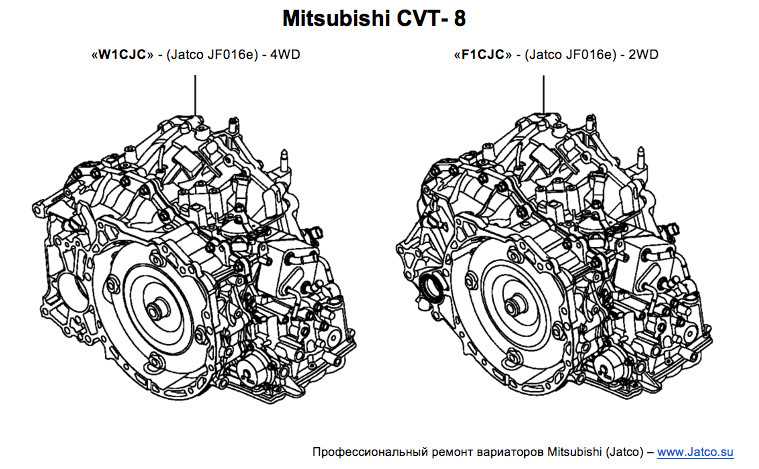

Key Components of the System

- Variable Pulleys

- Belt or Chain

- Control Module

- Fluid System

How It Operates

The operation of this innovative mechanism relies on the seamless adjustment of gear ratios, allowing for smooth acceleration and efficient fuel consumption. Unlike traditional systems, it eliminates distinct shift points, resulting in a continuous flow of power.

- Adaptive Gear Ratios

- Enhanced Performance

- Fuel Efficiency

Common Issues in CVT Systems

Continuous variable gear systems are vital components in modern vehicles, offering a smooth driving experience. However, like any mechanical system, they can encounter various problems that may affect performance and reliability.

One frequent issue is slipping, where the vehicle fails to accelerate as expected. This can lead to a noticeable decrease in power delivery, making it challenging to maintain speed during driving. The root cause of slipping often lies in worn or damaged elements within the system.

Another common concern involves overheating. Extended periods of operation under high load can generate excessive heat, which may lead to fluid breakdown and potential failure of internal components. Regular maintenance and monitoring fluid levels are crucial in preventing such occurrences.

Additionally, strange noises during operation, such as grinding or whining sounds, may indicate underlying problems. These noises can arise from misaligned parts or insufficient lubrication, signaling the need for immediate attention to avoid further damage.

Lastly, irregular shifting behavior can also be a red flag. If the system hesitates or struggles to change ratios smoothly, it may be a sign of electronic control issues or mechanical wear, necessitating thorough diagnostics to determine the appropriate course of action.

Tools Needed for Repair

When addressing issues with the automatic shifting mechanism, having the right equipment is essential for effective troubleshooting and service. This section outlines the necessary instruments and implements that facilitate the process, ensuring a successful outcome.

| Tool | Description |

|---|---|

| Socket Set | A comprehensive set of sockets to fit various bolt sizes for disassembly and assembly tasks. |

| Torque Wrench | An adjustable tool to apply precise torque to fasteners, ensuring proper installation. |

| Fluid Extractor | Used to remove old fluid efficiently and prepare for refilling with new fluid. |

| Diagnostic Scanner | A device that interfaces with the system to identify faults and gather data. |

| Repair Manual | A reference book that provides detailed guidance on procedures and specifications. |

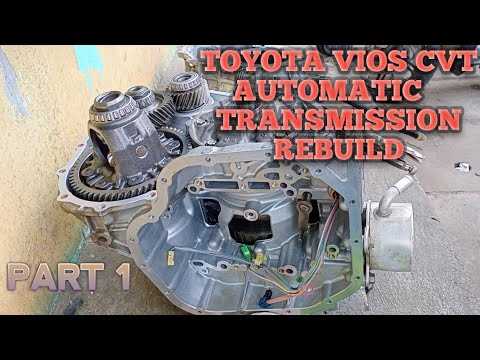

Step-by-Step Repair Process

This section outlines a detailed procedure for addressing issues within a specific automotive system. By following a systematic approach, you can ensure each phase is executed thoroughly, enhancing the overall efficiency and longevity of the mechanism.

1. Preparation: Before beginning, gather all necessary tools and materials. Ensure you have a clean workspace to avoid any contaminants that may affect the performance of the components.

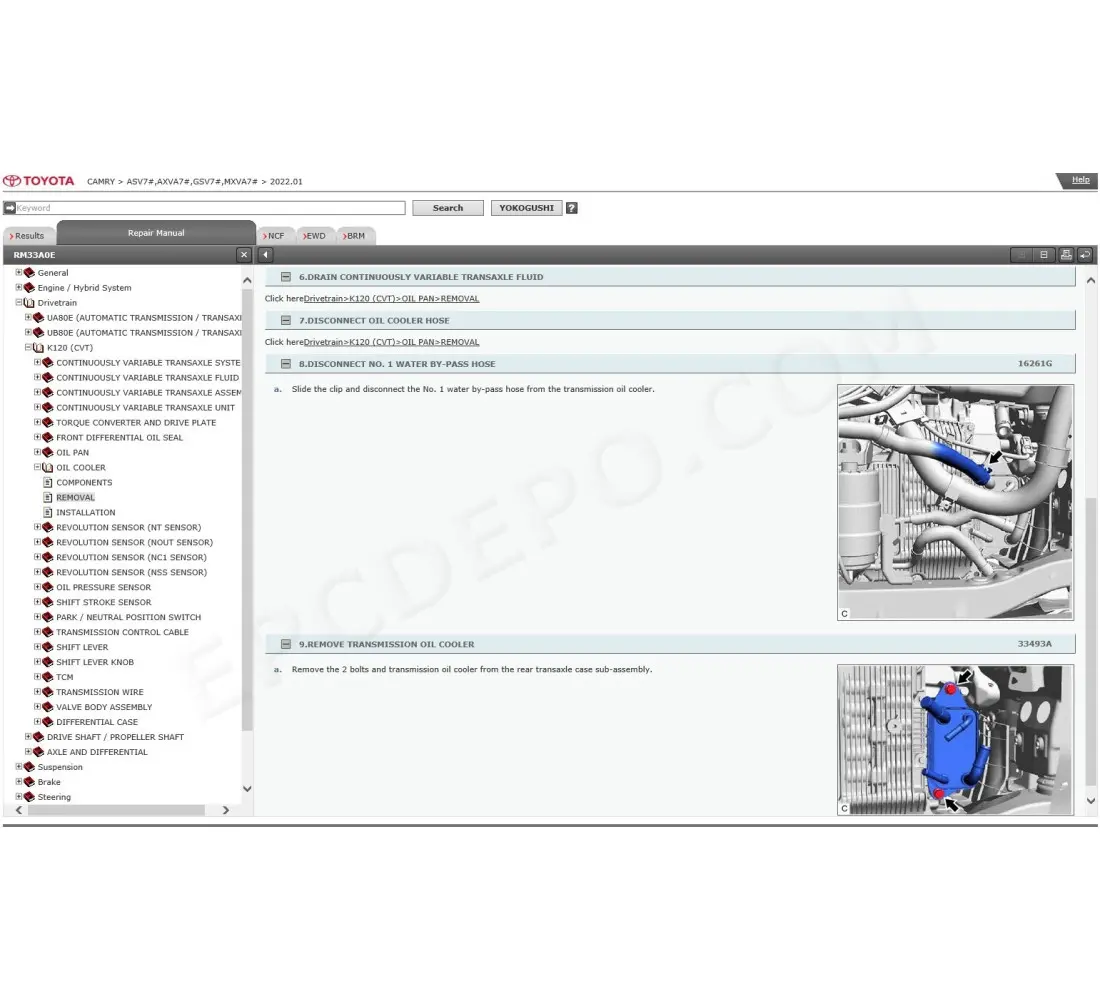

2. Diagnosis: Carefully assess the system to identify any anomalies. Listen for unusual noises and check for fluid leaks, which can provide crucial insights into underlying problems.

3. Disassembly: Once the issues are identified, proceed to dismantle the assembly with caution. Take note of the arrangement of parts, as this will assist in the reassembly phase.

4. Component Inspection: Examine each part for wear and damage. Look for signs of deterioration, such as cracks or excessive play, and determine which components require replacement.

5. Cleaning: Thoroughly clean all components using appropriate solvents. This step is vital to remove debris and old lubricants that could hinder performance when reassembled.

6. Replacement: Install any new or refurbished parts as necessary. Ensure that each component is fitted correctly and securely to prevent future issues.

7. Reassembly: Carefully reassemble the system, following the notes taken during disassembly. Ensure that all fasteners are torqued to the manufacturer’s specifications.

8. Testing: Finally, conduct a comprehensive test to confirm that the system operates smoothly. Monitor for any irregularities during this phase, as it is critical to verify the success of the procedure.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s drivetrain requires consistent care and attention. Adopting proper habits can significantly enhance its lifespan and performance, ultimately saving you time and money in the long run.

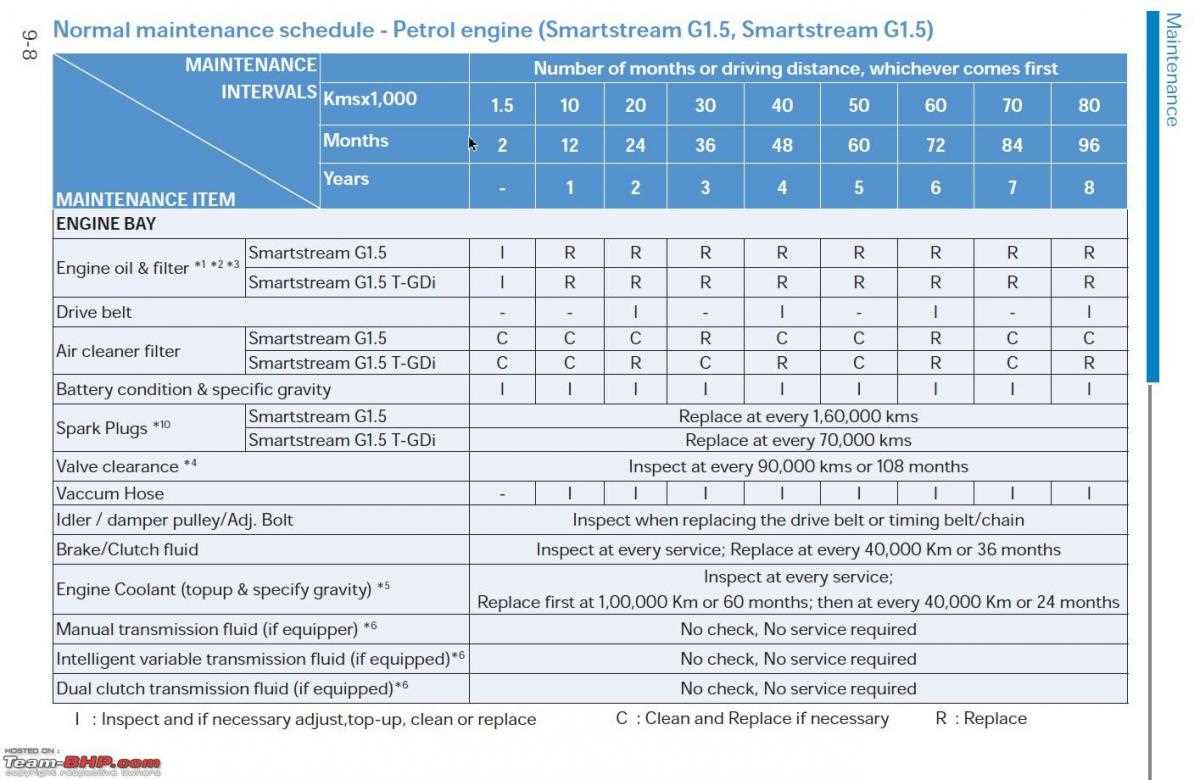

Regular Fluid Checks

Maintaining the appropriate fluid levels is essential for optimal operation. Inspecting and replacing fluids as needed can prevent excessive wear and tear.

Scheduled Inspections

Frequent examinations by a professional can identify potential issues before they escalate. Early detection is key to minimizing damage and ensuring smooth functionality.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Fluid Level Check | Every 3,000 miles | Look for leaks and ensure proper levels. |

| System Inspection | Every 6 months | Have a professional evaluate the system. |

| Fluid Change | Every 15,000 miles | Use manufacturer-recommended products. |

Signs Your CVT Needs Attention

Recognizing the indicators of potential issues in your vehicle’s shifting system is crucial for maintaining optimal performance. Addressing these signs promptly can prevent further complications and ensure a smoother driving experience.

Unusual Noises

If you start hearing unexpected sounds such as grinding, whining, or buzzing, it may be a sign that something is amiss. These noises can indicate that components within the system are not functioning correctly, necessitating immediate inspection.

Difficulty in Acceleration

Experiencing hesitation or delays when accelerating can be another warning signal. If your vehicle struggles to gain speed or feels sluggish, it might be time to have the shifting mechanism checked by a professional.

Pay attention to these signs to maintain your vehicle’s efficiency. Early detection can save you time and money in the long run.

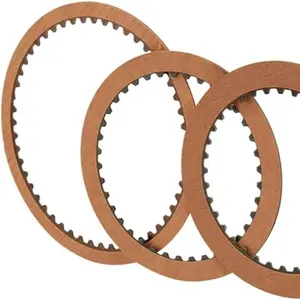

Choosing the Right Replacement Parts

Selecting suitable components for your vehicle’s system is crucial for ensuring optimal performance and longevity. Quality parts not only enhance functionality but also contribute to overall safety. It is essential to consider various factors when making your choice, including compatibility, durability, and manufacturer reputation.

Factors to Consider

When evaluating options, keep the following elements in mind:

| Factor | Description |

|---|---|

| Compatibility | Ensure the parts are specifically designed for your vehicle’s model and year. |

| Material Quality | Opt for components made from high-quality materials for increased reliability. |

| Brand Reputation | Research brands known for producing dependable parts, as this can affect overall performance. |

Where to Source Parts

Various outlets provide replacement components, including authorized dealerships, local auto parts stores, and online retailers. Each option has its advantages, such as pricing, availability, and warranty offerings. Always verify the credibility of the seller to avoid counterfeit products.

Diagnosing Electrical Problems

Identifying issues within electronic systems is crucial for ensuring optimal performance. This section explores various strategies to uncover faults that may hinder functionality.

Common Symptoms of Electrical Issues

- Intermittent operation of components

- Unusual sounds during operation

- Inconsistent power delivery

- Warning lights or indicators on the dashboard

Steps for Diagnosis

- Start with a visual inspection of wiring and connectors.

- Utilize a multimeter to check for proper voltage levels.

- Examine fuses and relays for any signs of damage or malfunction.

- Test individual components to isolate the source of the problem.

Testing Your CVT After Repairs

Once maintenance is completed, ensuring optimal performance is crucial. This phase involves a series of assessments designed to confirm that everything functions correctly. Proper evaluation not only safeguards your investment but also enhances the longevity of your vehicle.

Begin by taking the vehicle for a short drive, focusing on smooth acceleration and deceleration. Pay attention to any unusual noises or vibrations that may indicate underlying issues. Monitoring responsiveness during gear changes can reveal the effectiveness of recent adjustments.

Subsequently, check the fluid levels and quality. Clean, adequately filled fluids are essential for optimal operation. Any discoloration or burnt smell may suggest a need for further attention.

Finally, utilize diagnostic tools to analyze performance metrics. These readings provide valuable insights into the system’s efficiency and help identify any remaining concerns that need addressing. Consistent testing after any service ensures reliability and peace of mind on the road.

Cost Factors in CVT Repairs

Understanding the financial implications of servicing a specific type of automotive system is crucial for vehicle owners. Various elements contribute to the overall expenses, ranging from parts and labor to diagnostic assessments. Evaluating these components can help in making informed decisions regarding maintenance and potential upgrades.

One significant factor influencing costs is the quality of components used during the process. Higher-quality parts often come with a premium price but can lead to enhanced durability and performance. Conversely, opting for budget alternatives may save money initially but could result in additional expenses in the long run due to frequent replacements.

Labor charges also play a crucial role in the total expenses. Rates can vary significantly based on geographic location and the expertise of the technicians involved. Facilities with specialized knowledge in handling these intricate systems may command higher fees, but their proficiency can lead to more reliable outcomes.

Moreover, the complexity of the issue at hand affects pricing. Minor adjustments or fluid changes will typically be less expensive than extensive overhauls or replacements. A thorough diagnostic procedure is often necessary to pinpoint the exact nature of the problem, adding to the overall cost but ensuring a targeted solution.

In summary, multiple factors influence the expenses related to servicing this automotive system. Being aware of these elements can empower owners to make better choices, ensuring that they achieve the best balance between cost and quality in their vehicle maintenance efforts.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of automatic shifting systems. Whether you’re a seasoned technician or a curious car owner, you’ll find valuable insights to help you understand these mechanisms better.

Common Issues and Solutions

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Slipping during acceleration | Low fluid levels or contamination | Check and refill fluid; inspect for leaks |

| Unusual noises | Worn components or insufficient lubrication | Examine and replace damaged parts |

| Delayed shifting | Faulty sensors or low pressure | Test sensors and assess hydraulic pressure |

Maintenance Tips

Regular upkeep is crucial for optimal performance. Ensure fluid levels are checked frequently, and consider professional assessments to catch potential issues early.