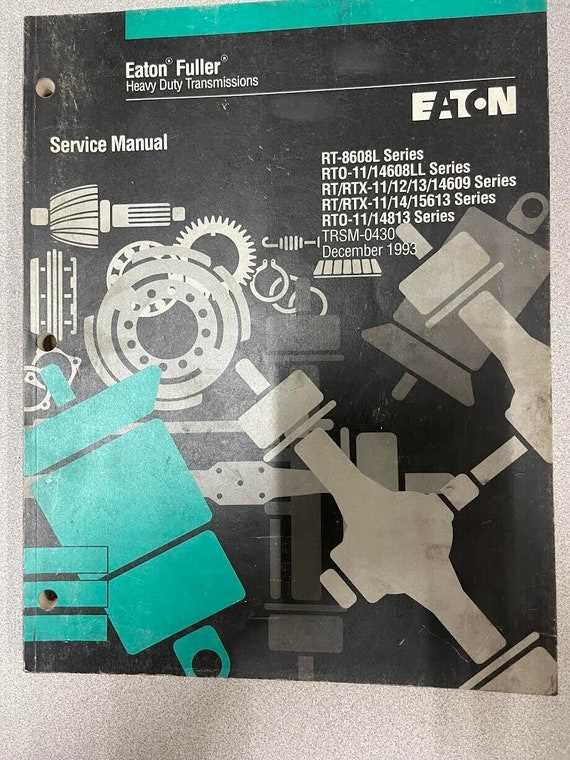

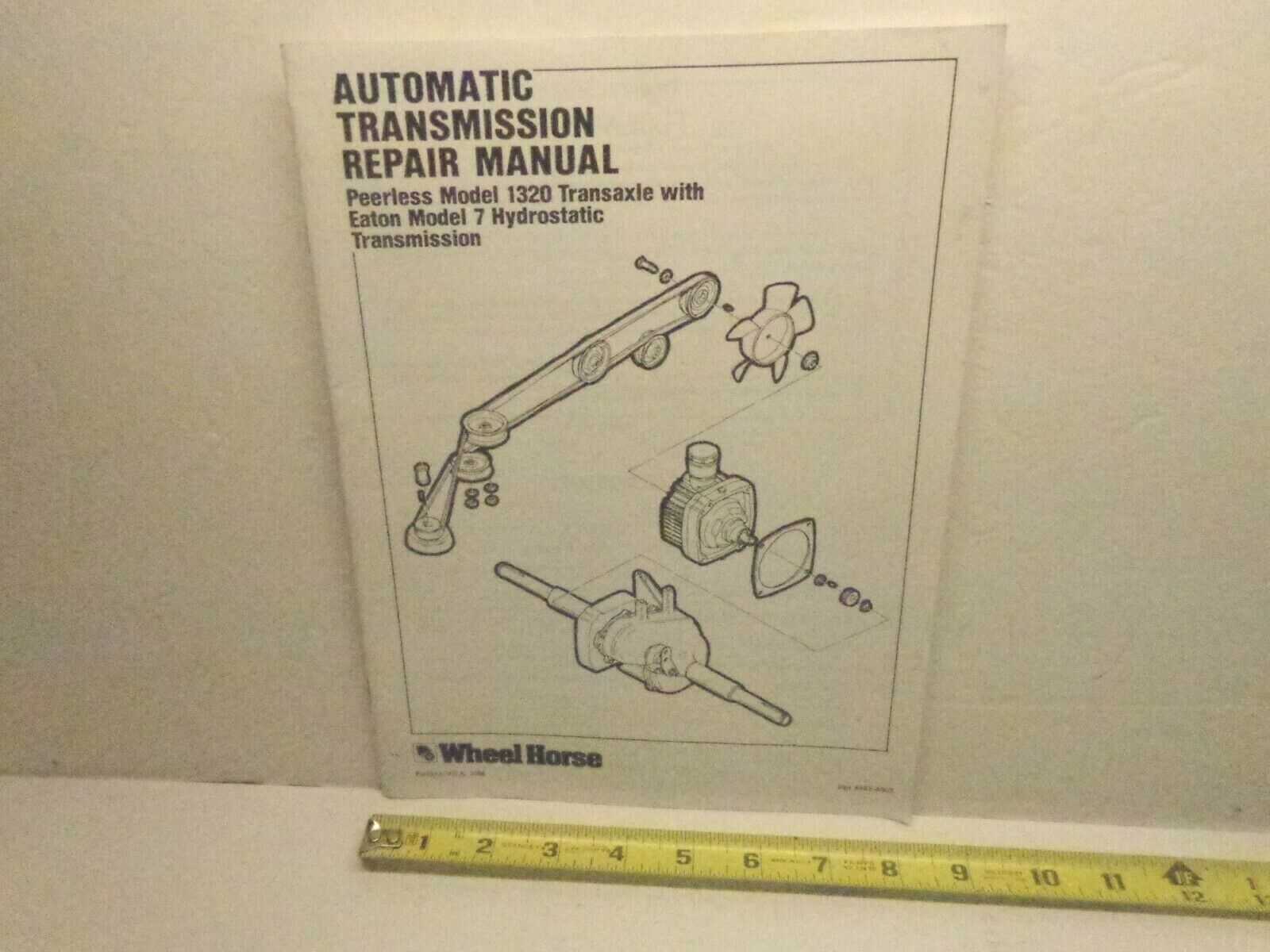

Eaton Transmission Repair Guide

When it comes to the intricate workings of vehicular systems, having access to comprehensive resources is crucial. This section delves into essential guidelines that aid in the upkeep and functionality of complex mechanisms found in many automotive applications. By grasping these principles, enthusiasts and professionals alike can enhance their knowledge and ensure optimal performance.

In the following passages, we will explore various strategies and techniques that are vital for maintaining these essential components. Whether you are a seasoned technician or a budding hobbyist, familiarizing yourself with these practices can empower you to tackle challenges effectively. Emphasizing hands-on approaches and thorough understanding, this resource serves as a valuable companion in your journey through the world of automotive systems.

By engaging with this information, you will be better prepared to navigate the complexities involved in the maintenance of these intricate systems. Knowledge is a powerful tool, and equipping yourself with the right techniques will not only bolster your skills but also contribute to the longevity and reliability of the vehicles you work on.

Eaton Transmission Overview

This section provides a comprehensive look at a well-known brand in the automotive industry, focusing on its sophisticated gear-shifting systems. These mechanisms are designed to enhance vehicle performance and efficiency, catering to both commercial and personal applications. Understanding their functionality is essential for effective maintenance and optimal operation.

The systems feature a variety of innovative technologies that ensure seamless gear changes. These advancements not only improve power delivery but also enhance fuel efficiency, making them a popular choice among vehicle manufacturers and fleet operators alike. With a focus on durability and reliability, these units are engineered to withstand demanding conditions.

In the realm of heavy-duty vehicles, the intricacies of these systems are crucial for achieving high performance under various loads and terrains. The design principles emphasize ease of use and user-friendly operation, which contribute to their widespread adoption in the market. Familiarity with their structure and function is invaluable for anyone involved in vehicle maintenance and optimization.

Common Issues and Symptoms

Understanding the frequent problems that arise with automotive gear systems is crucial for effective maintenance and timely intervention. Many drivers may experience various indicators of malfunction, ranging from unusual noises to performance issues. Recognizing these signs early can prevent more significant complications and costly repairs down the line.

Symptoms to Look Out For

Several key indicators can help identify potential difficulties within the system. Paying close attention to these symptoms can lead to prompt action and minimize damage.

| Symptoms | Description |

|---|---|

| Unusual Noises | Grinding, whining, or clunking sounds may indicate internal issues. |

| Slipping | Unexpected changes in gear engagement can signal underlying problems. |

| Fluid Leaks | Visible leaks beneath the vehicle can suggest seal or gasket failures. |

| Overheating | Excessive heat may point to fluid deficiencies or cooling issues. |

Preventive Measures

Regular maintenance checks are essential to prolong the life of the system. Monitoring fluid levels, inspecting for leaks, and addressing minor concerns promptly can help maintain optimal functionality.

Essential Tools for Repairs

When undertaking complex mechanical tasks, having the right equipment is crucial for ensuring efficiency and success. The right set of instruments not only streamlines the process but also minimizes the risk of damage to components. In this section, we will explore key implements that facilitate seamless maintenance and adjustment tasks.

Wrenches are indispensable in any toolkit, as they provide the necessary leverage to fasten or loosen various fixtures. A combination of sizes will cater to a wide range of applications, allowing for flexibility during the process.

Socket Sets enhance accessibility, especially in tight spaces. These sets typically include a variety of socket sizes that can quickly attach to ratchets, making it easier to tackle stubborn bolts or nuts without excessive effort.

Torque Tools are essential for applying specific force to fasteners, ensuring that each component is secured to the manufacturer’s specifications. This precision helps maintain optimal performance and longevity of the entire system.

Diagnostic Equipment plays a pivotal role in identifying issues that may not be visible to the naked eye. These devices can reveal underlying problems, guiding the technician towards effective solutions.

Finally, Lubricants and cleaning agents are vital for maintaining the smooth operation of moving parts. Proper application can prevent wear and tear, extending the lifespan of various elements.

Step-by-Step Disassembly Process

Understanding the procedure for taking apart a complex mechanical system is crucial for effective servicing. This section will guide you through a systematic approach to dismantling, ensuring that each component is carefully handled and cataloged for reassembly.

Preparation Phase

- Gather necessary tools: wrenches, screwdrivers, pliers, and a torque wrench.

- Establish a clean, organized workspace to prevent losing parts.

- Review any relevant documentation to familiarize yourself with the assembly layout.

Disassembly Steps

- Begin by removing external covers and shields to access the internal structure.

- Disconnect all electrical connectors and wiring harnesses carefully.

- Detach any linkage or mechanical connections that may hinder further access.

- Proceed to remove bolts and screws, keeping them sorted for easy reassembly.

- Extract larger components methodically, noting their position and orientation.

- Document each step with photographs or notes to aid in the reassembly process.

Key Components and Their Functions

Understanding the essential elements of a gear shifting system is crucial for effective maintenance and troubleshooting. Each part plays a significant role in ensuring smooth operation and performance, contributing to the overall functionality of the vehicle’s drivetrain.

| Component | Function |

|---|---|

| Gear Selector | Allows the driver to choose the desired gear ratio for optimal performance. |

| Clutch Assembly | Engages and disengages the engine from the drivetrain to facilitate smooth gear changes. |

| Input Shaft | Transfers power from the engine to the gear system, playing a vital role in the vehicle’s dynamics. |

| Output Shaft | Delivers power to the wheels, translating the rotational movement into forward motion. |

| Synchronizers | Help match the speeds of the gears during shifts, ensuring seamless transitions between ratios. |

Reassembly Best Practices

Successfully putting components back together requires careful attention to detail and adherence to certain guidelines. Ensuring each part fits correctly not only enhances performance but also prolongs the lifespan of the system.

Follow these essential practices for an effective reassembly process:

- Organize Parts: Keep all components sorted and labeled to avoid confusion during reassembly.

- Inspect for Wear: Examine each piece for signs of damage or wear that may necessitate replacement.

- Use Proper Tools: Select the appropriate tools for each task to prevent damage to delicate components.

When reassembling, consider the following steps:

- Start with a Clean Workspace: Ensure your area is free from debris and contaminants.

- Follow a Logical Sequence: Reassemble parts in the order specified in your reference guide to maintain consistency.

- Double-Check Alignments: Confirm that all components are aligned correctly before securing them in place.

By implementing these best practices, you can achieve a smooth and efficient reassembly process that enhances the overall functionality of the system.

Fluid Types and Maintenance Tips

Choosing the right liquids and understanding their maintenance is crucial for optimal performance and longevity of your system. Proper selection not only enhances functionality but also prevents potential issues that may arise from using unsuitable products. Regular upkeep ensures that all components operate smoothly, minimizing wear and tear.

Types of Fluids

There are various liquids available for different applications. Each type serves specific purposes and has unique properties that cater to the demands of the system. Below is a summary of the commonly used fluids:

| Fluid Type | Purpose | Characteristics |

|---|---|---|

| Hydraulic Fluid | Power transfer and lubrication | High viscosity, temperature stability |

| Gear Oil | Protection against wear | Good adhesion, high pressure tolerance |

| Coolant | Temperature regulation | Low freezing point, high boiling point |

Maintenance Recommendations

Regular inspections and fluid changes are vital for maintaining the efficiency of your system. Here are some essential tips:

- Check fluid levels regularly to avoid operational issues.

- Replace fluids as recommended by the manufacturer to ensure optimal performance.

- Monitor for any signs of contamination or degradation, which could indicate the need for immediate attention.

Diagnostic Techniques for Troubleshooting

Effective problem-solving in complex mechanical systems requires a systematic approach. This section explores various methods to identify and address issues that may arise, emphasizing the importance of thorough examination and testing. Utilizing a combination of observational skills, analytical thinking, and specialized tools can lead to efficient resolutions.

Visual Inspections

Starting with a comprehensive visual check can reveal obvious signs of wear, damage, or misalignment. Inspecting components for leaks, cracks, or unusual wear patterns is crucial. Noting any irregularities can guide further diagnostic steps and help prioritize areas for in-depth analysis.

Functional Testing

Conducting functional assessments is essential for determining the operational status of the system. Engaging various functionalities and monitoring responses can highlight performance discrepancies. Using diagnostic equipment to measure pressure, temperature, and other relevant parameters provides valuable insights into the underlying issues.

Transmission Upgrades and Enhancements

Improving the performance and reliability of a vehicle’s shifting mechanism can significantly enhance overall driving experience. Various modifications can be implemented to elevate efficiency, responsiveness, and durability. This section explores several options available for enthusiasts and professionals alike.

- Performance Kits: Specialized kits are designed to increase power output and optimize shifting speeds.

- Fluid Improvements: Upgrading to high-performance lubricants can reduce friction and enhance heat resistance.

- Electronic Enhancements: Incorporating advanced electronic controls can improve shift timing and precision.

Considerations for each enhancement may vary based on specific goals and driving conditions. Understanding the impact of these modifications ensures informed decisions are made for optimal results.

- Custom Calibration: Tailoring electronic settings can maximize performance based on individual driving habits.

- Reinforced Components: Using stronger materials can prolong the lifespan of critical parts.

- Weight Reduction: Streamlining design can lead to quicker responses and improved efficiency.

Evaluating the advantages and potential drawbacks of each option is crucial for achieving desired outcomes. Engaging with experienced professionals can provide valuable insights into the best upgrades for specific needs.

Safety Precautions During Repair

When undertaking maintenance on automotive components, ensuring safety is paramount. Adhering to proper protocols not only protects the individual performing the work but also safeguards the vehicle and surrounding environment. Here are essential guidelines to follow during the process.

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the workspace is well-ventilated to prevent inhalation of harmful fumes.

- Disconnect the vehicle’s battery to avoid electrical hazards.

- Use jack stands when lifting the vehicle to prevent accidents from slips or falls.

- Keep the workspace tidy and free of clutter to minimize trip hazards.

It is crucial to have a fire extinguisher accessible in case of emergencies. Additionally, following manufacturer guidelines and consulting technical documents can provide valuable insights into specific safety measures relevant to the components being serviced.

- Read through all safety warnings associated with the components.

- Double-check tools and equipment before use to ensure they are in good condition.

- Work with a partner when dealing with heavy parts to distribute weight safely.

By prioritizing these safety measures, individuals can enhance their protection while effectively maintaining automotive systems.

Finding Professional Repair Services

When it comes to maintaining and fixing complex machinery, locating skilled technicians is crucial. A qualified service provider can ensure that your equipment operates smoothly and efficiently, minimizing downtime and maximizing performance. Knowing where to seek these professionals can make all the difference in the longevity of your systems.

Here are some key points to consider when searching for expert services:

| Criteria | Description |

|---|---|

| Experience | Look for technicians with extensive backgrounds in handling specific machinery types, as they will have the necessary expertise. |

| Certifications | Ensure that the professionals have relevant certifications that demonstrate their qualifications and commitment to quality. |

| Reputation | Research online reviews and testimonials to gauge the reliability and service quality of the providers you are considering. |

| Cost | Compare pricing among different service options, but remember that the cheapest option may not always provide the best value. |

| Warranty | Check if the service provider offers warranties on their work, which can provide peace of mind regarding the durability of their repairs. |

By focusing on these elements, you can identify professionals who will effectively address your machinery’s needs, ensuring optimal performance and reliability.