Comprehensive Guide to Manual Transmission Repairs

In the world of automotive maintenance, understanding the intricate workings of gear shifting systems is essential for enthusiasts and professionals alike. These systems play a crucial role in the overall performance of a vehicle, and gaining insight into their components can significantly enhance your repair skills.

This section provides comprehensive instructions to help you navigate the complexities involved in servicing these vital systems. By following detailed procedures, you can ensure that each part is correctly addressed, leading to improved functionality and longevity.

Furthermore, having a solid grasp of the assembly and disassembly processes can save both time and resources. Whether you’re a seasoned mechanic or a curious novice, the information presented here will empower you to tackle repairs confidently and effectively.

Understanding Manual Transmission Basics

This section provides an overview of the essential principles behind the system responsible for power transfer in vehicles. Familiarity with its components and operation is crucial for anyone interested in automotive mechanics.

Key Components

- Clutch: Engages and disengages the engine from the system.

- Gear Set: Determines the ratio of engine speed to wheel speed.

- Selector Mechanism: Allows the driver to choose different ratios.

- Input and Output Shafts: Facilitate power flow between the engine and wheels.

Operating Principles

The functioning of this system relies on several fundamental concepts:

- Engagement: The driver uses the clutch to connect or disconnect the engine’s power.

- Gear Shifting: Changing gears alters the vehicle’s speed and torque.

- Synchronization: Smooth gear changes require precise timing and matching of speeds.

Understanding these basics lays the groundwork for more advanced topics related to the system’s maintenance and performance optimization.

Common Issues in Manual Gearboxes

Understanding the typical challenges faced by gear systems is essential for effective troubleshooting. Various factors can lead to performance issues, affecting the overall driving experience. Recognizing these problems early can prevent more severe damage and costly repairs.

Frequent Problems

Among the most common difficulties encountered are issues related to shifting, noise, and fluid leaks. Each of these can signal underlying complications that may require immediate attention.

Impact of Wear and Tear

As components endure regular use, they naturally experience wear and tear. This deterioration can manifest in several ways, often leading to more significant operational challenges if not addressed promptly.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Difficulty Shifting | Stiff or sticky gear engagement | Worn synchros, low fluid levels |

| Unusual Noises | Grinding or clunking sounds | Worn bearings, damaged gears |

| Fluid Leaks | Puddles under the vehicle | Worn seals, cracked cases |

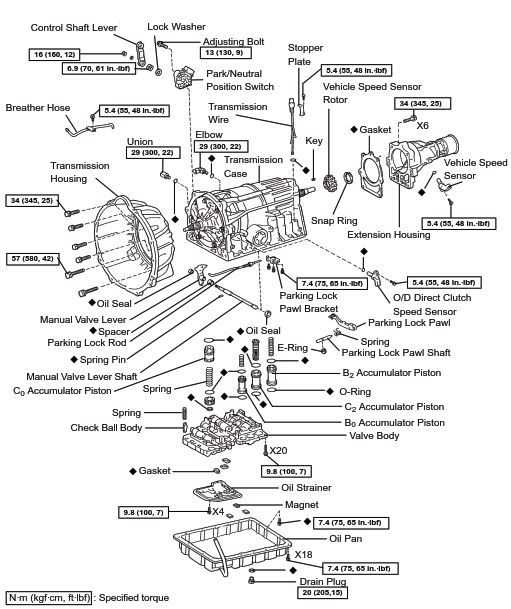

Tools Required for Repairs

When undertaking the task of overhauling a vehicle’s shifting system, having the right equipment is essential for achieving optimal results. This section outlines the necessary instruments and devices that will facilitate a seamless process, ensuring efficiency and accuracy in every step.

The toolkit should include basic hand tools such as wrenches, sockets, and screwdrivers, which are vital for loosening and tightening various components. Additionally, specialty tools designed specifically for this type of work can greatly enhance performance. These may include alignment tools and those for adjusting clutch mechanisms, which can be crucial for precise adjustments.

Moreover, a reliable hydraulic lift or jack will provide the necessary access to the vehicle’s undercarriage, allowing for more comfortable and thorough inspections. Safety equipment, such as gloves and goggles, should also be included to protect the technician throughout the procedure.

Lastly, having a comprehensive set of torque specifications and assembly diagrams can assist in ensuring that every part is reassembled correctly, leading to improved functionality and longevity of the system. With the right tools at hand, the process becomes more manageable and effective.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues with a specific mechanical system. Following these structured steps ensures a thorough assessment and resolution of any underlying problems, promoting optimal functionality and longevity.

- Preparation:

- Gather necessary tools and equipment.

- Ensure a clean and organized workspace.

- Review relevant guidelines and specifications.

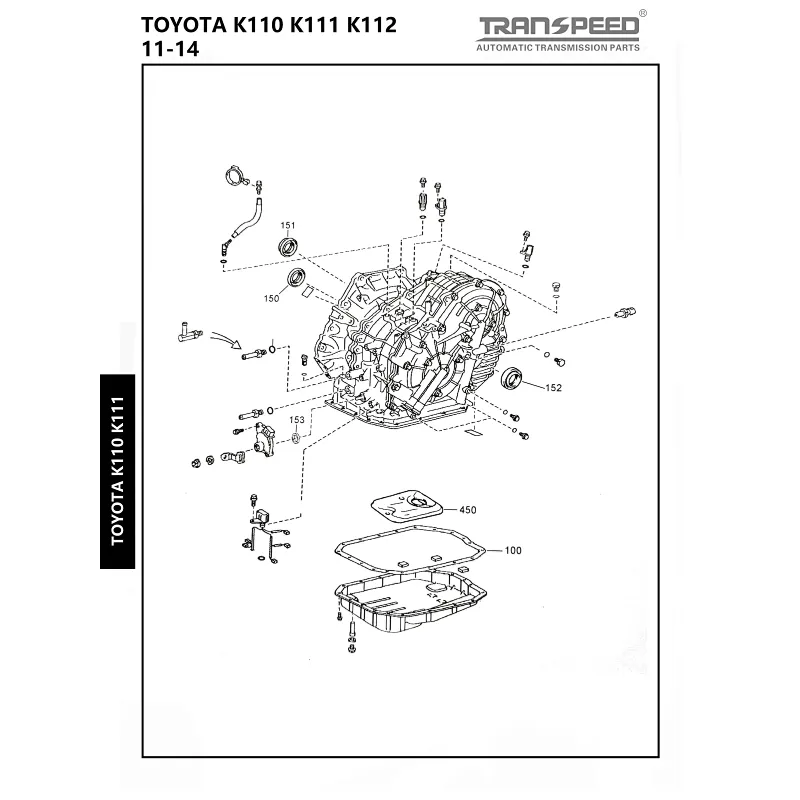

- Disassembly:

- Carefully remove any exterior components.

- Document the disassembly process for reassembly.

- Keep track of fasteners and small parts.

- Inspection:

- Examine all parts for wear and damage.

- Identify any components that require replacement.

- Check for proper alignment and connections.

- Replacement:

- Install new or refurbished components as needed.

- Follow specifications to ensure correct fitment.

- Utilize appropriate lubricants where necessary.

- Reassembly:

- Carefully reattach all removed components.

- Verify that all fasteners are secure.

- Consult documentation to ensure accuracy.

- Testing:

- Conduct tests to confirm proper operation.

- Monitor for unusual noises or issues.

- Make any necessary adjustments based on performance.

Replacing Clutch Components

Over time, essential parts responsible for the engagement and disengagement of power in a vehicle may experience wear and require replacement. This section outlines the steps necessary to effectively substitute these components, ensuring optimal performance and longevity.

Identifying Symptoms: Before beginning the replacement process, it’s crucial to recognize signs that indicate the need for new parts. Common indicators include difficulty in shifting gears, unusual noises during operation, and a spongy or unresponsive pedal feel.

Preparation: Start by gathering the necessary tools and components. A proper workspace is essential for efficiency and safety. Ensure that the vehicle is securely lifted and supported, providing adequate access to the area of interest.

Removal Process: Carefully detach the old components, taking note of their configuration for reference during reinstallation. Use appropriate techniques to avoid damaging surrounding elements. Inspect all removed parts for additional signs of wear.

Installation of New Parts: When placing the new components, ensure proper alignment and secure fastening according to specifications. This step is critical to avoid future complications and ensure smooth operation.

Testing: Once everything is in place, conduct a thorough check by engaging the pedal and shifting through all gears. Listen for any unusual sounds and feel for smooth operation to confirm successful replacement.

By following these guidelines, the process of substituting critical parts can be completed effectively, enhancing the vehicle’s overall functionality.

Fluid Maintenance and Replacement

Proper upkeep of internal fluids is essential for optimal functionality and longevity of any mechanical system. Regular monitoring and timely substitution of these vital substances can significantly enhance performance and prevent unnecessary wear and tear.

In this section, we will cover key practices for maintaining and replacing essential liquids, ensuring your system operates smoothly and efficiently.

- Regular Inspection: Check fluid levels frequently to identify any discrepancies that may indicate leaks or degradation.

- Fluid Quality Assessment: Observe the color and consistency of the liquid. Dark or contaminated fluids often signal the need for replacement.

- Scheduled Replacement: Follow the manufacturer’s guidelines for fluid change intervals to ensure optimal performance.

- Proper Disposal: Always dispose of used fluids responsibly, adhering to local regulations to minimize environmental impact.

By prioritizing fluid maintenance, you can help safeguard the integrity of your system and promote its reliable operation over time.

Troubleshooting Transmission Problems

Identifying issues within a vehicle’s shifting system can be a daunting task. Various symptoms can arise, indicating that something may be amiss. Recognizing these signs early can prevent further complications and ensure a smoother driving experience.

Common indicators of malfunction include unusual noises, difficulty in engaging gears, or unexpected slippage. By systematically examining each component and understanding the potential causes, you can effectively address these concerns.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| Grinding noise when shifting | Worn or damaged components | Inspect and replace as necessary |

| Inability to shift into gear | Fluid levels low or contaminated | Check and replace fluid |

| Unexplained slippage | Worn friction surfaces | Evaluate and replace components |

| Fluid leaks | Damaged seals or gaskets | Locate leaks and seal or replace |

Adjusting Gear Linkage Correctly

Proper calibration of the shifting mechanism is crucial for seamless operation and responsiveness. When this system is precisely aligned, it ensures smooth transitions between gears, enhancing the overall driving experience. This section outlines the necessary steps to achieve optimal adjustment for effective gear selection.

| Step | Description |

|---|---|

| 1 | Begin by inspecting the linkage components for wear or damage. Ensure all parts are clean and free of debris. |

| 2 | Loosen the securing fasteners on the linkage to allow for movement. |

| 3 | Shift into the neutral position and align the linkage accordingly. Ensure the connection points are positioned correctly. |

| 4 | Tighten the fasteners securely to maintain the alignment achieved during adjustment. |

| 5 | Test the gear selection by engaging each position and verifying smooth operation. |

Following these steps will help ensure the shifting mechanism operates efficiently, reducing the risk of misalignment and enhancing vehicle performance.

Preventative Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle’s power transfer system. By adhering to a few simple practices, you can help prevent costly issues down the line and maintain a smooth driving experience.

- Check fluid levels regularly to ensure they are within the recommended range.

- Inspect seals and gaskets for wear and replace them as needed to prevent leaks.

- Keep the components clean from dirt and debris to avoid potential damage.

- Perform routine inspections of linkage and associated mechanisms for proper function.

Incorporating these practices into your maintenance routine can enhance the reliability of your vehicle’s drivetrain and provide peace of mind during your travels.

When to Seek Professional Help

Recognizing the right moment to consult an expert can prevent further complications and ensure efficient resolution of issues. Certain situations require specialized knowledge and tools that go beyond basic troubleshooting.

- Persistent Issues: If problems continue despite your efforts, it’s time to consider professional assistance.

- Unfamiliar Symptoms: Uncommon sounds or behaviors that you can’t identify should be addressed by a qualified technician.

- Complex Repairs: When tasks require advanced techniques or specialized equipment, seeking help is advisable.

- Time Constraints: If your schedule doesn’t allow for in-depth repairs, professionals can save you valuable time.

- Safety Concerns: If you’re unsure about the safety of your vehicle, consult an expert to avoid potential hazards.

Understanding when to engage a professional can not only enhance the longevity of your vehicle but also ensure a safe and reliable driving experience.