Comprehensive Guide to U241E Transmission Repair

The process of enhancing and maintaining automotive systems is essential for ensuring optimal performance and longevity. This segment delves into comprehensive approaches to addressing common issues encountered in specific gear systems, providing step-by-step instructions and insights for successful interventions.

Understanding the intricacies involved in these operations can greatly facilitate troubleshooting and restoration efforts. Equipped with the right information, enthusiasts and professionals alike can navigate through various challenges, from identifying symptoms to implementing effective solutions.

Additionally, this guide offers valuable tips and tricks to simplify the workflow, making complex tasks more manageable. By fostering a thorough comprehension of the necessary techniques and tools, individuals can confidently embark on their journey towards efficient system enhancement.

U241e Transmission Overview

This section provides a comprehensive understanding of the specific type of gear mechanism found in various vehicles. Known for its advanced design, this system ensures smooth shifting and optimal power delivery, contributing significantly to overall performance and driving experience.

Featuring a sophisticated hydraulic control unit, this setup efficiently manages gear engagement and disengagement, allowing for seamless transitions during operation. Its engineering incorporates various sensors and electronic components that work in harmony to enhance responsiveness and reliability.

Additionally, the configuration is designed with durability in mind, capable of withstanding the rigors of daily use while maintaining peak efficiency. Regular maintenance and appropriate adjustments are essential for preserving functionality and extending the lifespan of this essential component.

Common Issues and Symptoms

Understanding the prevalent problems and their associated indicators can significantly aid in the effective troubleshooting of your vehicle’s drivetrain. Identifying these signs early can prevent further complications and ensure smoother operation.

Fluid Leaks

Fluid leaks are among the most common signs of potential complications. Any noticeable fluid beneath the vehicle, especially if it has a reddish tint, may indicate a serious issue. Addressing leaks promptly is crucial to maintain optimal performance.

Slipping Gears

Experiencing slipping gears can be alarming, often resulting in unexpected changes in speed or difficulty in maintaining acceleration. This symptom may signal underlying mechanical failures that require immediate attention to prevent further damage.

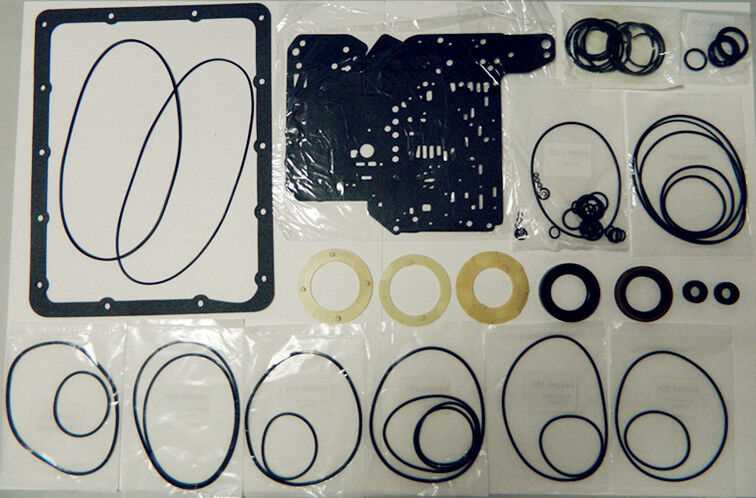

Tools Needed for Repair

To successfully address issues related to automatic gear systems, a variety of essential instruments and equipment are required. These tools not only facilitate the disassembly and reassembly of components but also ensure precise adjustments and measurements throughout the process.

Essential Instruments

- Wrenches and Sockets: For loosening and tightening bolts and nuts.

- Screwdrivers: Essential for handling screws of different types and sizes.

- Torque Wrench: To apply specific torque values for secure fittings.

- Pliers: Useful for gripping and manipulating various components.

Measurement Tools

- Calipers: For measuring gaps and component dimensions accurately.

- Micrometer: Essential for precise thickness measurements.

- Pressure Gauge: To check hydraulic fluid pressure levels.

Having these tools at hand will streamline the process and enhance the overall efficiency of the task at hand, leading to a successful outcome.

Step-by-Step Disassembly Process

This section outlines the procedure for systematically taking apart the unit, ensuring that all components are properly handled and documented. Following a structured approach not only aids in understanding the assembly but also facilitates reassembly, minimizing the risk of errors.

Preparation

- Gather necessary tools: wrenches, screwdrivers, and pliers.

- Set up a clean, organized workspace to prevent misplacing parts.

- Wear safety gear, including gloves and goggles, to ensure personal safety.

Disassembly Steps

- Remove the outer casing by unscrewing all fasteners.

- Carefully detach the electrical connections, labeling each wire for easy reconnection.

- Take out the internal components in the following order:

- First, remove the fluid pump assembly.

- Next, detach the valve body.

- Finally, take out the planetary gear set.

Component Inspection Techniques

Thorough examination of mechanical elements is crucial for ensuring optimal functionality and longevity of automotive systems. By employing effective assessment methods, technicians can identify wear, damage, or irregularities that could lead to performance issues. This section outlines various approaches to inspecting these critical components.

One effective method is the visual inspection, which allows for the identification of obvious signs of damage or degradation. Additionally, the use of specialized tools can enhance the accuracy of assessments. Below are common techniques utilized in evaluating mechanical components:

| Inspection Method | Description |

|---|---|

| Visual Inspection | A basic yet essential technique that involves checking for visible signs of wear, cracks, or misalignment. |

| Dimensional Measurement | Utilizes calipers and gauges to verify that parts meet specified tolerances and dimensions. |

| Non-Destructive Testing (NDT) | Includes methods like ultrasonic or magnetic particle testing to detect internal flaws without damaging components. |

| Functional Testing | Involves assessing the performance of components under operational conditions to ensure they meet functional requirements. |

| Leak Testing | Utilizes pressure or vacuum methods to identify potential leaks in seals and joints. |

By systematically applying these inspection techniques, technicians can ensure that every element operates efficiently, ultimately contributing to the reliability of the entire system.

Reassembly Best Practices

Effective reassembly is crucial for ensuring the longevity and optimal performance of the unit. Adhering to precise methods and techniques can prevent future issues and enhance reliability. This section outlines essential practices to follow during the reconstruction phase.

| Step | Description | Tips |

|---|---|---|

| 1 | Clean all components thoroughly before assembly to remove any contaminants. | Use a suitable solvent and lint-free cloths to avoid scratches. |

| 2 | Inspect each part for wear or damage; replace any defective items. | Utilize a magnifying glass for a detailed examination. |

| 3 | Organize all components and fasteners in a logical order for easier assembly. | Consider using labeled containers to keep track of parts. |

| 4 | Follow the recommended sequence for putting components back together. | Refer to diagrams or guides to ensure accuracy. |

| 5 | Apply appropriate lubricants to moving parts during reassembly. | Use only recommended lubricants to avoid incompatibility. |

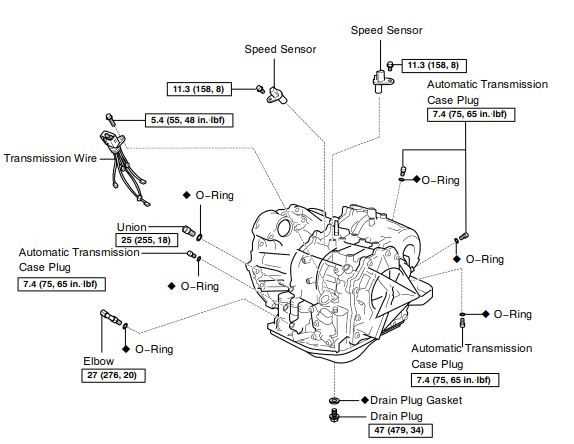

| 6 | Tighten fasteners to specified torque settings to prevent future failures. | Invest in a reliable torque wrench for consistent results. |

| 7 | Conduct a thorough final inspection before closing up the unit. | Double-check connections and alignment to ensure everything is correct. |

By following these best practices, the reconstruction process will be more efficient and effective, leading to a reliable final product. A meticulous approach not only extends the lifespan of the assembly but also enhances overall performance.

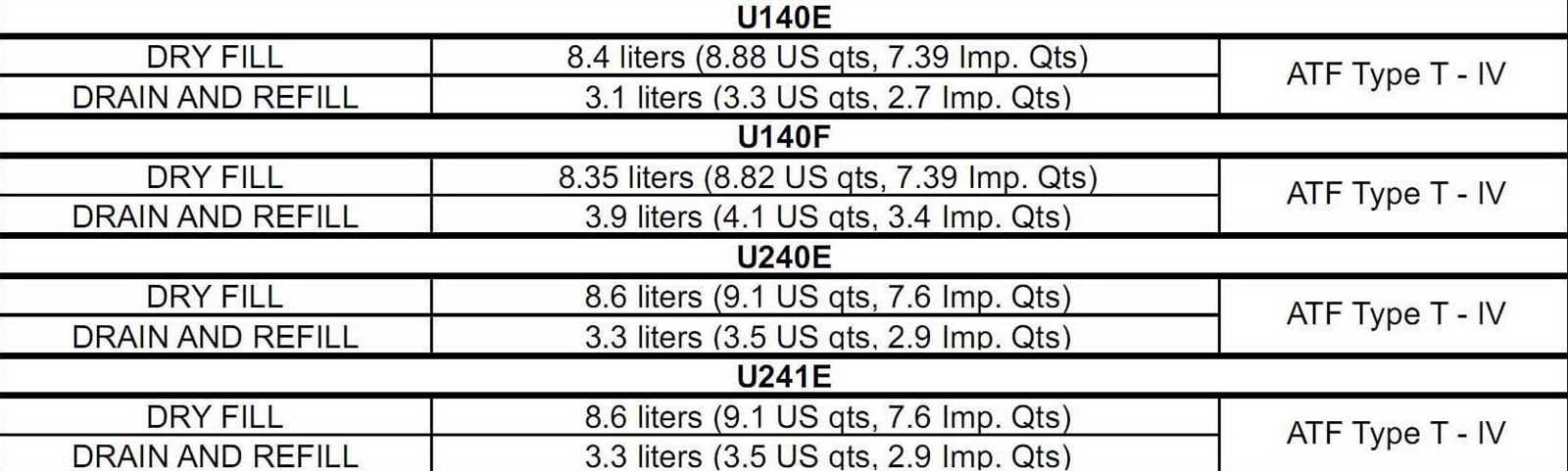

Fluid Change Recommendations

Regular maintenance of the hydraulic system is crucial for optimal performance and longevity. Ensuring the correct type and condition of the fluid helps prevent wear and enhances operational efficiency. Following the manufacturer’s guidelines for fluid replacement intervals can significantly impact the overall reliability of the system.

Recommended Fluid Types

It is essential to use fluids that meet the specifications outlined in the technical guidelines. Selecting the appropriate viscosity and composition will ensure compatibility with the internal components, providing necessary lubrication and protection against overheating.

Change Frequency

Changing the hydraulic fluid at regular intervals is vital. Typically, it is advisable to perform this service every 30,000 to 50,000 miles or according to specific recommendations in the technical documentation. Monitoring the fluid’s condition can also guide the timing of replacements, as contamination or degradation can necessitate more frequent changes.

Troubleshooting Electrical Problems

When dealing with issues related to electrical components, a systematic approach is essential for identifying and resolving malfunctions. Understanding the common symptoms and potential causes can greatly assist in the diagnostic process, ensuring a more efficient and effective solution.

Common Symptoms of Electrical Issues

- Intermittent or complete loss of functionality

- Erratic behavior of electronic systems

- Unexpected warning lights on the dashboard

- Unusual noises during operation

- Burning smell or signs of overheating

Steps for Diagnosis

- Begin by inspecting the wiring and connectors for signs of wear or damage.

- Utilize a multimeter to check for continuity and voltage at various points in the circuit.

- Review any fault codes generated by the onboard diagnostics system.

- Test individual components such as sensors and actuators for proper operation.

- Consult wiring diagrams to ensure all connections align with specifications.

Performance Testing After Repair

Following any restoration process, it is crucial to assess the functionality of the unit to ensure it operates optimally. This phase involves a series of evaluations designed to confirm that all components are working in harmony and that the system meets specified performance criteria. Comprehensive testing helps identify any lingering issues and verifies the effectiveness of the service performed.

Essential Testing Procedures

The following procedures should be conducted to validate performance:

- Fluid Leakage Inspection: Check for any signs of fluid leaks, which could indicate improper seals or fittings.

- Operational Sound Assessment: Listen for unusual noises during operation, as these can be signs of mechanical issues.

- Shift Quality Evaluation: Monitor the smoothness and responsiveness of shifts under various driving conditions.

Final Checks and Measurements

Before concluding the assessment, ensure the following checks are made:

- Measure the temperature of the system during operation to ensure it remains within the recommended range.

- Confirm that the pressure readings align with manufacturer specifications.

- Conduct a road test to evaluate performance under real-world conditions.

Completing these evaluations will provide confidence that the unit is performing as expected and ready for continued use. Regular follow-ups and maintenance checks can further enhance longevity and efficiency.

Maintenance Tips for Longevity

Ensuring the durability of your vehicle’s components involves regular upkeep and attention to detail. By following specific guidelines, you can enhance performance and extend the lifespan of essential systems.

- Regular Fluid Checks: Consistently monitor and replace fluids as necessary. Keeping them at optimal levels prevents overheating and ensures smooth operation.

- Routine Inspections: Schedule periodic assessments to identify wear and tear early. Look for leaks, unusual noises, and changes in performance.

- Timely Component Replacement: Replace worn parts promptly to avoid further damage. Utilize high-quality replacements for better reliability.

- Proper Driving Habits: Adopt driving practices that reduce stress on the system. Avoid aggressive acceleration and heavy towing whenever possible.

- Environment Considerations: Be mindful of operating conditions. Extreme temperatures and harsh terrains can impact performance, so adapt maintenance accordingly.

By implementing these practices, you can foster a reliable and efficient vehicle, minimizing the likelihood of unexpected failures and costly repairs.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of automatic gear systems. Here, you will find essential information to assist you in resolving prevalent issues and understanding the intricacies of these mechanisms.

| Question | Answer |

|---|---|

| What are the signs of malfunction in automatic gear systems? | Common indicators include unusual noises, slipping gears, delayed shifting, and fluid leaks. |

| How often should the fluid be changed? | It is recommended to replace the fluid every 30,000 to 60,000 miles, but check your vehicle’s specifications for precise intervals. |

| Can I perform maintenance tasks myself? | Basic tasks like fluid checks and filter replacements can often be done at home; however, complex repairs should be handled by professionals. |

| What tools are necessary for basic maintenance? | Essential tools include a socket set, wrenches, a fluid pump, and a funnel for fluid changes. |

| Is it safe to drive with noticeable issues? | Driving with signs of dysfunction can lead to more severe damage; it is best to address the problems promptly. |