Volvo I-Shift Transmission Repair Guide

Maintaining the efficiency of a vehicle’s power delivery system is crucial for optimal performance. This section delves into the essential aspects of servicing a complex gear arrangement that plays a pivotal role in ensuring smooth transitions and enhanced drivability. Understanding the intricacies involved in this process is key to achieving longevity and reliability in automotive operations.

Proper upkeep not only involves addressing wear and tear but also entails comprehending the underlying mechanisms that contribute to effective functionality. With the right knowledge and techniques, one can navigate through the various components, ensuring that each element operates harmoniously. This approach is vital for both seasoned technicians and enthusiasts alike.

Equipping oneself with the necessary insights and strategies can significantly improve the longevity of these sophisticated systems. The following sections will provide detailed guidance on the steps involved, helping you to tackle any challenges with confidence and expertise.

Common Issues with i-Shift System

The automated gear shifting system is known for its efficiency and performance; however, it may encounter several challenges that can affect its operation. Understanding these common issues is essential for maintaining optimal functionality.

1. Inconsistent Shifting Behavior: One of the most frequently reported problems is erratic or delayed shifting. This can occur due to sensor malfunctions or calibration issues, leading to a less responsive driving experience.

2. Fluid Contamination: Contaminated fluid can hinder the system’s performance. Regular checks and maintenance are crucial to ensure that the fluid remains clean and free of debris, which can cause wear and tear on components.

3. Electrical Failures: Electrical issues, such as faulty wiring or sensor failures, can disrupt the system’s communication, resulting in improper shifting or warning alerts. Identifying and addressing these electrical problems is vital for smooth operation.

4. Clutch Wear: Over time, the clutch can wear down, affecting the system’s ability to engage and disengage effectively. Monitoring the condition of the clutch is important to prevent further complications and ensure longevity.

5. Software Glitches: Software malfunctions can lead to unexpected behavior in the system. Regular updates and diagnostic checks can help mitigate these issues and improve overall performance.

Maintenance Practices for Longevity

Ensuring the long-lasting performance of any complex mechanism requires a consistent and thorough approach to upkeep. Regular maintenance not only enhances efficiency but also extends the operational lifespan of the system. Implementing best practices can significantly reduce the risk of unexpected failures and costly repairs.

One of the key aspects of effective maintenance is routine inspections. Checking for wear and tear, fluid levels, and potential leaks can prevent minor issues from escalating into major problems. Additionally, adhering to a scheduled servicing plan is crucial, as it allows for timely interventions based on manufacturer recommendations.

Utilizing high-quality lubricants and fluids is essential for optimal functionality. These products are specifically designed to reduce friction and wear, contributing to smoother operation and greater durability. Furthermore, ensuring that components are properly calibrated can enhance performance and prevent premature degradation.

Lastly, staying informed about advancements in technology and maintenance techniques can provide significant advantages. Regularly updating knowledge and skills related to care practices will empower operators to make informed decisions, ultimately fostering a reliable and efficient system.

Diagnostic Tools and Techniques

Effective troubleshooting of modern automotive systems requires a blend of advanced equipment and systematic approaches. Employing the right instruments and methods enables technicians to pinpoint issues swiftly, ensuring efficient resolution and minimizing downtime.

Electronic Scanners are essential tools that interface with a vehicle’s onboard computer systems. These devices read diagnostic trouble codes (DTCs) and provide valuable data regarding system performance, facilitating the identification of underlying problems.

Multimeters play a crucial role in diagnosing electrical issues. By measuring voltage, current, and resistance, these instruments help technicians evaluate the integrity of various components, ensuring they operate within specified parameters.

Pressure gauges are used to assess fluid dynamics within systems, revealing insights into operational effectiveness. Anomalies in pressure readings can indicate potential leaks or blockages, guiding further investigation.

Combining these tools with visual inspections allows for a comprehensive analysis. Technicians often examine wiring harnesses, connectors, and mechanical parts to identify signs of wear, corrosion, or damage that could affect functionality.

Implementing a systematic approach, including data logging during test drives, can reveal performance trends and anomalies not captured by static diagnostics. This holistic strategy enhances the diagnostic process, leading to more accurate outcomes and improved vehicle reliability.

Step-by-Step Repair Procedures

This section outlines a comprehensive approach to addressing issues related to automatic gear systems. Following a systematic method ensures efficiency and effectiveness in resolving common challenges that may arise during operation. Each step is designed to guide users through the essential processes needed to restore functionality.

Preparation and Safety Measures

Before beginning any maintenance work, ensure that the work area is clean and well-lit. Gather all necessary tools and protective equipment. Disconnect power sources to avoid accidental activation of systems. This preparation phase is crucial for ensuring both safety and efficiency during the subsequent tasks.

Inspection and Diagnosis

Start by conducting a thorough inspection of the unit. Look for visible signs of wear, leaks, or damage. Use diagnostic tools to assess the performance of components and identify any irregularities. This initial evaluation will provide valuable insights into the underlying issues that need to be addressed in the repair process.

Replacing Components in the Transmission

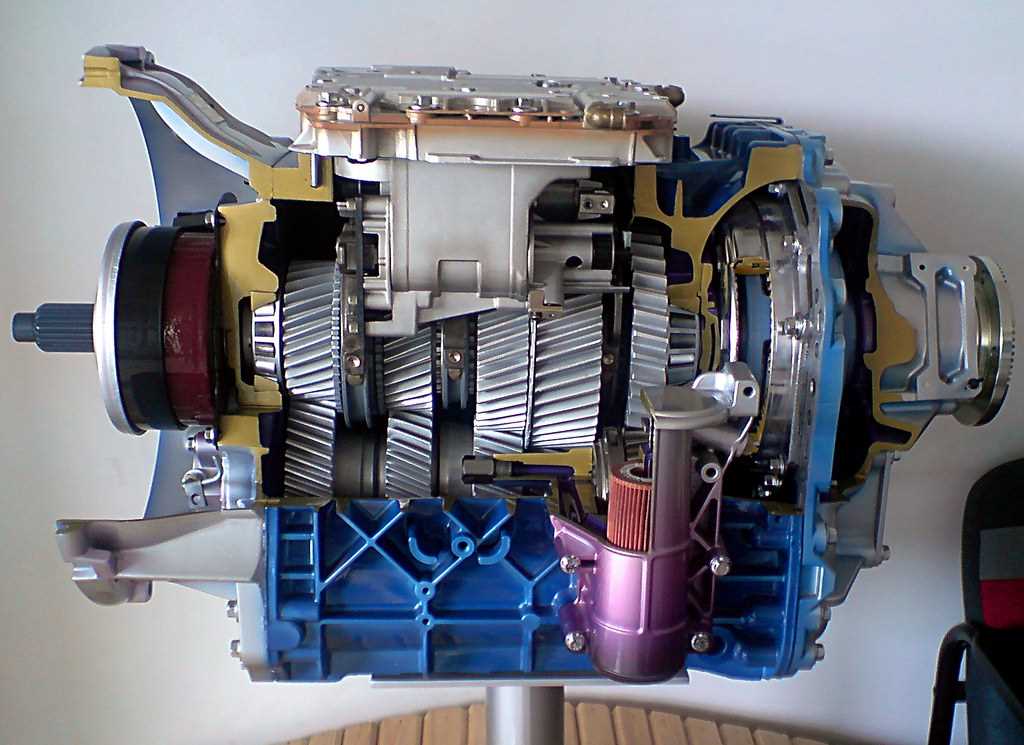

Maintaining optimal performance in automated gear systems involves the careful replacement of various elements. This process ensures smooth operation and extends the lifespan of the entire assembly. Understanding the components and the method of their replacement is crucial for effective servicing.

Before beginning the replacement, it’s essential to gather the necessary tools and components:

- Socket set and wrenches

- Screwdrivers

- Replacement parts specific to the assembly

- Sealing compounds or gaskets

Follow these general steps for component replacement:

- Preparation: Disconnect the power supply and ensure the system is cool to prevent injuries.

- Disassembly: Carefully remove the outer casing and any obstructing parts to access the inner workings.

- Component Removal: Take out the faulty or worn components, noting their arrangement for proper reinstallation.

- Replacement: Install the new parts, ensuring a secure fit and proper alignment.

- Reassembly: Reverse the disassembly process, ensuring all seals and connections are tight.

- Testing: Once everything is reassembled, reconnect the power and perform a functionality test to confirm successful installation.

Regular maintenance and prompt replacement of worn components can prevent larger issues, ensuring the system functions efficiently.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues can significantly improve the performance and reliability of the system. It involves systematic checks of components and connections to ensure everything operates as intended. Understanding common symptoms and their potential causes is crucial for effective diagnostics.

Begin by inspecting all relevant wiring and connections for any signs of wear, damage, or corrosion. Ensuring that the power supply is stable and sufficient is also essential. If any irregularities are noted, addressing them promptly can prevent further complications.

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No response from the system | Power supply failure | Check fuses and power connections |

| Unexpected shifts | Sensor malfunction | Inspect and replace faulty sensors |

| Warning lights activated | Diagnostic codes present | Read and interpret diagnostic trouble codes |

| Intermittent faults | Loose connections | Secure and clean all electrical connections |

Fluid Types and Maintenance Guidelines

Maintaining optimal performance in automated gear systems requires careful attention to the types of liquids used and adherence to maintenance practices. Selecting the correct fluids and ensuring their timely replacement are essential for the longevity and efficiency of the components involved.

Types of Fluids

- Hydraulic Fluids: Essential for the operation of various mechanical elements, these fluids facilitate smooth movement and function.

- Lubricants: Critical for reducing friction between moving parts, ensuring they operate smoothly under varying loads.

- Cooling Liquids: Help to maintain optimal temperature levels, preventing overheating and potential damage during operation.

Maintenance Recommendations

- Regularly check fluid levels to ensure they are within the recommended range.

- Change fluids at the specified intervals to prevent degradation and contamination.

- Monitor for leaks and signs of wear, addressing issues promptly to avoid costly repairs.

- Use only fluids that meet manufacturer specifications to ensure compatibility and performance.

By following these guidelines, users can help ensure that their automated systems operate efficiently and reliably for years to come.

Understanding Software Updates

Regular enhancements to system software play a crucial role in maintaining optimal performance and reliability. These updates often address various aspects, including functionality improvements, security patches, and compatibility adjustments with new components or features. Understanding the significance of these upgrades can greatly enhance the user experience.

Why Updates Matter

Software updates are essential for ensuring that the latest advancements and fixes are integrated into the system. They help prevent potential issues that may arise from outdated software, which can lead to inefficiencies or malfunctions. Keeping the system up-to-date guarantees that users benefit from the most current innovations and performance optimizations.

How Updates Are Implemented

Typically, updates can be installed manually or automatically, depending on user preferences and system capabilities. Automated processes often simplify the management of software changes, ensuring that updates occur seamlessly without requiring user intervention. However, manual checks can also be beneficial, allowing users to review changes and understand their impact before implementation.

Staying Informed

Users should remain informed about available updates and their specific benefits. Often, release notes accompany updates, detailing new features, improvements, and any resolved issues. This information can guide users in understanding how each update enhances their overall experience.

Safety Precautions During RepairsFeel free to modify or expand on any of these headings as needed!

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. When engaging in mechanical work, it is essential to adhere to specific guidelines that promote a secure environment. Understanding these precautions helps safeguard both the individual performing the tasks and the equipment involved.

Wear Appropriate Personal Protective Equipment (PPE): Always don suitable protective gear such as gloves, goggles, and sturdy footwear. This equipment shields against potential hazards like sharp objects, chemical spills, and falling components.

Work in a Well-Ventilated Area: Proper airflow is vital, especially when handling substances that emit fumes. Ensure that the workspace is adequately ventilated to minimize inhalation risks and enhance comfort during the process.

Follow Manufacturer Guidelines: Adhering to the specific instructions provided by the manufacturer can greatly reduce risks. These guidelines often contain critical information regarding safe handling and operation of equipment, ensuring tasks are performed correctly.

Ensure Stability of the Vehicle: Before beginning any work, ensure that the vehicle is securely positioned. Use appropriate supports and blocks to prevent movement that could lead to accidents while performing tasks.

Keep the Workspace Organized: A tidy work area minimizes distractions and reduces the chance of accidents. Ensure tools and parts are stored properly to avoid tripping hazards and to enhance efficiency during the maintenance process.