Frigidaire Washing Machine Repair Guide

Understanding the intricacies of household appliances can greatly enhance their longevity and functionality. This guide aims to empower users with the knowledge necessary to tackle common issues that may arise during operation. By familiarizing yourself with the inner workings and possible complications, you can take proactive steps to ensure optimal performance.

Throughout this section, you will discover a variety of techniques for diagnosing problems, performing essential upkeep, and implementing effective solutions. Each approach is designed to be user-friendly, catering to both novices and those with a bit more experience. With the right information at your fingertips, you can confidently address various concerns and extend the lifespan of your equipment.

Whether dealing with unusual noises, inefficient cycles, or other challenges, having a solid understanding of your appliance’s mechanics is invaluable. By following the guidance provided, you can navigate the complexities with ease and maintain a smooth operating experience.

Common Issues in Frigidaire Washers

Numerous challenges can arise during the operation of these appliances, often causing inconvenience for users. Understanding the frequent problems can facilitate quicker resolutions and enhance the overall user experience.

Draining Problems

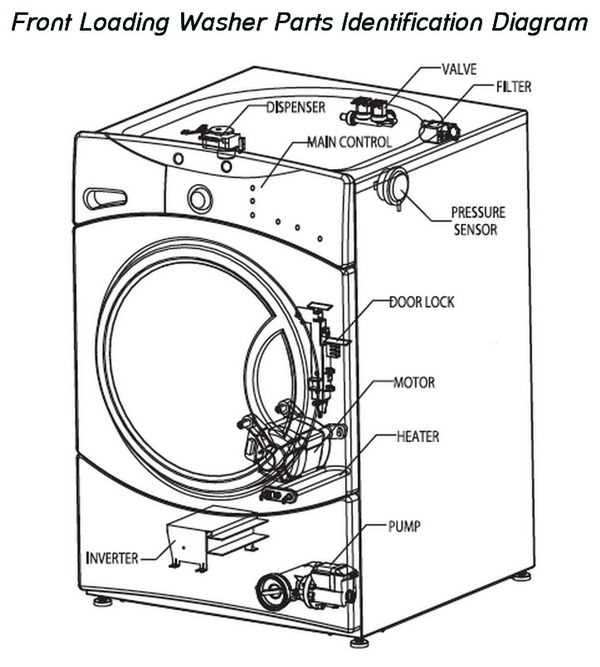

One of the most prevalent concerns involves inadequate drainage. This can manifest as water remaining in the drum after a cycle, often due to clogged filters or malfunctioning pumps. Regular maintenance and inspection can help mitigate these issues.

Cycle Failures

Another common occurrence is the failure of the device to complete its cycles. This may be attributed to various factors, including door latch malfunctions or electrical disruptions. Identifying and addressing these components can restore functionality and prevent future interruptions.

Essential Tools for Repairs

Having the right equipment is crucial when addressing issues with home appliances. A well-stocked toolkit not only simplifies the troubleshooting process but also ensures that tasks can be completed efficiently and effectively. Below are key instruments that every homeowner should consider for successful interventions.

Basic Hand Tools

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and standard)

- Utility knife

Specialized Instruments

- Multimeter for electrical testing

- Tape measure for precise measurements

- Level to ensure proper alignment

- Flashlight to illuminate hard-to-reach areas

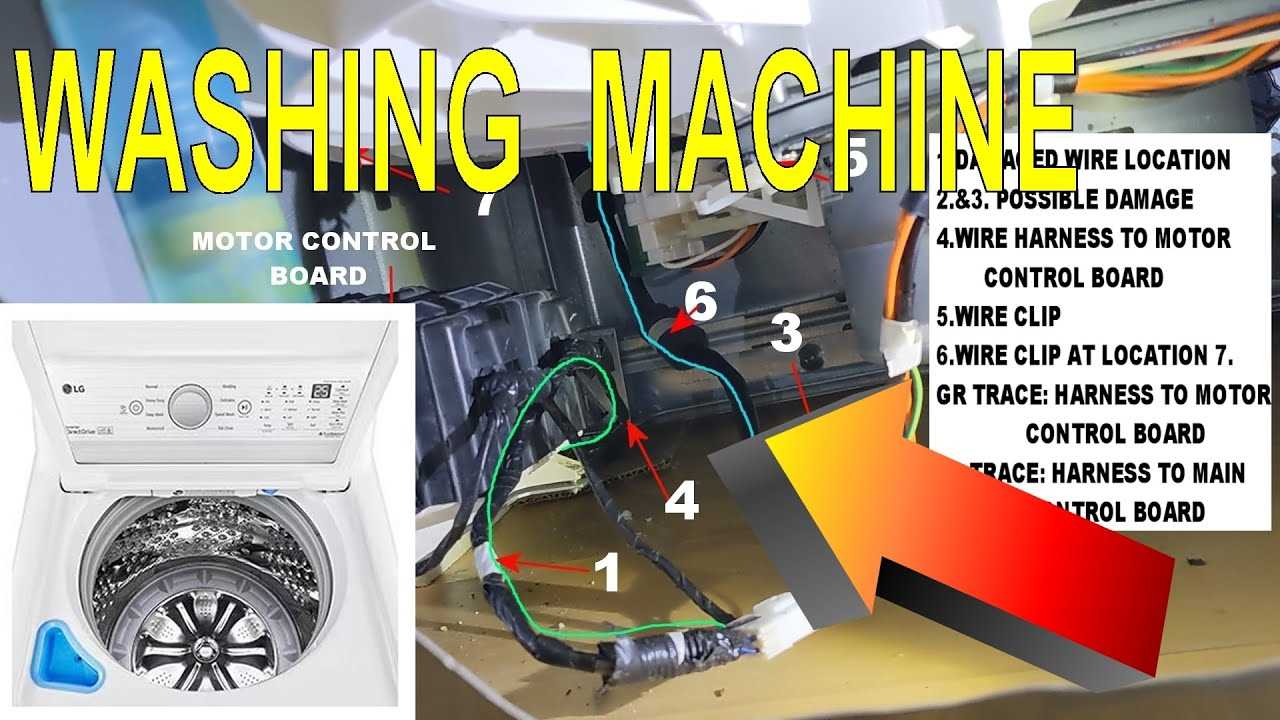

Troubleshooting Electrical Problems

When facing issues related to electrical components, it is essential to identify the source of the malfunction efficiently. Common symptoms may include unexpected shutdowns, failure to start, or unusual noises, which often indicate underlying electrical faults that need attention.

Begin by checking the power supply to ensure that the appliance is receiving adequate voltage. Inspect the circuit breaker or fuse box for any tripped breakers or blown fuses that could disrupt electrical flow. If power supply issues are ruled out, examine the wiring for any signs of damage, such as fraying or exposed wires, which could lead to short circuits.

Next, focus on the internal components. Test the control board and any switches for continuity using a multimeter. Faulty relays or timers can also contribute to operational failures, so verifying their functionality is crucial. Always ensure safety precautions are followed by disconnecting the unit from the power source before conducting any inspections.

If problems persist after these checks, it may be beneficial to consult a professional technician who can perform more in-depth diagnostics. Identifying and resolving electrical issues promptly will help restore the functionality of the appliance and prevent further damage.

Understanding Drum and Agitator Issues

When dealing with the inner workings of a laundry appliance, problems related to the rotating component and its agitator can often arise. These issues may affect the overall performance and efficiency of the unit, leading to unsatisfactory results. Understanding the common complications can help in diagnosing and resolving them effectively.

Common Symptoms

- No rotation during cycles

- Strange noises while operating

- Inconsistent cleaning results

- Leaking water from the base

Possible Causes

- Worn Bearings: Over time, the bearings may degrade, causing friction and preventing smooth rotation.

- Agitator Malfunction: A malfunctioning agitator can hinder the effective movement of garments, leading to ineffective cleaning.

- Obstructed Components: Objects trapped within the drum or agitator can lead to operational issues and unusual noises.

- Drive Belt Issues: A damaged or loose drive belt may fail to transmit motion correctly, affecting both components.

By being aware of these symptoms and potential causes, users can take informed steps to troubleshoot and resolve issues efficiently.

Water Drainage Solutions

Effective removal of excess liquid is crucial for optimal performance. Various issues can arise that hinder this process, leading to potential problems such as leaks or inefficient operation. Understanding these challenges can assist in implementing appropriate remedies.

Common Issues

Several factors can contribute to inadequate drainage. These include clogs in the hoses, malfunctioning components, or incorrect installation. Identifying these issues early can prevent further complications.

Solutions

Addressing drainage problems typically involves a few straightforward steps. Regular maintenance, including inspecting hoses and cleaning filters, is essential. Below is a table summarizing effective methods:

| Problem | Solution |

|---|---|

| Clogged Drain Hose | Detach and clear the hose of any obstructions. |

| Faulty Pump | Check for proper operation and replace if necessary. |

| Improper Installation | Ensure all components are correctly positioned and secure. |

Addressing Noise and Vibration

Excessive sounds and oscillations during operation can indicate underlying issues that require attention. Identifying the source of these disturbances is essential for restoring optimal function and ensuring a smooth experience.

Common Causes

Several factors may contribute to unwanted noise and vibration. Below are some of the most frequent culprits:

| Cause | Description |

|---|---|

| Unbalanced Load | An uneven distribution of items can lead to instability and movement during cycles. |

| Worn Components | Parts such as bearings or dampeners may wear out, resulting in increased noise levels. |

| Improper Installation | Incorrect leveling can cause excessive movement and noise during operation. |

Solutions

Addressing these issues involves a few straightforward steps. Ensuring even load distribution, checking for worn parts, and verifying proper installation can significantly reduce disturbances. Regular maintenance is key to preventing these problems from arising in the first place.

Repairing Leaks and Water Damage

Addressing issues related to fluid escape and the resulting harm is crucial for maintaining optimal function and longevity. Whether the source is a faulty connection or wear and tear, timely intervention can prevent further complications.

Start by identifying the root cause of the leakage. Common sources include worn seals, loose connections, or damaged hoses. Once the issue is pinpointed, proceed with the appropriate corrective measures.

| Issue | Possible Solution |

|---|---|

| Worn seals | Replace with new seals to ensure a tight fit. |

| Loose connections | Tighten all fittings and check for cracks. |

| Damaged hoses | Inspect and replace hoses as necessary. |

| Clogged drains | Clear any blockages to restore proper flow. |

After implementing the solutions, monitor the area for any signs of recurring issues. Keeping a regular maintenance schedule can further enhance the effectiveness of these interventions.

Replacing Belts and Hoses

Maintaining optimal performance of household appliances often involves addressing wear and tear on essential components. Among these, the flexible connectors and driving bands are critical for efficient operation. This section covers the steps required for replacing these vital parts, ensuring longevity and effectiveness.

Before beginning the replacement process, gather the necessary tools and materials:

- New belts and hoses

- Screwdriver set

- Wrench set

- Utility knife

- Replacement clamps (if needed)

Follow these steps to successfully replace the flexible connectors and driving bands:

- Disconnect the appliance from the electrical outlet to ensure safety.

- Remove any panels or coverings that obstruct access to the components.

- Carefully detach the old belts and hoses, noting their positions for correct reinstallation.

- Inspect the pulleys and connections for any signs of damage or wear, replacing them as necessary.

- Install the new belts and hoses in the reverse order of removal, ensuring they fit snugly and securely.

- Reattach any panels or coverings that were removed during the process.

- Reconnect the unit to power and perform a test cycle to confirm everything is functioning properly.

By following these guidelines, you can enhance the efficiency and lifespan of your appliance, preventing further issues down the line.

Maintaining Your Washing Machine

Regular upkeep of your appliance can significantly extend its lifespan and enhance its efficiency. Implementing simple practices ensures that it operates smoothly, minimizing potential issues and promoting optimal performance.

Key Maintenance Tips

To maintain peak functionality, consider the following recommendations:

| Task | Frequency |

|---|---|

| Clean the drum | Monthly |

| Inspect hoses for leaks | Every 3 months |

| Check and clean filters | Every 6 months |

| Run a maintenance cycle | Monthly |

Common Signs of Wear

Be attentive to unusual noises, vibrations, or error codes, as these can indicate underlying issues. Addressing problems promptly can prevent further damage and costly repairs.

Identifying Error Codes

Understanding the meaning behind various indicators on your appliance can help diagnose issues effectively. Each code serves as a signal, guiding users toward potential malfunctions and the necessary steps to address them.

Common Error Signals

- Code E1: Indicates a drainage problem. Check for clogs in the drain hose.

- Code E2: Suggests an issue with water supply. Ensure the inlet valve is functioning correctly.

- Code E3: Points to overloading. Reduce the load for optimal performance.

Steps to Take

- Refer to the product’s documentation for a comprehensive list of codes.

- Verify each component associated with the identified code.

- Reset the unit and observe if the error persists.

When to Call a Professional

Identifying when to seek assistance from a skilled technician can be crucial for resolving complex issues effectively. While some problems can be addressed with basic knowledge and tools, others require expertise that goes beyond typical troubleshooting. Understanding the signs can save time and prevent further damage.

Complex Issues

When the situation involves intricate components or requires specialized tools, it is advisable to consult a professional. Symptoms such as unusual noises, persistent error codes, or failure to complete cycles often indicate underlying problems that necessitate expert intervention.

Safety Concerns

Any issue that poses potential safety risks should be addressed immediately by a qualified technician. Electrical malfunctions, water leaks, or faulty components can lead to hazardous situations, making it essential to prioritize safety over DIY attempts.