Guide to Repairing a Manual Washing Machine

Maintaining household appliances is essential for ensuring their longevity and optimal performance. Often, users encounter various challenges that can disrupt their daily routines. Understanding the underlying problems and finding effective solutions can significantly enhance the functionality of these devices.

In this section, we will explore practical approaches to resolving typical issues faced with laundry devices. By gaining insight into common malfunctions and their causes, individuals can confidently tackle problems and restore their appliances to full working order. This knowledge empowers users to make informed decisions regarding maintenance and troubleshooting.

It is crucial to familiarize oneself with the basic components and operational principles of the equipment. Equipped with this information, users can efficiently diagnose issues and implement corrective measures, ultimately extending the life of their essential home equipment.

Identifying typical challenges faced by household laundry devices is crucial for effective troubleshooting. Recognizing these issues can facilitate smoother operations and extend the lifespan of your equipment. This section will explore common problems users encounter, providing insight into potential causes and solutions.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| No Power | Power cord damage, faulty outlet | Check connections, replace the power cord |

| Unusual Noises | Loose parts, foreign objects | Inspect and tighten components, remove debris |

| Water Leakage | Hose damage, worn seals | Replace hoses, check seals |

| Not Draining | Clogged filter, pump failure | Clean filter, inspect pump operation |

| Inadequate Cleaning | Overloading, wrong detergent | Reduce load size, use appropriate detergent |

Identifying Noise Problems in Machines

Unusual sounds during operation can indicate underlying issues that require attention. Recognizing these noises is essential for maintaining optimal functionality and preventing further complications.

Common sounds include:

- Banging: Often suggests loose components or objects inside.

- Squeaking: May indicate worn belts or misaligned parts.

- Grinding: Usually points to serious mechanical wear.

Monitoring these auditory signals is crucial for timely interventions and ensuring longevity.

How to Fix Drainage Issues

Addressing water flow complications is essential for ensuring optimal functionality of your appliance. Various factors can contribute to these issues, and understanding them is the first step toward resolution.

Begin by examining the drainage hose for any kinks or blockages that might hinder proper water expulsion. Ensure that the hose is positioned correctly and is not submerged in water, as this can cause backflow.

Next, check the filter for debris or buildup. A clogged filter can impede water flow and lead to inefficient performance. Cleaning the filter regularly helps maintain smooth operation.

Inspect the pump as well; any obstructions in the pump can prevent water from exiting effectively. Clearing any foreign objects and ensuring the pump operates smoothly is crucial for resolving drainage difficulties.

Lastly, if problems persist, consider consulting a professional for a thorough examination, as underlying issues may require specialized attention.

Addressing Water Leakage Concerns

Water leakage is a common issue that can lead to significant problems if not addressed promptly. Understanding the potential sources of leaks and implementing effective solutions is essential for maintaining optimal performance.

Common Causes of Leakage

- Worn out seals or gaskets

- Loose connections in hoses

- Damaged water inlet valves

- Cracks in the container

Steps to Mitigate Leakage

- Inspect all seals and replace any that appear worn.

- Ensure all hoses are tightly secured and free of damage.

- Examine the water inlet valve for any signs of malfunction.

- Look for cracks in the container and consider patching or replacing if necessary.

Inspecting and Repairing Belts

Proper assessment of the components responsible for movement is essential for ensuring optimal performance. This section focuses on identifying potential issues with the drive mechanisms that connect various parts. Regular inspections can prevent more serious problems down the line.

Identifying Wear and Tear

Begin by examining the belts for signs of fraying, cracking, or stretching. Any visible damage can hinder functionality and should be addressed immediately. It’s crucial to check the tension to ensure that the belts are neither too loose nor overly tight, as this can affect overall operation.

Replacing Components

If any components show significant wear, replacement is necessary. Choose high-quality substitutes that match the specifications. Follow the manufacturer’s guidelines for installation to guarantee a proper fit and efficient performance.

Troubleshooting Electrical Problems

Electrical issues can significantly hinder the functionality of any appliance. Identifying and addressing these concerns is essential for restoring proper operation. This section aims to provide guidance on common electrical difficulties that may arise.

First, ensure that the power source is active. Check the outlet by plugging in another device to confirm it is functioning. If the power is not reaching the unit, inspect the cord for any signs of damage or wear.

Next, examine the internal components for any loose connections. Disassemble the relevant parts carefully, ensuring safety precautions are followed. Look for disconnected wires or burnt fuses that may require attention.

Finally, if problems persist, consider consulting a professional. Sometimes, intricate issues may not be easily diagnosed without expert knowledge. Proper assessment can prevent further complications and ensure the longevity of your appliance.

Checking the Agitator Functionality

Evaluating the performance of the central component responsible for movement is essential for effective operation. This process ensures that the mechanism is functioning properly and efficiently, contributing to the overall performance of the appliance.

Visual Inspection

Begin with a thorough visual examination to identify any apparent issues:

- Look for any visible signs of wear or damage.

- Check for loose or detached parts that may hinder functionality.

- Inspect the surrounding area for any obstructions.

Operational Testing

Next, perform a simple operational check:

- Run a short cycle without any load.

- Observe the movement of the component throughout the cycle.

- Listen for unusual sounds that may indicate malfunction.

After these evaluations, you can determine whether further action is necessary to enhance performance.

Cleaning and Maintaining Filters

Regular upkeep of filtration systems is essential for optimal performance. This process ensures that unwanted particles do not accumulate, thus enhancing overall efficiency. Neglecting this aspect can lead to reduced effectiveness and potential issues down the line.

To properly maintain the filters, follow these steps:

- Turn off the device and unplug it to ensure safety.

- Locate the filters, which are typically found in accessible compartments.

- Remove the filters carefully, taking note of their placement for reassembly.

- Inspect the filters for any blockages or build-up.

- Clean the filters under running water, using a soft brush if necessary.

- Allow the filters to dry completely before reinserting them.

Regular cleaning is recommended every few months, but frequency may vary based on usage. Keeping the filters in good condition not only prolongs the life of the system but also ensures it operates efficiently.

Examining Hoses for Damage

Inspecting the flexible tubes that transport liquids is crucial for maintaining optimal performance. Over time, these conduits may develop wear or become compromised, leading to leaks or malfunctions. A thorough examination can help identify potential issues before they escalate.

Signs of Wear

Look for visible cracks, frays, or bulges along the surface of the hoses. Any discoloration or stiffness can also indicate aging material that may no longer function effectively. Addressing these signs promptly can prevent further complications.

Connection Integrity

Ensure that all attachments are secure and free from leaks. Check the fittings for corrosion or damage, which can weaken the connection. Maintaining tight seals is essential for efficient operation and to avoid potential water loss.

Understanding Control Panel Malfunctions

The control interface of any appliance plays a crucial role in its functionality. When issues arise within this section, it can lead to confusion and operational difficulties. Identifying the symptoms of these malfunctions is essential for effective troubleshooting.

Common Signs of Issues

- Unresponsive buttons or switches

- Inconsistent display readings

- Failure to initiate settings

- Unusual sounds when pressing controls

Possible Causes

- Electrical connection problems

- Faulty circuitry

- Wear and tear on components

- Moisture intrusion in the panel

Addressing these issues promptly can enhance performance and prolong the lifespan of the device. Regular maintenance and careful monitoring of the control interface can prevent significant disruptions.

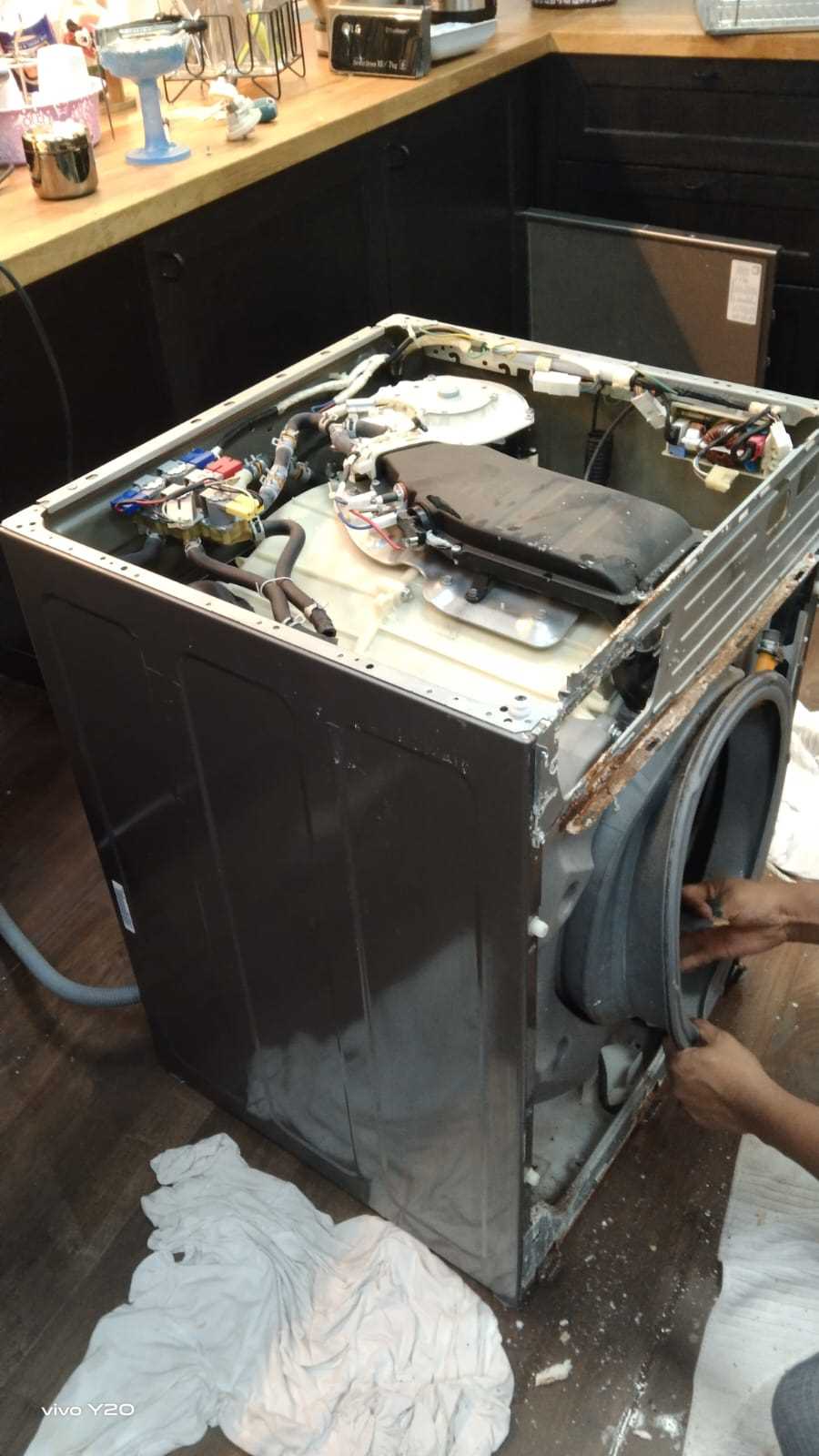

Reassembling After Repairs

After completing the necessary adjustments, it’s essential to ensure that all components are accurately placed back into their original configuration. This process guarantees optimal functionality and safety of the unit.

Begin by gathering all parts and tools used during the disassembly phase. Carefully follow the steps in reverse order, ensuring that each piece is securely fastened and aligned correctly. Pay attention to any connections or seals that may require special handling.

| Component | Reassembly Steps |

|---|---|

| Cover | Align the cover with the main body and secure it using the screws. |

| Hoses | Reconnect hoses ensuring they are tightly fitted to prevent leaks. |

| Control Panel | Reattach the control panel and ensure all wiring is correctly connected. |

| Drum | Make sure the drum is seated properly before closing the access door. |

Preventative Maintenance Tips for Longevity

Maintaining your appliance in optimal condition is essential for extending its lifespan and ensuring efficient operation. Regular attention to certain aspects can significantly reduce the likelihood of issues arising over time.

Routine Cleaning: Keeping the exterior and interior clean helps prevent build-up that can affect performance. Use a gentle cleaner and soft cloth to wipe surfaces regularly.

Check Hoses: Inspect hoses for any signs of wear or leaks. Replacing old or damaged hoses promptly can prevent potential flooding and enhance functionality.

Monitor Usage: Adhering to the manufacturer’s guidelines regarding load size and frequency of use can minimize strain. This practice promotes better operation and reduces wear.

Perform Periodic Inspections: Regularly examining the appliance for unusual sounds or vibrations can help catch problems early. Addressing minor issues before they escalate is key to longevity.

Keep Ventilation Clear: Ensuring that airflow around the device is unobstructed allows for proper functioning and heat dissipation, which is vital for longevity.

By implementing these simple yet effective practices, you can enhance the durability and reliability of your appliance, ensuring it serves you well for years to come.