Comprehensive Guide to Repairing the Karcher K2 Pressure Washer

This section aims to provide valuable insights into maintaining and troubleshooting common cleaning devices. Understanding the intricacies of these machines can enhance their longevity and efficiency. By familiarizing yourself with potential issues and solutions, you can ensure optimal performance during usage.

In the following paragraphs, we will explore various aspects of device maintenance. Emphasis will be placed on identifying common malfunctions, implementing corrective measures, and tips for regular upkeep. This comprehensive approach will equip you with the knowledge necessary to address concerns effectively.

With the right information at hand, users can tackle challenges confidently. By taking proactive steps, you can minimize downtime and maximize the utility of your cleaning equipment. Let’s delve into the essential strategies for keeping your device in top shape.

This section explores frequent challenges encountered with a specific cleaning device. Understanding these problems can aid in troubleshooting and enhance user experience.

Typical Challenges

Users may face various malfunctions that hinder the device’s performance. Identifying these issues promptly can prevent further complications.

Understanding the Problems

| Issue | Description | Possible Solutions |

|---|---|---|

| No Power | The device fails to turn on. | Check the power supply and connections. |

| Low Water Pressure | The output pressure is significantly reduced. | Inspect for blockages in hoses or nozzles. |

| Leaks | Water escapes from various joints. | Tighten fittings or replace damaged seals. |

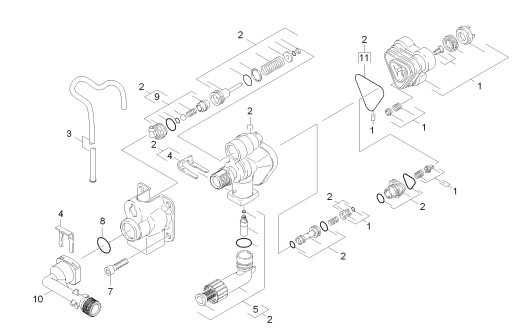

Understanding Pressure Washer Components

Maintaining optimal performance in high-efficiency cleaning devices requires familiarity with their essential elements. Each component plays a crucial role in the overall functionality, contributing to effective operation and longevity.

Core Parts and Their Functions

At the heart of these machines lies a powerful motor, which drives the entire system. This motor is responsible for generating the necessary force to propel water through the system. Additionally, a robust pump transforms regular water into a high-velocity stream, enhancing cleaning efficiency.

Accessory Elements

Further enriching the cleaning process are various accessories that aid in the application of pressure. Nozzles can be swapped to adjust the intensity and focus of the stream, allowing for versatility in tackling different surfaces. Moreover, a reliable hose connects these components, ensuring a seamless flow and maximizing performance during use.

Step-by-Step Troubleshooting Guide

This section aims to provide a comprehensive approach to diagnosing and resolving common issues encountered during operation. Following a systematic method can help identify problems efficiently and restore functionality without unnecessary complications.

Start by reviewing the symptoms of malfunction and proceed through the checklist below for effective troubleshooting:

| Symptom | Possible Cause | Solution |

|---|---|---|

| No operation | Power supply issue | Check the electrical outlet and power cord for damage. |

| Weak output | Clogged nozzle | Clean or replace the nozzle to ensure proper flow. |

| Unusual noise | Internal blockage | Inspect internal components and remove any obstructions. |

| Leakage | Damaged seals | Examine seals and replace any that are worn or broken. |

By carefully following these steps, users can effectively identify and resolve issues, ensuring optimal performance of the equipment.

Essential Tools for Repairs

Having the right instruments is crucial for addressing issues effectively. This section outlines the necessary equipment that can facilitate the maintenance of your device, ensuring optimal performance and longevity.

Below is a list of essential tools that you should consider keeping on hand:

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers helps in removing and securing fasteners of different sizes. |

| Wrench Set | These are used for tightening and loosening nuts and bolts, providing better grip and torque. |

| Pliers | Essential for gripping, twisting, and cutting wires or components during the process. |

| Multimeter | This device measures voltage, current, and resistance, aiding in electrical troubleshooting. |

| Replacement Parts | Having spare components allows for quick fixes and minimizes downtime. |

By ensuring that these tools are readily available, you can streamline the process of maintaining your equipment, making it more efficient and effective.

How to Disassemble the Unit

Taking apart the equipment requires careful attention to detail and methodical steps. This section will guide you through the process of disassembly, ensuring that you can access internal components safely and effectively.

- Gather Your Tools:

Before starting, ensure you have the necessary tools on hand:

- Screwdriver set

- Pliers

- Wrench

- Tweezers

- Power Off and Disconnect:

Always ensure the unit is powered off and unplugged to avoid any electrical hazards. Disconnect any hoses or attachments that may be present.

- Remove External Panels:

Carefully unscrew and remove the outer casing. Keep track of all screws and components removed during this step.

- Access Internal Components:

Once the outer shell is removed, you will have access to the internal parts. Take note of the arrangement and connections of various components.

- Handle with Care:

As you disassemble, ensure that you handle each component with care to prevent any damage. If necessary, document the disassembly process with pictures for easy reassembly.

Following these steps will help you successfully take apart the device for inspection or maintenance. Always refer to any specific guidelines related to your equipment for best practices.

Replacing Faulty Seals and Hoses

Over time, wear and tear can lead to the deterioration of vital components within cleaning equipment. Addressing these issues promptly is crucial to maintaining optimal performance and preventing further damage. This section will guide you through the process of identifying and replacing compromised seals and hoses, ensuring your device operates effectively.

Identifying the Problem

To begin, inspect the seals and hoses for any signs of damage such as cracks, leaks, or excessive wear. A thorough examination will help you determine which parts require replacement. Pay attention to any unusual noises or decreased efficiency, as these can indicate underlying issues with the components.

Replacement Process

Once you have identified the faulty parts, proceed with the replacement. First, disconnect the device from its power source to ensure safety. Next, carefully remove the damaged seals and hoses, taking note of their placement. Install the new components in the same configuration, ensuring a snug fit to prevent leaks. Finally, reassemble the unit and perform a test run to verify that the replacements have resolved the issues.

Cleaning the Water Filter

Maintaining optimal performance requires regular attention to the filtration system. A clean filter ensures that the unit operates efficiently and prolongs its lifespan. This section outlines the steps necessary for proper cleaning and maintenance of the water filtration component.

Step-by-Step Cleaning Process

Begin by disconnecting the device from the power source and ensuring that all water connections are secure. Remove the filter, which is typically located near the inlet. Rinse it thoroughly under running water to eliminate any debris or build-up. If necessary, use a soft brush to gently scrub the surface and dislodge stubborn particles.

Reassembly and Final Checks

After cleaning, ensure that the filter is completely dry before reattaching it. Secure all connections tightly and check for any leaks. Conduct a brief test run to confirm that everything is functioning correctly. Regular maintenance of the filtration system will help maintain the effectiveness of the equipment.

Electrical System Diagnostics

This section focuses on evaluating and troubleshooting the electrical components of the device to ensure optimal performance. Understanding the functionality of each element is essential for effective maintenance and problem resolution.

Begin by identifying common issues that may arise within the electrical framework:

- Power supply interruptions

- Faulty wiring connections

- Component failures

- Malfunctioning switches and controls

Follow these steps for a systematic approach to diagnostics:

- Disconnect the device from the power source.

- Inspect all visible wiring for signs of wear or damage.

- Use a multimeter to test voltage levels at various points.

- Check the functionality of switches and circuit breakers.

- Identify and replace any defective components.

After addressing any identified issues, reassemble the system and perform a thorough functional test to confirm that all components are operating as intended.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your cleaning equipment requires regular care and attention. By following a few straightforward practices, you can extend the life of your device and maintain its efficiency for years to come.

Regular Cleaning

After each use, it’s essential to remove any dirt or debris that may have accumulated. This not only keeps the unit looking its best but also prevents blockages that can hinder functionality. A gentle wipe down of external surfaces and a thorough rinse of the intake components will promote efficient operation.

Periodic Inspections

Routine checks of hoses and connections are crucial for identifying wear and tear early. Look for signs of damage, such as cracks or leaks, and replace any worn parts immediately. Timely maintenance can prevent minor issues from becoming significant problems, ensuring consistent performance.