Comprehensive Guide to Repairing Kenmore 500 Washing Machines

Understanding the complexities of household appliances can significantly enhance their longevity and performance. In many cases, owners encounter various challenges that require practical solutions. This section aims to provide comprehensive insights into diagnosing and resolving typical malfunctions, ensuring efficient operation for years to come.

Every device has its own set of characteristics and potential pitfalls. By familiarizing oneself with these intricacies, individuals can confidently address concerns that may arise. This resource offers step-by-step guidance, making it easier to tackle even the most perplexing scenarios.

Equipped with the right knowledge, anyone can become adept at identifying issues and implementing effective fixes. Whether it’s minor adjustments or more involved procedures, understanding the fundamentals can save time and resources while maximizing the appliance’s functionality.

Understanding Your Kenmore 500 Model

This section aims to provide insights into a popular household appliance, focusing on its features, functionality, and the common issues users may encounter. By familiarizing yourself with this specific design, you can enhance your experience and address minor challenges effectively.

Familiarity with the layout and components is crucial for efficient usage and maintenance. Below is a brief overview of the key features and specifications of this model:

| Feature | Description |

|---|---|

| Control Panel | Easy-to-use interface with various settings for different fabric types. |

| Cycling Options | Multiple wash cycles tailored for specific cleaning needs. |

| Capacity | Generous space to accommodate larger loads while maintaining efficiency. |

| Energy Efficiency | Designed to consume less water and energy, contributing to savings. |

Understanding these elements will help in utilizing the appliance to its fullest potential, ensuring optimal performance and longevity.

Common Issues and Solutions

In the realm of household appliances, various complications can arise during operation, often causing inconvenience. Understanding these typical problems and their respective remedies can enhance the longevity and efficiency of your unit.

Unusual Noises

One prevalent issue is the occurrence of unexpected sounds during use. These noises may stem from loose components or foreign objects trapped within the system. To address this, first, ensure that the unit is level and stable. If the problem persists, inspect the interior for any debris that may be causing the disturbance.

Ineffective Cleaning Performance

Another frequent concern is subpar cleaning results. This may result from overloading, using incorrect detergent types, or worn-out parts. For optimal performance, avoid exceeding load capacity and select a detergent suited for the task. Regularly check and replace any worn components to maintain efficiency.

Tools Needed for Repairs

Having the right equipment is essential for any maintenance task. Proper tools not only streamline the process but also enhance safety and efficiency. Below is a list of necessary implements to ensure effective troubleshooting and fixing of common issues.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for removing various components.

- Socket Wrench Set: These are useful for loosening and tightening nuts and bolts in tight spaces.

- Pliers: Needle-nose and regular pliers help grip, twist, and cut wires as needed.

- Multimeter: Essential for measuring voltage, current, and resistance, assisting in electrical diagnostics.

- Flashlight: Good illumination is key when working in dark or cramped areas.

- Utility Knife: Handy for cutting through various materials during disassembly.

- Work Gloves: Protect hands from sharp edges and ensure a secure grip on tools.

These items will prepare you for most common challenges, allowing for effective intervention and maintenance of the unit.

Step-by-Step Troubleshooting Guide

This guide offers a systematic approach to identifying and resolving common issues that may arise with your home appliance. Following these steps can help you diagnose problems effectively, ensuring optimal functionality and longevity of the device.

1. Identify the Issue: Begin by observing the symptoms. Is the device not starting, making unusual noises, or failing to complete its cycle? Documenting these signs will provide clarity as you progress through the troubleshooting process.

2. Check the Power Supply: Ensure that the appliance is securely plugged in and that the outlet is functioning. Test the outlet with another device if necessary. If the appliance has a reset button, consider using it as a preliminary step.

3. Inspect the Hoses: Look for any kinks or blockages in the hoses connected to the unit. Clean or replace any damaged hoses to restore proper water flow.

4. Evaluate the Control Settings: Confirm that the settings are correctly configured for the desired function. Sometimes, selecting the wrong cycle can lead to unexpected results.

5. Run a Diagnostic Test: If available, initiate any built-in diagnostic functions. This may help pinpoint specific issues or error codes that can guide your next steps.

6. Consult the Documentation: Refer to the user guide or online resources for troubleshooting tips specific to your device’s model. This can provide valuable insights into resolving persistent problems.

7. Seek Professional Assistance: If the issue remains unresolved after following these steps, it may be time to contact a qualified technician. Professional evaluation can ensure that more complex problems are addressed safely and effectively.

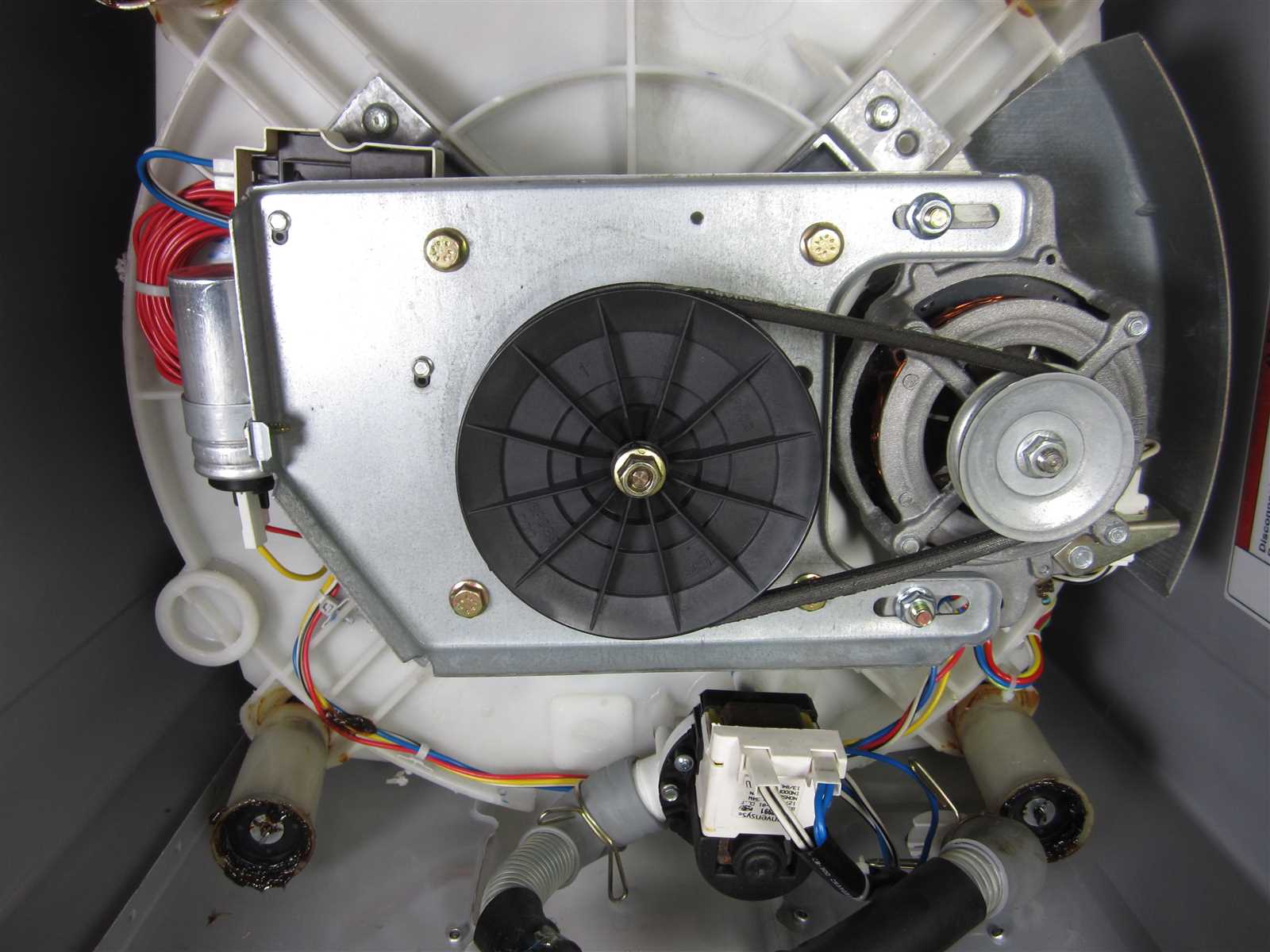

How to Access Internal Components

Gaining entry to the inner workings of your appliance is essential for troubleshooting and maintenance. Understanding the steps involved can help you identify issues more effectively and facilitate any necessary interventions.

Follow these general guidelines to safely access the internal parts:

- Ensure the device is unplugged from the power source to prevent any electrical hazards.

- Remove any external panels or covers that may be obstructing access. This often involves unscrewing several fasteners.

- Carefully detach any components that might be in the way, such as hoses or wiring, taking note of their original positions for reassembly.

- Use appropriate tools to loosen and remove any additional screws securing the inner sections.

- Once you have accessed the interior, take care to handle all components gently to avoid damage.

By following these steps, you can effectively reach the critical parts that may require inspection or replacement.

Electrical Troubleshooting Tips

This section aims to provide valuable guidance for diagnosing and resolving electrical issues that may arise in various household appliances. A systematic approach can help identify faults and ensure safe operation.

- Check Power Supply: Ensure that the device is plugged in and that the outlet is functioning properly. Use a multimeter to measure voltage if necessary.

- Inspect Cords and Connectors: Look for any visible damage to power cords and connectors. Frayed wires can lead to shorts and malfunctions.

- Examine Circuit Breakers: Verify that circuit breakers are not tripped. Reset any that are, and note if it trips again, indicating a deeper issue.

- Test Fuses: Replace any blown fuses. If a new fuse blows immediately, further investigation is required to find the source of the fault.

Following these basic steps can help pinpoint electrical problems, making it easier to address them effectively. Always prioritize safety when handling electrical components.

Maintaining Your Washing Machine

Regular upkeep is essential for ensuring optimal performance and longevity of your appliance. Simple habits can greatly enhance its efficiency and reduce the likelihood of issues arising over time.

Routine Inspections: Periodically examine all components for any signs of wear or damage. This includes checking hoses for leaks and ensuring that seals are intact. Early detection of potential problems can save you time and expense.

Cleaning: Keep the interior clean by running a maintenance cycle with a suitable cleaner. Regularly remove any debris or residue that may accumulate, particularly in detergent dispensers and filters. This helps maintain fresh conditions and prevents unpleasant odors.

Proper Usage: Adhere to manufacturer guidelines regarding load sizes and detergent types. Overloading can strain components, while using incorrect products can lead to build-up and inefficiency. Follow these recommendations to ensure optimal functioning.

Leveling: Ensure that your appliance is level. An unbalanced unit can lead to excessive vibration and noise, affecting performance and potentially causing damage. Adjust the feet as necessary to maintain stability.

Professional Servicing: Consider scheduling professional maintenance annually. Technicians can perform thorough inspections and address any underlying issues that may not be apparent. Regular servicing can significantly extend the lifespan of your appliance.

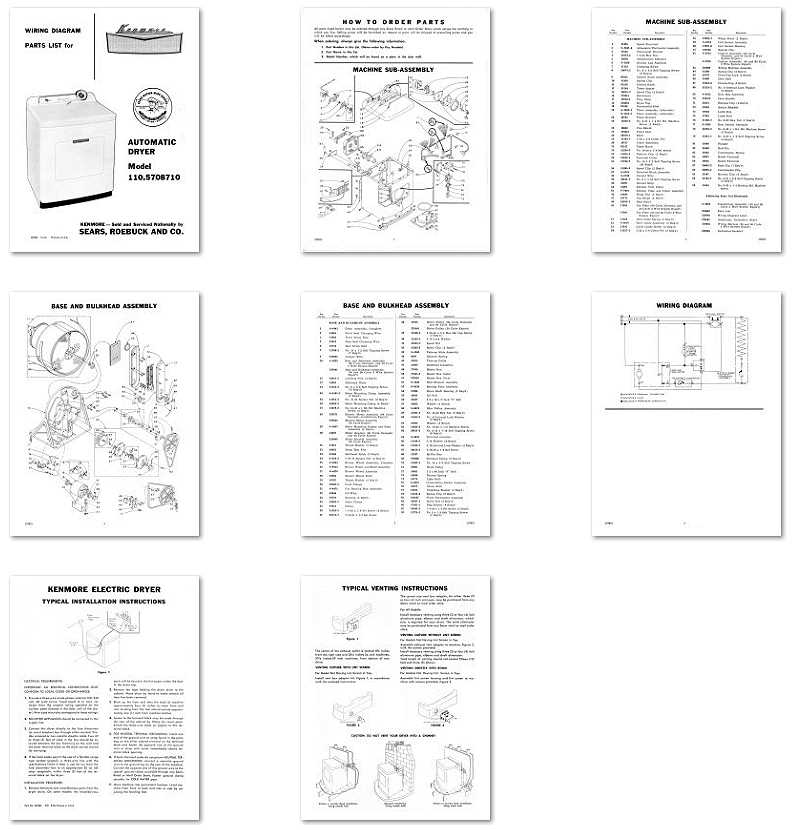

Identifying Faulty Parts

Recognizing malfunctioning components is crucial for efficient troubleshooting. A systematic approach can help isolate issues and facilitate repairs. Understanding common signs of failure allows users to take appropriate actions and minimize further complications.

Common Indicators of Malfunction

Various symptoms can suggest that a component is not operating correctly. Notable signs include unusual noises, leaks, and inconsistent performance. Observing these indicators can assist in determining which part may require attention.

Typical Components to Inspect

When assessing functionality, several key elements warrant closer examination. Regular checks can prevent prolonged disruptions and ensure optimal operation.

| Component | Common Issues | Signs of Failure |

|---|---|---|

| Drive Belt | Wear and Tear | Squeaking sounds, slipping |

| Water Pump | Blockages | Pooling water, odd noises |

| Control Board | Electrical Failures | Inconsistent settings, error codes |

| Hoses | Leaks | Wet spots, dripping |

Replacing the Drive Belt

Changing the drive belt is a crucial task for maintaining optimal performance of your appliance. Over time, this component can wear out, leading to issues such as improper spinning or noisy operation. Addressing this problem promptly can enhance efficiency and prolong the lifespan of your device.

Tools Required: To begin, gather necessary tools including a screwdriver, a socket set, and pliers. Having these items ready will facilitate a smoother replacement process.

Steps to Follow: First, disconnect the power supply to ensure safety during the procedure. Next, remove the access panel to reach the internal components. Carefully examine the existing belt for any signs of damage or wear. If replacement is needed, detach the old belt by loosening the pulleys. Install the new belt by routing it according to the manufacturer’s specifications, ensuring a snug fit around the drum and motor.

Once installed, reassemble the access panel and reconnect the power supply. Run a short cycle to verify that the appliance operates smoothly and efficiently. This simple yet vital maintenance task can make a significant difference in performance.

Fixing Drainage Problems

Issues with water removal can lead to various complications during the cleaning process. Addressing these concerns promptly is essential for maintaining optimal functionality. This section outlines common challenges and practical solutions to ensure effective water drainage.

Common Causes of Drainage Issues

- Clogged hoses

- Faulty pump

- Blocked filters

- Improper installation

Steps to Resolve Drainage Issues

- Inspect the drainage hose for any blockages or kinks. Clear any obstructions to ensure smooth water flow.

- Examine the pump for signs of malfunction. If necessary, replace the pump to restore functionality.

- Check and clean the filter to remove debris that may impede water movement.

- Verify the installation setup, ensuring that the appliance is positioned correctly for optimal drainage.

Addressing Noise and Vibration Issues

Experiencing unusual sounds and vibrations from a household appliance can be a source of concern for many users. Identifying the root causes of these disturbances is essential for restoring quiet operation and ensuring longevity. This section aims to explore common issues related to unwanted noise and movement, as well as effective solutions to mitigate them.

Common Causes of Noise

Various factors may contribute to the sounds emanating from the unit. Loose components, unbalanced loads, and worn-out parts are typical culprits. Additionally, foreign objects trapped within the appliance can generate rattling noises during operation. Regular inspections can help in pinpointing these issues before they escalate.

Vibration Management

Excessive vibration often arises from uneven footing or an unbalanced interior. Ensuring that the unit is level and securely positioned can significantly reduce this problem. Adjusting the leveling feet and checking for any obstructions beneath the appliance are simple steps that can make a substantial difference.

Maintenance Tips

Routine maintenance plays a crucial role in minimizing noise and vibration. Regularly checking and tightening screws, replacing worn parts, and cleaning the interior can prevent disturbances. Furthermore, using vibration pads or mats can provide additional support, absorbing shocks and stabilizing the appliance during use.

By addressing these issues promptly and maintaining the equipment diligently, users can enjoy quieter and smoother operation for years to come.

Safety Precautions During Repair

When undertaking maintenance tasks on household appliances, ensuring personal safety and preventing potential hazards is essential. Proper precautions can minimize risks and promote a secure working environment.

General Safety Guidelines

- Always disconnect the power source before beginning any work.

- Wear appropriate protective gear, such as gloves and safety goggles.

- Ensure the workspace is clean and free of clutter to prevent accidents.

- Keep tools organized and within reach to avoid unnecessary movement.

Handling Components Safely

- Be cautious when dealing with sharp edges and moving parts.

- Store hazardous materials securely and follow disposal guidelines.

- Use tools specifically designed for the tasks to prevent injuries.

- Check for leaks or damages before handling any parts.

When to Call a Professional

There are instances when seeking expert assistance becomes essential. While many issues can be addressed through basic troubleshooting, some problems may require specialized knowledge and tools that only a trained technician can provide.

Identifying the right moment to enlist professional help can save time and prevent further damage. Below are common scenarios indicating that it’s time to contact a qualified specialist.

| Signs to Consider | Recommended Action |

|---|---|

| Unusual noises or vibrations | Contact a technician for assessment |

| Failure to start or operate correctly | Seek professional evaluation and service |

| Leakage or water accumulation | Call an expert to investigate the source |

| Burning smells or electrical issues | Immediately contact a qualified technician |

| Error codes that cannot be resolved | Request help from a knowledgeable professional |