Comprehensive Guide to Kenmore Elite Front Load Washer Repairs

In today’s fast-paced world, efficient home appliances are essential for managing daily tasks. Understanding the intricacies of these devices can greatly enhance their longevity and performance. This section provides insights into common issues and solutions, ensuring optimal functionality and convenience.

By delving into various components and mechanisms, users can develop a clearer understanding of how to troubleshoot and address minor problems. This knowledge not only empowers individuals to tackle challenges independently but also fosters a sense of confidence in utilizing such equipment effectively.

Through careful examination and step-by-step guidance, you can navigate the complexities of your appliance with ease. Whether it’s understanding specific functions or identifying malfunctions, this resource aims to equip you with the tools needed for successful management.

Common Issues with Kenmore Elite Washers

Owners of advanced laundry machines often encounter a range of challenges that can disrupt their washing experience. Understanding these frequent complications can help in troubleshooting and restoring optimal functionality.

1. Water Drainage Problems: One of the most prevalent issues is inadequate drainage, which may lead to water accumulation inside the drum. This can stem from clogged hoses or a malfunctioning pump.

2. Unusual Noises: Unwanted sounds during operation, such as banging or grinding, can indicate issues with the drum or belt. These noises often signal that components require inspection or replacement.

3. Door Lock Malfunctions: A failure in the locking mechanism can prevent the appliance from starting. This problem may arise from electrical faults or physical obstructions.

4. Error Codes: Many sophisticated models display error codes to signify specific malfunctions. Familiarity with these codes can expedite troubleshooting efforts and identify necessary repairs.

5. Odor and Mold Development: Over time, moisture can lead to unpleasant smells and mold growth. Regular maintenance and cleaning routines are essential to mitigate this issue.

By addressing these common challenges, users can maintain the efficiency and longevity of their washing machines.

Troubleshooting Water Drain Problems

Addressing issues related to water drainage is crucial for maintaining optimal performance in any laundry appliance. Identifying and resolving these complications can prevent further damage and ensure effective operation. This section outlines common causes and solutions for drainage challenges.

Common Causes

- Clogged drain hose: Debris may accumulate, obstructing water flow.

- Faulty drain pump: Malfunctioning pumps can impede water removal.

- Improper installation: Incorrect positioning of the drain hose may lead to drainage issues.

- Blocked filters: Filters may collect lint and debris, affecting drainage efficiency.

Solutions

- Inspect the drain hose for kinks or blockages, ensuring it is clear.

- Check the drain pump for proper operation; replace if necessary.

- Ensure the drain hose is installed at the correct height and angle.

- Clean or replace filters to maintain optimal water flow.

How to Access Internal Components

Gaining entry to the internal mechanisms of your appliance is essential for troubleshooting and performing necessary maintenance. This section outlines the steps to safely access these areas, ensuring a thorough understanding of the layout and function of various parts.

Required Tools

- Screwdriver (Phillips and flathead)

- Pliers

- Socket set

- Flashlight

- Safety gloves

Steps to Access

- Ensure the unit is disconnected from the power source to prevent any accidents.

- Remove any visible screws on the back or top panel using the screwdriver.

- Carefully pry off the panel to expose the internal area.

- If needed, detach additional components such as hoses or wiring to gain better access.

- Utilize the flashlight to inspect components for wear or damage.

Understanding Control Panel Functions

The control interface of a laundry appliance serves as the central hub for user interaction, allowing seamless operation and customization of wash cycles. Familiarizing oneself with these functions can enhance the efficiency of the laundering process, ensuring garments are cleaned according to specific needs.

Settings Overview: Each button and dial on the panel corresponds to particular functionalities, such as cycle selection, temperature adjustments, and spin speed. Understanding these options empowers users to tailor their experience based on fabric type and soil level.

Indicators and Alerts: Visual signals play a crucial role in communicating the machine’s status. Light indicators inform users about the current cycle, while alerts may indicate when maintenance is necessary or if an issue arises during operation. Recognizing these signals can prevent potential mishaps and prolong the unit’s lifespan.

Child Lock and Safety Features: Many models are equipped with features designed to enhance safety during use. Engaging the child lock prevents accidental changes to settings, ensuring a secure environment in homes with young children.

By comprehensively understanding the control panel’s functions, users can optimize their appliance’s performance, leading to improved results and a more user-friendly experience.

Cleaning the Door Seal Effectively

Maintaining the integrity of the seal is crucial for optimal performance and hygiene. Regular cleaning prevents the buildup of mold and mildew, ensuring that the appliance operates efficiently. This section outlines an effective approach to keep the door gasket in top condition.

To begin, gather the necessary materials, which will help in achieving a thorough clean:

| Materials Needed |

|---|

| White vinegar |

| Baking soda |

| Soft cloth or sponge |

| Old toothbrush |

| Water |

Start by mixing equal parts of white vinegar and water in a spray bottle. Generously apply the solution to the rubber seal, allowing it to penetrate for several minutes. This will help break down any residue. Next, use the old toothbrush to gently scrub the areas where dirt or grime has accumulated. Rinse the cloth or sponge in clean water and wipe down the seal to remove any cleaning solution. Finally, dry the gasket thoroughly to prevent moisture buildup, ensuring longevity and hygiene.

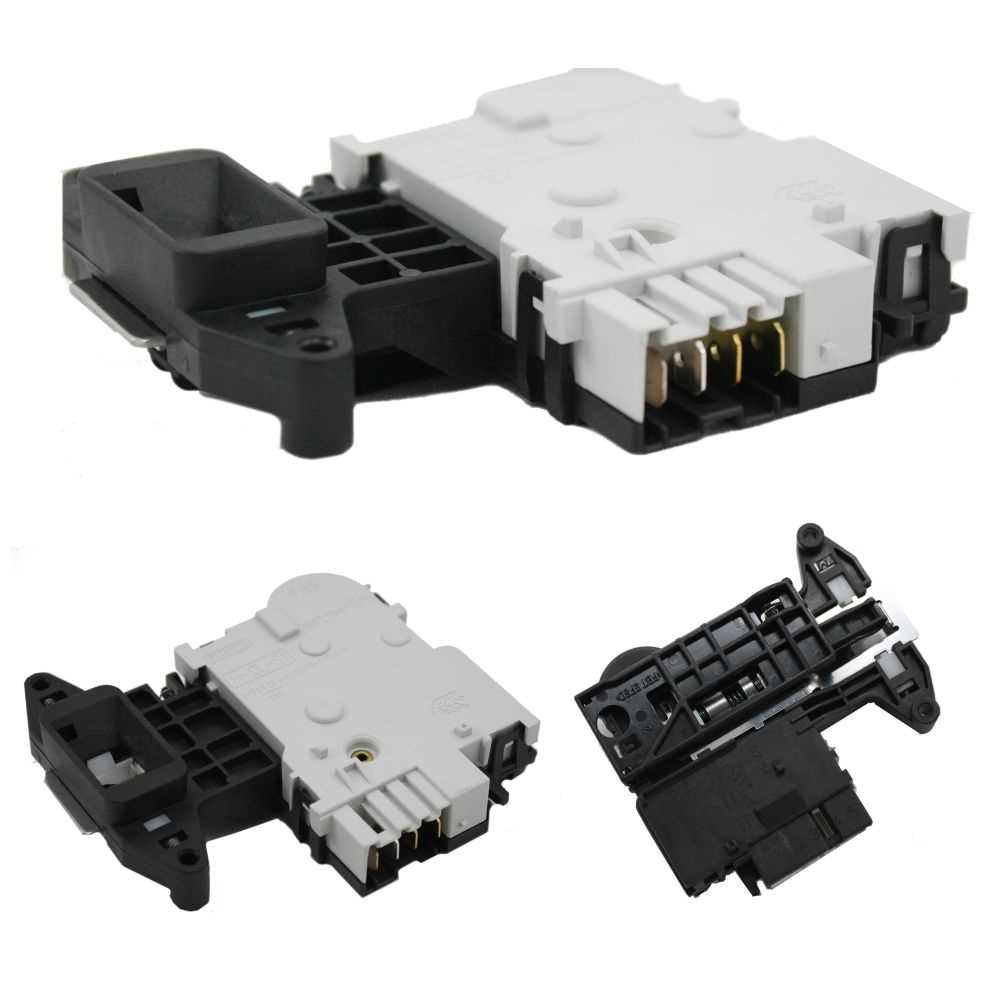

Replacing the Door Lock Assembly

Maintaining the functionality of your appliance often requires addressing components that may wear out over time. One critical part that may need attention is the locking mechanism that secures the access point during operation. Ensuring this component is in good working order is essential for safe and efficient use.

To successfully replace the locking mechanism, follow these essential steps:

| Step | Description |

|---|---|

| 1 | Unplug the appliance from the power source to ensure safety before beginning any work. |

| 2 | Remove the front panel screws and gently detach the panel to access the locking assembly. |

| 3 | Locate the old locking mechanism and disconnect any wiring harnesses attached to it. |

| 4 | Unscrew the locking assembly from its mounting position and remove it. |

| 5 | Install the new locking mechanism by reversing the removal steps, ensuring all connections are secure. |

| 6 | Reattach the front panel, ensuring it is aligned correctly and all screws are tightened. |

| 7 | Plug the appliance back in and test the new assembly for proper operation. |

Following these steps will help ensure that the locking mechanism functions correctly, contributing to the overall efficiency of your appliance.

Fixing Unusual Noises During Operation

Unexpected sounds from your appliance during its cycle can indicate underlying issues that require attention. Addressing these noises promptly can help prevent further complications and ensure smooth functioning. Here, we explore common causes and potential solutions to resolve these disturbances.

Common Sources of Noise

- Vibration: Excessive shaking can lead to clattering sounds. This often results from an uneven surface or an overfilled drum.

- Foreign Objects: Items left in pockets may become lodged in the drum or pump, causing rattling or grinding sounds.

- Motor Issues: Unusual whirring may indicate motor problems, which could stem from wear or electrical faults.

Troubleshooting Steps

- Check the appliance’s levelness. Adjust the feet as necessary to eliminate wobbling.

- Inspect the drum for any foreign objects. Remove items that may cause interference.

- Listen for any signs of motor distress. If the noise persists, consider consulting a professional for an evaluation.

By taking these steps, you can often identify and resolve noise-related issues, ensuring your appliance operates efficiently and quietly.

Adjusting Washer Level for Stability

Ensuring proper alignment of your appliance is essential for optimal performance and longevity. An uneven surface can lead to excessive vibrations, noise, and potential damage. Therefore, adjusting the balance of the unit is a crucial step in maintaining its functionality.

To achieve stability, start by checking the surface where the appliance is placed. It should be level and solid. Use a spirit level to confirm alignment from both side to side and front to back. If adjustments are necessary, locate the adjustable feet on the bottom of the unit. These can typically be turned by hand or with a tool to raise or lower each corner as needed.

After making adjustments, recheck the level to ensure it is now aligned correctly. A well-balanced unit will operate more quietly and efficiently, reducing wear and tear over time. Lastly, always double-check that the machine is secure and doesn’t rock when you apply pressure. This simple maintenance task can prevent future issues and enhance your appliance’s performance.

Common Error Codes Explained

Understanding the various indicators that signal issues within a laundry appliance can greatly aid in troubleshooting. Each code serves as a prompt, highlighting specific malfunctions or maintenance needs, allowing users to address problems efficiently.

Here is a breakdown of frequently encountered codes and their meanings:

| Error Code | Description |

|---|---|

| F01 | Indicates a communication error between the control board and the motor control unit. |

| F02 | Suggests that the machine is unable to drain water, potentially due to a clogged pump. |

| F03 | Signals a fault with the water level sensor, which may need inspection or replacement. |

| F04 | Indicates an issue with the door lock mechanism, preventing the door from being secured. |

| F05 | Alerts to a temperature sensor malfunction, which could affect wash cycles. |

Replacing the Drum Bearings Safely

Ensuring optimal performance of a laundry appliance often requires the replacement of essential components, such as the rotating cylinder’s support elements. This process, while manageable, demands careful attention to safety protocols and proper technique to prevent accidents and damage.

Preparation and Safety Precautions

Before beginning the replacement, gather all necessary tools and materials, including wrenches, screwdrivers, and the new support elements. Always disconnect the appliance from the power source to eliminate any risk of electric shock. Wearing protective gear, such as gloves and safety glasses, is advisable to safeguard against sharp edges and potential debris.

Step-by-Step Replacement Process

Start by removing the front access panel, which typically involves unscrewing several fasteners. Once open, gently detach the drum assembly to expose the support components. Carefully extract the old elements, ensuring not to damage surrounding parts. Install the new support elements by following the manufacturer’s specifications closely, ensuring a secure fit. Finally, reassemble the access panel and reconnect the power supply, testing the unit to confirm proper operation.

Maintaining Regular Checks on the support elements can prolong the lifespan of your laundry appliance and enhance its efficiency. Regular maintenance helps prevent unexpected failures and ensures consistent performance.

Maintenance Tips for Longevity

To ensure the enduring performance of your appliance, regular upkeep is essential. Implementing effective strategies can significantly extend its lifespan and maintain optimal functionality.

Regular Cleaning

Keep the interior and exterior clean to prevent build-up that can lead to malfunctions. Wipe down surfaces regularly and run cleansing cycles as recommended. Use suitable cleaning agents to avoid damaging sensitive components.

Routine Inspections

Conduct periodic checks on hoses and connections to identify signs of wear or leaks. Ensuring that all parts are in good condition can help prevent larger issues down the line. Additionally, monitor for any unusual noises during operation, which may indicate underlying problems.

Parts and Tools Needed for Repairs

When addressing issues with household appliances, having the right components and instruments is essential for effective resolution. This section outlines the necessary items that can facilitate the process, ensuring a smooth and efficient approach.

The following components may be required based on the specific issues encountered:

- Drive belts

- Door seals

- Control boards

- Water pumps

- Drum bearings

In addition to replacement parts, specific tools can significantly aid in the task:

- Screwdrivers (Phillips and flathead)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and slip-joint)

- Tape measure

- Multimeter for electrical diagnostics

Being equipped with these items will not only streamline the troubleshooting process but also enhance the overall effectiveness of the maintenance tasks.