Comprehensive Guide to Repairing Your Maytag Neptune Front Load Washer

Home appliances are vital components of our daily routines, and when they encounter issues, it can disrupt our lives significantly. Understanding how to address common problems and perform necessary upkeep can save time and resources. This comprehensive guide is designed to empower you with the knowledge needed to handle complications effectively.

In the following sections, we will delve into various troubleshooting techniques and maintenance tips for your high-efficiency laundry appliance. Whether you’re dealing with unusual noises, inefficient cleaning, or leaks, the information provided here will equip you with the skills to diagnose and rectify these issues.

By familiarizing yourself with the intricacies of your machine, you’ll not only enhance its longevity but also ensure optimal performance. This guide serves as a valuable resource, enabling you to take charge of your appliance’s functionality and keep it running smoothly for years to come.

Overview of Maytag Neptune Washers

This section provides a comprehensive look at a popular series of laundry appliances known for their efficiency and advanced features. These machines are designed to handle various fabric types while ensuring optimal cleaning performance. Understanding their functionality and design elements can help users make the most of their laundry experience.

Key Features

- High efficiency: These appliances consume less water and energy compared to traditional models.

- Advanced technology: Incorporates smart sensors for load detection and optimal wash cycles.

- Variety of settings: Offers multiple wash options to accommodate different fabric care requirements.

- Durability: Constructed with robust materials, ensuring longevity and reliable performance.

Common Concerns

While these machines are designed for excellence, users may encounter a few issues over time. Here are some frequently reported concerns:

- Noise during operation: Some users have noted unusual sounds during specific cycles.

- Water drainage problems: Occasional clogs or drainage issues may arise, affecting performance.

- Control panel malfunctions: Users may experience difficulties with electronic controls or settings.

Addressing these concerns through regular maintenance and understanding troubleshooting steps can enhance the lifespan and functionality of these appliances.

Common Issues with Front Load Washers

When it comes to modern laundry machines, users often encounter a range of challenges that can affect performance and efficiency. Understanding these common problems can help in maintaining optimal functioning and prolonging the lifespan of the appliance.

- Odor Issues: Accumulation of moisture and detergent residue can lead to unpleasant smells.

- Clogged Drains: Debris and lint can obstruct drainage systems, causing water to accumulate.

- Door Seal Damage: Worn or damaged seals can result in leaks and moisture retention.

- Unbalanced Loads: Uneven distribution of clothes can cause excessive vibration and noise during cycles.

- Error Codes: Many machines display error codes that indicate specific malfunctions, requiring troubleshooting.

Addressing these issues promptly can enhance performance and ensure a smoother laundry experience.

Understanding Error Codes and Messages

Error codes and messages are essential indicators of the operational status of your appliance. They serve as a communication tool between the machine and the user, providing crucial insights into potential issues that may arise during cycles. Recognizing these codes can help you diagnose problems quickly and efficiently, ultimately leading to informed decisions regarding troubleshooting or professional assistance.

Each error code typically corresponds to a specific issue, whether it relates to mechanical failures, sensor malfunctions, or incorrect settings. For instance, a code might indicate that the door is not securely closed or that there is a problem with the water supply. Understanding these signals can save you time and frustration, allowing you to address concerns before they escalate.

In addition to the codes themselves, many models provide accompanying messages that offer further context. These messages may describe the nature of the problem in greater detail or suggest possible solutions. Paying attention to these notifications can enhance your troubleshooting experience, ensuring that you tackle the root of the issue effectively.

Tools Needed for Repairs

When addressing issues with your appliance, having the right instruments is crucial for effective troubleshooting and resolution. The proper tools not only facilitate the process but also ensure safety and efficiency while working on the unit.

Essential items typically include a set of screwdrivers, both Phillips and flat-head, to tackle various screws found throughout the device. A socket set is also important for loosening bolts and securing components. Pliers can assist in gripping or bending parts, while a multimeter is invaluable for electrical diagnostics. Additionally, a level may be needed to ensure the appliance is correctly positioned, which can impact its performance.

Having a sturdy flashlight can help illuminate dark areas inside the machine, allowing for better visibility during inspections. Finally, gloves and safety goggles are recommended to protect yourself from potential hazards while performing any tasks. Equipping yourself with these tools will significantly enhance your ability to address any challenges that arise.

Step-by-Step Diagnostic Procedures

Effective troubleshooting involves a systematic approach to identify and resolve issues efficiently. This section outlines a series of structured steps to guide you through the diagnostic process, ensuring that potential problems are pinpointed accurately and effectively.

Initial Assessment

Begin by conducting a preliminary evaluation of the appliance’s performance. Observe any unusual sounds, vibrations, or error codes displayed on the interface. Document these observations, as they will serve as valuable clues during the diagnostic procedure.

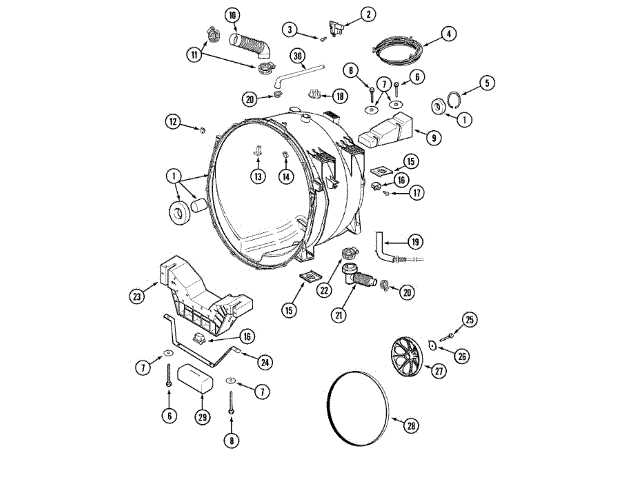

Component Inspection

Next, focus on inspecting the individual components. Check for common issues such as blockages in hoses, wear and tear on seals, and electrical connections. Pay close attention to the motor and control panel, as these are often critical areas for malfunction. Use a multimeter to test electrical continuity and verify that all parts are functioning as intended.

Replacing the Door Seal Effectively

Maintaining a watertight seal is crucial for optimal performance in your appliance. Over time, wear and tear can lead to leaks, resulting in potential damage and inefficiency. This section provides guidance on how to effectively replace the door gasket, ensuring a snug fit that prevents moisture from escaping.

Gathering Necessary Tools

Before beginning the replacement process, it’s essential to collect the appropriate tools. You’ll typically need a screwdriver, a utility knife, and a pair of gloves. Having these items on hand will streamline your work and help you avoid unnecessary interruptions.

Steps for Replacement

Start by disconnecting the appliance from its power source. Carefully remove the old seal by cutting away any retained debris with your utility knife. Next, clean the area where the new seal will fit, ensuring it’s free of dirt and residue. Align the new gasket, making sure it fits snugly into the groove, and secure it by pressing firmly around the entire perimeter. Finally, reconnect the power and run a test cycle to confirm that everything is functioning correctly.

By following these steps, you can effectively restore the integrity of your appliance, preventing leaks and enhancing its overall efficiency.

Cleaning the Pump and Filter

Regular maintenance of the drainage system is essential for ensuring optimal performance and longevity of your appliance. Over time, debris and residue can accumulate in the pump and filter, potentially leading to blockages and inefficient operation. This section outlines the necessary steps to effectively clean these components.

Tools and Materials Needed

- Soft cloth or sponge

- Bucket or shallow pan

- Small brush (e.g., toothbrush)

- Warm soapy water

Steps for Cleaning

- Begin by turning off the machine and disconnecting it from the power source.

- Locate the access panel, usually found at the front or bottom of the unit.

- Place a bucket or shallow pan beneath the pump to catch any residual water.

- Carefully remove the filter cover and take out the filter.

- Inspect the filter for debris and rinse it under warm water.

- Use a small brush to gently scrub any stubborn buildup.

- Check the pump area for any clogs and clean as necessary.

- Reinsert the filter and secure the cover, ensuring it is tightly closed.

- Reconnect the power and run a short cycle to test the system.

By routinely cleaning the pump and filter, you can help maintain efficient drainage and prevent future issues, ensuring that your appliance operates smoothly.

How to Address Drum Noise Problems

Unwanted sounds during operation can be both annoying and indicative of underlying issues within your appliance. Understanding how to diagnose and resolve these disturbances is essential for maintaining optimal functionality and longevity.

Common Causes of Noise

Several factors may contribute to drum noise, including unbalanced loads, worn-out components, or foreign objects trapped inside. Inspecting these elements can often lead to effective solutions.

Troubleshooting Steps

Begin by examining the load for balance; uneven items can create excessive vibrations. Next, check for any loose parts or damage to the drum itself. If foreign objects are suspected, carefully inspect the drum area. Regular maintenance can also help prevent future issues.

Troubleshooting Water Drainage Issues

Effective drainage is crucial for maintaining the functionality of your appliance. When water does not drain properly, it can lead to various problems, including unpleasant odors and potential damage. This section will help you identify common causes and provide steps to resolve these issues.

Common Causes of Drainage Problems

- Clogged Drain Hose: A blockage in the hose can prevent water from exiting the unit.

- Blocked Pump Filter: Debris accumulation in the filter can hinder water flow.

- Pump Failure: A malfunctioning pump may not be able to expel water effectively.

- Improper Installation: If the drainage hose is not positioned correctly, it can cause backflow.

Steps to Resolve Drainage Issues

- Inspect the drain hose for kinks or obstructions. Ensure it is installed at the proper height and angle.

- Remove and clean the pump filter to eliminate any debris that may be blocking it.

- Test the pump by running a drain cycle and listening for unusual noises that may indicate a problem.

- If issues persist, consider checking for clogs in the drainage system beyond the appliance, such as the home’s plumbing.

By following these troubleshooting steps, you can effectively identify and rectify water drainage issues, ensuring your appliance operates smoothly.

Maintaining Your Washer for Longevity

Proper care and regular upkeep are essential for ensuring the durability and efficiency of your appliance. By following a few simple practices, you can extend its lifespan and keep it functioning at optimal levels. Here, we outline key strategies to maintain your device effectively.

Regular Cleaning

Keeping your appliance clean is vital to prevent buildup and maintain performance. Here are some cleaning tips:

| Area | Cleaning Frequency | Recommended Method |

|---|---|---|

| Drum | Monthly | Run a hot cycle with vinegar |

| Seals | Weekly | Wipe with a damp cloth |

| Detergent Drawer | Monthly | Remove and rinse thoroughly |

Optimal Usage Practices

Adopting good habits during use can also enhance longevity. Avoid overloading the appliance and use the appropriate settings for each load type. Regularly inspect hoses and connections for wear and tear to prevent leaks and ensure safety.

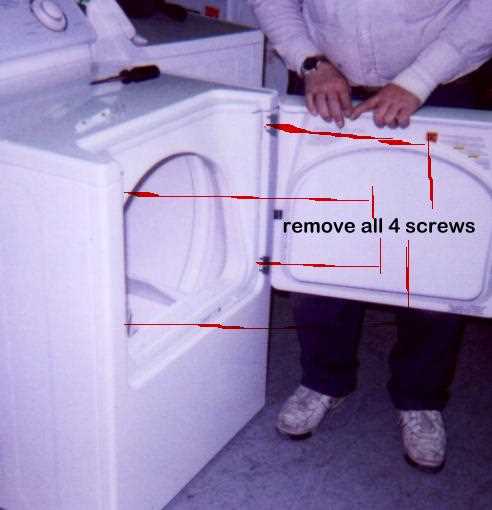

Accessing Internal Components Safely

When it comes to performing maintenance or troubleshooting issues, gaining safe access to the internal parts of your appliance is crucial. Proper procedures ensure not only your safety but also the integrity of the machine. Familiarizing yourself with the necessary steps and precautions can prevent accidents and damage during the process.

Before starting, always disconnect the device from its power source to eliminate any risk of electric shock. This involves unplugging the unit or turning off the circuit breaker that supplies power to it. Additionally, ensure that the appliance is empty and dry to avoid any water hazards.

Once you’ve ensured a safe environment, gather the right tools for the task. Having a set of screwdrivers, pliers, and a flashlight will aid in navigating the internal structure. As you proceed, document your steps and the components you remove to simplify reassembly later. Keep all screws and small parts organized to avoid losing them during the process.

When accessing internal components, take care to handle everything gently. Avoid using excessive force, as this can lead to damage. Be mindful of any sharp edges or moving parts that may be present. Always refer to any available guidelines or instructions for specific disassembly processes relevant to your appliance.

By following these steps, you can safely explore and address issues within your appliance, ensuring it remains functional and reliable for years to come.

When to Call a Professional Technician

Understanding when to seek assistance from a skilled technician is crucial for maintaining the longevity and efficiency of your appliance. While many issues can be addressed through basic troubleshooting, certain signs indicate that professional intervention is necessary to avoid further damage or safety risks.

| Signs You Need a Professional | Description |

|---|---|

| Unusual Noises | If your device is making loud or strange sounds, it may indicate a mechanical failure that requires expert evaluation. |

| Persistent Error Codes | Repeated error messages that do not resolve with simple resets often signal deeper underlying issues. |

| Leaks or Water Accumulation | Any signs of leaking fluids can pose serious risks and should be addressed immediately by a professional. |

| Failure to Start | If the unit does not power on or complete its cycle, it may require specialized knowledge for proper diagnosis. |

| Odors | Unpleasant or burning smells can indicate electrical problems or overheating components that need urgent attention. |

By recognizing these indicators, you can make informed decisions about when to reach out for expert help, ensuring that your appliance remains in optimal working condition.