Comprehensive Guide to Maytag Neptune Washing Machine Repair

Understanding the intricacies of household devices can significantly enhance their longevity and performance. Often, minor issues can escalate into major problems if not addressed promptly. This section aims to equip you with essential knowledge to navigate the common challenges faced with your equipment.

When your unit exhibits unusual behavior, it’s crucial to identify the root cause efficiently. This guide will provide valuable insights into potential malfunctions and step-by-step approaches to resolving them. Whether it’s addressing erratic noises or improper functioning, having a reliable resource at hand can make all the difference.

By familiarizing yourself with the components and their functions, you can tackle issues proactively. The following information will serve as a practical reference, enabling you to perform necessary adjustments and ensure optimal operation of your appliance.

Overview of Maytag Neptune Washing Machine

This section provides a comprehensive look at a popular line of household appliances designed for effective clothing care. Known for their advanced features and robust performance, these units are a favorite among many consumers. Understanding their functionality and components is crucial for optimal usage and maintenance.

Key Features

- Energy efficiency that reduces utility bills.

- Various settings for different fabric types.

- Large capacity to accommodate bulk loads.

- Advanced technology for improved cleaning performance.

Common Specifications

- Dimensions tailored for standard laundry rooms.

- Multiple spin speeds for customizable drying options.

- Intuitive controls for ease of use.

- Durable construction for long-lasting reliability.

Understanding these features and specifications can enhance user experience and ensure the longevity of the appliance. Proper care and knowledge of functionalities are essential for maintaining efficiency and performance.

Common Issues with Neptune Models

When dealing with specific appliance models, users often encounter a range of recurring challenges that can hinder performance and efficiency. Understanding these prevalent problems can help in troubleshooting and maintaining optimal functionality.

Drainage Problems: One of the most frequent concerns involves improper water removal. This can result from clogs in the drainage system or malfunctioning pumps, leading to standing water and potential damage.

Noisy Operation: Excessive noise during cycles is another common issue. This could be caused by worn-out bearings, loose components, or items caught in the drum, disrupting normal function.

Unbalanced Loads: An unsteady load can trigger the appliance’s safety mechanisms, causing it to halt mid-cycle. This often occurs when heavy items are mixed with lighter ones, requiring users to redistribute their laundry for balanced performance.

Temperature Fluctuations: Users may also notice inconsistent temperature settings, affecting the effectiveness of the cleaning process. This can stem from faulty thermostats or heating elements, which may require assessment and potential replacement.

Display Issues: Malfunctions in the control panel can lead to difficulties in selecting cycles or understanding operational status. This may involve software glitches or hardware failures that need attention.

By identifying these common challenges, owners can take proactive steps toward resolution and ensure their appliances operate smoothly for years to come.

Understanding Error Codes and Solutions

Error codes serve as essential indicators that alert users to specific issues within their appliances. These codes simplify troubleshooting by providing clear information about potential malfunctions, allowing for more efficient problem-solving. Familiarity with these signals can empower users to address concerns promptly and effectively.

Common Error Codes and Their Meanings

Each appliance may display a range of codes, each corresponding to different problems. For instance, a code might indicate an issue with drainage, while another may suggest a temperature inconsistency. Understanding these codes is crucial, as it enables users to identify the nature of the malfunction and assess whether it requires professional attention or can be resolved independently.

Effective Solutions for Common Issues

Once a code is recognized, users can take specific actions to remedy the situation. For example, if the drainage code appears, checking for clogs in hoses or filters may resolve the problem. Similarly, if a temperature-related code is displayed, ensuring that the thermostat is functioning properly could restore normal operation. Taking these steps can often mitigate the need for external service, leading to quicker resolutions.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving issues that may arise with your appliance. By following a systematic process, you can identify common problems and determine the appropriate solutions, ensuring optimal functionality and longevity.

Identify the Issue

The first step is to recognize the specific problem. Observe any unusual sounds, error codes, or malfunctions. Take note of the circumstances under which the issue occurs, as this information can significantly aid in troubleshooting.

Follow a Systematic Process

Begin by checking the power source; ensure that the device is plugged in and that the outlet is functional. Next, examine the connections and hoses for any signs of damage or blockages. If necessary, consult the user guide for additional insights into common faults. Document your findings as you progress, which will help in further diagnostics or when seeking professional assistance if required.

Once you’ve addressed these initial checks, proceed with more detailed inspections based on the symptoms observed. Patience and methodical analysis will lead you closer to an effective resolution.

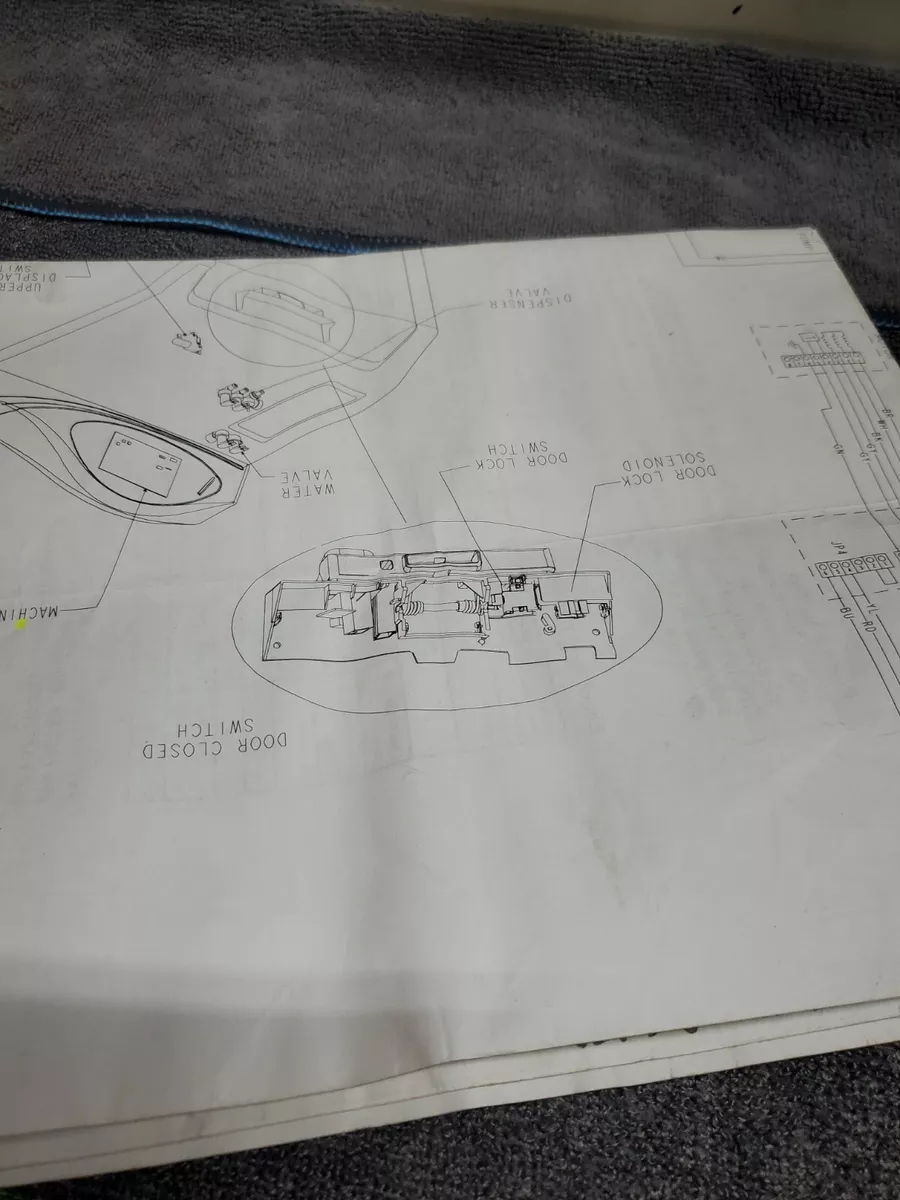

How to Access Internal Components

Gaining entry to the inner workings of your appliance is crucial for effective troubleshooting and maintenance. Understanding how to safely access these parts can help you diagnose issues and perform necessary tasks with confidence.

Before beginning, ensure that the device is unplugged and that you have the appropriate tools on hand. Here’s a step-by-step guide to facilitate the process:

- Gather Tools: Prepare screwdrivers, pliers, and a flashlight for visibility.

- Remove the Front Panel:

- Locate the screws securing the front panel.

- Carefully unscrew and set the panel aside.

- Detach the Top Cover:

- Identify and remove screws at the back of the top cover.

- Slide the cover towards the rear and lift it off.

- Access the Interior:

- Inspect the components such as belts, drums, and electrical connections.

- Take note of any wear or damage.

- Reassemble:

- Once maintenance is complete, reverse the disassembly steps.

- Ensure all screws are tightened and the covers fit securely.

By following these steps, you can successfully reach the internal parts, enabling efficient upkeep and timely fixes.

Replacing the Drive Belt Instructions

Replacing the drive belt is an essential maintenance task that can significantly improve the performance of your appliance. A worn or broken belt can lead to issues such as improper spinning or failure to agitate. This guide outlines the steps needed to successfully replace the drive belt, ensuring your unit operates smoothly once again.

Before beginning, gather the necessary tools, including a screwdriver, pliers, and a replacement belt compatible with your model. Follow these detailed steps to complete the process:

| Step | Action |

|---|---|

| 1 | Unplug the unit to ensure safety while working. |

| 2 | Remove the front or rear access panel using a screwdriver. |

| 3 | Locate the old drive belt and inspect its condition. |

| 4 | Carefully detach the belt from the pulleys and motor. |

| 5 | Position the new belt around the motor pulley and drum. |

| 6 | Ensure the belt is properly aligned and tensioned. |

| 7 | Replace the access panel and secure it with screws. |

| 8 | Plug the unit back in and test its functionality. |

After completing these steps, your appliance should be ready for use. Regular maintenance and timely replacement of components like the drive belt can prolong the lifespan and efficiency of your equipment.

Fixing Water Drainage Problems

Issues with liquid expulsion can significantly affect the performance of your appliance. Identifying and resolving these complications is crucial for maintaining optimal functionality and avoiding further damage. Various factors can contribute to inadequate drainage, and understanding them is the first step toward finding a solution.

Common Causes

Several elements can lead to drainage issues. Clogs in the drain hose, blockages in the pump, or problems with the drainage system itself are frequent culprits. It’s essential to systematically inspect each component to determine the root of the problem.

Troubleshooting Steps

Begin by checking the drain hose for kinks or obstructions. If the hose appears intact, examine the filter and pump for debris. Cleaning these parts can often resolve the issue. Additionally, ensure that the drainage system is properly installed and not too high off the ground, as this can impede flow.

Testing and Solutions

After conducting visual inspections and cleaning, perform a test cycle to assess if the problem persists. If drainage issues continue, further investigation may be necessary, which could include examining the motor or control board. Always consult a professional if you’re unsure about the next steps, as proper troubleshooting is key to a long-lasting solution.

Addressing Unusual Noises During Operation

Unexpected sounds during operation can be concerning, indicating potential issues that require attention. Identifying the source and understanding the types of noises can help in diagnosing the underlying problems effectively. It is essential to approach these irregularities systematically to ensure optimal functionality.

Common Sounds and Their Meanings

| Noise Type | Possible Cause |

|---|---|

| Thumping | Unbalanced load or worn suspension components |

| Squeaking | Worn drive belt or faulty motor bearings |

| Grinding | Foreign object in the drum or worn gear assembly |

| Rattling | Loose parts or debris caught in the drum |

Troubleshooting Steps

To address these sounds, start by inspecting the load for balance and removing any foreign items. Next, check the drive belt and motor components for wear. If problems persist, consider seeking professional assistance to prevent further damage and ensure thorough diagnostics.

Cleaning and Maintaining Your Washer

Regular upkeep of your appliance is essential for optimal performance and longevity. By implementing simple cleaning routines and maintenance practices, you can prevent common issues and ensure your device operates efficiently. This section outlines key steps to keep your unit in top shape.

Routine Cleaning Tasks

To maintain peak functionality, consider the following tasks:

- Wipe down the exterior regularly to remove dust and grime.

- Clean the detergent dispenser to prevent buildup of residues.

- Inspect and clean the door seal to avoid mildew and odors.

- Run a cleaning cycle with appropriate solutions to eliminate internal residue.

Periodic Maintenance Tips

In addition to routine cleaning, perform these maintenance tasks periodically:

- Check hoses for any signs of wear or leaks and replace if necessary.

- Ensure the filter is clean and free of debris to promote proper drainage.

- Level the unit to prevent excessive vibration during operation.

- Schedule professional inspections if you notice unusual noises or performance issues.

Implementing these practices will help extend the life of your appliance and enhance its efficiency, making laundry day a smoother experience.

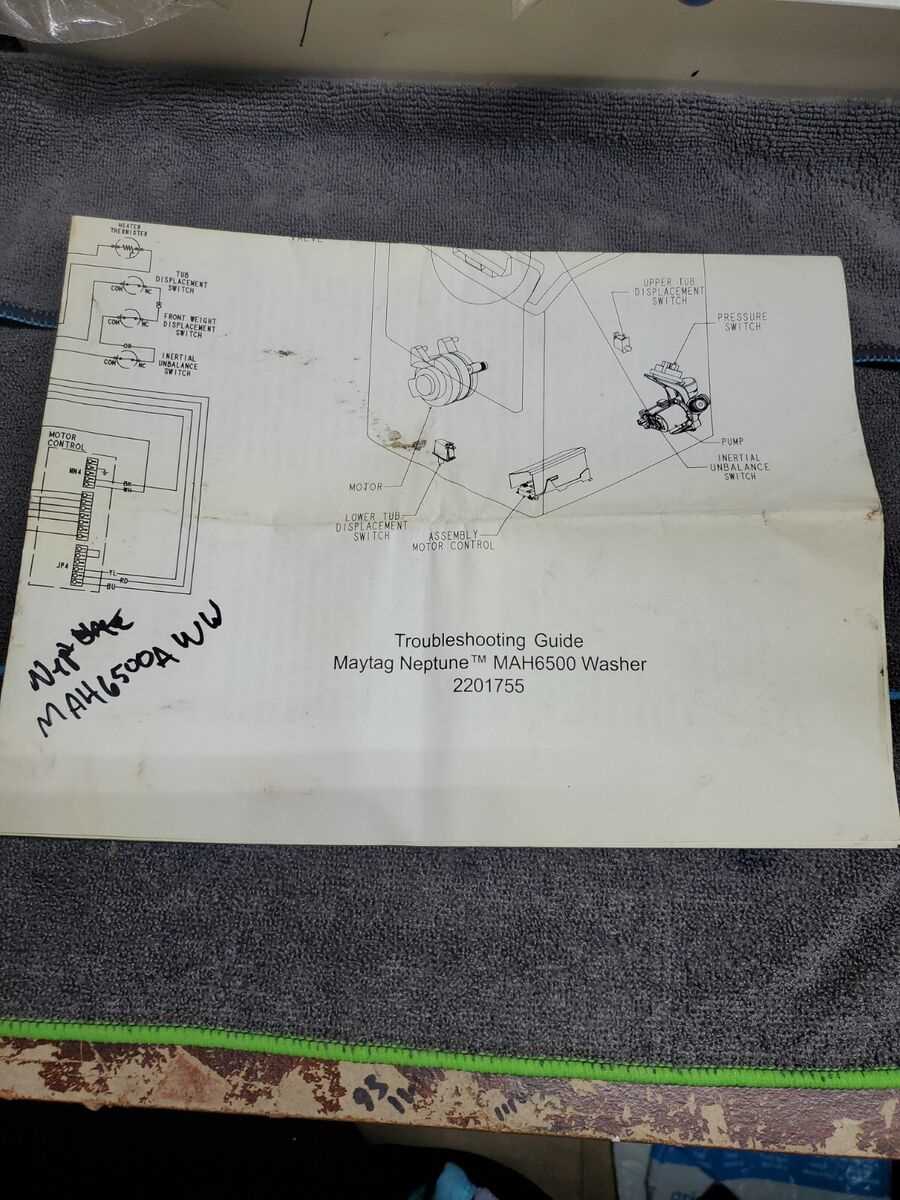

Diagnosing Electrical Problems Effectively

Identifying issues within electrical appliances can be a daunting task. However, with a systematic approach, you can pinpoint the source of malfunctions efficiently. This section outlines essential steps and considerations to help you navigate the troubleshooting process.

Begin by gathering the necessary tools, including a multimeter, to measure voltage and continuity. Familiarize yourself with the basic components of the unit, such as power sources, control boards, and wiring. Understanding how these parts interact will enhance your diagnostic capabilities.

Next, systematically check for common issues:

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| No Power | Device unresponsive | Check outlet, circuit breaker, and power cord |

| Intermittent Functionality | Device stops unexpectedly | Inspect connections and control board |

| Unusual Noises | Clicking or buzzing sounds | Examine motor and internal components for wear |

| Error Codes | Specific codes displayed | Refer to manufacturer documentation for guidance |

After identifying a potential issue, perform further tests using your tools. Verify voltage levels at various points and check for continuity in wiring. Document your findings to track progress and ensure nothing is overlooked.

By following these steps, you can effectively diagnose electrical issues, leading to informed decisions on repairs and maintenance.

When to Call a Professional Technician

Understanding when to seek the expertise of a skilled technician can save time, effort, and potentially costly repairs. While many issues can be addressed with basic troubleshooting, some situations require specialized knowledge and tools that only a professional possesses.

If you notice persistent leaks, unusual noises, or error codes that do not resolve with standard resets, it’s time to consider professional help. Additionally, if the appliance fails to operate altogether despite following basic guidelines, reaching out to an expert is advisable.

Complicated electrical or mechanical problems, especially those involving internal components, should never be tackled without the appropriate experience. Attempting to fix such issues without proper training can lead to further damage and safety hazards.

In cases of significant wear and tear or when dealing with older units, a technician’s assessment can provide valuable insights into whether repair or replacement is the more economical choice. Ultimately, trusting a professional ensures that the work is performed safely and efficiently.

Parts Replacement: A Comprehensive List

This section aims to provide an extensive overview of components that may require substitution during the maintenance process. Understanding which elements can fail and how to identify them is crucial for efficient troubleshooting and ensuring optimal functionality.

Common Components Needing Replacement

Several parts are frequently subject to wear and tear. These include seals, belts, and filters. Seals can deteriorate over time, leading to leaks, while belts might stretch or break, causing operational failures. Filters are essential for maintaining performance and should be checked regularly for clogs.

Less Common Yet Vital Parts

In addition to the more frequently replaced elements, certain components may also require attention, though less often. These include control boards, sensors, and pumps. A malfunctioning control board can disrupt the entire system, while faulty sensors may fail to provide accurate readings. Pumps, critical for drainage, can also become blocked or damaged, necessitating timely intervention.

Preventative Care Tips for Longevity

Ensuring the durability and efficient performance of your laundry appliance involves implementing a series of proactive measures. Regular maintenance and mindful usage can significantly extend the lifespan of your equipment, minimizing the likelihood of unexpected breakdowns and costly repairs.

Here are some essential tips to help you maintain your appliance effectively:

| Tip | Description |

|---|---|

| Regular Cleaning | Remove lint and debris from filters and hoses to prevent clogs and ensure optimal airflow. |

| Check Hoses | Inspect water supply hoses for signs of wear or leaks; replace them every few years to avoid potential flooding. |

| Balanced Loads | Avoid overloading the drum. Distributing items evenly prevents strain on the motor and drum bearings. |

| Level the Unit | Ensure the appliance is level to minimize vibrations that can lead to mechanical issues over time. |

| Run Maintenance Cycles | Utilize any self-cleaning or maintenance cycles regularly to keep internal components in good condition. |

By adopting these practices, you can enjoy enhanced reliability and longevity, ensuring your equipment serves you well for years to come.