Repairing Your Simoniz Pressure Washer

Ensuring the longevity and efficiency of your cleaning apparatus requires proper upkeep and understanding of its components. This section delves into essential troubleshooting techniques and maintenance practices tailored for high-performance devices designed to eliminate stubborn grime and dirt.

Regular inspections are crucial in identifying potential issues before they escalate. Familiarizing yourself with the various elements of your cleaning apparatus can significantly enhance its functionality. In this guide, we provide a comprehensive overview of common challenges users may encounter, along with effective solutions to address them.

By following these best practices, you can ensure your device remains in optimal working condition. Knowledge and proactive measures are key to maximizing performance and achieving satisfactory results in your cleaning endeavors.

This section will provide an in-depth overview of various models available in the market. Understanding the different variations and features is essential for selecting the right equipment for specific tasks. Each model caters to unique needs, making it crucial to know their specifications and functionalities.

Key Features to Consider

When evaluating different models, several features should be taken into account, such as power output, water flow rate, and design. These elements significantly influence the performance and efficiency of the equipment.

Model Comparison Table

| Model Name | Power (HP) | Flow Rate (GPM) | Weight (lbs) |

|---|---|---|---|

| Model A | 1.5 | 1.2 | 30 |

| Model B | 2.0 | 1.5 | 35 |

| Model C | 2.5 | 1.8 | 40 |

Common Issues with Simoniz Washers

Users often encounter a variety of challenges when operating these cleaning devices. Understanding these typical problems can aid in effective troubleshooting and maintenance, ensuring optimal performance and longevity.

Power Supply Complications

One of the most frequent concerns relates to power connectivity. Devices may fail to start due to issues with electrical outlets, extension cords, or internal wiring. Checking the power source is essential before further investigation.

Water Flow Problems

Another common issue involves inconsistent water flow. Blockages in hoses or nozzles can hinder performance. Regular cleaning of these components can prevent buildup and maintain efficient operation. Inspecting for kinks in hoses also helps ensure a steady supply.

Essential Tools for Repair

Having the right equipment is crucial for ensuring effective maintenance and restoration of your cleaning device. Whether addressing minor issues or conducting thorough servicing, the following tools will help streamline the process and enhance efficiency.

Basic Tools

- Socket set – Essential for loosening and tightening various bolts and nuts.

- Wrench – A must-have for gripping and turning fasteners.

- Screwdriver set – Useful for adjusting screws of different sizes.

- Pliers – Great for gripping, twisting, and cutting wire.

Specialized Equipment

- Pressure gauge – Important for checking and monitoring the pressure levels.

- Multimeter – A versatile tool for diagnosing electrical issues.

- Oil can – Necessary for lubrication of moving parts.

- Cleaning brush – Helps in removing dirt and debris from components.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing and resolving common issues encountered with high-performance cleaning devices. By following this structured guide, users can efficiently identify problems and implement appropriate solutions, ensuring optimal functionality.

Begin by inspecting the power source. Verify that the device is properly connected and that the outlet is functioning. If the equipment fails to start, check for any blown fuses or tripped circuit breakers.

Next, examine the hose and attachments for blockages. Accumulation of debris can hinder water flow, resulting in diminished performance. Detach the hose and flush it out to remove any obstructions.

If the output pressure is inconsistent, assess the nozzle for wear or damage. A clogged or deteriorated nozzle can disrupt water delivery. Cleaning or replacing the nozzle may restore normal function.

Finally, ensure that all connections are secure. Loose fittings can lead to leaks and reduce efficiency. Tightening these connections can help maintain proper operation and prevent water loss.

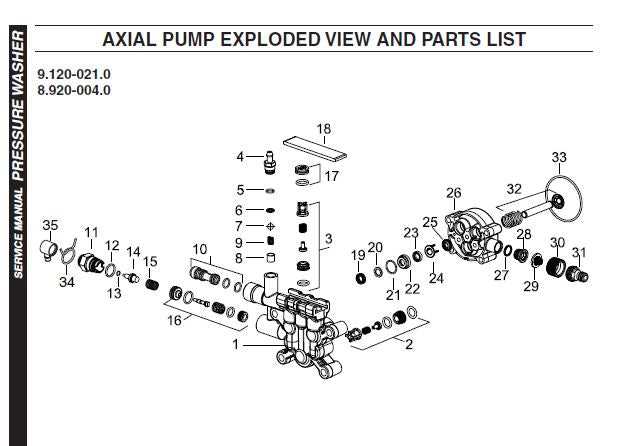

How to Replace the Pump

Replacing the pump in your cleaning device can enhance its efficiency and prolong its lifespan. This section provides a comprehensive guide on how to successfully carry out this essential maintenance task.

Tools Required

| Tool | Purpose |

|---|---|

| Screwdriver | To remove screws securing the pump |

| Wrench | To loosen and tighten fittings |

| Replacement Pump | To install in place of the old unit |

| Sealant | To ensure watertight connections |

Step-by-Step Process

Begin by disconnecting the device from its power source to ensure safety. Next, remove any housing or covers that obstruct access to the pump. Carefully unscrew and detach the old pump, taking note of the positioning of hoses and fittings for reassembly. Install the new pump by reversing the removal process, ensuring all connections are secure and using sealant where necessary to prevent leaks. Finally, replace any covers and reconnect the power source before testing the unit for proper functionality.

Cleaning the Filter and Nozzle

Regular maintenance of the filtration system and dispensing tips is essential for optimal functionality. Over time, debris and residues can accumulate, affecting performance and efficiency. Ensuring these components are clean will enhance the effectiveness of your equipment.

Steps for Cleaning the Filter

- Disconnect the equipment from the power source to ensure safety.

- Locate the filter, typically found near the inlet.

- Remove the filter gently, taking care not to damage it.

- Rinse the filter under running water to eliminate dirt and impurities.

- If heavily soiled, use a mild detergent and a soft brush for thorough cleaning.

- Allow the filter to dry completely before reinserting it.

Steps for Cleaning the Nozzle

- Inspect the nozzle for any blockages or debris.

- Remove the nozzle from the attachment.

- Soak it in warm, soapy water for a few minutes.

- Use a small brush or toothpick to clear any stubborn clogs.

- Rinse the nozzle thoroughly with clean water.

- Reattach the nozzle securely to the equipment.

By following these cleaning steps regularly, you can maintain the efficiency of your device and prolong its lifespan.

Electrical System Diagnostics

This section focuses on the assessment of the electrical components in the device, ensuring optimal performance and safety. Understanding the intricacies of the electrical layout can help identify potential issues that may hinder functionality.

Begin by examining the power source, ensuring that connections are secure and free from corrosion. A multimeter can be employed to measure voltage levels, confirming that the system is receiving the appropriate power supply. It’s essential to check for any blown fuses or tripped circuit breakers, as these can disrupt the entire operation.

Next, inspect the wiring harness for any signs of wear, fraying, or damage. Faulty wiring can lead to intermittent failures or complete shutdowns. Testing individual components, such as switches and relays, can also reveal hidden problems that may not be immediately apparent.

Regular diagnostics not only enhance the lifespan of the unit but also ensure that it operates safely and efficiently. By addressing electrical issues promptly, you can avoid more significant problems down the line.

Understanding Hose and Connections

Proper knowledge of hoses and connections is essential for ensuring optimal functionality of cleaning equipment. These components play a crucial role in delivering water efficiently, making it vital to understand their types, maintenance, and potential issues that can arise.

Types of Hoses

There are various types of hoses designed for different applications. Some are constructed for high-pressure scenarios, while others are more suited for general use. Material quality is a key factor, as durable materials can resist wear and tear, ultimately extending the lifespan of the equipment.

Common Connection Issues

Connections can often become a source of complications if not properly maintained. Leaks can occur due to wear or improper fittings, leading to decreased efficiency. Regular inspection and timely replacement of worn-out parts are necessary to prevent such issues and ensure seamless operation.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your cleaning equipment. By following a few simple practices, you can ensure optimal performance and avoid unnecessary breakdowns.

Regular Cleaning: After each use, thoroughly clean the exterior and any components to prevent the buildup of dirt and grime. This helps maintain functionality and appearance.

Check Hoses and Connections: Inspect all hoses and connections for wear and tear. Replace any damaged parts promptly to avoid leaks and maintain efficient operation.

Use the Correct Detergents: Utilize appropriate cleaning solutions that are compatible with your device. Using unsuitable products can lead to damage and reduced efficiency.

Store Properly: When not in use, store your equipment in a dry, sheltered area. Protecting it from the elements minimizes corrosion and extends its life.

Periodic Professional Servicing: Schedule routine check-ups with a qualified technician. Regular inspections can catch potential issues early and ensure everything is functioning correctly.

Identifying Leaks and Seals

Understanding the sources of unwanted fluid escape is crucial for maintaining optimal performance in any cleaning device. Proper detection of such issues can help in preserving functionality and extending the lifespan of the equipment.

Common Signs of Leaks

Look for visible moisture accumulation around the unit or any unusual wet spots on the surface where the device is stored. These indicators often suggest a breach in one of the seals or connections.

Inspecting Seals and Connections

Regularly check all joints and seals for signs of wear or damage. A compromised seal may appear cracked or worn down, leading to inefficiencies. It is essential to examine these areas closely to ensure a tight fit.

Testing for Integrity

To confirm the presence of leaks, perform a pressure test. By running the unit while monitoring for fluid escape, you can identify problem areas that require immediate attention. Addressing these concerns promptly can prevent more significant issues down the line.

Repairing the Pressure Control Valve

This section provides guidance on addressing issues related to the component that regulates water flow and pressure in cleaning devices. Ensuring this part functions correctly is essential for optimal performance and efficiency.

To successfully address malfunctions, follow these steps:

- Gather Necessary Tools:

- Wrench set

- Screwdriver

- Sealant tape

- Replacement parts

- Identify the Problem:

Common signs of a faulty component include inconsistent pressure, leaks, or unusual noises. Observing these issues will guide you in determining the necessary actions.

- Disassemble the Unit:

Carefully remove the casing to access the component. Take note of the assembly for reinstallation.

- Inspect for Damage:

Check for worn seals, cracks, or other visible defects that may affect functionality.

- Replace Faulty Parts:

If any components are damaged, replace them with suitable alternatives. Ensure the new parts match the specifications.

- Reassemble the Device:

Put everything back together, ensuring all connections are tight and secure. Use sealant tape to prevent leaks.

- Test Functionality:

After reassembly, perform a test run to verify that the component operates correctly. Monitor for leaks or pressure issues during operation.

By following these steps, you can effectively address issues related to the water flow regulation component, ensuring reliable operation and longevity of your cleaning equipment.

When to Seek Professional Help

Identifying the right moment to consult an expert can significantly enhance the longevity and efficiency of your equipment. Certain situations may require specialized knowledge or tools that go beyond standard maintenance.

Consider reaching out to a professional in the following scenarios:

- Persistent Issues: If problems continue despite your attempts to resolve them.

- Complex Repairs: For tasks that involve intricate components or systems.

- Safety Concerns: When dealing with electrical or high-pressure systems that pose potential hazards.

- Warranty Considerations: If your device is still under warranty, unauthorized repairs may void it.

- Lack of Time or Resources: When you’re unable to dedicate sufficient time or tools to the task.

By recognizing these indicators, you can ensure that your equipment receives the best care possible, preventing further damage and maintaining its performance.