Guide to Repairing Whirlpool Cabrio Washers

Maintaining home appliances is essential for ensuring their longevity and optimal performance. Understanding common issues and their solutions can empower users to address problems effectively. This section provides insights into troubleshooting techniques that can simplify the process of keeping your appliance in excellent working condition.

By familiarizing yourself with the various components and functionalities, you can better navigate potential malfunctions. Whether it’s understanding unusual noises or addressing drainage concerns, being proactive can save both time and money. This guide aims to equip you with the knowledge needed to tackle common challenges and enhance your appliance’s efficiency.

This section aims to highlight typical challenges encountered by users of automatic laundry appliances. Understanding these common problems can facilitate troubleshooting and maintenance, ensuring efficient operation and prolonging the lifespan of the machine.

- Inconsistent washing results

- Unusual noises during cycles

- Water drainage issues

- Problems with the spin cycle

- Door locking malfunctions

Addressing these issues promptly can prevent further complications and maintain optimal performance. Regular maintenance checks and being aware of these common signs can save time and resources.

Troubleshooting Spin Cycle Problems

Issues during the spin cycle can lead to damp clothes and frustration. Identifying the underlying causes is essential for effective resolution. This section will guide you through common problems and their solutions.

Common Issues

- Poor drainage

- Unbalanced load

- Faulty lid switch

- Motor problems

Solutions

- Check Drainage: Ensure the drainage hose is not clogged or kinked.

- Redistribute Load: Balance the items in the drum for optimal spinning.

- Inspect Lid Switch: Test the lid switch for proper functionality. Replace if necessary.

- Examine Motor: Verify the motor’s condition and connections. Seek professional help if issues persist.

Understanding Error Codes

Modern laundry appliances often display error codes to indicate specific issues that may arise during operation. These codes serve as a diagnostic tool, allowing users to identify and address potential problems effectively.

Recognizing these codes is crucial for maintaining optimal performance. Here are some common aspects to consider:

- Code Interpretation: Each code corresponds to a particular fault or malfunction. Familiarizing yourself with these codes can simplify troubleshooting.

- Common Codes: Many models share similar error codes. Understanding the most frequent ones can expedite the diagnosis process.

- Manufacturer’s Guidelines: Consult the provided documentation for specific meanings of each code. This resource often includes potential solutions.

By understanding the significance of these indicators, users can take proactive measures to resolve issues, ensuring the appliance operates smoothly.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your home appliance requires consistent care and attention. By implementing a few straightforward practices, you can significantly extend the lifespan of your unit, preventing unnecessary breakdowns and costly repairs.

Regular Cleaning

Frequent cleaning is essential to maintain optimal performance. Remove any lint or debris from filters and interior compartments. Wipe down surfaces with a damp cloth to prevent the buildup of residue, which can lead to malfunction.

Proper Usage

Following the manufacturer’s guidelines for loading and operation is crucial. Avoid overloading, as this can strain components and decrease efficiency. Additionally, using the correct settings for different fabrics ensures gentle treatment and helps maintain the appliance’s integrity.

Investing time in these maintenance practices can lead to enhanced performance and a longer operational life.

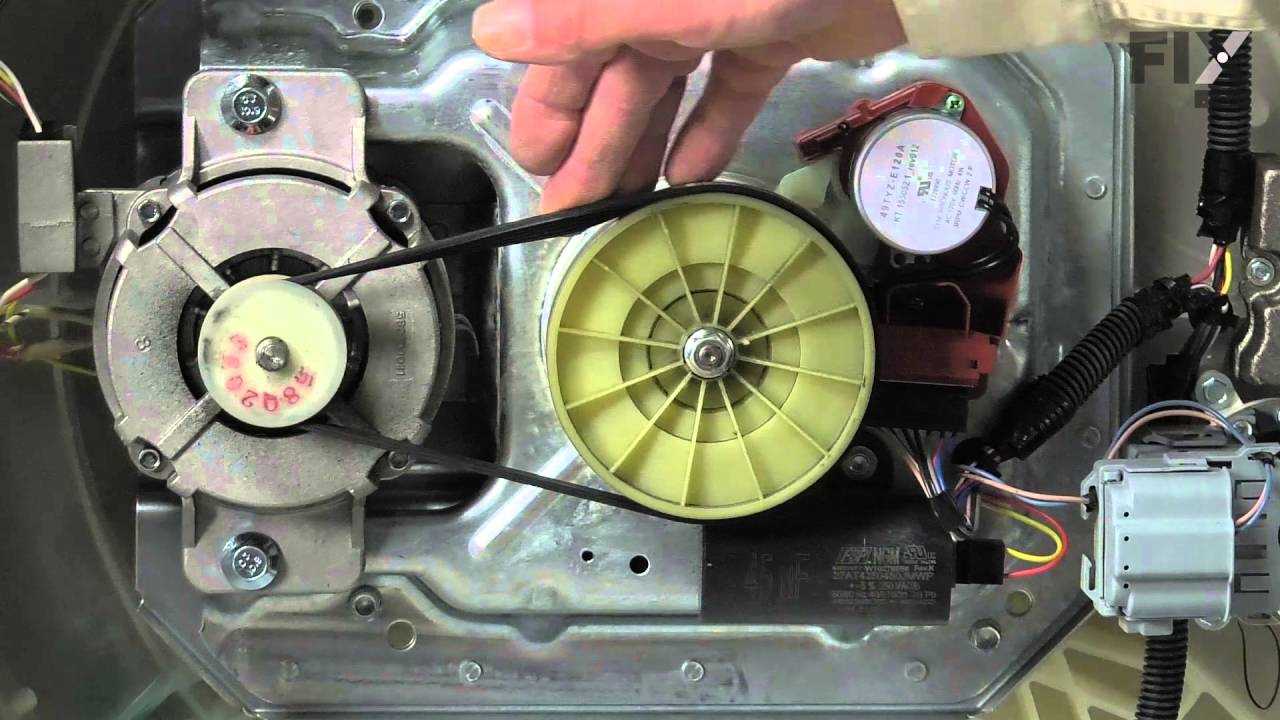

Replacing Essential Components

When maintaining a laundry appliance, certain parts may require replacement over time to ensure optimal performance. Addressing these essential components can significantly improve the efficiency and longevity of the device.

Common parts that may need to be replaced include:

- Drive belt

- Motor coupler

- Water pump

- Suspension rods

- Control board

Each of these elements plays a critical role in the functionality of the appliance. Regular inspection can help identify wear and tear early, allowing for timely replacements. Here’s a brief overview of how to handle the replacement process:

- Safety First: Always disconnect the appliance from the power source before starting any work.

- Access the Component: Remove any necessary panels or covers to reach the part that needs replacing.

- Remove the Old Part: Carefully detach the worn component, taking note of how it was installed for reference.

- Install the New Part: Position the new component in place, ensuring it is secured correctly.

- Reassemble: Replace any panels or covers that were removed and restore the power supply.

By following these steps, you can effectively replace vital components, ensuring the appliance operates smoothly and efficiently.

Cleaning the Washer Drum

Maintaining the interior of your laundry appliance is essential for optimal performance and longevity. A clean drum not only enhances washing efficiency but also prevents unpleasant odors and mold growth. Regular cleaning can significantly improve the overall washing experience.

Recommended Cleaning Solutions

For effective cleaning, consider using natural solutions like vinegar or baking soda. These ingredients are gentle yet powerful in breaking down residues and eliminating odors. Mix a cup of vinegar or baking soda with water and run a hot cycle to refresh the drum.

Cleaning Frequency

It is advisable to clean the drum every few months, depending on usage. Frequent use or high humidity can accelerate buildup. By establishing a regular cleaning schedule, you can ensure that your appliance remains in peak condition, providing you with fresh and clean laundry.

Improving Water Drainage Efficiency

Enhancing the effectiveness of water removal in laundry appliances is crucial for optimal performance. Efficient drainage not only prevents excess moisture but also contributes to the longevity of the unit and the cleanliness of garments. Understanding the underlying mechanisms can aid in achieving better outcomes during the washing process.

Regular Maintenance Checks

Conducting frequent inspections of drainage components can significantly impact performance. Ensure that all hoses are clear of blockages and properly positioned. Cleaning filters on a routine basis can also help maintain optimal water flow, preventing buildup that may hinder drainage efficiency.

Proper Installation Techniques

Correctly installing drainage systems is essential for effective water removal. Positioning hoses at the right height can facilitate proper flow and minimize backflow issues. Additionally, ensuring that connections are secure prevents leaks that could compromise the entire system’s functionality.

How to Reset Your Appliance

Resetting your household device can often resolve various issues and restore its proper functionality. This simple process can help eliminate minor glitches and enhance the overall performance of your equipment.

Steps to Perform a Reset

To initiate a reset, start by unplugging the appliance from the power source. Wait for approximately one minute before reconnecting it. This brief period allows any residual power to dissipate, effectively refreshing the system.

Troubleshooting Tips

If the device does not respond after the reset, check the power outlet to ensure it is functioning correctly. Additionally, inspect the cord for any visible damage. In case problems persist, consider consulting the manufacturer’s guidelines for further troubleshooting.

Electrical Troubleshooting Steps

This section outlines essential procedures for diagnosing electrical issues in a laundry appliance. Following these steps can help identify faults and ensure proper functioning.

Begin by checking the power source. Ensure that the appliance is plugged in and that the outlet is functioning correctly. If necessary, use a multimeter to verify the voltage.

If the appliance is receiving power, inspect the door latch mechanism. A malfunctioning latch can prevent the machine from operating. Ensure that the latch engages properly and is free of obstructions.

Next, examine the control panel for any error codes or flashing lights. These indicators can provide insight into specific issues. Refer to your device’s documentation to interpret these signals.

| Step | Action |

|---|---|

| 1 | Check power outlet and plug |

| 2 | Inspect door latch functionality |

| 3 | Review control panel indicators |

Finally, if problems persist, consider testing the internal components, such as wiring and motors. Look for any signs of damage or wear that could contribute to electrical failures.

Addressing Noise During Operation

When appliances produce unexpected sounds during use, it can be concerning for users. Identifying the source of these noises is crucial for effective troubleshooting and ensuring optimal functionality. Various factors, including mechanical components, load distribution, and installation aspects, can contribute to the problem.

Common Causes of Noise: Unbalanced loads often lead to excessive vibration, resulting in loud clattering sounds. Additionally, worn or damaged parts, such as bearings or belts, may create grinding or squeaking noises. It’s essential to inspect these components regularly.

Solutions and Preventive Measures: To minimize noise, always load the appliance evenly. Regular maintenance checks can help detect and replace worn parts before they escalate into more significant issues. Consulting the manufacturer’s guidelines can provide specific recommendations for maintaining quiet operation.