Whirlpool Front Load Washer Repair Guide

When dealing with household laundry equipment, understanding its functionality and maintenance can greatly enhance its performance and longevity. This section provides a comprehensive overview of common issues that users may encounter, alongside practical solutions to ensure optimal operation.

Addressing problems with your washing machine not only helps in restoring its efficiency but also saves time and money in the long run. By following the outlined steps and insights, you can empower yourself to tackle various challenges effectively, ensuring that your appliance runs smoothly.

From minor inconveniences to more significant complications, being equipped with the right knowledge will aid in making informed decisions. This resource aims to equip users with the necessary tools and techniques to manage and rectify common setbacks, ultimately leading to a hassle-free laundry experience.

Whirlpool Front Load Washer Overview

This section provides a comprehensive look at a popular type of home appliance designed for efficient laundry care. These machines are engineered to deliver superior cleaning performance while minimizing water and energy consumption.

Key features often include:

- Energy-efficient operation, contributing to lower utility bills.

- Advanced technology for optimal cleaning results.

- Varied wash cycles to accommodate different fabric types.

- Space-saving design, perfect for smaller laundry areas.

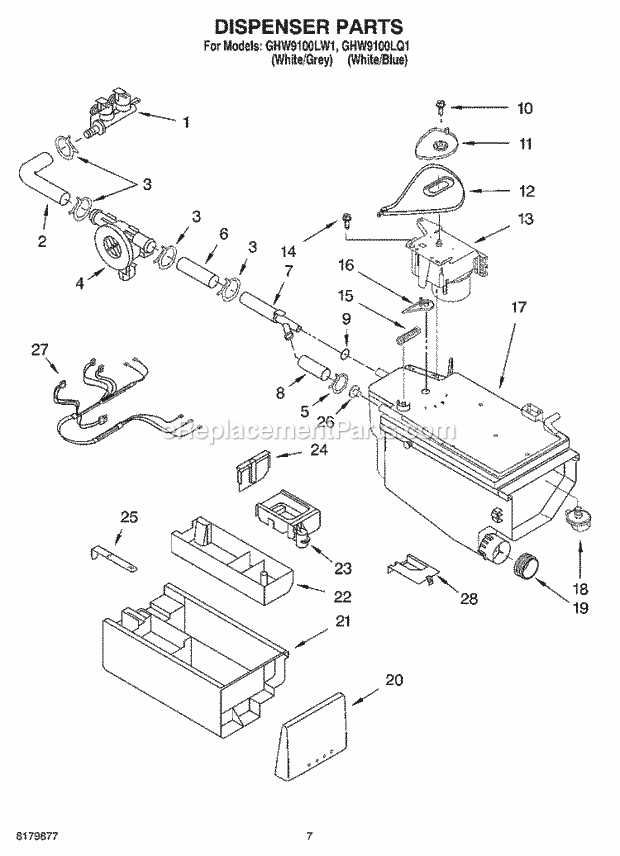

Understanding the components and functionalities of this appliance can enhance its use and maintenance:

- Control panel: User-friendly interface for selecting cycles and settings.

- Drum design: Maximizes space and improves wash action.

- Water inlet and drainage systems: Ensure proper water flow and removal.

- Detergent dispenser: Convenient storage for washing agents.

By familiarizing oneself with these aspects, users can effectively manage their appliance and troubleshoot common issues that may arise during its lifespan.

Common Issues and Solutions

When using a laundry machine, various challenges can arise that may disrupt its normal operation. Understanding these common problems and their corresponding solutions can help you maintain optimal performance and prolong the lifespan of your appliance.

One frequent issue is inadequate cleaning of garments, often due to overloaded cycles or improper detergent use. Ensuring the machine is not packed too tightly and using the appropriate type and amount of detergent can greatly enhance washing efficiency.

Another prevalent concern is excessive noise during operation. This can stem from items trapped in the drum or an unbalanced load. Checking for foreign objects and redistributing the contents evenly can mitigate this problem.

Water drainage problems are also common. A clogged hose or a malfunctioning pump can prevent proper drainage. Regularly inspecting the drain hose and cleaning the filter can help resolve these issues effectively.

Lastly, unexpected error codes may appear on the display, indicating various malfunctions. Referencing the user guide for troubleshooting tips specific to each code can provide insight into necessary actions to take.

Tools Required for Repair

When addressing issues with a laundry appliance, having the right equipment is essential for an effective resolution. A well-prepared toolkit can make the process smoother and more efficient, ensuring that tasks are completed without unnecessary delays.

Below is a list of essential items that should be included in your toolkit:

- Screwdrivers: Various sizes and types, including flathead and Phillips, are necessary for loosening and tightening screws.

- Wrenches: Adjustable and socket wrenches are important for loosening bolts and nuts.

- Pliers: Needle-nose and standard pliers help grip and manipulate small parts.

- Multimeter: This tool is crucial for diagnosing electrical issues and checking continuity.

- Hoses: Extra hoses may be needed for replacements or testing water flow.

- Towels or Rags: Useful for cleaning up spills and keeping the work area tidy.

- Flashlight: Adequate lighting is essential for inspecting dark areas within the appliance.

By ensuring that these tools are readily available, you can facilitate a more effective troubleshooting process and increase the likelihood of a successful outcome.

Step-by-Step Troubleshooting Guide

This section provides a detailed approach to diagnosing and resolving common issues that may arise with your appliance. By following these structured steps, you can systematically identify problems and apply appropriate solutions to restore functionality.

Identifying Common Issues

Begin by observing the symptoms your unit is exhibiting. Is it failing to start, making unusual noises, or experiencing drainage problems? Noting these signs can significantly streamline the troubleshooting process.

Implementing Solutions

After pinpointing the issue, proceed with possible solutions. For instance, if the appliance won’t turn on, check the power supply and ensure that the door is securely closed. If you encounter noise during operation, inspect for foreign objects within the drum. Always prioritize safety by unplugging the unit before conducting any inspections or repairs.

By adhering to this methodical approach, you can effectively troubleshoot and resolve issues, ensuring your device operates smoothly.

Cleaning and Maintenance Tips

Proper upkeep is essential for ensuring the longevity and efficiency of your appliance. Regular cleaning and maintenance not only enhance performance but also prevent common issues that can arise over time. Following a few straightforward practices can keep your unit in top shape.

Regularly clean the drum: To prevent odors and residue buildup, run an empty cycle with hot water and a suitable cleaner. This simple step helps maintain a fresh interior.

Check and clean filters: Periodically inspect filters for lint and debris. Keeping them clear ensures optimal water flow and helps avoid drainage problems.

Wipe down exterior surfaces: Use a damp cloth to clean the outside, removing dust and spills. This practice not only improves aesthetics but also helps prevent corrosion.

Leave the door ajar: After each use, keep the door slightly open to allow airflow. This simple action helps to reduce moisture buildup and prevents mold growth.

Incorporating these practices into your routine will help maintain your appliance’s efficiency and extend its lifespan, ensuring that it continues to perform effectively for years to come.

How to Replace Door Seal

Replacing the door seal of a washing appliance is a straightforward task that can significantly enhance the performance and efficiency of the machine. This component is crucial for preventing leaks and maintaining the internal environment during cycles.

Follow these steps to successfully change the door seal:

- Begin by unplugging the machine to ensure safety while working.

- Open the door and inspect the existing seal for any signs of damage or wear.

- Carefully remove the retaining ring that holds the seal in place. You may need a flathead screwdriver to pry it off gently.

- Once the ring is removed, pull the old seal away from the door and the drum. Make sure to clear any debris or detergent residue.

- Take the new seal and align it properly around the opening of the drum. Ensure it fits snugly into the groove.

- Reattach the retaining ring by pressing it down firmly until it secures the new seal in place.

- Close the door and check for any gaps or misalignments. Ensure that the seal is evenly seated all around.

- Plug the appliance back in and run a short cycle to test for leaks.

Regular maintenance of the door seal can prolong the life of your appliance and enhance its efficiency. Always keep an eye on its condition and replace it promptly if any issues arise.

Motor Problems and Fixes

This section addresses common issues related to the motor of your appliance and provides effective solutions. The motor is a critical component, responsible for driving the drum during various cycles. When problems arise, it can lead to inefficient operation or complete failure to function.

Symptoms of Motor Malfunctions

One of the first indicators of motor issues may be unusual noises during operation. Grinding or squeaking sounds can suggest wear or misalignment. Additionally, if the drum fails to rotate, this may indicate a problem with the motor or its connections.

Common Causes

Several factors can lead to motor-related problems. Overheating due to prolonged use, electrical issues, or faulty wiring can impair performance. In some cases, debris may obstruct moving parts, causing strain on the motor.

Potential Solutions

To troubleshoot motor issues, first, check for any visible blockages or debris around the motor area. If the appliance emits unusual sounds, inspect the mounting and connections for signs of wear. In cases of overheating, allowing the unit to cool down may restore functionality. If electrical faults are suspected, consult a professional for thorough diagnostics and repairs.

Maintenance Tips

Regular maintenance can prevent motor problems. Ensure the appliance is clean and free of lint and debris, and perform routine checks on electrical connections to avoid future complications.

Drainage Issues: Causes and Fixes

When a washing appliance fails to drain properly, it can lead to a variety of problems, including water accumulation and inefficient cleaning cycles. Understanding the potential causes of these drainage challenges is essential for effective troubleshooting and resolution. This section outlines common issues, their origins, and suitable solutions to restore optimal performance.

Common Causes of Drainage Problems

Several factors may contribute to inadequate drainage in a washing appliance:

| Cause | Description |

|---|---|

| Clogged Drain Hose | Obstructions in the drain hose can impede the flow of water, preventing proper drainage. |

| Blocked Filter | Debris accumulation in the filter can restrict water flow, leading to drainage issues. |

| Pump Malfunction | A faulty pump may not effectively remove water from the appliance, causing standing water. |

| Improper Installation | If the appliance is not installed at the correct height, it can affect drainage capabilities. |

Solutions to Address Drainage Issues

Addressing drainage problems often involves a few straightforward steps:

First, inspect the drain hose for any visible blockages or kinks that could hinder water flow. If necessary, detach the hose and clean it thoroughly. Next, locate and clean the filter to ensure it is free of debris. If the pump appears to be malfunctioning, consider testing it for operational integrity or replacing it if needed. Lastly, verify the installation height of the appliance to ensure it is set correctly for optimal drainage.

Water Inlet Valve Repair Steps

This section outlines the essential procedures for addressing issues related to the water intake component in your appliance. By following these guidelines, you can effectively troubleshoot and resolve common malfunctions associated with water flow, ensuring optimal performance.

Required Tools and Materials

| Tool/Material | Purpose |

|---|---|

| Screwdriver | To remove screws securing the access panel |

| Multimeter | For testing electrical continuity |

| Pliers | To disconnect water hoses |

| Replacement Valve | To replace a faulty component |

Step-by-Step Procedure

Begin by disconnecting the appliance from the power supply and turning off the water supply. Next, use a screwdriver to remove the access panel, allowing you to access the water intake component. Carefully detach the water hoses using pliers, making sure to have a towel handy to catch any residual water.

Once the hoses are disconnected, utilize a multimeter to check for continuity in the valve. If the readings indicate a fault, replace the defective part with a new one. After installation, reattach the hoses and secure the access panel back in place. Finally, restore the water and power supply to test the functionality of the newly installed component.

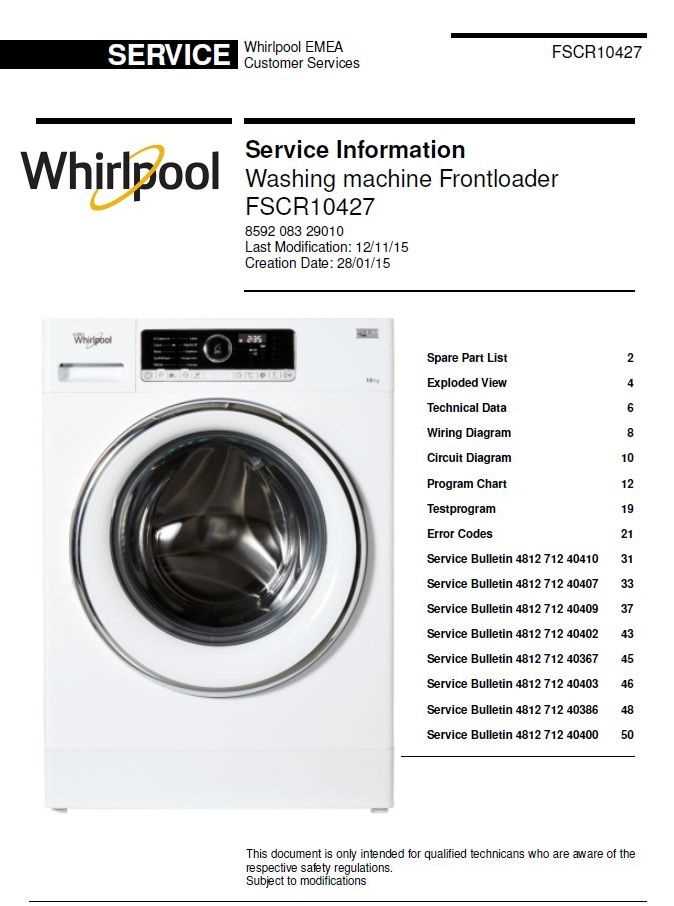

Electrical Component Troubleshooting

This section focuses on diagnosing and resolving issues related to electrical components within a laundry appliance. Understanding the role of each part is crucial for effective troubleshooting and ensuring optimal performance.

Identifying Common Issues: Begin by checking for visible signs of damage or wear on the wiring and connectors. Look for frayed wires, loose connections, or burnt components, as these can lead to malfunction. It’s important to maintain a systematic approach when evaluating the electrical system.

Using a Multimeter: A multimeter is an essential tool for measuring voltage, current, and resistance. By testing different components, such as the motor, sensors, and control boards, you can pinpoint areas that may be causing problems. Make sure to follow safety guidelines when working with electrical systems.

Consulting the Wiring Diagram: Reference the wiring diagram specific to the appliance model for accurate troubleshooting. This diagram provides valuable insights into the electrical layout, helping you trace circuits and identify faulty components more efficiently.

Replacements and Repairs: Once you have identified the problematic parts, consider whether they can be repaired or need to be replaced. Always use components that meet manufacturer specifications to ensure compatibility and safety. Proper installation is vital to prevent future issues.

Understanding Error Codes

Error codes serve as essential indicators that help users identify issues within their appliance. These codes can be deciphered to understand the underlying problems, allowing for quicker resolutions and optimal performance.

Each code corresponds to a specific malfunction, which can vary in severity. By interpreting these signals accurately, users can determine whether a professional intervention is necessary or if the problem can be addressed independently.

- Common Error Codes:

- Code 1: Indicates a door issue, such as improper closure.

- Code 2: Signals a water supply problem, possibly due to a blocked inlet.

- Code 3: Suggests an imbalance, often resulting from unevenly distributed items.

- Troubleshooting Steps:

- Check the user manual for the specific error code.

- Inspect the appliance for any visible issues, such as leaks or blockages.

- Reset the appliance by unplugging it for a few minutes.

By staying informed about these indicators and taking the appropriate steps, users can enhance their understanding and maintain the efficiency of their appliance.

Replacement Parts and Where to Buy

Finding the right components for your appliance is crucial for restoring its functionality. This section highlights various options for sourcing essential elements that may need to be replaced during maintenance or upgrades.

Types of Components Available

- Drum seals

- Motor belts

- Water pumps

- Control boards

- Door latches

Where to Purchase

- Authorized Retailers: Many brand-specific stores provide original components, ensuring compatibility and quality.

- Online Marketplaces: Websites like Amazon and eBay offer a wide variety of parts from different manufacturers, often at competitive prices.

- Local Repair Shops: Visiting nearby service centers can also yield necessary parts, along with expert advice.

- Manufacturer Websites: Directly ordering from the official site guarantees authentic products.

Preventive Measures for Longevity

Maintaining the efficiency and extending the lifespan of your appliance requires a combination of regular upkeep and mindful usage. Implementing certain practices can help ensure that the device operates smoothly and remains in optimal condition over the years.

Here are some essential preventive measures to consider:

| Measure | Description |

|---|---|

| Regular Cleaning | Keep the drum and door seals clean to prevent mildew buildup. Wipe down the interior and exterior frequently. |

| Check Hoses | Inspect water hoses for any signs of wear or leaks, replacing them every few years to avoid potential damage. |

| Use Appropriate Detergent | Select the right type of cleaning agent, ensuring it’s compatible to prevent residue accumulation. |

| Avoid Overloading | Do not exceed the recommended capacity, as this can strain the motor and other components. |

| Maintain Level Position | Ensure the device is level to reduce vibration and prevent mechanical issues during operation. |

By following these practices, you can enhance the functionality and durability of your appliance, ensuring it serves you well for many years to come.