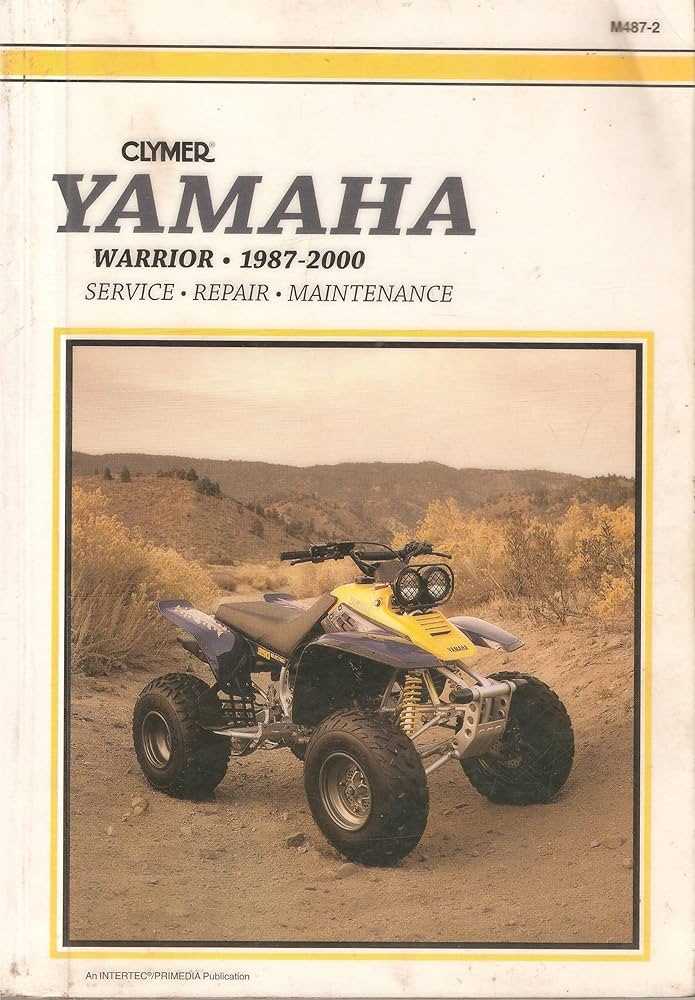

1988 Yamaha Warrior 350 Repair Manual Guide

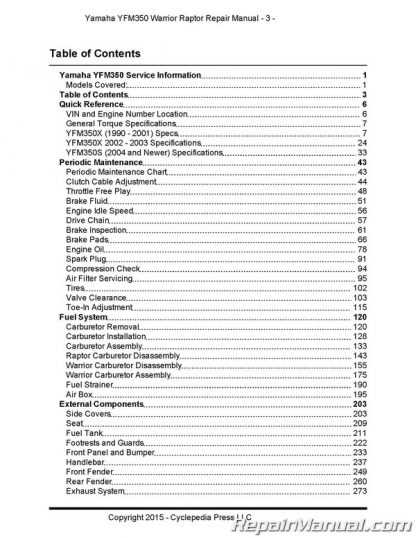

Owning an all-terrain vehicle requires a solid understanding of its functionality and care. Proper maintenance not only enhances performance but also prolongs the lifespan of your machine. This section delves into essential procedures and insights for ensuring that your vehicle operates smoothly, addressing common challenges and solutions along the way.

The information provided here is designed for enthusiasts and owners alike, offering practical advice to navigate the intricacies of upkeep. From basic checks to advanced techniques, this guide aims to empower users with the knowledge needed to tackle any issues that may arise during ownership.

By following these guidelines, you can maintain optimal performance and enjoy every ride with confidence. Equip yourself with the necessary skills and understanding to keep your vehicle in top shape for all your adventures.

Overview of Yamaha Warrior 350

This section provides a comprehensive examination of a popular all-terrain vehicle known for its reliability and performance. Designed to tackle various terrains, this machine has gained a reputation among enthusiasts for its robust engineering and ease of maintenance.

Key Features

The vehicle is equipped with a powerful engine that delivers impressive torque, making it suitable for both recreational riding and more challenging conditions. Its suspension system ensures a smooth ride, while the lightweight frame enhances maneuverability. Additionally, the intuitive controls allow riders to operate the vehicle with ease.

Maintenance Insights

Proper upkeep is essential for optimal functionality and longevity. Regular checks on fluid levels, tire pressure, and brake systems are recommended to ensure safety and performance. Familiarity with the essential components will aid in timely interventions and repairs, contributing to an enjoyable riding experience.

Common Issues with the Warrior 350

This section addresses typical challenges faced by owners of a specific all-terrain vehicle model. Understanding these frequent problems can help users troubleshoot effectively and maintain optimal performance.

| Issue | Description | Possible Solutions |

|---|---|---|

| Starting Problems | Difficulty in starting the engine, often due to fuel or electrical issues. | Check the battery charge, inspect the fuel lines, and ensure proper spark plug function. |

| Overheating | Engine may run too hot, leading to potential damage. | Inspect the cooling system, check coolant levels, and ensure airflow around the engine is unobstructed. |

| Transmission Issues | Difficulty shifting gears or unusual noises during operation. | Check the fluid levels, inspect the linkage, and ensure proper maintenance of the transmission system. |

| Brake Problems | Reduced braking efficiency or uneven wear on brake pads. | Inspect brake fluid levels, replace worn pads, and check for any leaks in the system. |

Maintenance Tips for Longevity

Ensuring the durability of your all-terrain vehicle involves regular upkeep and attention to detail. By following a consistent maintenance routine, you can enhance performance and extend the lifespan of your machine, allowing for enjoyable rides for years to come.

Regular Inspections

Conducting frequent checks on key components is essential. Examine the brakes, tires, and suspension to ensure they are functioning optimally. Look for any signs of wear or damage, and address issues promptly to prevent further complications.

Fluid Management

Maintaining proper fluid levels is crucial for the overall health of your vehicle. Regularly check the oil, coolant, and fuel, ensuring they are clean and at appropriate levels. Replace fluids as recommended by the manufacturer to keep the engine running smoothly and efficiently.

Emphasizing preventive care through these simple practices can significantly enhance your vehicle’s performance. Always refer to the guidelines provided for specific maintenance recommendations, and don’t hesitate to consult a professional if you encounter any difficulties.

Essential Tools for Repairs

When tackling maintenance tasks on your all-terrain vehicle, having the right instruments at your disposal can make all the difference. A well-equipped toolkit not only streamlines the process but also ensures that you can address a variety of issues effectively. Below are some key implements that are indispensable for any enthusiast looking to perform tasks with confidence.

Must-Have Instruments

Each type of task requires specific tools. Here is a breakdown of essential items you should consider including in your toolkit:

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts in various sizes. |

| Wrench Set | Essential for turning nuts and bolts, especially in tight spaces. |

| Screwdriver Set | Used for fastening and loosening screws of different types. |

| Pliers | Great for gripping, bending, and cutting wires or components. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

Additional Helpful Tools

While the basics are crucial, there are additional implements that can enhance your maintenance efforts:

| Tool | Purpose |

|---|---|

| Multimeter | For diagnosing electrical issues by measuring voltage, current, and resistance. |

| Shop Manual | A comprehensive guide providing detailed instructions and specifications. |

| Oil Filter Wrench | Specifically designed for removing and installing oil filters. |

| Cleaning Supplies | Essential for maintaining the vehicle’s appearance and performance. |

| Safety Gear | Protective equipment to ensure personal safety during maintenance tasks. |

Engine Troubleshooting Techniques

Identifying and resolving engine issues is crucial for maintaining optimal performance. Effective diagnostic methods allow one to pinpoint problems before they escalate, ensuring longevity and reliability. This section outlines essential techniques for troubleshooting common engine malfunctions.

Common Symptoms and Their Causes

Understanding symptoms is the first step in effective troubleshooting. Here are several typical indicators along with potential causes:

| Symptom | Possible Cause |

|---|---|

| Difficulty starting | Weak battery or faulty starter motor |

| Unusual noises | Lack of lubrication or worn components |

| Overheating | Coolant leak or malfunctioning thermostat |

| Poor acceleration | Clogged fuel filter or dirty air intake |

Diagnostic Steps

To effectively diagnose engine issues, follow these steps:

1. Conduct a visual inspection to identify leaks, cracks, or loose connections.

2. Use diagnostic tools to read error codes and assess performance metrics.

3. Test individual components such as the ignition system and fuel delivery system.

4. Analyze fluid levels and quality, including oil and coolant, to detect abnormalities.

Electrical System Diagnosis Guide

This section provides essential insights into diagnosing issues within the electrical framework of your vehicle. A well-functioning electrical system is crucial for the overall performance, reliability, and safety of the machine. Understanding the components and their interactions will enable you to identify problems effectively and implement solutions with confidence.

Initial Assessment

Begin by inspecting the battery, as it serves as the heart of the electrical system. Ensure that the terminals are clean and tightly connected. A weak or dead battery can cause a range of problems, including starting issues and malfunctioning electrical components.

Wiring Inspection

Examine the wiring harness for any signs of wear, damage, or corrosion. Look for frayed wires, loose connections, or broken insulation, as these can lead to short circuits or intermittent failures. Addressing these issues early can prevent more significant complications.

Testing Components

Utilize a multimeter to test individual electrical components, such as the starter motor, alternator, and fuses. Measure voltage and resistance to ensure each part operates within its specified parameters. This diagnostic approach allows for pinpointing faulty components that may require replacement.

Continuity Checks

Perform continuity tests on circuits to ensure there are no breaks. A lack of continuity indicates an interruption in the flow of electricity, which can hinder the operation of various systems. Follow the wiring diagram to trace and verify each circuit systematically.

Final Steps

After identifying and resolving any issues, conduct a thorough test of the entire electrical system to confirm that everything functions as intended. Regular maintenance and monitoring of the electrical system will help prevent future problems and extend the lifespan of your vehicle.

Suspension Adjustments and Repairs

The suspension system plays a crucial role in providing a smooth ride and maintaining stability. Proper adjustments and maintenance are essential to enhance performance and ensure safety during operation. This section focuses on various techniques to fine-tune the suspension setup and address common issues that may arise over time.

To achieve optimal handling characteristics, begin by assessing the current suspension settings. This includes checking the preload, compression, and rebound settings. Adjusting the preload allows for customization based on the rider’s weight and intended usage. A balanced compression and rebound setting ensures that the suspension reacts appropriately to terrain variations, preventing excessive bottoming out or harshness during rides.

Regular inspections of suspension components are vital to identify wear or damage. Inspect the springs, shock absorbers, and linkage for signs of fatigue. If any parts exhibit leaks or significant wear, replacement may be necessary to maintain performance. When replacing components, consider upgrading to higher-quality parts for improved durability and responsiveness.

After making adjustments or repairs, test the vehicle to evaluate changes in handling and comfort. Fine-tuning may be required to achieve the desired performance. By routinely checking and adjusting the suspension system, riders can ensure a safe and enjoyable experience on various terrains.

Brake System Maintenance Procedures

Proper upkeep of the braking system is crucial for ensuring optimal performance and safety. Regular checks and maintenance can prevent unexpected failures and enhance the longevity of the components involved. This section outlines essential procedures to maintain and service the braking mechanism effectively.

Inspection of Brake Components

Begin by examining the brake pads and rotors for signs of wear. Look for uneven surfaces, cracks, or excessive thinning of the pads. Ensure that the rotors are smooth and free of any grooves that could affect braking efficiency. Replace any components that show significant deterioration.

Brake Fluid Checks

Regularly check the brake fluid level in the reservoir. If the fluid appears dirty or contaminated, it should be flushed and replaced with fresh fluid. Ensure that the fluid used meets the specifications for the braking system to maintain proper hydraulic function.

Adjustment of Brake System

Proper adjustment of the braking system is essential for responsive performance. Check the tension of the brake cables and make necessary adjustments to ensure they are neither too tight nor too loose. This ensures that the brakes engage and release smoothly.

Cleaning and Lubrication

Periodically clean the brake components to remove dust and debris. Use a suitable cleaner and avoid harsh chemicals that could damage the parts. After cleaning, apply a thin layer of lubricant to the moving parts to prevent rust and ensure smooth operation.

Test and Verify

After performing maintenance, always test the braking system. Take the vehicle for a short ride to assess brake responsiveness and listen for any unusual sounds. Ensure that the braking power is consistent and effective, making adjustments if necessary.

Transmission Issues and Solutions

The transmission system plays a crucial role in the overall performance of an all-terrain vehicle. Problems in this area can lead to decreased efficiency, unusual noises, or difficulties in gear shifting. Understanding common issues and their solutions can help maintain optimal functionality.

Here are some frequent transmission problems and effective solutions:

- Difficulty Shifting Gears:

- Check for low fluid levels; refill as necessary.

- Inspect the clutch adjustment; ensure it’s correctly set.

- Examine the shift linkage for wear or misalignment.

- Strange Noises:

- Identify if the sounds are due to low fluid; top off as needed.

- Listen for grinding noises, indicating potential gear wear or damage.

- Check for loose or damaged components within the transmission.

- Fluid Leaks:

- Inspect seals and gaskets for deterioration; replace if necessary.

- Look for cracks in the transmission case that may require sealing or welding.

- Monitor fluid levels regularly to catch leaks early.

By recognizing these common transmission issues and implementing the suggested solutions, you can enhance the longevity and performance of your vehicle’s transmission system.

Body and Frame Repair Tips

Maintaining the structural integrity of your vehicle is crucial for optimal performance and safety. Proper care and attention to the body and frame can enhance longevity and functionality. This section offers insights into effective strategies for addressing common issues that may arise.

Inspecting for Damage

Regular assessments are essential to identify any signs of wear or damage. Look for cracks, rust, or misalignments in the frame. Pay attention to the mounting points and suspension components, as these areas often bear the most stress. Early detection of these issues can prevent more extensive repairs down the line.

Repair Techniques

When addressing frame damage, consider using welding techniques for small cracks or breaks. For rust, a thorough cleaning followed by a rust-inhibiting primer can help preserve metal integrity. If you encounter significant structural damage, professional assistance may be required to ensure safe and reliable repairs. Always prioritize quality materials and techniques to maintain the overall durability of your vehicle.

Upgrades and Modifications Options

Enhancing the performance and functionality of your all-terrain vehicle can significantly improve your riding experience. Various upgrades and modifications can be made to optimize power, handling, and overall durability. This section explores popular options that can elevate the capabilities of your machine.

Performance Enhancements

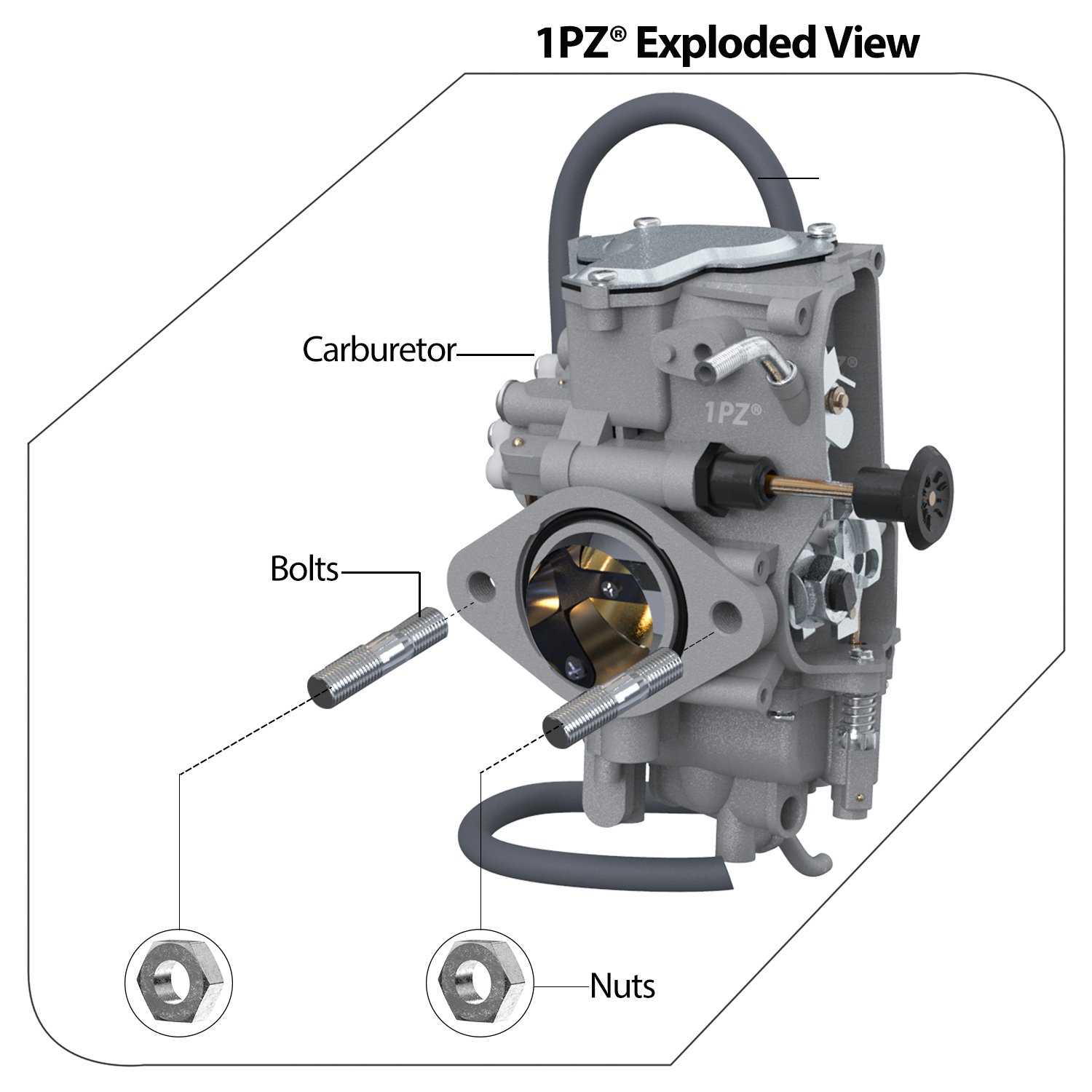

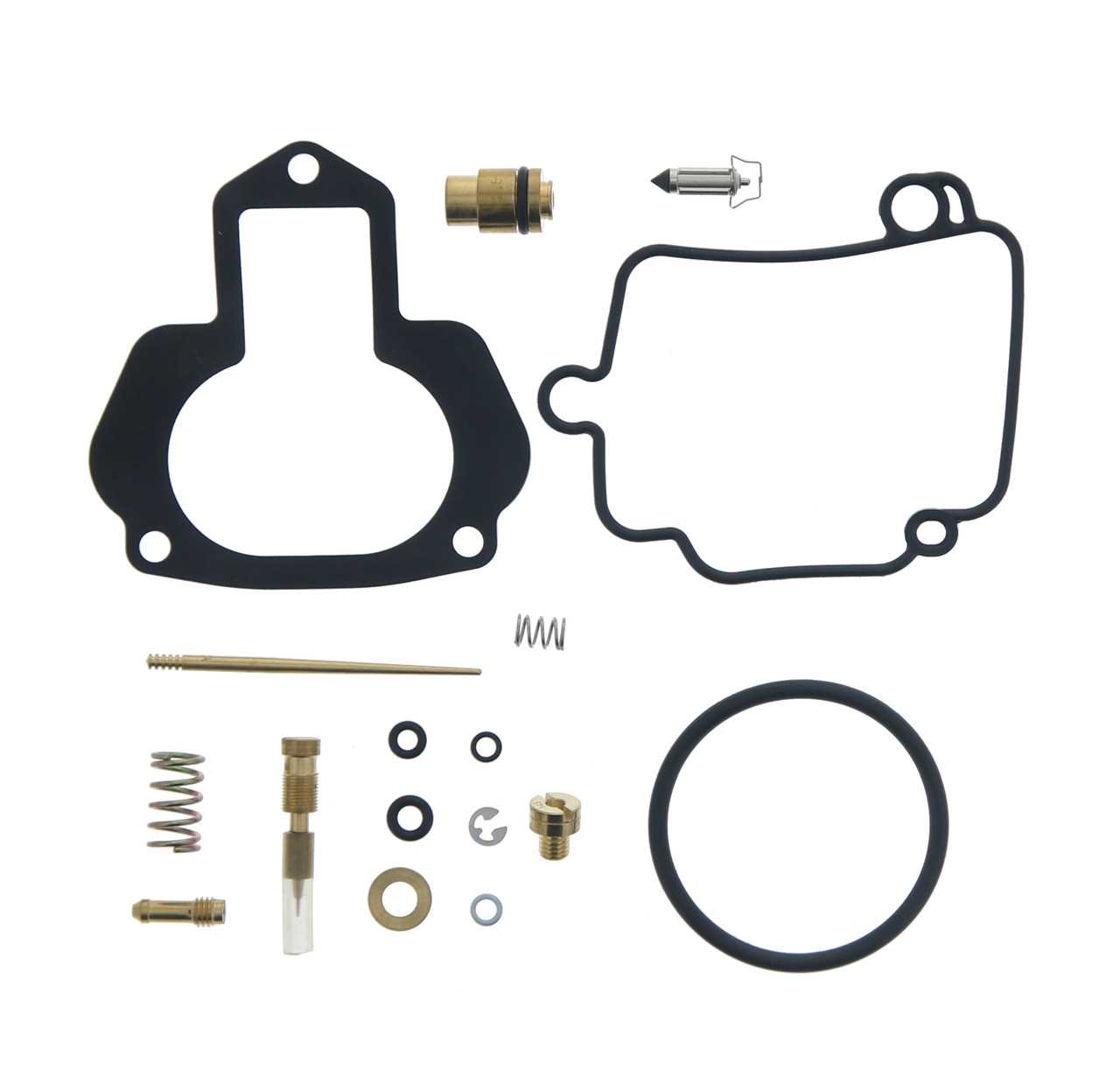

Boosting engine output is a common modification. Upgrading the exhaust system can improve airflow, while a high-performance air filter can enhance combustion efficiency. Additionally, tuning the carburetor or installing a fuel management system allows for better fuel-air mixture adjustments, resulting in increased horsepower and torque.

Suspension and Handling Improvements

For improved handling on rugged terrains, consider upgrading the suspension components. Aftermarket shocks can provide better damping and adjustable settings, enhancing stability and comfort during rides. Furthermore, installing wider tires can improve traction, allowing for better control over uneven surfaces.

Where to Find Replacement Parts

Locating suitable components for your all-terrain vehicle can be crucial for maintaining its performance and longevity. There are various avenues to explore when searching for necessary items, ensuring you have access to quality parts that fit your specific model.

- Online Retailers: Numerous e-commerce platforms specialize in vehicle parts. Websites like Amazon, eBay, and dedicated motorcycle parts retailers often have extensive inventories.

- Local Dealerships: Visiting authorized dealers can provide you with genuine parts that match your machine’s specifications. They often have knowledgeable staff who can assist with your inquiries.

- Salvage Yards: These facilities may have used parts available at a fraction of the cost. It can be an economical option if you’re willing to search through inventory.

- Aftermarket Suppliers: Many companies manufacture compatible components that may offer enhanced performance or durability. Researching reputable brands can yield good results.

- Forums and Community Groups: Engaging with online forums or local clubs can provide leads on where to find specific parts. Members often share their experiences and sources.

Exploring these options can enhance your chances of finding the right components, ensuring your vehicle remains in optimal condition.