Comprehensive Guide to Repairing the 1996 Yamaha 40 HP Outboard Motor

Maintaining a small marine engine is crucial for ensuring optimal performance and longevity. Proper upkeep not only enhances reliability on the water but also prevents costly repairs down the line. This guide focuses on the fundamental aspects of engine care, providing invaluable insights for both novice and experienced users.

Understanding the Mechanics is the first step toward effective maintenance. Familiarizing oneself with the engine’s components and their functions can greatly simplify troubleshooting. Recognizing the common signs of wear and tear can help in addressing issues before they escalate.

Step-by-step procedures for routine checks and necessary adjustments will empower users to handle minor issues independently. This approach not only builds confidence but also fosters a deeper connection with the equipment, enhancing the overall boating experience.

Overview of the 1996 Yamaha 40 HP

This segment provides a comprehensive look at a specific model of marine propulsion systems designed for small to medium-sized vessels. Known for its reliability and performance, this engine is a popular choice among boating enthusiasts and professionals alike.

The power unit features a robust design, ensuring it can withstand various marine conditions while delivering efficient operation. With an emphasis on fuel efficiency and durability, it is ideal for both recreational use and fishing expeditions.

Key features include a lightweight construction that enhances maneuverability, along with an advanced cooling system that prevents overheating during extended use. The user-friendly controls facilitate smooth handling, making it accessible for both seasoned operators and newcomers.

Additionally, the maintenance of this power unit is straightforward, allowing for easy troubleshooting and upkeep. Regular servicing can extend its lifespan significantly, ensuring optimal performance over the years.

Overall, this model remains a favored option in its category, offering a combination of power, efficiency, and reliability that meets the needs of various boating applications.

Common Issues with Outboard Motors

Marine propulsion systems can encounter a variety of challenges that affect their performance and reliability. Understanding these frequent problems is crucial for ensuring smooth operation and longevity. Many factors can contribute to malfunctions, ranging from mechanical wear to environmental influences.

Fuel System Problems

One of the most prevalent issues involves the fuel system. Clogged filters and fuel line blockages can prevent proper flow, leading to poor engine performance. Additionally, the presence of water or impurities in the fuel can result in incomplete combustion, causing the motor to run inefficiently.

Electrical Failures

Electrical components are also susceptible to failure. Corroded connections, worn-out wiring, and malfunctioning ignition systems can lead to starting difficulties or inconsistent power output. Regular inspection and maintenance of these parts are essential to avoid unexpected breakdowns and ensure reliable operation.

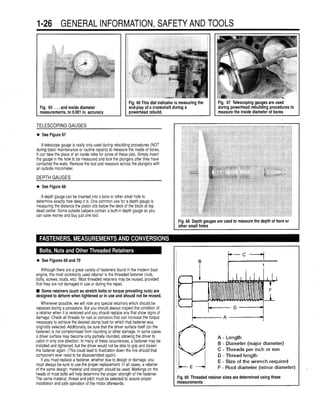

Essential Tools for Repairs

When tackling maintenance tasks, having the right instruments at your disposal is crucial for achieving optimal results. Whether you are troubleshooting issues or performing routine upkeep, a well-equipped toolkit can make all the difference in efficiency and effectiveness.

Basic Hand Tools

Among the most fundamental items, a set of hand tools forms the backbone of any repair endeavor. Wrenches, screwdrivers, and pliers are indispensable for loosening or tightening various components. An adjustable wrench is particularly useful, as it can accommodate different sizes of nuts and bolts, making it versatile for various tasks.

Diagnostic Equipment

In addition to standard hand tools, having diagnostic equipment is vital for identifying underlying problems. A multimeter allows you to check electrical connections and measure voltage levels, which is essential for troubleshooting issues. Furthermore, a compression tester can provide insights into the health of the engine, enabling you to pinpoint performance issues effectively.

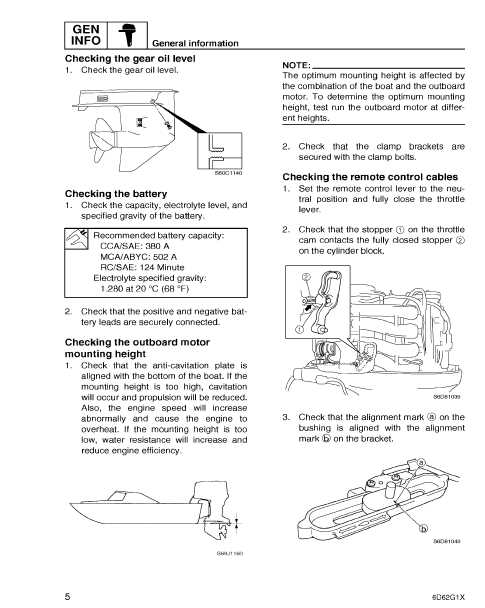

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to ensuring the longevity and optimal performance of your marine engine. Regular upkeep is essential for preventing issues and enhancing efficiency, allowing for a smooth experience on the water.

Initial Inspection

Begin with a thorough examination of the engine. Check for any visible wear, leaks, or corrosion. Pay special attention to the fuel lines and connections, ensuring they are secure and free of damage. Document any findings to track potential problems over time.

Fluid Changes

Changing fluids is crucial for maintaining performance. Replace the oil and ensure the fuel filter is clean. Use high-quality replacements to enhance durability. Regularly inspect the cooling system, ensuring it operates efficiently and is free from blockages.

How to Identify Engine Problems

Recognizing issues with your engine can prevent more significant damage and costly repairs. Understanding the signs of malfunction is crucial for maintaining optimal performance. Here are some common indicators to watch for when assessing engine health.

- Unusual Noises: Listen for strange sounds such as knocking, grinding, or high-pitched whines. These can signal internal problems or component wear.

- Excessive Vibration: Noticeable shaking or vibrations during operation may indicate misalignment or balance issues.

- Difficulty Starting: If the engine struggles to turn over or requires multiple attempts to start, it could point to electrical or fuel delivery issues.

- Loss of Power: A decrease in acceleration or power output suggests underlying performance problems that need immediate attention.

- Overheating: Regularly check the temperature gauge. Consistently high readings may indicate coolant system failures or obstructions.

- Fluid Leaks: Inspect for any signs of leaking fluids, such as oil or fuel, as these can lead to severe engine complications.

By being attentive to these signs, you can take timely action to diagnose and resolve engine issues, ensuring a smoother and more reliable operation.

Electrical System Troubleshooting Tips

Understanding and diagnosing issues within the electrical system of your vessel can be essential for ensuring optimal performance. Common problems may arise due to a variety of factors, including faulty connections, damaged components, or inadequate power supply. This section will provide practical guidance to help identify and resolve typical electrical malfunctions.

Begin by inspecting the connections. Loose or corroded terminals can lead to intermittent power loss. Ensure that all connections are tight and free of rust or debris. Next, check the fuses and circuit breakers, as these components protect the system from overloads. Replace any blown fuses with ones that match the required specifications.

| Common Issues | Possible Causes | Troubleshooting Steps |

|---|---|---|

| No Power | Dead battery, loose connections | Test battery voltage, inspect all terminals |

| Intermittent Power | Corroded terminals, damaged wiring | Clean connections, check for frayed wires |

| Dim Lights | Insufficient voltage, faulty switches | Measure voltage at the lights, test switches |

| Engine Won’t Start | Defective starter, faulty ignition | Test starter operation, check ignition system |

By systematically addressing these common issues, you can enhance the reliability of the electrical system, ensuring that your craft operates smoothly and efficiently. Regular maintenance and checks will further reduce the likelihood of future problems.

Fuel System Cleaning Procedures

Maintaining the cleanliness of the fuel system is essential for optimal engine performance. Regular cleaning helps to prevent clogs, enhance fuel flow, and improve overall efficiency. This section outlines the necessary steps and considerations for ensuring the fuel delivery components are free from contaminants.

The cleaning process involves several key tasks, including inspecting, flushing, and replacing critical elements of the fuel system. Following these procedures will not only extend the lifespan of the engine but also ensure a smoother operation.

| Step | Description |

|---|---|

| 1. Inspection | Examine the fuel lines, filters, and injectors for signs of wear, damage, or blockages. |

| 2. Fuel Filter Replacement | Replace the fuel filter to remove accumulated debris and contaminants. |

| 3. Flushing | Use a specialized cleaner to flush the fuel system, ensuring all passages are cleared. |

| 4. Injector Cleaning | Clean the fuel injectors using ultrasonic cleaning or a dedicated injector cleaning kit. |

| 5. System Check | After cleaning, check the entire system for leaks and proper operation before use. |

Implementing these cleaning procedures regularly will help maintain the integrity of the fuel system, ultimately leading to improved engine performance and reliability.

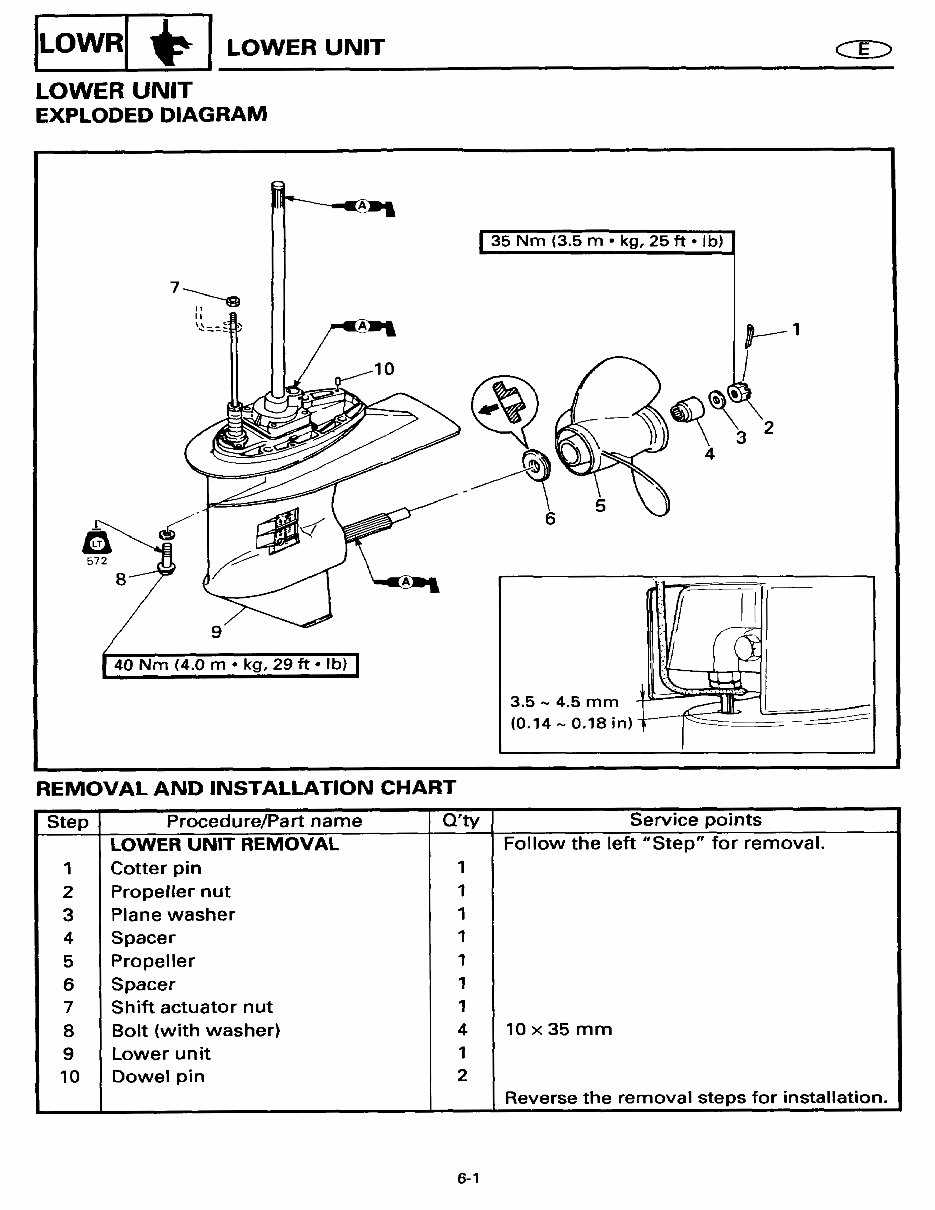

Replacing the Propeller: A Guide

Changing the propeller is an essential task for ensuring optimal performance of your watercraft. A well-functioning propeller directly impacts speed, fuel efficiency, and maneuverability. This guide will walk you through the steps necessary to safely and effectively replace the propeller on your engine.

Tools and Materials Needed

Before starting the replacement process, gather the necessary tools and materials. You will need a propeller removal tool, a wrench or socket set, grease, and of course, the new propeller. Having everything on hand will streamline the procedure and minimize downtime.

Step-by-Step Replacement Process

Begin by securely lifting the vessel and ensuring it is stable. Next, locate the propeller nut and use the appropriate wrench to loosen it. Carefully remove the old propeller, inspecting the shaft for any signs of damage or wear. Once the shaft is clean, apply a thin layer of grease to it before attaching the new propeller. Align it properly and tighten the nut securely. Finally, double-check your work to ensure everything is in place before lowering the boat back into the water.

Importance of Regular Oil Changes

Maintaining the longevity and performance of any mechanical system relies heavily on routine maintenance practices. One critical aspect of this upkeep is the timely replacement of lubrication fluids. Regularly changing these fluids ensures that the internal components remain adequately protected from wear and tear, which can lead to more significant issues down the line.

Effective lubrication is essential for minimizing friction between moving parts. Over time, lubricants can break down and become contaminated with debris and impurities. This degradation can result in reduced efficiency and increased operational temperatures, ultimately compromising the machinery’s functionality. By performing oil changes at recommended intervals, one can help maintain optimal performance and extend the lifespan of the engine.

Additionally, monitoring fluid quality allows for early detection of potential problems. Regular maintenance not only ensures that the engine runs smoothly but also helps identify signs of wear or damage before they escalate. This proactive approach can save both time and money by preventing costly repairs and minimizing downtime.

In conclusion, prioritizing routine fluid replacements is a fundamental practice that contributes to the overall health of any engine. By investing in regular oil changes, one can enjoy improved reliability and efficiency, making it a wise choice for anyone looking to protect their machinery.

Adjusting the Carburetor Settings

Fine-tuning the fuel delivery system is essential for optimal engine performance. Proper adjustments ensure that the air-fuel mixture is balanced, which directly influences efficiency, power output, and overall functionality. This section outlines the steps to effectively modify the settings of the fuel mixing component.

Before proceeding with adjustments, it is crucial to understand the different components involved. Typically, there are several screws that regulate fuel flow and air intake. Identifying these elements will facilitate a smoother adjustment process.

| Component | Function | Adjustment Tips |

|---|---|---|

| Idle Mixture Screw | Regulates fuel at low speeds | Turn clockwise to lean the mixture; counterclockwise to enrich it. |

| Main Jet Adjustment | Controls fuel delivery at higher speeds | Check for responsiveness; adjust based on engine performance. |

| Throttle Plate Position | Affects airflow | Ensure it opens fully; adjust linkage if necessary. |

Once you have identified and adjusted the necessary components, it is advisable to perform a test run. Pay attention to engine behavior, such as acceleration and responsiveness, and make further adjustments as needed. Regular maintenance and tuning will prolong the life of the engine and enhance its performance.

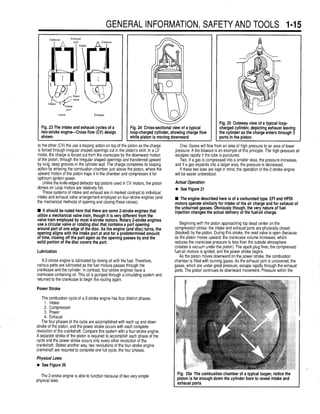

Understanding the Cooling System

The cooling mechanism is a vital component in maintaining optimal operating temperatures for marine engines. It prevents overheating, which can lead to severe damage, ensuring the longevity and efficiency of the machinery. A well-functioning cooling system is essential for performance and reliability on the water.

Components of the Cooling Mechanism

The cooling setup typically consists of several key elements, including the water intake, pump, thermostat, and heat exchanger. The water intake draws in external water, which is then circulated through the engine. The pump plays a crucial role in maintaining the flow, while the thermostat regulates temperature by controlling the flow of water based on the engine’s heat levels. Lastly, the heat exchanger dissipates heat effectively, allowing for cooler operation.

Importance of Regular Maintenance

Routine maintenance of the cooling system is critical. Over time, debris and minerals can accumulate, obstructing water flow and diminishing efficiency. Regular inspections and cleaning of components can prevent potential issues, ensuring the engine runs smoothly and efficiently. Monitoring coolant levels and replacing worn parts promptly can save time and resources in the long run.

Resources for Spare Parts

Finding the right components for your marine engine can significantly enhance performance and longevity. Various sources provide access to both genuine and aftermarket parts, ensuring you have options that suit your needs and budget. Whether you are looking for a simple replacement or a more complex assembly, understanding where to look can streamline your repair process.

Online Retailers

Numerous online platforms specialize in selling marine components. These retailers often feature extensive catalogs, allowing you to search for specific items easily. Be sure to compare prices and check customer reviews to ensure reliability.

Local Dealers and Shops

Visiting local marine supply stores can be beneficial. Many shops offer personalized service and advice, which can help you make informed decisions. They may also have access to parts that are not readily available online.

| Source | Advantages | Considerations |

|---|---|---|

| Online Retailers | Wide selection, competitive pricing | Shipping times, potential for incorrect parts |

| Local Dealers | Personalized service, immediate access | Higher prices, limited stock |

| Salvage Yards | Cost-effective options, rare finds | Condition of parts, no returns |

Safety Tips for Outboard Repair

When working on marine engines, ensuring personal safety should be a top priority. Engaging in maintenance tasks can present various risks, so it is essential to take preventive measures to protect yourself and those around you.

Wear Appropriate Gear: Always don protective equipment, such as gloves, goggles, and a dust mask. This will help shield you from debris, chemicals, and sharp objects that may be present during the process.

Work in a Ventilated Area: If performing tasks that involve fumes or chemicals, ensure your workspace is well-ventilated. Fresh air circulation is crucial to prevent inhalation of harmful substances.

Disconnect Power Sources: Before starting any work, make sure to disconnect the battery or any power sources. This precaution helps prevent accidental starts and reduces the risk of electric shock.

Keep Tools Organized: Maintain a tidy workspace by organizing your tools and materials. This minimizes the risk of accidents caused by misplaced items and helps streamline the task at hand.

Know Your Limits: If you encounter complex issues beyond your expertise, don’t hesitate to seek professional help. Trying to fix challenging problems without the necessary knowledge can lead to injuries or further damage.

Follow Manufacturer Guidelines: Always refer to recommended procedures and specifications. Adhering to these guidelines ensures that safety standards are met and that the engine operates efficiently.

By incorporating these safety practices, you can help create a safer environment for yourself and anyone nearby while working on marine engines.