Comprehensive Repair Guide for the 2001 Yamaha Big Bear 400

Ensuring the longevity and optimal performance of your all-terrain vehicle is essential for both safety and enjoyment. Proper maintenance can significantly enhance the riding experience and prevent costly repairs down the line. This guide aims to provide comprehensive insights into the upkeep of your machine, highlighting key areas that require attention and care.

Understanding the intricacies of your vehicle is crucial for any owner. Familiarizing yourself with the components and systems not only empowers you to troubleshoot minor issues but also prepares you for more significant challenges. Whether it’s the engine, suspension, or electrical system, a basic understanding can save time and resources.

In the following sections, we will delve into practical advice and detailed procedures for regular servicing. By adhering to these guidelines, you can maintain your vehicle in peak condition, ensuring it remains reliable and ready for adventure.

Understanding the Yamaha Big Bear 400

This section delves into the characteristics and functionalities of a popular off-road vehicle known for its versatility and durability. Designed to handle various terrains, it has become a favorite among outdoor enthusiasts and workers alike. Its robust design and powerful engine provide the necessary performance for both recreational and utilitarian purposes.

The vehicle features a reliable drivetrain and an ergonomic layout, ensuring a comfortable riding experience. With a focus on practicality, it offers ample storage options, making it suitable for carrying equipment or supplies on extended journeys. Maintenance and care play crucial roles in sustaining its longevity, allowing owners to maximize their investment.

Exploring the components and systems involved in this model reveals its engineering excellence. Understanding the specifications can aid users in making informed decisions regarding upgrades and modifications to enhance performance. Overall, this model stands as a testament to reliability and adaptability in the world of off-road transportation.

Key Features of the 2001 Model

The featured model stands out in its class due to a combination of innovative design and robust performance characteristics. Designed for both recreational use and utility purposes, it provides a balanced experience for riders seeking versatility and reliability.

Engine Performance: Equipped with a powerful engine, this vehicle delivers impressive torque and acceleration. Its responsive throttle ensures a smooth ride across various terrains, making it ideal for both trail riding and heavy-duty tasks.

All-Wheel Drive System: The all-wheel drive capability enhances traction and stability, allowing riders to navigate challenging landscapes with confidence. This feature is particularly beneficial in muddy or uneven conditions, ensuring optimal control.

Durable Frame Construction: Built with a sturdy chassis, this model offers enhanced durability and longevity. Its rugged construction is designed to withstand the rigors of outdoor adventures, making it a reliable choice for enthusiasts and workers alike.

Comfortable Seating: The seating arrangement prioritizes rider comfort, with ergonomic designs that reduce fatigue during extended rides. Ample legroom and supportive cushions ensure a pleasant experience, whether on short trips or long excursions.

Storage Solutions: With multiple storage options available, this vehicle is perfect for carrying gear and essentials. The strategically placed compartments allow for easy access while maintaining a balanced weight distribution.

Advanced Suspension System: The enhanced suspension setup provides a smooth ride over rough terrains. This feature absorbs shocks effectively, ensuring that riders remain comfortable even on bumpy paths.

Common Issues with the Big Bear

Many enthusiasts encounter a variety of challenges when maintaining their all-terrain vehicles. Understanding these frequent problems can help owners address them promptly and ensure optimal performance. Below are some of the typical concerns associated with these rugged machines.

1. Starting Difficulties: One common issue is trouble starting the engine. This can stem from a weak battery, faulty starter, or issues with the ignition system. Regular maintenance of electrical components can help prevent these problems.

2. Fuel System Problems: Another frequent concern is related to the fuel system. Clogged filters, dirty carburetors, or issues with the fuel pump can lead to poor performance. Ensuring a clean fuel system is essential for efficient operation.

3. Overheating: Overheating can occur due to low coolant levels, a malfunctioning radiator, or issues with the water pump. Keeping an eye on the cooling system can help avoid serious engine damage.

4. Brake Issues: Problems with braking can manifest as squeaking or decreased responsiveness. Worn brake pads or low fluid levels may be the culprits. Regular inspection and timely replacement of components are vital for safety.

5. Transmission Troubles: Difficulty shifting gears is a common complaint. This may be caused by low transmission fluid or internal component wear. Routine checks can help maintain smooth gear transitions.

By being aware of these typical issues, owners can take proactive steps to keep their vehicles in top condition and enjoy their adventures without interruption.

Essential Tools for Repairs

When it comes to maintaining and fixing vehicles, having the right instruments at your disposal is crucial. A well-equipped workspace not only enhances efficiency but also ensures that tasks are completed safely and effectively. Here, we’ll explore the fundamental tools every enthusiast should have on hand for tackling a variety of maintenance challenges.

Basic Hand Tools

Starting with the basics, a selection of hand tools is indispensable. These include wrenches, screwdrivers, and pliers. Each tool serves a specific purpose, from tightening bolts to loosening screws. A well-organized toolbox with different sizes and types will make any task easier and more straightforward.

Power Tools and Accessories

In addition to hand tools, power tools can significantly speed up the process of working on machinery. An electric drill is particularly versatile, useful for drilling holes or driving screws. Furthermore, having a grinder or sander can help with finishing touches or modifying components. Proper maintenance of these tools is equally important to ensure their longevity and reliability.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your all-terrain vehicle. This section outlines a comprehensive approach to routine care that every owner should follow. By adhering to these steps, you can prevent issues and enhance the reliability of your machine.

Essential Maintenance Tasks

- Check and change the oil regularly.

- Inspect the air filter and replace it if necessary.

- Examine the brakes for wear and ensure proper function.

- Inspect tire pressure and tread depth.

- Clean and lubricate the chain to prevent rust and wear.

Seasonal Preparations

- Spring: Perform a thorough inspection after winter storage, checking fluid levels and battery health.

- Summer: Ensure cooling systems are functioning and clean the exterior to prevent debris buildup.

- Fall: Prepare for storage by cleaning, changing oil, and stabilizing fuel.

- Winter: Store in a dry location, disconnect the battery, and cover to protect from the elements.

Following these guidelines will help you maintain your vehicle in peak condition, allowing for a safe and enjoyable riding experience.

Engine Troubleshooting Techniques

Diagnosing issues within a powertrain requires a systematic approach to identify and resolve malfunctions effectively. By understanding the common symptoms and employing various strategies, you can enhance the performance and reliability of your vehicle.

Start by observing the engine behavior during operation. Listen for unusual noises, monitor for vibrations, and check for any warning lights on the dashboard. These indicators can provide initial clues about underlying problems.

Next, conduct a visual inspection of key components, such as the fuel system, ignition system, and electrical connections. Look for signs of wear, corrosion, or leaks that may disrupt normal function. Pay special attention to hoses, wires, and connectors that may have degraded over time.

Utilize diagnostic tools to gather data from the engine control unit (ECU). This can help pinpoint specific error codes that relate to malfunctioning systems. Following the manufacturer’s guidelines for code interpretation will aid in accurate diagnosis.

Performing a compression test can also reveal critical information about the engine’s internal health. Low compression may indicate issues with valves, piston rings, or gaskets, necessitating further investigation.

Lastly, consult technical resources or community forums for additional insights and experiences shared by other users. Collaborative knowledge can often lead to innovative solutions for persistent issues.

Electrical System Diagnostics

The efficiency and functionality of an electrical setup are crucial for optimal performance. Proper diagnostics can identify issues within the system, ensuring that each component operates harmoniously. This section outlines the fundamental approaches to troubleshooting electrical concerns, focusing on systematic checks and tests.

Begin by inspecting the battery, as it serves as the primary power source. Check for voltage levels, connections, and signs of corrosion. Next, examine the wiring harness for fraying or damage that could disrupt the flow of electricity. Lastly, verify the integrity of fuses and relays to ensure they are functioning correctly.

| Component | Common Issues | Diagnostic Steps |

|---|---|---|

| Battery | Low voltage, corrosion | Measure voltage, clean terminals |

| Wiring Harness | Frayed wires, loose connections | Inspect visually, test continuity |

| Fuses | Blown fuses, improper ratings | Check for continuity, replace as needed |

| Relays | Failure to activate | Test operation, listen for clicking |

By systematically evaluating these components, one can effectively diagnose and address electrical issues, leading to enhanced performance and reliability.

Transmission and Drive System Insights

The transmission and drive system of an all-terrain vehicle is crucial for ensuring smooth operation and optimal performance. Understanding the intricacies of this system can enhance maintenance and improve overall functionality, allowing riders to tackle various terrains with confidence.

Key Components and Their Functions

The primary elements of the transmission include the gearbox, drive shafts, and differentials. Each component plays a significant role in transferring power from the engine to the wheels. The gearbox facilitates gear shifting, allowing for speed adjustments and torque distribution. Drive shafts connect the gearbox to the wheels, ensuring that power is efficiently transmitted, while differentials enable smooth cornering by allowing the wheels to rotate at different speeds.

Common Issues and Maintenance Tips

Over time, wear and tear can affect the performance of the transmission and drive system. Common problems include slipping gears, unusual noises, and leaks. Regular inspections and timely fluid changes can help prevent these issues. Additionally, ensuring that all connections are secure and that the components are lubricated properly will enhance longevity and reliability.

In summary, a thorough understanding of the transmission and drive system not only aids in effective troubleshooting but also promotes a safer and more enjoyable riding experience.

Suspension Adjustments Explained

Understanding how to properly adjust the suspension on your vehicle is crucial for enhancing performance, comfort, and handling. By making the right modifications, you can significantly improve your riding experience and ensure that your machine performs optimally under various conditions.

Why Suspension Adjustments Matter

Suspension settings directly influence how your vehicle interacts with the terrain. Proper adjustments can help in achieving:

- Improved stability during rides

- Enhanced traction on uneven surfaces

- Increased comfort for the rider

- Better control in turns and obstacles

Key Components to Adjust

When tuning the suspension, several key components come into play:

- Preload: Adjusting the preload affects the initial compression of the springs, impacting ride height and handling.

- Damping: This controls the speed at which the suspension compresses and rebounds, crucial for managing how the vehicle reacts to bumps.

- Compression Settings: Fine-tuning compression settings can help in managing how the suspension absorbs shocks from the terrain.

- Rebound Settings: Adjusting rebound controls the speed at which the suspension returns to its original position after compression.

By carefully adjusting these components, you can tailor the suspension to fit your riding style and the conditions you frequently encounter.

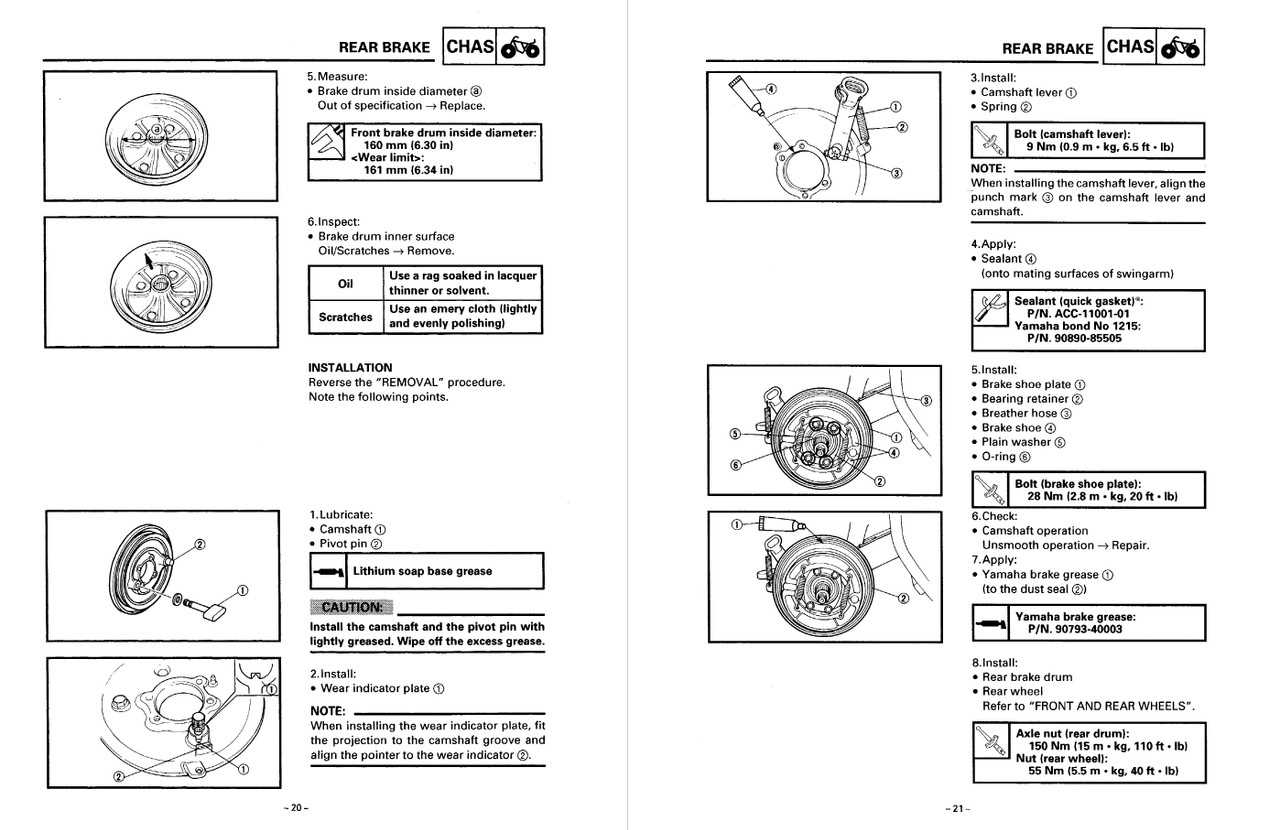

Braking System Maintenance Tips

Proper upkeep of your vehicle’s stopping mechanism is essential for safety and performance. Regular attention to this critical system can prevent accidents and prolong the lifespan of components. Here are some practical suggestions to ensure optimal functionality.

1. Regular Inspection: Periodically examine brake pads, rotors, and fluid levels. Look for signs of wear, such as uneven thickness or scoring on the rotors, which could indicate the need for replacement.

2. Fluid Check: Brake fluid should be clean and at the appropriate level. Contaminated or low fluid can lead to brake failure. Make sure to replace it according to the manufacturer’s recommendations.

3. Listen for Unusual Noises: Pay attention to any squealing or grinding sounds when applying the brakes. These noises may signal that brake pads are worn and require immediate attention.

4. Maintain Proper Alignment: Ensure that your wheels are aligned correctly. Misalignment can cause uneven wear on brake components, leading to premature failure.

5. Test the Brake System: Perform routine tests of the braking system to ensure it responds effectively. A soft or spongy brake pedal can indicate air in the brake lines or a hydraulic issue.

6. Professional Servicing: Consider scheduling regular service appointments with a qualified technician. They can provide a thorough inspection and address any underlying issues that may not be immediately apparent.

By following these tips, you can maintain the efficiency of your vehicle’s braking system and enhance your overall driving safety.

Upgrading Parts for Enhanced Performance

Improving the capabilities of your vehicle can significantly enhance your riding experience. Upgrading various components not only boosts power and efficiency but also contributes to better handling and durability. By selecting high-quality aftermarket parts, enthusiasts can tailor their machines to suit their specific needs, whether for recreational use or more demanding conditions.

Key Components to Consider

One of the most impactful upgrades involves the engine system. Installing a performance exhaust can increase airflow, resulting in improved horsepower and torque. Additionally, upgrading the air intake allows for better fuel combustion, enhancing overall engine efficiency. Suspension components are equally important; enhancing shock absorbers and springs can lead to improved stability and comfort, especially on rugged terrain.

Electronics and Accessories

Modernizing electronic systems can also yield substantial benefits. Incorporating advanced ignition systems can provide more precise timing, optimizing engine performance. Furthermore, adding quality lighting solutions can enhance visibility during night rides, increasing safety. Accessories like better grips and seats not only enhance comfort but can also improve control and confidence while navigating diverse landscapes.

Finding Quality Replacement Parts

When it comes to maintaining your vehicle, sourcing high-quality components is crucial for ensuring optimal performance and longevity. Identifying reliable suppliers and understanding what to look for in parts can significantly enhance your maintenance efforts.

One of the first steps in locating trustworthy replacements is to research reputable manufacturers. Opt for well-established brands known for their durability and reliability. Customer reviews and ratings can provide valuable insights into the performance and quality of specific products.

Additionally, consider purchasing from authorized dealers or specialized retailers. These vendors often offer genuine components that meet industry standards, reducing the risk of acquiring subpar items. It’s also advisable to compare prices from different sources to ensure you’re getting the best value without compromising on quality.

Lastly, joining online forums or communities dedicated to your vehicle model can be a great resource. Enthusiasts often share their experiences, recommend suppliers, and provide tips on finding the best parts, ensuring you make informed choices for your maintenance needs.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to prevent accidents and injuries. This section outlines essential practices that should be followed when working on machinery or vehicles.

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep the workspace organized to minimize the risk of tripping or misplacing tools.

Before starting any task, it’s important to:

- Disconnect the battery or remove the ignition key to prevent accidental starts.

- Read through any guidelines or instructions carefully to understand the process and tools required.

- Ensure all tools are in good condition and suitable for the job at hand.

Additionally, be mindful of the following:

- Use jack stands and other supports when working under vehicles to avoid crushing hazards.

- Keep flammable materials away from hot surfaces and open flames.

- Stay focused and avoid distractions while working to maintain concentration and control.

By adhering to these precautions, you can significantly reduce the risk of injury and ensure a safer working environment.