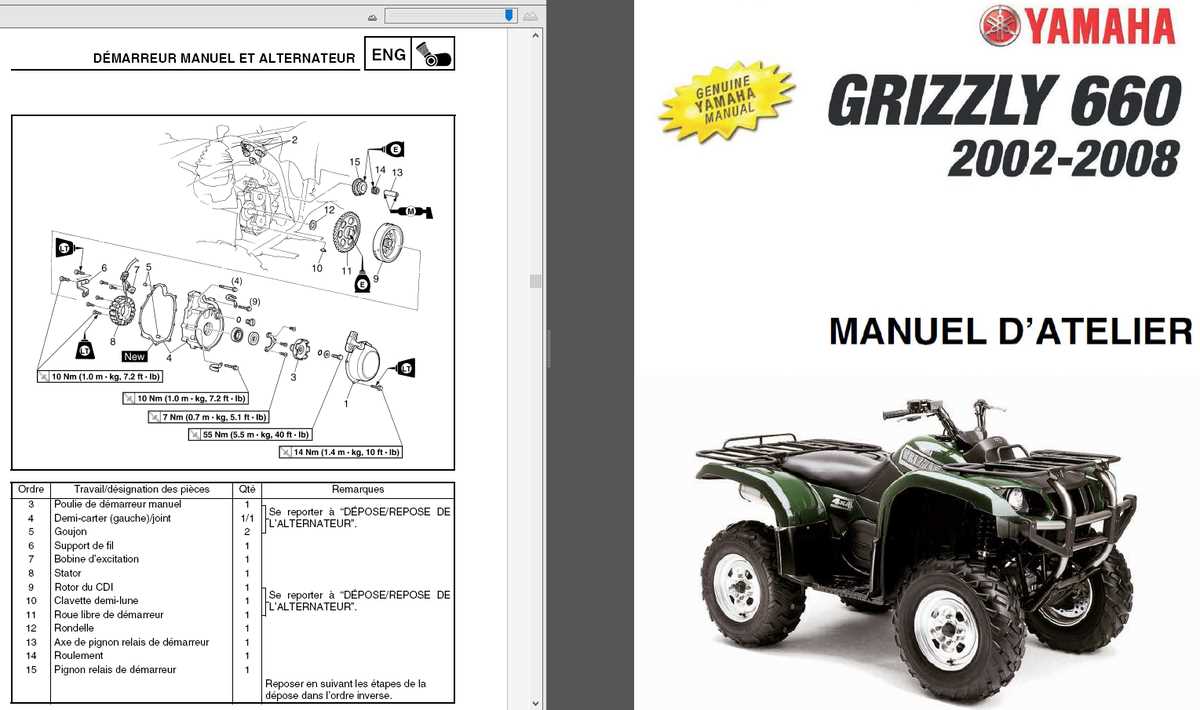

Comprehensive Repair Guide for the 2003 Yamaha Grizzly 660

Proper upkeep of all-terrain vehicles is essential for ensuring optimal performance and longevity. This section delves into the intricacies of servicing and maintaining a specific model, providing insights into essential practices and recommendations.

Within this guide, readers will discover a comprehensive overview of the procedures necessary to address common issues, conduct routine inspections, and perform significant adjustments. By following these structured instructions, vehicle owners can enhance their understanding of mechanical components, facilitating smoother operation and preventing potential breakdowns.

Moreover, the emphasis on safety and precautionary measures throughout the maintenance process ensures that users can confidently engage in these tasks. With detailed steps and helpful tips, this resource aims to empower owners to take charge of their vehicles’ health, ultimately leading to a more enjoyable riding experience.

Overview of 2003 Yamaha Grizzly 660

This section provides a comprehensive insight into a well-regarded all-terrain vehicle known for its robust performance and versatile features. Designed for both recreational and utility purposes, this model has garnered a loyal following among enthusiasts and outdoor adventurers alike.

Key Features

Equipped with a powerful engine, this machine delivers exceptional torque and acceleration, making it suitable for various terrains. The independent suspension system ensures a smooth ride, enhancing comfort during long journeys. Additionally, advanced handling capabilities contribute to its popularity, allowing riders to navigate challenging landscapes with ease.

Maintenance Considerations

Regular upkeep is essential to ensure optimal performance and longevity. Routine checks on the drivetrain, fluid levels, and tire conditions can prevent potential issues. Furthermore, utilizing quality components during servicing can enhance reliability and performance, keeping this vehicle in prime condition for years to come.

Common Issues and Troubleshooting

This section provides an overview of typical problems that users may encounter and offers practical solutions to address them. Understanding these common challenges can significantly enhance the performance and longevity of the vehicle.

Frequent Problems

- Starting Difficulties: Issues with ignition or fuel delivery can prevent the engine from starting.

- Electrical Failures: Problems with wiring or battery can lead to malfunctioning lights and accessories.

- Transmission Issues: Difficulty in shifting gears may indicate problems with the transmission fluid or internal components.

- Overheating: This may result from coolant leaks or a malfunctioning radiator.

Troubleshooting Tips

- Check the battery connections and charge level if starting is problematic.

- Inspect fuses and wiring for signs of damage to address electrical failures.

- Ensure the transmission fluid is at the correct level and condition for smooth gear changes.

- Examine the cooling system for leaks and ensure the radiator is functioning properly to prevent overheating.

Essential Tools for Repairs

Having the right instruments is crucial for any maintenance task. Whether you are tackling a minor adjustment or a significant overhaul, the correct equipment can make the process more efficient and effective. Below are some fundamental tools that should be part of every enthusiast’s toolkit.

Basic Hand Tools

Basic hand tools are indispensable for various tasks. These include wrenches, screwdrivers, pliers, and sockets. Each tool serves a unique purpose, enabling users to tackle different aspects of their equipment with precision.

Specialized Equipment

In addition to standard tools, specialized equipment can greatly enhance your maintenance capabilities. These may include torque wrenches, diagnostic scanners, and other items designed for specific tasks. Investing in these tools ensures that you can handle complex repairs with confidence.

| Tool Type | Purpose |

|---|---|

| Wrench | Tightening and loosening nuts and bolts |

| Screwdriver | Driving screws into various materials |

| Pliers | Gripping and bending materials |

| Torque Wrench | Ensuring proper tightness |

| Diagnostic Scanner | Identifying issues through error codes |

Step-by-Step Maintenance Procedures

This section outlines essential procedures for keeping your vehicle in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of the machine. Following these detailed steps will help ensure that your equipment remains reliable and efficient.

Below is a comprehensive guide to key maintenance tasks:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours or annually | Replace old oil with new to maintain engine health and performance. |

| Air Filter Inspection | Every 50 hours | Check and clean the air filter to prevent dust and debris from entering the engine. |

| Battery Maintenance | Every month | Inspect battery terminals for corrosion and ensure a secure connection. |

| Tire Pressure Check | Every ride | Ensure tires are inflated to the recommended pressure for optimal traction and handling. |

| Brake Fluid Level Check | Every 100 hours | Monitor and top up brake fluid as necessary for effective stopping power. |

By adhering to these maintenance procedures, you can ensure that your vehicle operates smoothly and remains in peak condition for years to come.

Understanding the Electrical System

The electrical framework of an all-terrain vehicle plays a crucial role in its overall functionality and performance. This intricate network is responsible for powering essential components such as the ignition, lighting, and various electronic systems. A thorough comprehension of this system is vital for effective maintenance and troubleshooting, ensuring reliable operation in diverse conditions.

Key Components

At the heart of the electrical system lies the battery, which serves as the primary energy source. It provides the necessary power to start the engine and operate electrical devices. Additionally, the voltage regulator maintains a consistent voltage level, protecting sensitive components from damage. Understanding these parts, along with the wiring harness and fuses, is essential for diagnosing issues and ensuring optimal performance.

Troubleshooting Common Issues

Identifying problems within the electrical system often begins with checking the battery’s charge and connections. Loose or corroded terminals can lead to intermittent failures, affecting the entire system’s reliability. Furthermore, inspecting fuses and wiring for signs of wear or damage can help pinpoint faults. Regular maintenance and vigilance can significantly extend the lifespan of the electrical components, preventing unexpected breakdowns.

Suspension and Handling Adjustments

Proper tuning of the suspension and handling systems is crucial for achieving optimal performance and comfort during rides. These adjustments not only enhance stability but also improve the overall experience by allowing the vehicle to respond effectively to varying terrains.

Suspension settings can be modified to cater to different riding conditions. Adjusting the preload can help accommodate the rider’s weight and any additional cargo. This modification affects the sag of the suspension, which is vital for maintaining proper handling characteristics.

Another key aspect is the compression and rebound damping. These controls determine how quickly the suspension absorbs shocks and returns to its original position. Fine-tuning these settings ensures that the vehicle remains stable over rough surfaces while providing comfort on smoother trails.

Lastly, tire pressure plays a significant role in handling. Maintaining the correct inflation level helps optimize traction and stability, contributing to a safer and more enjoyable ride. Regular checks and adjustments based on terrain and load can significantly enhance performance.

Engine Specifications and Upgrades

This section provides an overview of the power unit characteristics and potential enhancements for improved performance. Understanding the specifications is crucial for effective maintenance and optimal functionality. Various upgrades can elevate the capabilities of the machine, ensuring it operates at peak efficiency.

Engine Characteristics

The power source features a robust design, typically with a displacement that supports significant torque and horsepower. It employs a four-stroke configuration, promoting better fuel efficiency and lower emissions. The cooling system is designed to maintain optimal operating temperatures, ensuring longevity and reliability.

Potential Enhancements

Several modifications can be considered to boost performance. Upgrading the air intake system can improve airflow, enhancing combustion efficiency. Additionally, a performance exhaust can reduce back pressure, leading to increased horsepower. Regular tuning and the use of high-quality lubricants can also contribute to smoother operation and prolonged engine life.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount for both the individual and the equipment. Adhering to proper guidelines can significantly reduce the risk of accidents and enhance the overall efficiency of the process. Understanding the necessary precautions will help in creating a secure work environment.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear, such as gloves, goggles, and sturdy footwear, to shield against potential hazards. |

| Ventilation | Work in a well-ventilated area to prevent inhalation of harmful fumes and ensure a fresh airflow. |

| Tool Inspection | Regularly check tools for damage or wear to avoid malfunction during use, which can lead to injuries. |

| Stability of the Vehicle | Ensure that the vehicle is parked on a level surface and secured properly to prevent rolling or tipping. |

| Battery Precautions | Disconnect the battery before starting any electrical work to avoid short circuits and electrical shocks. |

By following these essential guidelines, individuals can minimize risks and ensure a more effective and safe maintenance experience. Remember that caution and preparation are key components in preventing accidents during servicing tasks.

Recommended Fluids and Lubricants

Proper maintenance of your vehicle relies heavily on the selection of appropriate fluids and lubricants. These substances play a crucial role in ensuring optimal performance and longevity of various components. Choosing the right products helps prevent wear and tear while enhancing overall functionality.

Below are some recommended categories of fluids and lubricants for effective maintenance:

- Engine Oil:

- Use high-quality oil that meets the manufacturer’s specifications.

- Regularly check and change oil to maintain engine health.

- Transmission Fluid:

- Opt for fluids designed for the specific transmission type.

- Change fluid periodically to ensure smooth gear shifts.

- Brake Fluid:

- Utilize fluids that conform to the required standards for brake systems.

- Regularly inspect and replace to ensure braking efficiency.

- Coolant:

- Select a coolant suitable for the engine type.

- Monitor levels and replace as necessary to prevent overheating.

- Grease and Lubricants:

- Employ high-performance greases for joints and bearings.

- Apply lubricants to moving parts to reduce friction and wear.

Regular checks and adherence to the recommended products will significantly contribute to the reliable operation of your vehicle, ensuring it remains in peak condition for years to come.

Parts Replacement and Sourcing

Ensuring optimal performance of your all-terrain vehicle often involves the timely replacement of components. Sourcing the right parts is crucial for maintaining functionality and safety. This section provides insights into effective strategies for obtaining necessary components, ensuring reliability and compatibility.

Identifying Components: Start by accurately identifying the parts that require replacement. Refer to the vehicle’s specifications and diagrams to ensure you are sourcing the correct items. A precise identification will prevent the acquisition of incompatible parts that could lead to further issues.

Where to Source: Parts can be obtained from various sources, including authorized dealers, online retailers, and local motorcycle shops. Each option has its advantages. Authorized dealers often provide OEM parts, which guarantee compatibility, while online platforms may offer competitive pricing and a broader selection.

Considerations for Quality: When sourcing components, consider the quality and brand reputation. High-quality parts may come at a higher price, but they often ensure better performance and longevity. Reading reviews and seeking recommendations can aid in making informed choices.

Used vs. New Parts: Evaluate the pros and cons of purchasing used parts. While they can be cost-effective, ensure they are in good condition and have not been subjected to excessive wear. New components typically provide greater reliability but may involve a higher investment.

By following these guidelines, you can effectively manage parts replacement and sourcing, ensuring your vehicle remains in top condition for all your adventures.